Novel heat accumulation concrete for solar thermal power station and preparation method for novel heat accumulation concrete

A technology of solar heat and concrete, which is applied in the field of building materials, can solve the problems of low thermal conductivity of concrete, instability of concrete, low thermal stability, etc., achieve good mechanical properties and stability, improve thermal properties, and be easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method for a new type of heat storage concrete used in solar thermal power plants, using geopolymer formed by calcined metakaolin-modified water glass as the cementitious material, basalt as the coarse aggregate, and steel slag sand as the fine aggregate ( fine aggregate), and steel fiber, organic fiber, graphite powder and water reducing agent are mixed into it at the same time, and it is formulated according to Table 1. After conventional stirring, molding and maintenance, the heat conducting The tube was heated to a temperature of 45±5°C for 6h, and then heated to a temperature of 85±5°C for 6h.

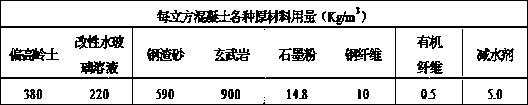

[0027] Table 1

[0028]

[0029] in:

[0030] Metakaolin: obtained by calcining kaolin at 650°C for 8 hours.

[0031] Modified water glass solution: a water glass solution modified by NaOH solution with a modulus of 1.2 and a Baume degree of 40%.

Embodiment 2

[0040]A preparation method for a novel heat storage concrete used in a solar thermal power station, comprising the steps of:

[0041] The geopolymer formed by calcined metakaolin-modified water glass is used as cementitious material, basalt is used as coarse aggregate, copper ore sand is used as fine aggregate (fine aggregate), and steel fiber and organic fiber are mixed into it , graphite powder and water reducing agent, and according to Table 2, after conventional stirring, molding and maintenance, before formal use, heat it up to 50±5°C for 8 hours through the embedded heat pipe, and then Heat up to 90±5°C for 8h.

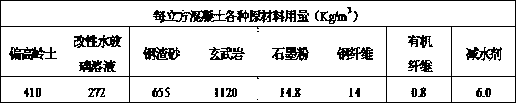

[0042] Table 2

[0043]

[0044] in:

[0045] Metakaolin: obtained by calcining kaolin at a temperature of 700°C for 6 hours.

[0046] Modified water glass solution: a water glass solution modified by NaOH solution with a modulus of 1.2 and a Baume degree of 40%.

[0047] Copper ore sand: its fineness modulus is 3.0.

[0048] Basalt: basalt with a parti...

Embodiment 3

[0055] A preparation method for a novel heat storage concrete used in a solar thermal power station, comprising the steps of:

[0056] The geopolymer formed by calcined metakaolin-modified water glass is used as the cementitious material, the basalt is used as the coarse aggregate, and the ordinary sand, steel slag sand, and copper ore sand are used as the fine aggregate (fine aggregate). Mix steel fiber, organic fiber, and graphite powder, and mix according to Table 3. After conventional stirring, molding, and curing, heat it up to 55±5°C through the embedded heat pipe before it is officially used. 12h, then heated to 100±5℃ for 12h.

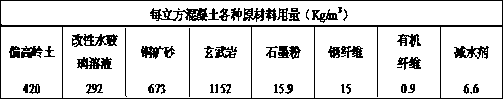

[0057] table 3

[0058]

[0059] in:

[0060] Metakaolin: obtained by calcining kaolin at a temperature of 750°C for 5 hours;

[0061] Modified water glass: a water glass solution modified by NaOH solution with a modulus of 1.2 and a Baume degree of 38%;

[0062] Ordinary sand: its fineness modulus is 2.6.

[0063] Copper ore sand: its...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com