Ore dressing method and ore dressing system suitable for lean magnetite ores

A beneficiation method and technology of lean magnetite, which is applied in the process flow and the change rule of process parameters, iron ore crushing and beneficiation equipment, can solve the problems of large amount of medium ore, large amount of regrind in the return process, and high grade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

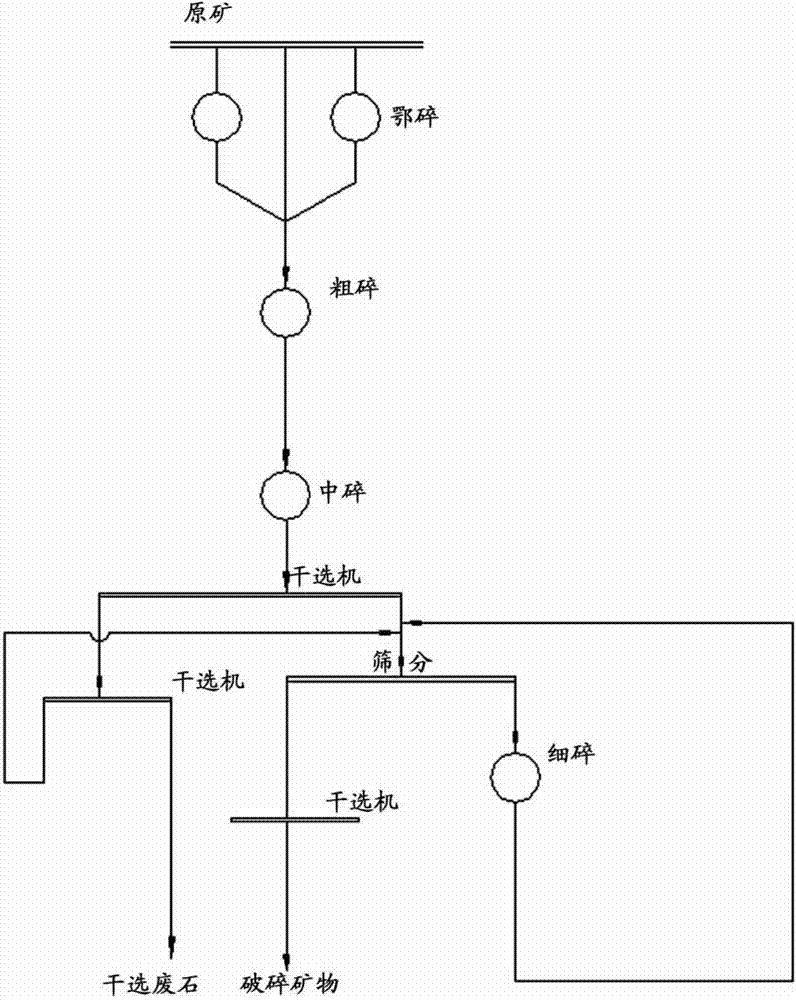

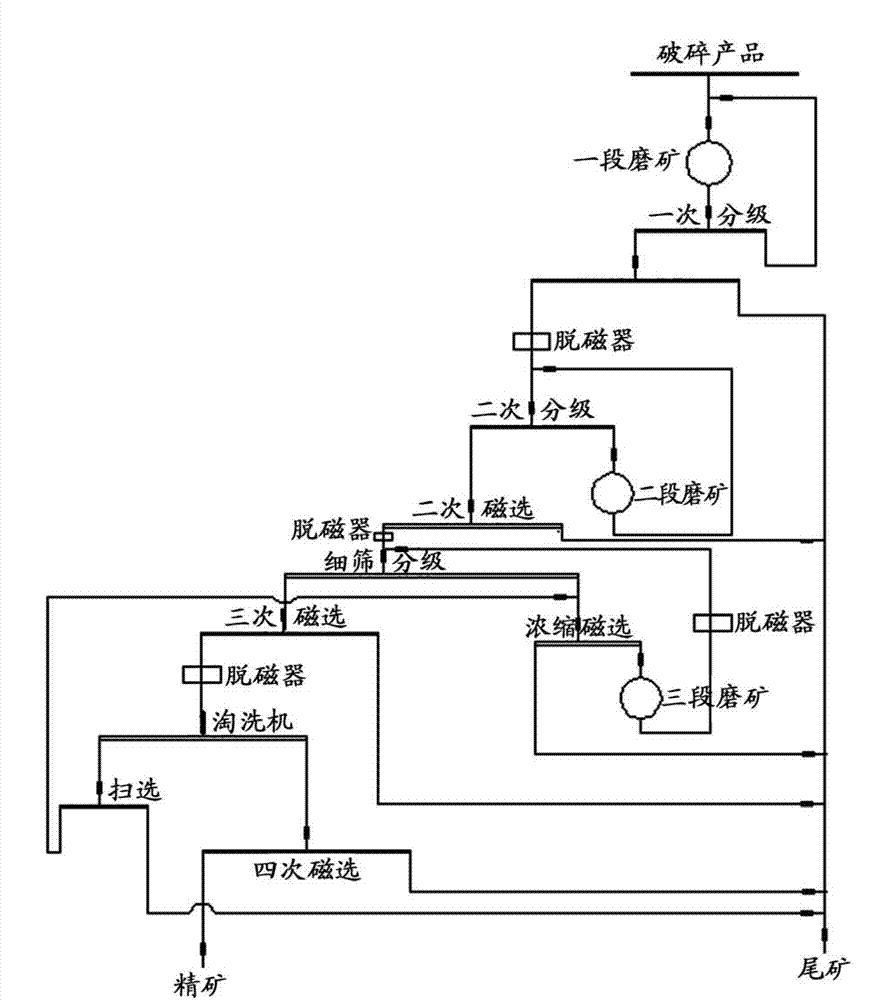

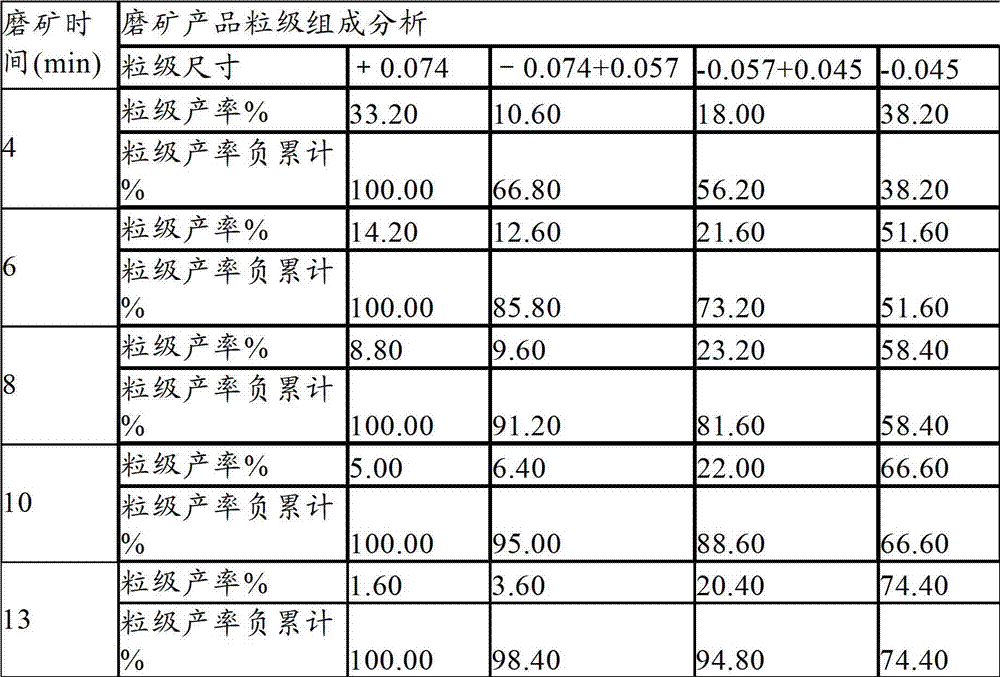

Method used

Image

Examples

Embodiment approach

[0143] As a specific implementation, after the products under the high-frequency fine sieve pass through the elutriation machine (model CH-CXJ24000, 13 sets) to further improve the concentrate grade (the ore feeding amount of the elutriation machine is 23~29t / h, and the ore concentration is ≥ 30%, feed particle size 0~0.045mm%≥75%), concentrate product particle size 0~0.045mm≥75%, concentration 26~29%, grade ≥66%.

[0144] In a specific embodiment, the parameters of the elutriation machine are: 1.80A current in the fixed magnetic field; 2.80A circulating magnetic field current, automatic adjustment; 4 seconds cycle time; three-way circulation; new water rising speed 5.05cm / s Under certain conditions, the grade of total iron in concentrates separated by magnetic gravity separation equipment can reach more than 66%, which is more than 3% higher than that before parameter optimization.

[0145] Preferably, the following steps are also included after the ninth magnetic separation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

| Magnetic field strength | aaaaa | aaaaa |

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com