Biological heap leaching technology for stripmining copper sulfide mines

A technology for copper sulfide ore and biological heap, which is applied in the direction of improving process efficiency, can solve the problems of difficult to realize rational utilization of copper-containing waste rock resources, low copper-containing grade, and high oxidation degree, and achieves easy access, short process and high technological simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A large-scale copper mine in China used open-pit mining in the early days. There are 250 million tons of open-pit stripped copper-bearing waste ores, the average copper grade is 0.229%, and the amount of copper metal is 554,000 tons. The main metal minerals in copper-bearing waste rocks are pyrite, followed by chalcopyrite, with a small amount of hematite, limonite, chalcocite, blue chalcocite, bornite, sphalerite and galena , copper blue, etc. The main gangue minerals in copper-bearing waste rocks are quartz, chlorite, mica, kaolinite, etc. After years of oxidation and alteration, and some oxidized ores were piled up in the waste rock during the stripping operation, the oxidation degree of copper ore minerals in the copper-bearing waste rock in the waste rock field has increased, and the average oxidation rate is about 5%. .

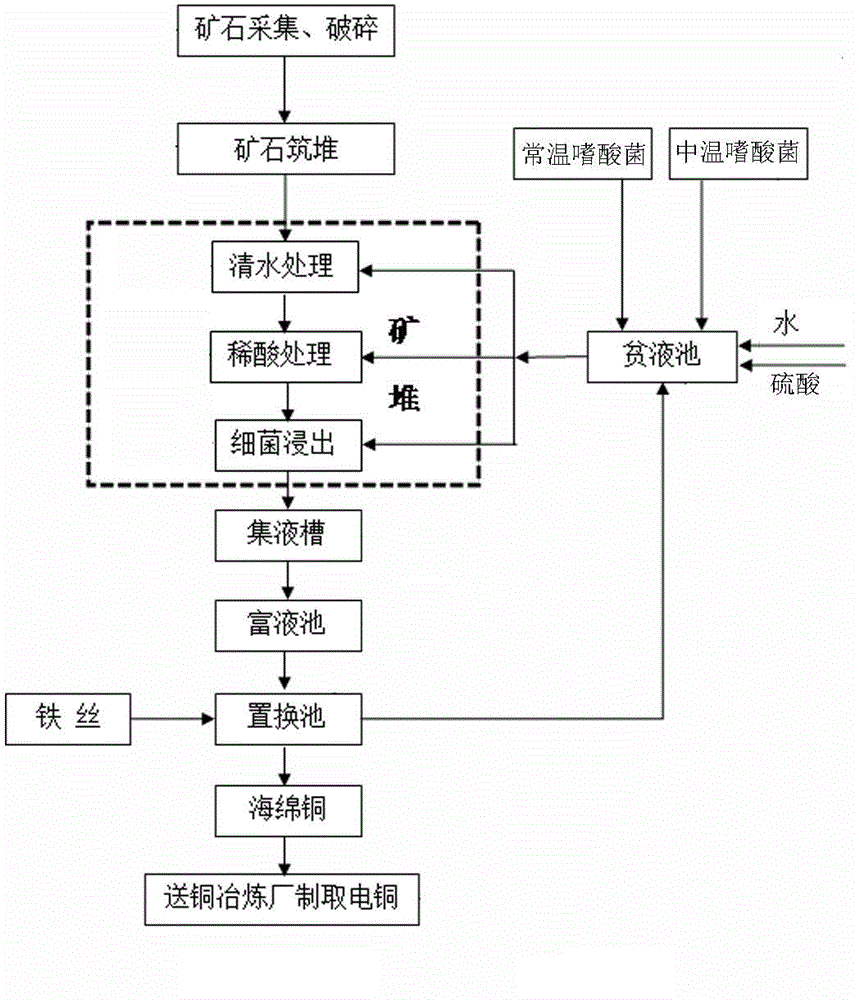

[0021] like figure 1 As shown, the bioheap leaching process includes the following steps:

[0022] (1) Bacteria selection, domestication and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com