Air-cooling thermotube-type machine room air-conditioning system

A computer room air-conditioning and air-cooling technology, which is applied in air-conditioning systems, heating and ventilation control systems, heating and ventilation safety systems, etc., can solve problems such as large operating temperature differences, low energy efficiency ratio, and complex air quality problems, and achieve Improve refrigeration efficiency and ensure safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

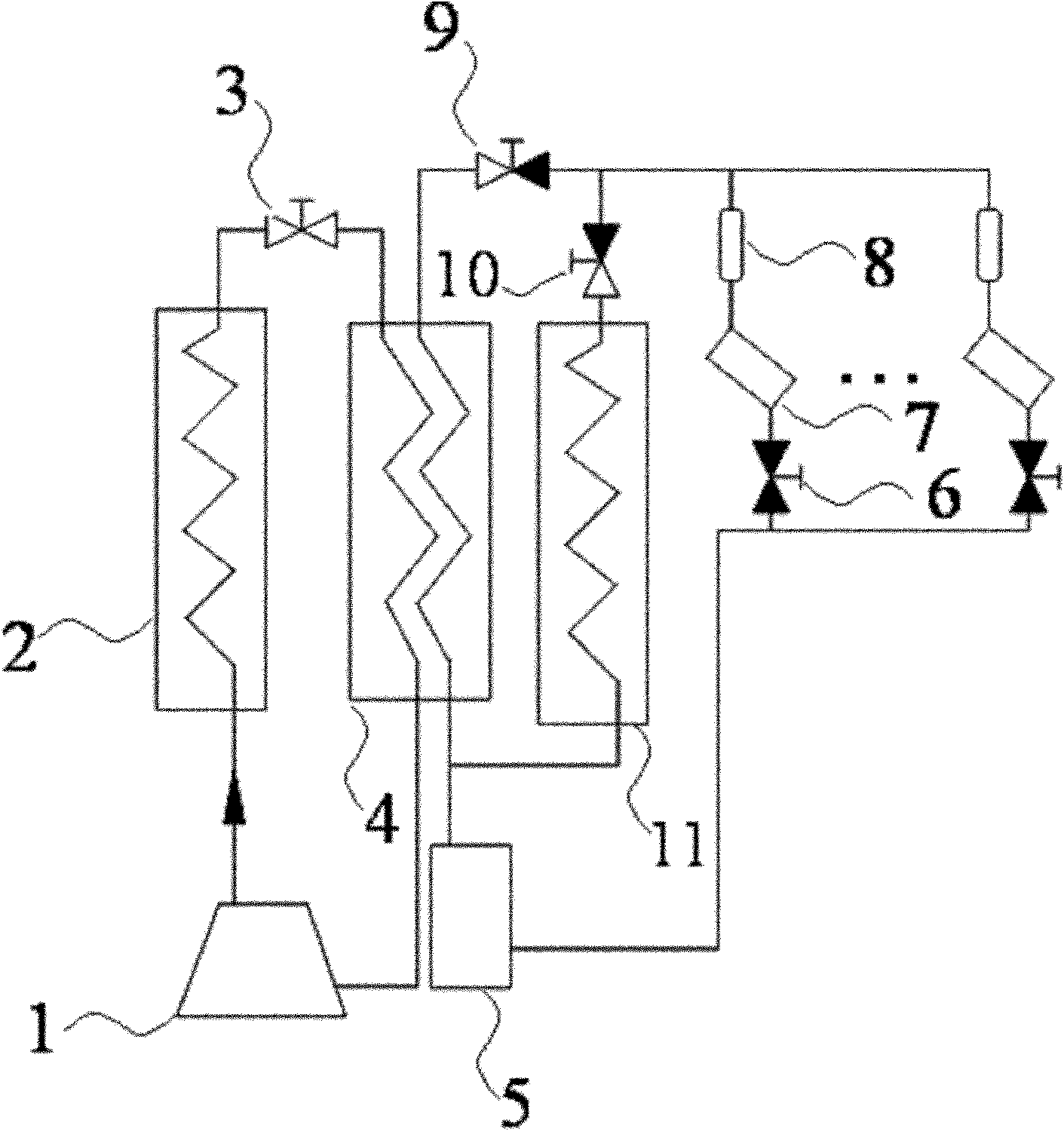

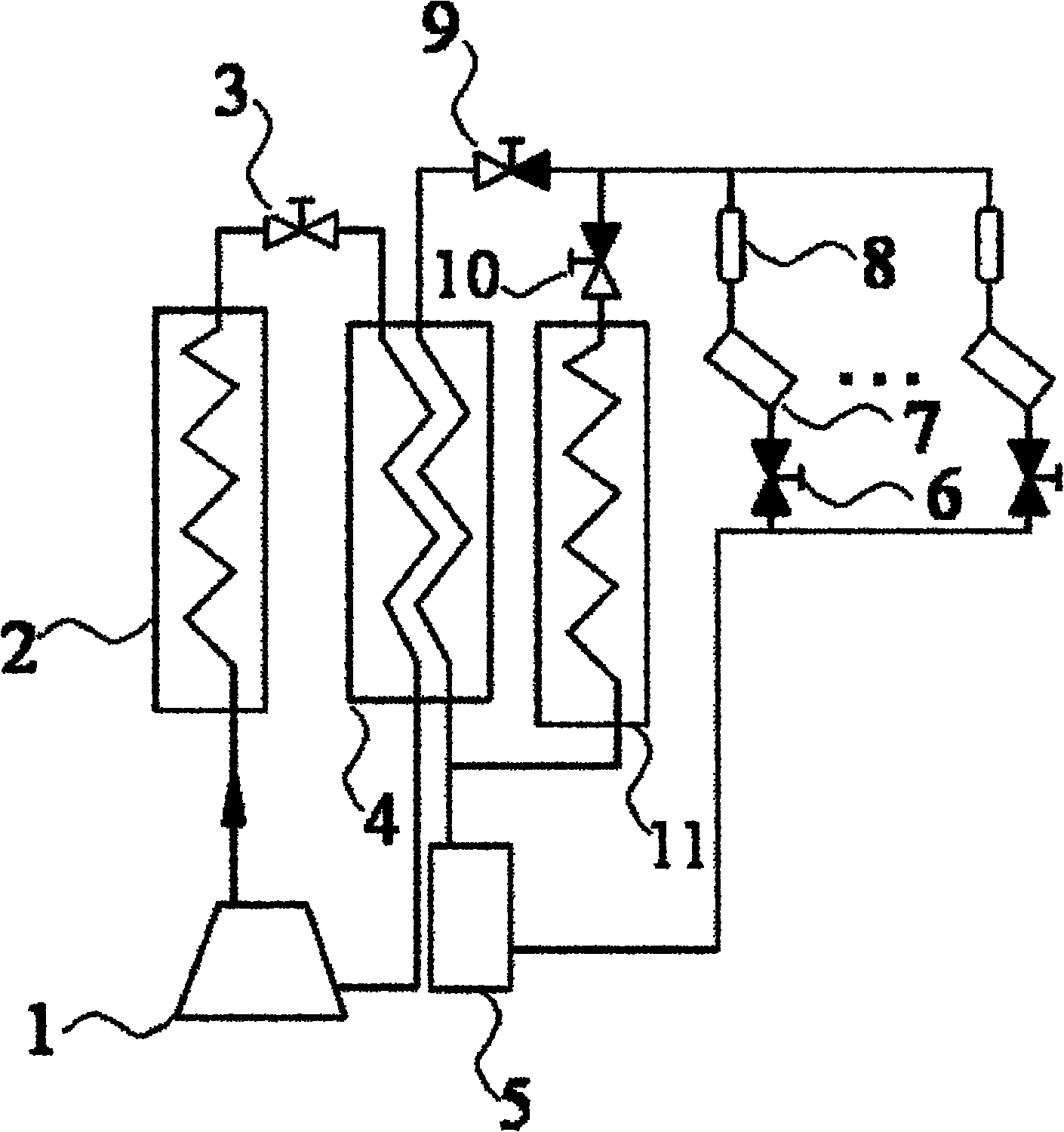

[0026] Such as figure 1 As shown, the air-cooled heat pipe type computer room air-conditioning system of the present invention includes a compressor 1, a first air-cooled condenser 2, a throttling device 3, an evaporative condenser 4, a liquid storage tank 5, a flow balance valve 6, and a terminal heat exchanger device 7, bubble pump 8, first refrigerant switching valve 9, second refrigerant switching valve 10 and second air-cooled condenser 11.

[0027] The high-pressure exhaust port of the compressor 1 is sequentially connected with the first air-cooled condenser 2, the throttling device 3, the evaporation side of the evaporative condenser 4, and the low-pressure suction port of the compressor 1 to form a compression refrigeration cycle;

[0028] The condensing side outlet of the evaporative condenser 4 is sequentially connected with the liquid storage tank 5, the flow balance valve 6, the terminal heat exchanger 7, the air bubble pump 8, the first refrigerant switching valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com