Ferro-nickel alloy production technology with laterite nickel ore processed through oxygen enrichment hot air shaft furnace

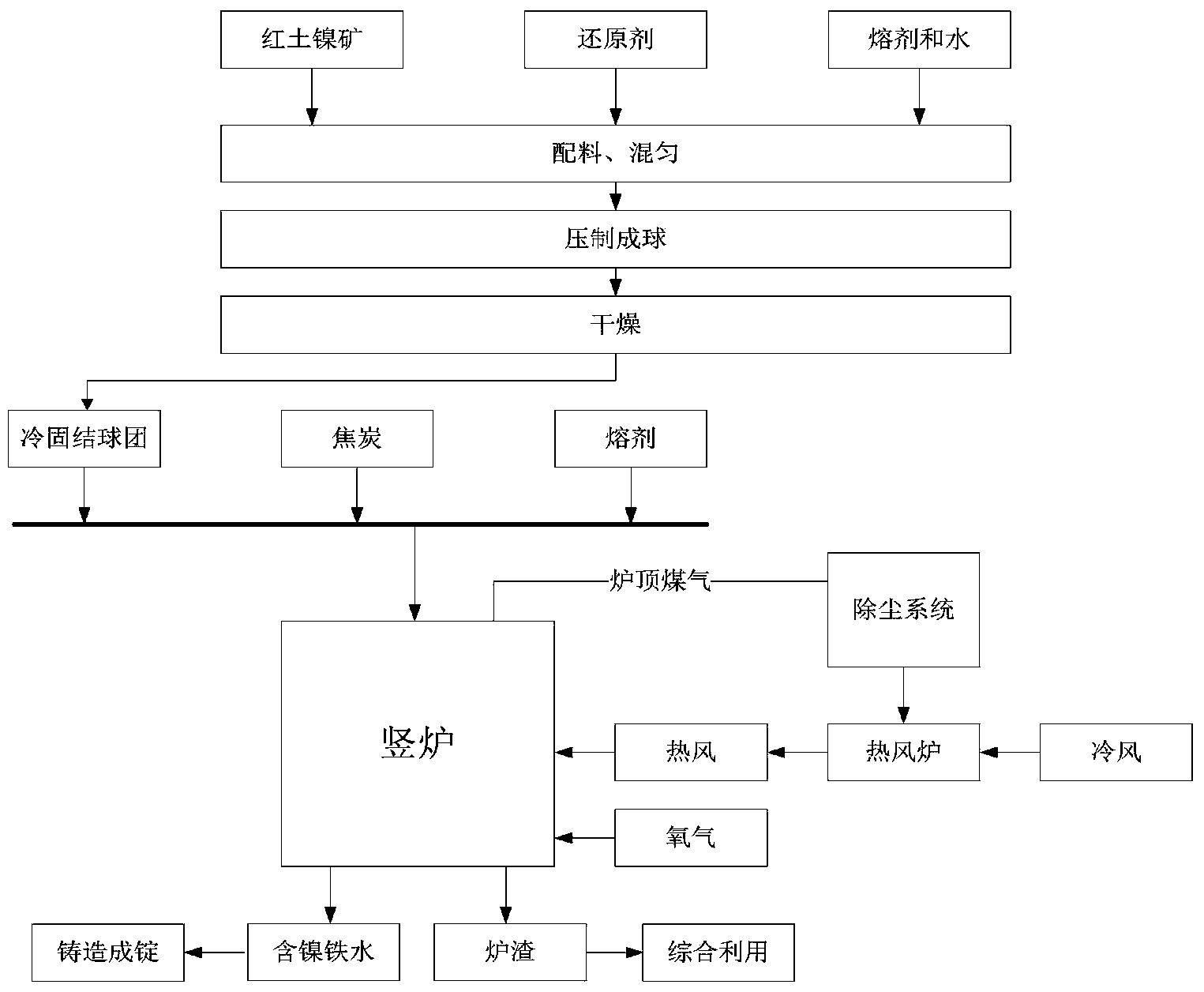

A technology of laterite nickel ore and oxygen-enriched hot air, applied in shaft furnaces, furnaces, furnace types, etc., can solve the problems of easy ring formation, low treatment efficiency and serious pollution of rotary kilns, and achieve strong adaptability of raw materials and high treatment efficiency. , the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0022] The composition of laterite nickel ore selected is Ni: 1.30%, Fe: 25%; anthracite powder is used as reducing agent, its fixed carbon content is about 80%, ash content is about 12%, and volatile matter is about 8%; limestone powder is used as Flux, its CaO content is about 52%. Add the laterite nickel ore to the dryer for drying, and crush it to below 10 mesh by the crusher. Add anthracite powder, limestone powder and water according to the ratio of laterite nickel ore: anthracite powder: flux: water about 100:6:20:17 , mixed thoroughly, pressed into blocks under a pressure of not less than 20MPa, dried and put into the stock yard.

[0023] Put the dried laterite nickel ore pellets and coke into the shaft furnace, and blow oxygen-enriched hot air into the tuyere at the lower part of the shaft furnace. , release a lot of heat, this area is the highest temperature of the shaft furnace, the temperature can reach 2000 ℃. The high-temperature furnace gas generated by the tu...

Embodiment approach 2

[0026] The composition of laterite nickel ore selected is Ni: 1.80%, Fe: 20%; coke powder is used as reducing agent, its fixed carbon content is about 85%, ash content is about 13%, and volatile matter is about 2%; limestone powder is used as Flux, its CaO content is about 52%. Add the laterite nickel ore to the dryer for drying, and crush it to below 10 mesh by the crusher. Add coke powder, limestone and water according to the ratio of laterite nickel ore: coke powder: flux: water about 100:5:20:17, After fully mixing, press into blocks under a pressure of not less than 20MPa, and put them into the stockyard after drying. Put the dried laterite nickel ore pellets and coke into the oxygen-enriched hot blast shaft furnace for smelting, and the smelting process is similar to Embodiment 1.

[0027] In the nickel-iron alloy obtained in this example, the nickel content is 7-12%, the iron content is 84-89%, the iron yield is 60-80%, and the nickel yield is greater than 90%. The ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volatile matter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com