Oil shale dry-wet mixing method dry distillation technology and heat accumulating type external firing shale oven

An oil mother shale, regenerative technology, applied in the petroleum industry, special forms of dry distillation, indirect heating dry distillation, etc., to increase convective heat transfer, reduce energy loss, and facilitate heat exchange.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

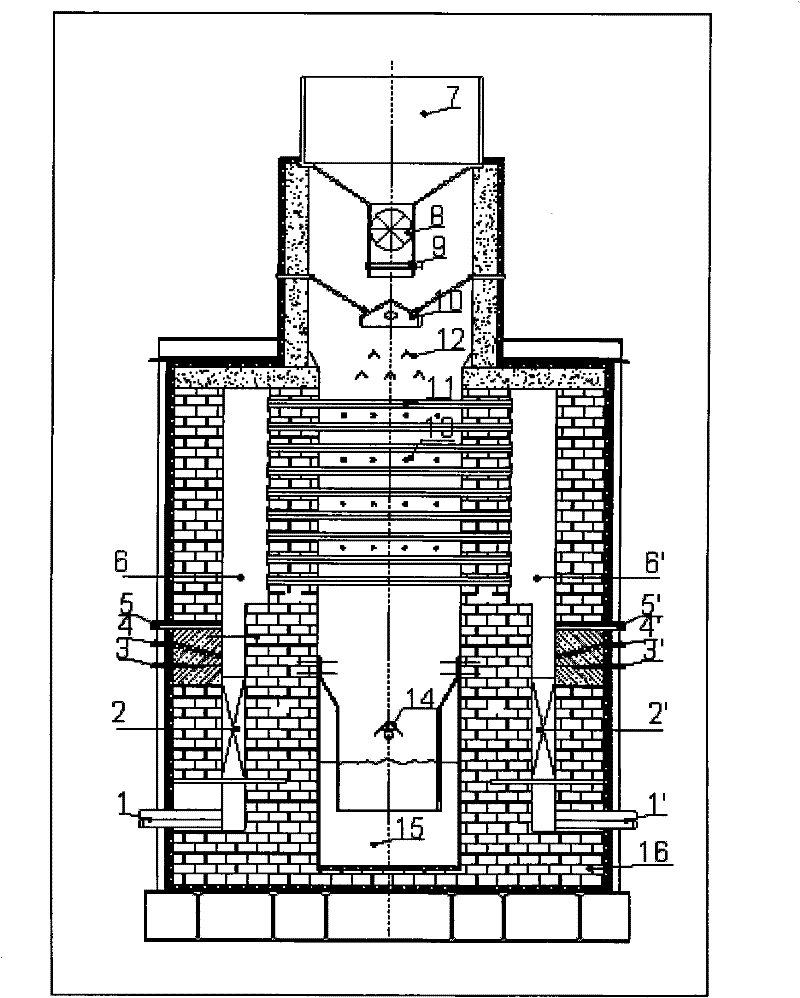

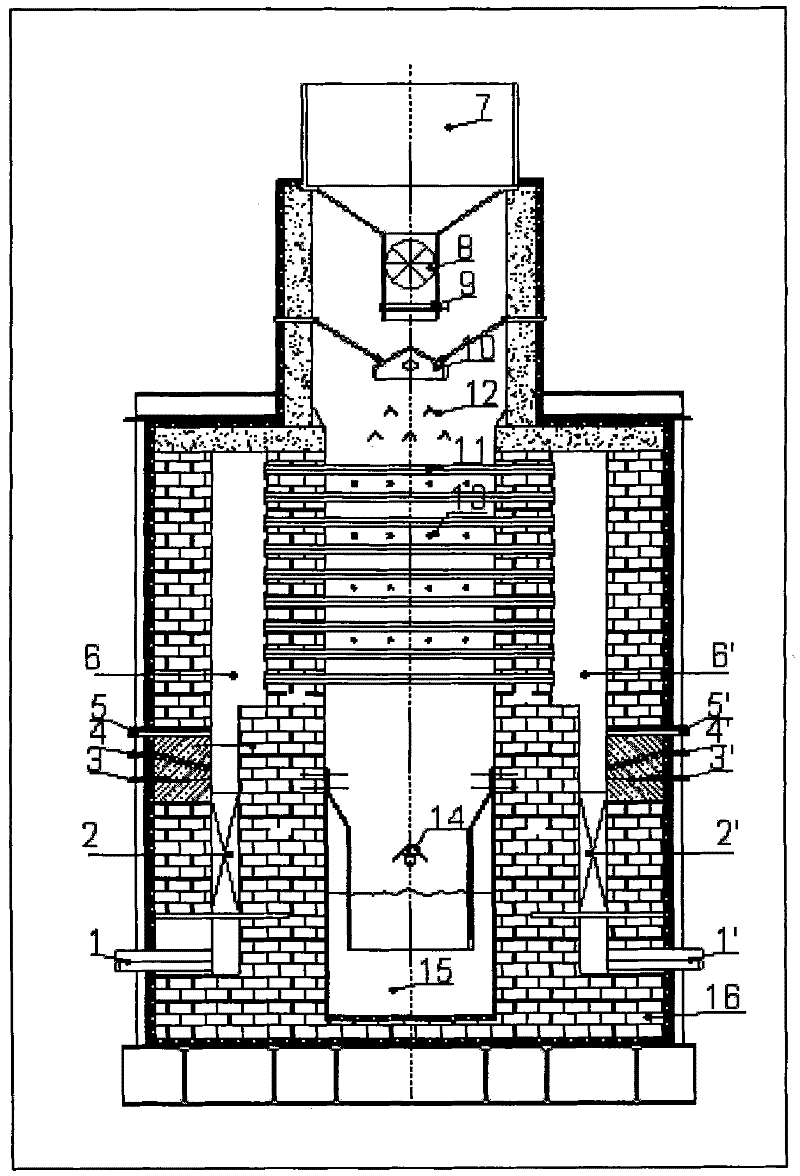

[0022] exist figure 1 In the process, the material (oil shale particles) passes through the electric star valve (8) in the silo (7), and then passes through the electric gate valve (9) (where 8 and 9 play the role of gas locking and discharging) and descends into the carbonization furnace. The material falls vertically after being evenly distributed by the distributor (12), and the falling speed of the material is controlled by the water-sealed slag discharge device (15). The material in the carbonization furnace body is heated by the heat exchange tube bundle (11) to complete the carbonization process. The dry distillation oil gas produced by dry distillation is discharged outside the furnace through the air umbrella (10). The cold cycle gas is sprayed from the cold cycle gas nozzle (14) to recover the sensible heat of semi-coke. The material feeder (13) is vertically arranged with the heat exchange tube bundle (11), and the rotation of the material guide (13) drives the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com