Continuous casting process and continuous casting machine for extra-thick plate blank

A technology of extra-thick slab and continuous casting process, which is applied in the field of extra-thick slab continuous casting, which can solve the problems of surface and internal quality defects, lack of bending and straightening equipment, and difficulty in ensuring the quality of casting slabs, so as to achieve good internal quality , Avoid overcooling or overheating pouring, solve the effect of center segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

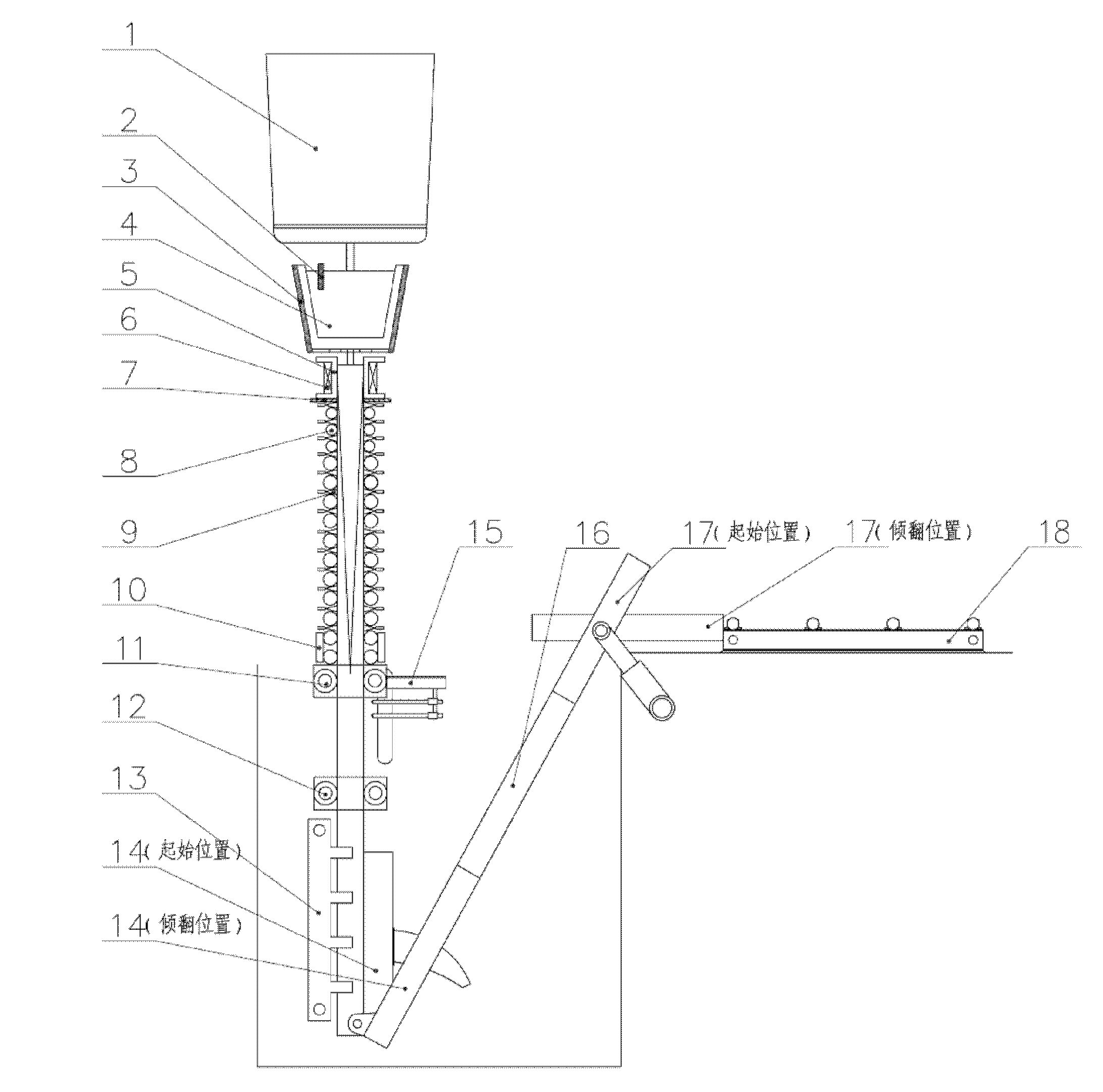

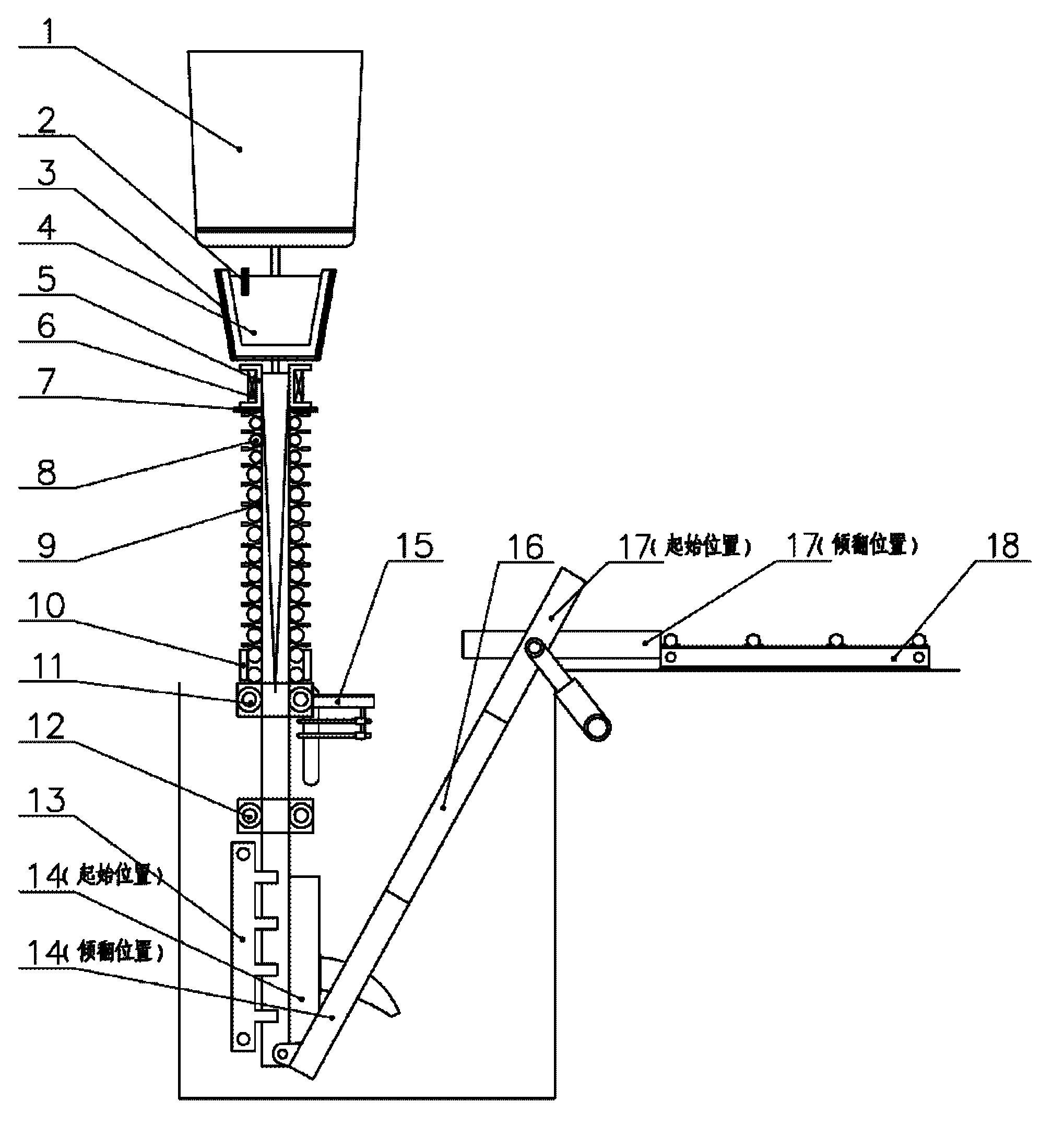

[0031] The continuous casting process of this embodiment is implemented to produce extra-thick slabs with a cross-sectional size of 2000×600 mm, and the variety is DH40 oil production platform steel. After the 100-200t molten steel comes out of the converter and is refined in the secondary refining furnace, the ladle containing the refined molten steel is transported to the rotary table, and after the rotary table is rotated to the pouring position, it is poured into the ladle 1, and the molten steel passes through the bottom of the ladle 1. The shroud is injected into the tundish 4 . The extra-thick slab continuous casting adopts a vertical casting machine, and the foundation pit of the casting machine is 25-40m deep. Due to the low casting speed of the extra-thick slab continuous casting, the tundish 4 is equipped with a continuous temperature measuring device 2 and a heating device 3 , control the superheat of molten steel in the tundish 4 to be stable at 10-30°C.

[0032]...

Embodiment 2

[0036] The continuous casting process of this embodiment is implemented to produce extra-thick slabs with a cross-sectional size of 2100×700 mm, and the variety is 16MnR container steel plates. After the 180-250t molten steel comes out of the converter and is refined in the secondary refining furnace, the ladle containing the refined molten steel is transported to the rotary table, and after the rotary table is rotated to the pouring position, it is poured into the ladle 1, and the molten steel passes through the bottom of the ladle 1. The shroud is injected into the tundish 4 . The continuous casting of extra-thick slab adopts a vertical casting machine. The foundation pit of the casting machine is 25-40m deep. Due to the low casting speed of continuous casting of extra-thick slab, a continuous temperature measuring device 2 and a heating device 3 are installed in the tundish. Control the superheat of molten steel in the tundish at 10-30°C.

[0037] After the submerged nozzl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com