Method and device for treating ammonia-nitrogen wastewater and recovering ammonia

A technology for ammonia nitrogen wastewater and ammonia recovery, applied in water/sewage treatment, chemical instruments and methods, heating water/sewage treatment, etc., can solve problems such as hidden dangers of ammonia-containing steam, avoid secondary pollution, and reduce comprehensive energy consumption , the effect of reducing the condensing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

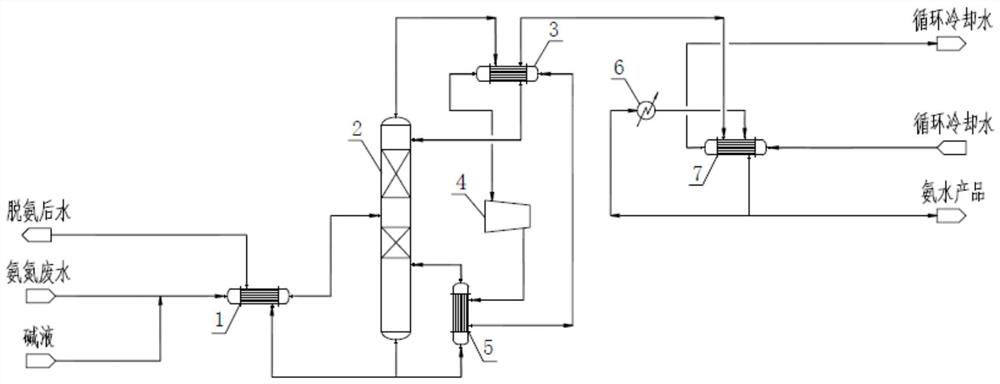

[0043] Such as figure 1 As shown, this embodiment provides an ammonia nitrogen wastewater treatment and ammonia recovery device, including a wastewater preheater 1, a ammonia removal tower 2, a heat pump condenser 3, a heat pump compressor 4, a heat pump reboiler 5, and spray liquid cooling 器6 and spray condenser 7.

[0044] The ammonia removal tower 2 is a vertical single tower body, including a rectifying section and a stripping section, and the rectifying section is located above the stripping section. Ammonia nitrogen wastewater inlet is set between the rectification section and the stripping section, the rectification section is equipped with an ammonia-containing steam outlet and a dilute ammonia water return port, and the stripping section is equipped with a water outlet and stripping steam after deamination. Inlet.

[0045] The wastewater preheater 1 is in communication with the ammonia nitrogen wastewater inlet and the deammination water outlet of the ammonia removal tower...

Embodiment 2

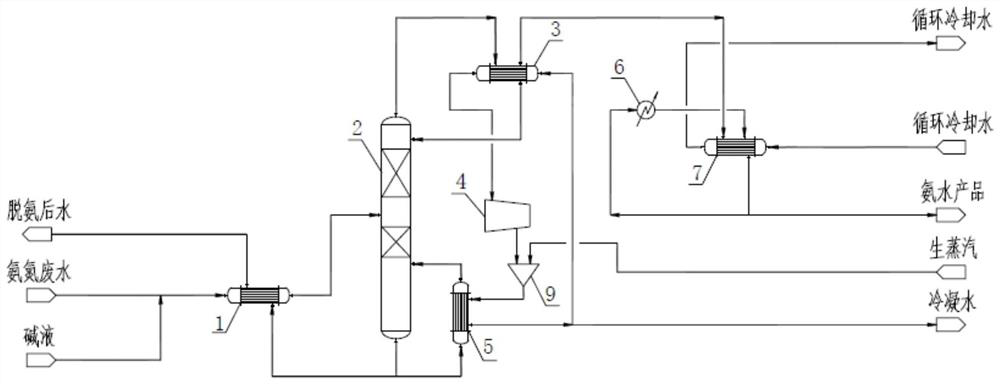

[0064] The difference between embodiment 2 and embodiment 1 in terms of equipment is that a steam mixer 9 is connected between the hot side of the heat pump compressor 4 and the heat pump reboiler 5, and a condensation is connected between the heat pump reboiler 5 and the heat pump condenser 3 Water extraction pipeline.

[0065] The difference in method is that the raw steam and the heat pump working fluid water vapor are mixed through the steam mixer 9 and passed into the heat pump reboiler 5 to supply heat to the heat pump reboiler 5; the raw steam exchanges heat with the heat pump working fluid water vapor After that, condensed water is formed, part of which is returned to the cold side of the heat pump condenser 3 as the heat pump working fluid, and the other part is produced to keep the total amount of the heat pump working fluid in the circulating state in balance.

[0066] In this embodiment, the flow of ammonia nitrogen wastewater is 30m 3 / h, the ammonia nitrogen content i...

Embodiment 3

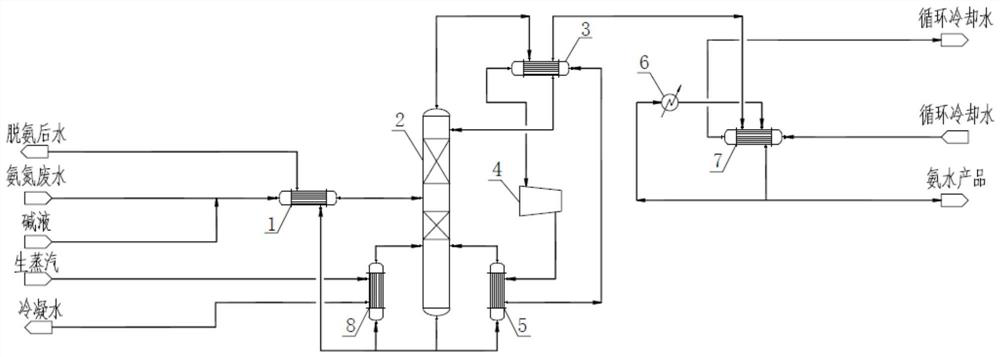

[0070] The difference between Embodiment 3 and Embodiment 1 in the device is that it also includes a raw steam reboiler 8, which uses raw steam as a heating working medium. The hot side of the raw steam reboiler 8 is connected with a heating working fluid introduction pipe and a heating working fluid extraction pipe. The cold side of the raw steam reboiler 8 is connected with the deammination tower 2 through the deammination water introduction pipe and the steam outlet pipe. The water introduction pipeline after deamination is in communication with the deamination water outlet of the deamination tower 2, and the steam outlet pipeline is in communication with another stripping steam inlet provided in the stripping section of the deamination tower 2.

[0071] The difference in method is that a raw steam reboiler 8 other than the heat pump reboiler 5 is added, and the raw steam is used as a heating working medium to provide stripping steam to the ammonia removal tower 2, specifically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com