Collecting agent for high-sulfur copper mine

A collector, copper ore technology, applied in solid separation, flotation and other directions, can solve the problems of low copper concentrate recovery rate, excessive sulfur content, corporate and social losses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

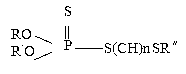

[0025] a, preparation of alkyl dithiophosphoric acid thioether ester

[0026] 38Kg of commercially available chloroethyl benzyl sulfide was slowly added dropwise to the 60Kg butanol solution in which 41Kg of ethylammonium black drug was dissolved, and it was 2 hours from the beginning of the dropwise addition to the end of the addition. In an alkaline environment formed by pyridine or sodium carbonate, stir and keep warm at 90°C for 20 minutes, cool to room temperature, ammonium chloride precipitates, filter to remove ammonium chloride, depressurize the reactor, and distill off butanol. The oily ethyl dithiophosphoric acid thioether ester is obtained and filled into a plastic-lined iron drum. The effective content of the ethyl dithiophosphoric acid thioether ester in this reaction can reach 75%, and the yield is about 85%.

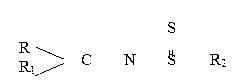

[0027] b, preparation of thiazonitrile ester

[0028] Add 17Kg of carbon disulfide into the reactor for stirring and pass cooling brine, successively add...

Embodiment 2

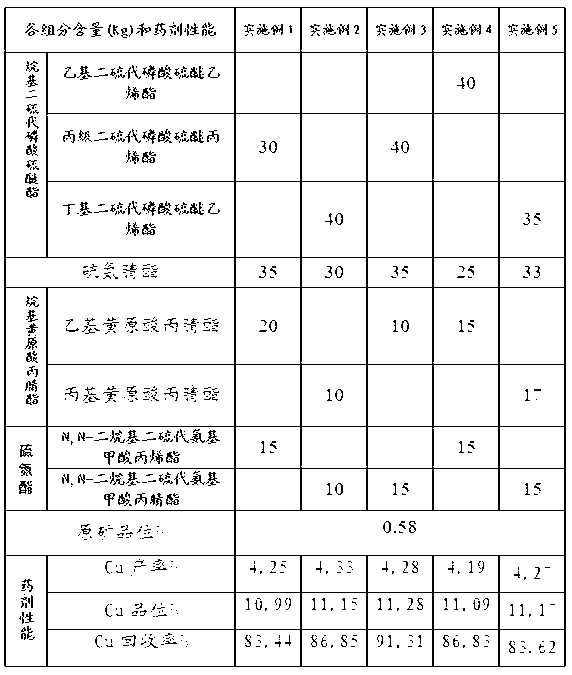

[0035] Under normal temperature and pressure, the alkyl dithiophosphoric acid thioether ester, thiazonitrile ester, ethyl xanthate propionitrile ester, and thiazolate prepared by the method of Example 1 were selected according to the groups specified in the following table 1. Put it into the stirring tank in different amounts, and stir and mix at room temperature for 50 minutes to obtain the collector composition of the present invention. Then the collector was used for beneficiation test of copper ore, and the test results are listed in Table 1.

Embodiment 3

[0037] Under normal temperature and pressure, the alkyl dithiophosphoric acid thioether ester, thiazonitrile ester, ethyl xanthate propionitrile ester, and thiazolate prepared by the method of Example 1 were selected according to the groups specified in the following table 1. Put it into the stirring tank in different amounts, and stir and mix at room temperature for 45 minutes to obtain the collector composition of the present invention. Then the collector was used for beneficiation test of copper ore, and the test results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com