Process for blasting oxygen-enriched hot blast to blast furnace and device applied to same

A technology of oxygen-enriched hot air and blowing device, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., and can solve the problems of increasing blast furnace smelting costs, inconvenience, and complicated equipment and pipelines in iron and steel enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

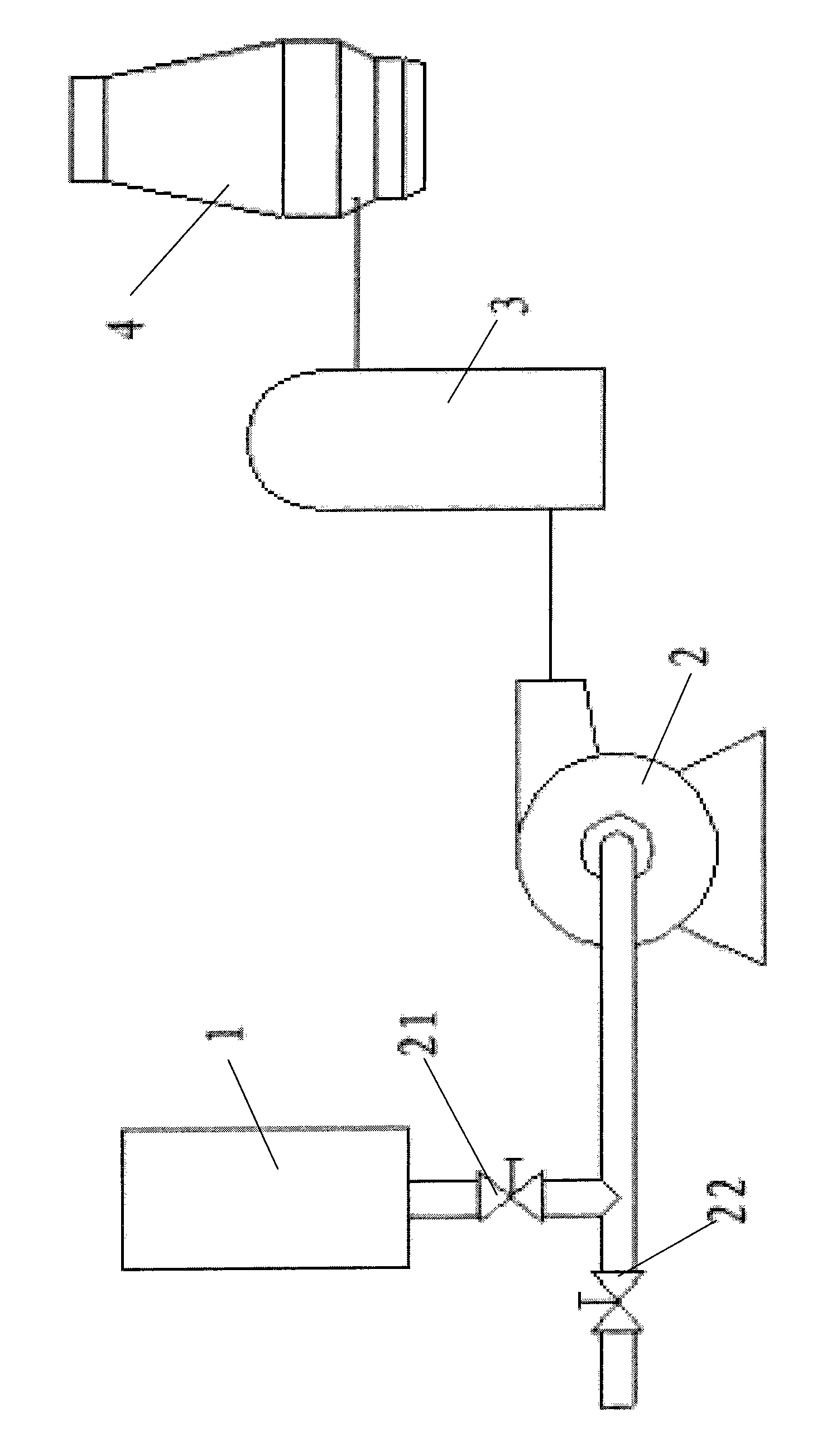

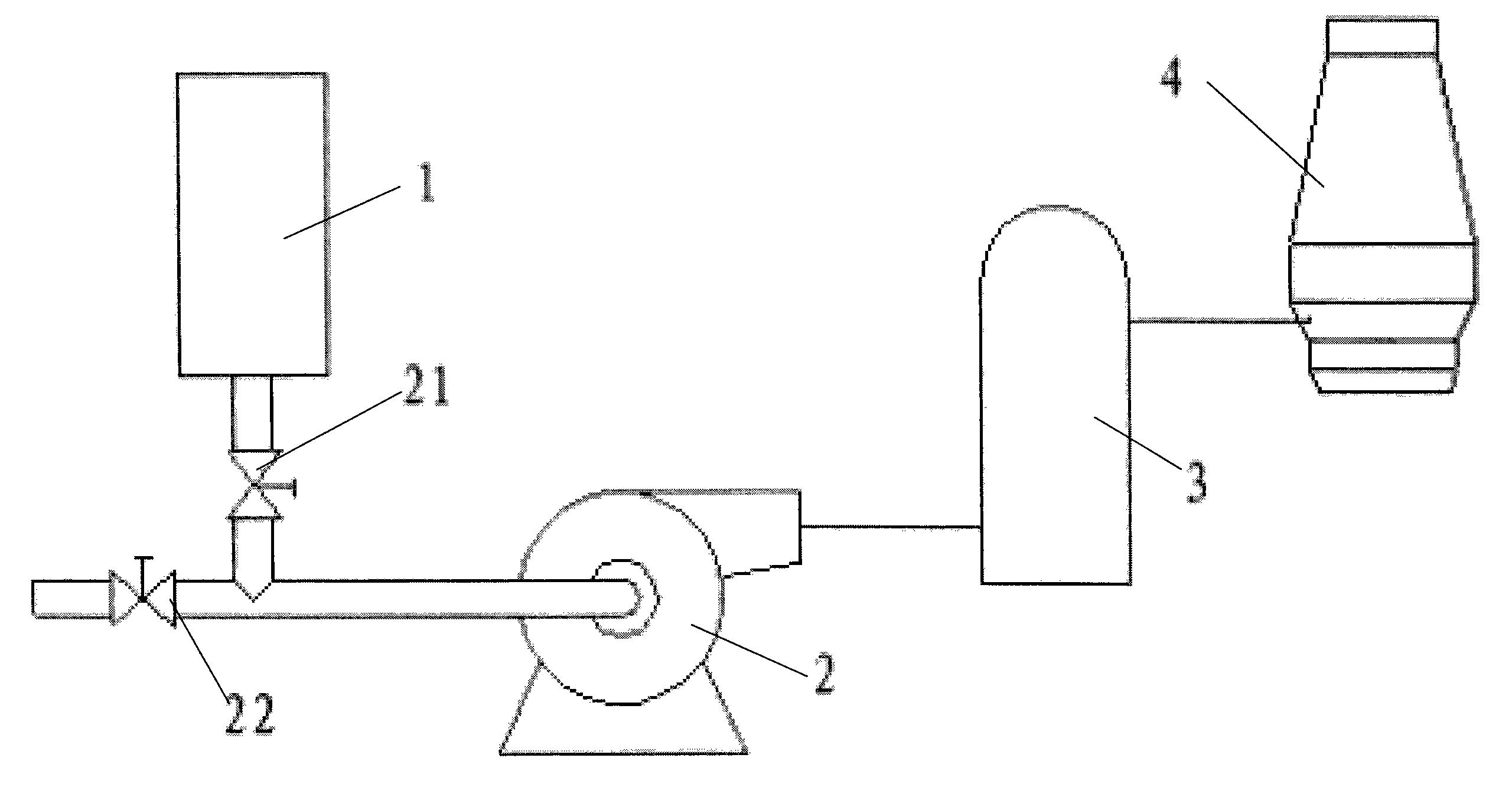

[0014] see figure 1 As shown, a blast furnace oxygen-enriched hot blast blast device of the present invention includes an oxygen-enriched production device 1 , a blower 2 and a hot blast stove 3 .

[0015] Wherein, the blower 2 is a blowing system of a traditional blast furnace, and a low-cost centralized oxygen-enrichment production device 1 is connected in parallel at the air inlet of the blower 2 .

[0016] Set a control valve 21 on the pipeline connecting the inlet of the blower and the outlet of the oxygen-enriched production device, and set a control valve 22 on the pipeline connecting the inlet of the blower and the air, and the control valves 21 and 22 can be connected to the remote control system through the communication system , to achieve automatic control.

[0017] Through the control valves 21 and 22, the arbitrary switching between air combustion and oxygen-enriched combustion can be realized, and the oxygen concentration of the combustion gas can be adjusted a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com