Leaching residue grading and series flotation method for complex copper mine

A flotation and slag leaching technology, which is applied in the field of graded series flotation of heap leaching leaching slag, can solve the problems of idle land resources, ineffective use of wet leaching slag, acid pollution and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

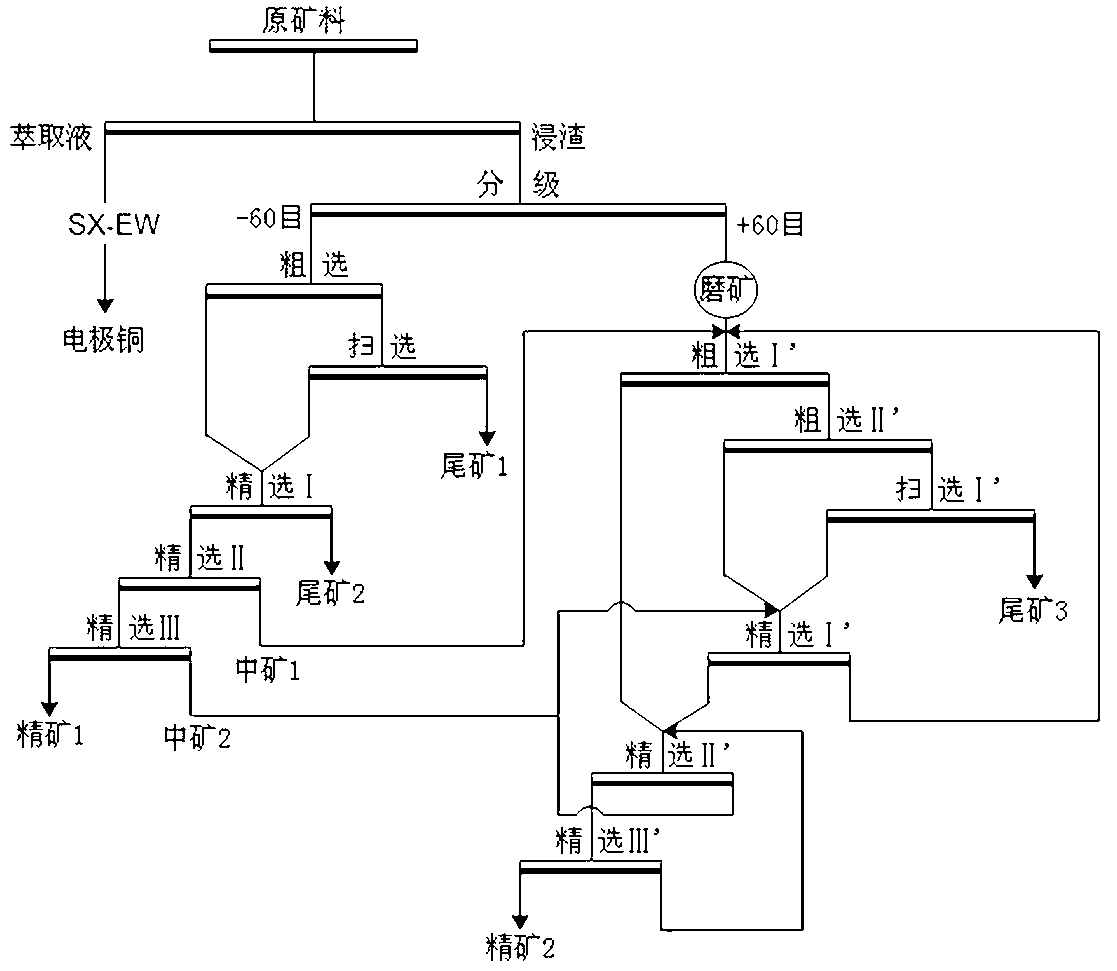

[0035] Such as figure 1 As shown, the low-copper high-sulfur ore with a particle size of -3mm was heap leached by the SX-EW method, and the remaining 1 ton of leaching residue after leaching was sieved with a Taylor sieve according to 60 mesh to obtain a fine-grained ore under a 60-mesh sieve. And +60 mesh sieve coarse-grained ore. Fine-grained ore of -60 mesh enters the stirring tank, and butyl xanthate and terpineol oil are added as usual to adjust the pulp and enter the roughing process; the ore pulp after roughing is used as the raw material for the beneficiation I process, and the underflow is used as the raw material for the sweeping process; Routinely add butyl xanthate and terpineol oil into the scavenging flotation tank, the scavenging foam is used as the raw material for the process of beneficiation I, and the scavenging pulp is used as tailings 1 and enters the tailings pond for storage; Collector and dispersant are added, the foam from the upper level of beneficia...

Embodiment 2

[0039]The low-grade high-sulfur ore with a particle size of -2.5mm is heap leached by the SX-EW method, and the remaining 1 ton of leaching residue after leaching is screened with a Taylor sieve according to 80 mesh to obtain fine-grained ore under the -80 mesh sieve and + Coarse ore on 80 mesh sieve. The -80 mesh fine-grained ore enters the stirring tank, and is routinely added with butyl xanthate, sodium sulfate and terpineol oil to adjust the slurry and enters the roughing process; the ore pulp after roughing is used as the raw material for the selection I process, and the underflow is used as the scavenging process. Raw materials: Add butyl xanthate and terpineol oil into the scavenging flotation tank according to the routine, and the scavenging foam is used as the raw material for the selection I process, and the scavenging pulp is used as tailings 1 and enters the tailings pond for storage; Add dispersant and go through beneficiation I process, the obtained foam is added...

Embodiment 3

[0043] Use the SX-EW method to heap leaching the low-grade high-sulfur ore with a particle size of -4mm, and grind the remaining 1 ton of leached slag after leaching until the fineness is -200 mesh, accounting for more than 65%. The fine-grained ore under the -100 mesh sieve and the coarse-grained ore on the +100 mesh sieve are obtained. Fine-grained ore of -100 mesh enters the stirring tank, and Z-200, copper sulfate and terpineol oil are added as usual to adjust the pulp and enter the roughing process; the pulp after roughing is used as the raw material for the selection I process, and the underflow is used as the raw material for the sweeping process Add Z-200 and terpineol oil into the scavenging flotation tank according to the routine, and the scavenging foam is used as the raw material of the selection I process, and the scavenging pulp is used as tailings 1 and enters the tailings pond for storage; Dispersant is routinely added, and the foam from the upper level of bene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com