Heading and loading machine for drilling and digging

It is a dual-purpose technology, which is applied to cutting machinery, earthwork drilling, drilling equipment, etc., and can solve problems such as high energy consumption, low construction efficiency, and large equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

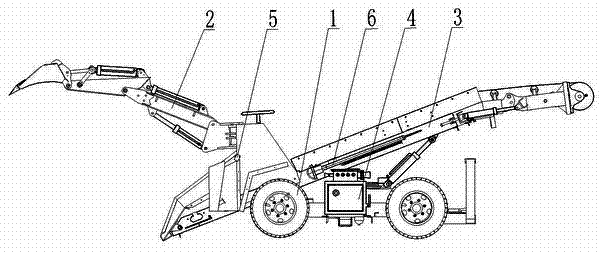

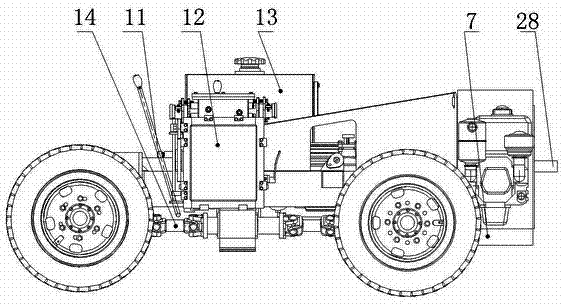

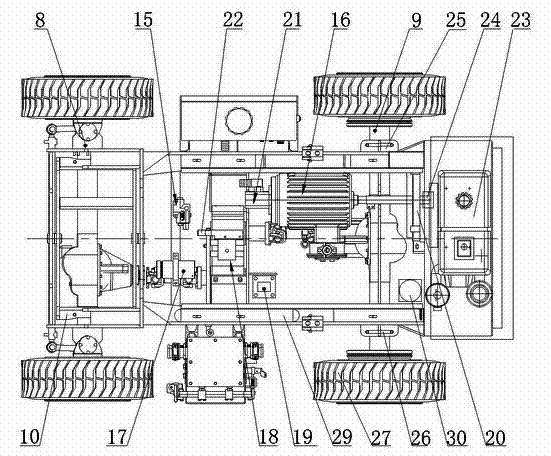

[0026] Such as figure 1 As shown, the present invention integrates a vehicle chassis 1 , an excavation loading mechanism 2 , a conveying and unloading mechanism 3 , a hydraulic drilling rig 6 , an electrical control system 4 , a hydraulic system and its operating mechanism 5 . This machine drives the motor with an external power supply or its own diesel engine as the power source. It uses electric power, hydraulic pressure and mechanical transmission. It combines the working mechanism and the walking mechanism in the form of a vehicle to form a self-moving pick-up machine to realize the walking and turning of the whole machine. ,brake. The excavating and loading mechanism 2 has functions such as turning, digging, and loading and loading; the conveying and unloading mechanism 3 has functions such as pushing shovel, collecting, receiving, conveying, unloading, lifting, and folding (or telescopic); the hydraulic drilling rig 6. It has functions such as rock drilling and drilling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com