Ethanol distillation dehydration energy saving technique and device

A technology of ethanol distillation and ethanol tower, which is applied in the chemical industry, petroleum industry, preparation of hydroxyl compounds, etc., can solve problems such as waste of heat energy, and achieve the effects of reducing production costs, saving production costs, and huge economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

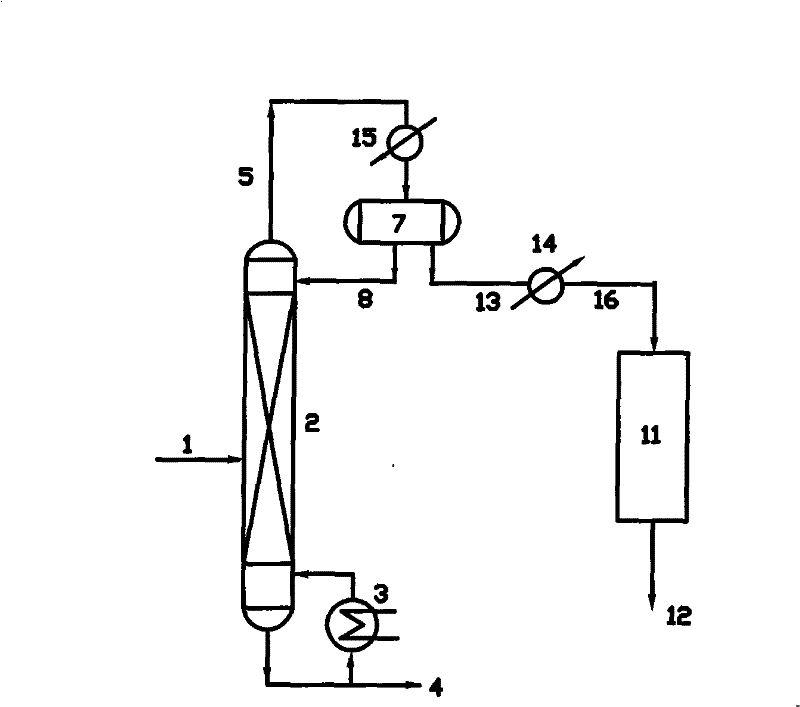

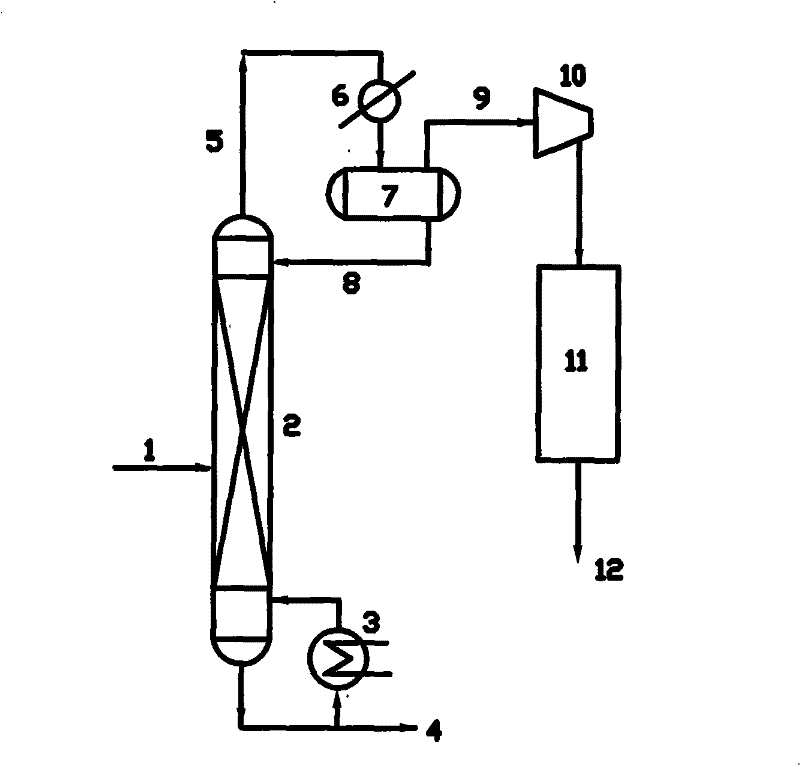

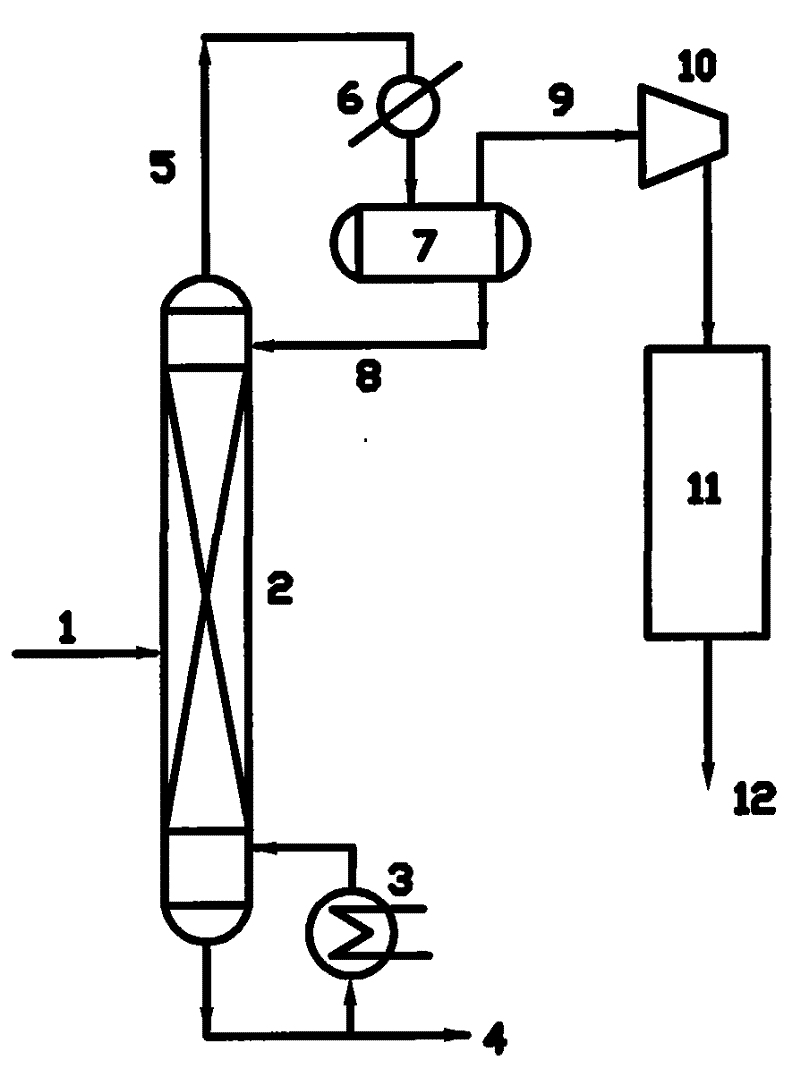

[0021] The technology and equipment provided by the present invention will be further described below in conjunction with the accompanying drawings.

[0022] The present invention is achieved through the following technical solutions:

[0023] Such as figure 2 As shown, the overhead gas phase 5 obtained after the ethanol raw material 1 passes through the ethanol rectification tower 2 enters the partial condenser 6, and the obtained mixed material enters the reflux storage tank 7, and the liquid phase material therein returns to the ethanol rectification tower 2 as reflux liquid 8 , the gas phase material 9 enters the compressor 10, enters the adsorption unit 11 after being pressurized, and obtains the required high-concentration ethanol product 12 after adsorption.

[0024] The technology and equipment of the present invention can be applied to the production process of high-concentration ethanol. In order to better illustrate the advantages of the present invention in terms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com