Internal energy integrated rectifying device for three-component separation and rectification method using same

An internal energy, three-component technology, applied in the field of rectification, can solve the problems of underutilization of heat, high condensation load and reboil load, so as to improve heat utilization rate, reduce reboil load and condensation load, and reduce effective The effect of energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

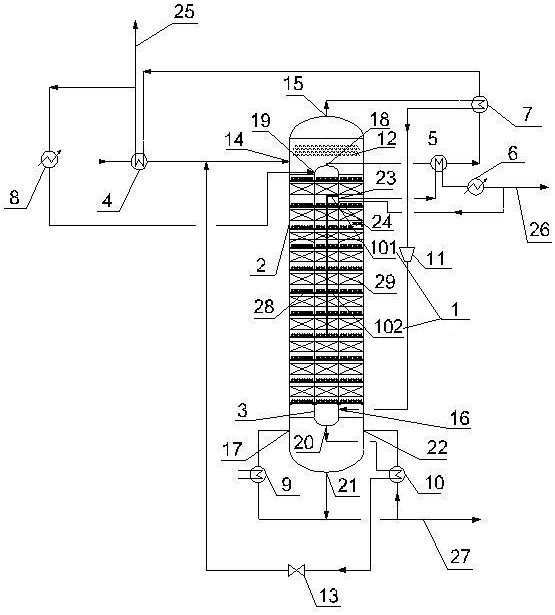

[0035] This embodiment discloses a rectification device with internal energy integration for the separation of three components:

[0036] The rectification device comprises a rectification tower with inner and outer double-layer tower bodies, the outer tower body 2 is a stripping section, the inner tower body 3 is a rectification section, and the inner tower body is provided with a partition 1, the partition The plate 1 is composed of a first partition 101 arranged in the radial direction and a second partition 102 arranged in the axial direction. The first partition 101 is arranged on the upper part of the inner tower body 3, and its outer edge and the inner tower body 3. The tower wall is sealed, and the inner edge is connected and sealed with the top of the second partition 102, and the side of the second partition 102 is sealed with the inner tower body 3 tower walls, and the bottom is kept at a distance from the bottom of the inner tower bottom 3; The feed inlet I14 arran...

Embodiment 2

[0039] This embodiment discloses the method utilizing the device of embodiment 1 to carry out rectification:

[0040] After the feed is heated by the feed preheater 4, it enters the outer tower body 2 of the rectification tower through the feed inlet I14 for gas-liquid exchange. After the liquid phase is separated, the gas outlet I15 enters the compressor 11 through the compressor inlet superheater 7 to increase the pressure, and then enters the bottom of the inner tower body 3 through the feed inlet II16 to provide reboiling heat for the inner tower body 3; The bottom liquid phase of the outer tower body 2 is divided into three parts after the liquid outlet I21, one part is discharged from the tower bottom discharge pipe 27, and the other part is returned to the outer layer tower body 2 through the reboiler 10 through the feed inlet V22 The bottom provides reboil heat for the outer tower body 2, and the third part returns to the bottom of the outer tower body 2 through the au...

Embodiment 3

[0042] The present embodiment provides a kind of concrete process parameter and the result that utilize the method for embodiment 2 to carry out rectification:

[0043] The feed to the rectification tower is a benzene-cyclohexane system with a feed rate of 100 kmol / h, of which benzene and cyclohexane are 75% and 25% (mol fraction) respectively. The benzene-cyclohexane system is separated by extractive distillation, the extractant is N,N-dimethylformamide, and the feed rate of the extractant is 300 kmol / h. In this embodiment, the extractant N,N-dimethylformamide and the benzene-cyclohexane system of the material to be separated are fed at the same position, and the separated extractant is not recycled; the extractant can also be fed into The feed position is set higher than the feed position of the substance to be separated. After the extractant is separated from the substance to be separated, it can be recycled, and only a small amount of fresh extractant needs to be added. N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com