Ni-containing stainless steel smelting method

A smelting method and stainless steel technology, applied in the field of Ni-containing stainless steel smelting, can solve the problems of uneconomical, high cost, waste of resources, etc., and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

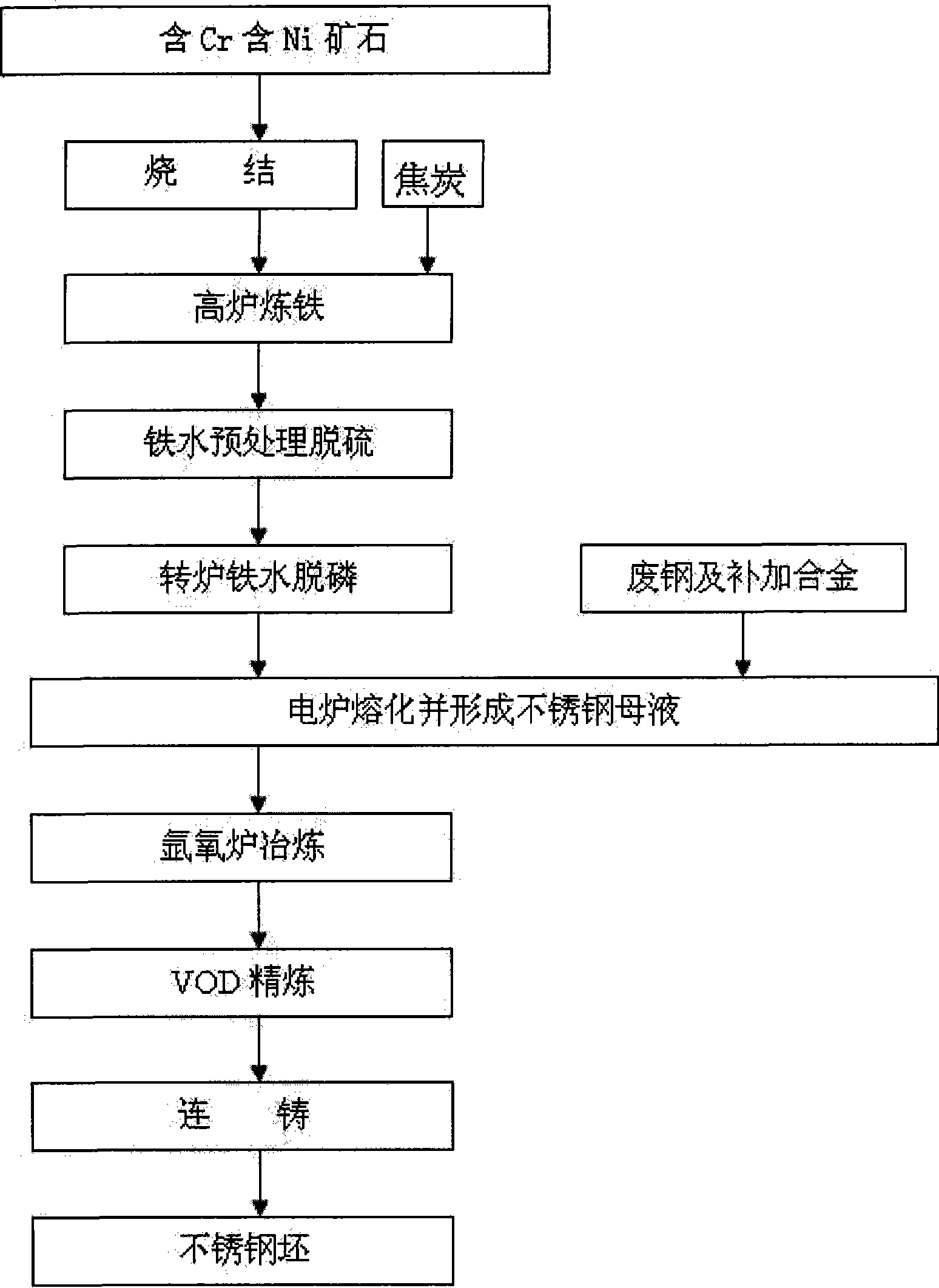

[0029] Such as figure 1 As shown, it is a stainless steel smelting process flow, and the Ni-containing stainless steel smelting method mainly includes the following steps:

[0030] Sinter low-grade nickel-containing and chromium-containing ores; smelt the sintered ores in a blast furnace; pretreat molten iron for desulfurization and dephosphorization; and form stainless steel mother liquor, melt alloys and stainless steel scraps in electric furnaces, and smelt stainless steel in argon-oxygen furnaces , VOD furnace refining; continuous casting into stainless steel billet.

[0031] The low-grade nickel-containing and chromium-containing ore is laterite ore, which is a nickel oxide ore containing 0.8-2.2% of Ni, 1-3% of Cr and 20-40% of Fe. The Ni content is generally >0.5%, and it is not worth using any lower. When using blast furnace to smelt molten iron, low-grade nickel-containing and chromium-containing ores are added to the charge of the blast furnace, and the high reduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com