Acidic full-vanadium-titanium pellets and preparation method thereof

A technology of pelletizing and vanadium-titanium magnetite concentrate, which is applied in the field of metallurgy to achieve the effects of wide application range, reduced coke ratio, and improved technical and economic indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The preparation method of the acidic all-vanadium-titanium pellets of the present invention comprises the following steps: batching, mixing, drying, moistening, grinding, pelletizing, drying, preheating, roasting, cooling, and sieving; after sieving, blast furnace smelting can be carried out.

[0016] The pellet raw material of the present invention is mainly composed of all-vanadium-titanium magnetite concentrate, and the ratio can be as high as 100%, and a small amount of binder such as bentonite is added to pelletize and roast to prepare finished pellets. The composition content of the used all-vanadium titanium magnetite concentrate is calculated as: Fe 2 o 3 : 40-50%, FeO: 29-33%, SiO 2 : 2.5-4.5%, CaO: 1.5-2.2%, MgO: 2.0-3.2%, Al 2 o 3 : 3.0-4.5%, V 2 o 5 : 0.55-0.65%, TiO 2 : 10-15%, S: 0.4-0.6%, P0.001-0.003%, of which TFe: 52-58%, TFe is Fe in ore 2 o 3 The total amount of iron element with FeO.

[0017] The unique design concept of the present inventi...

Embodiment 1

[0025] This example was prepared in the laboratory. In order to compare with the existing pellets of vanadium-titanium magnetite concentrate + ordinary concentrate, two experiments were carried out in this embodiment, and the binder used was bentonite. Table 1 is the raw material composition of the used vanadium-titanium magnetite concentrate, wherein, V 2 o 5 0.65%, TiO 2 was 11.16%.

[0026] Table 1 raw material composition (%)

[0027] raw material name

TF

Fe 2 o 3

FeO

SiO 2

CaO

MgO

Al 2 o 3

S

P

Ordinary concentrate

63.25

61.38

26.12

5.47

1.23

0.90

1.00

0.324

0.035

Vanadium Titanium Magnetite Concentrate

55.56

46.39

29.72

3.35

1.92

2.56

3.31

0.441

0.002

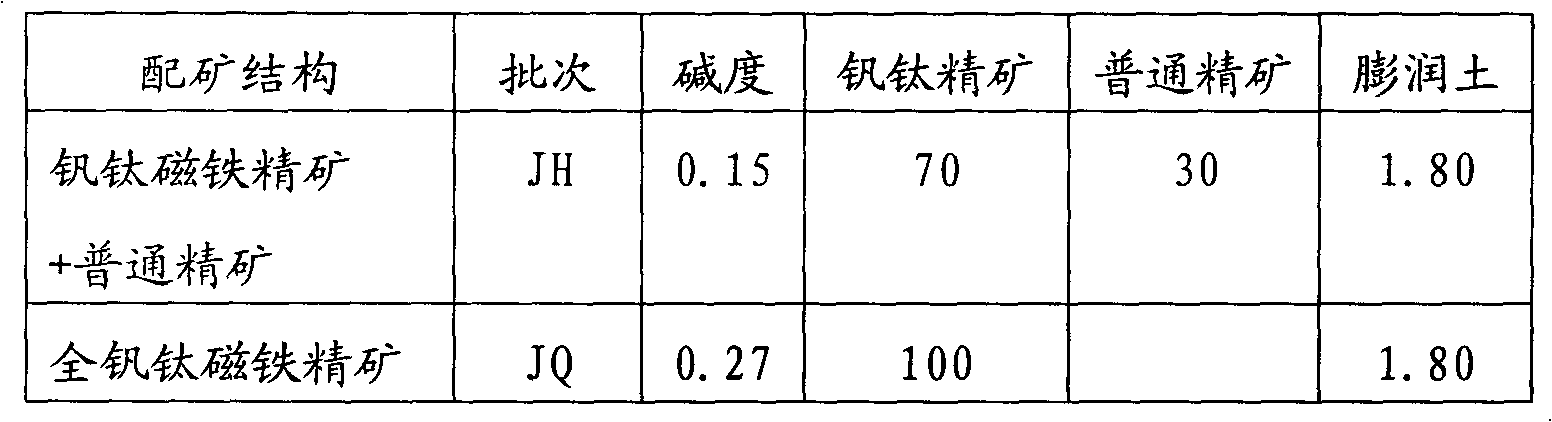

[0028] Table 2 Ingredients scheme (%)

[0029]

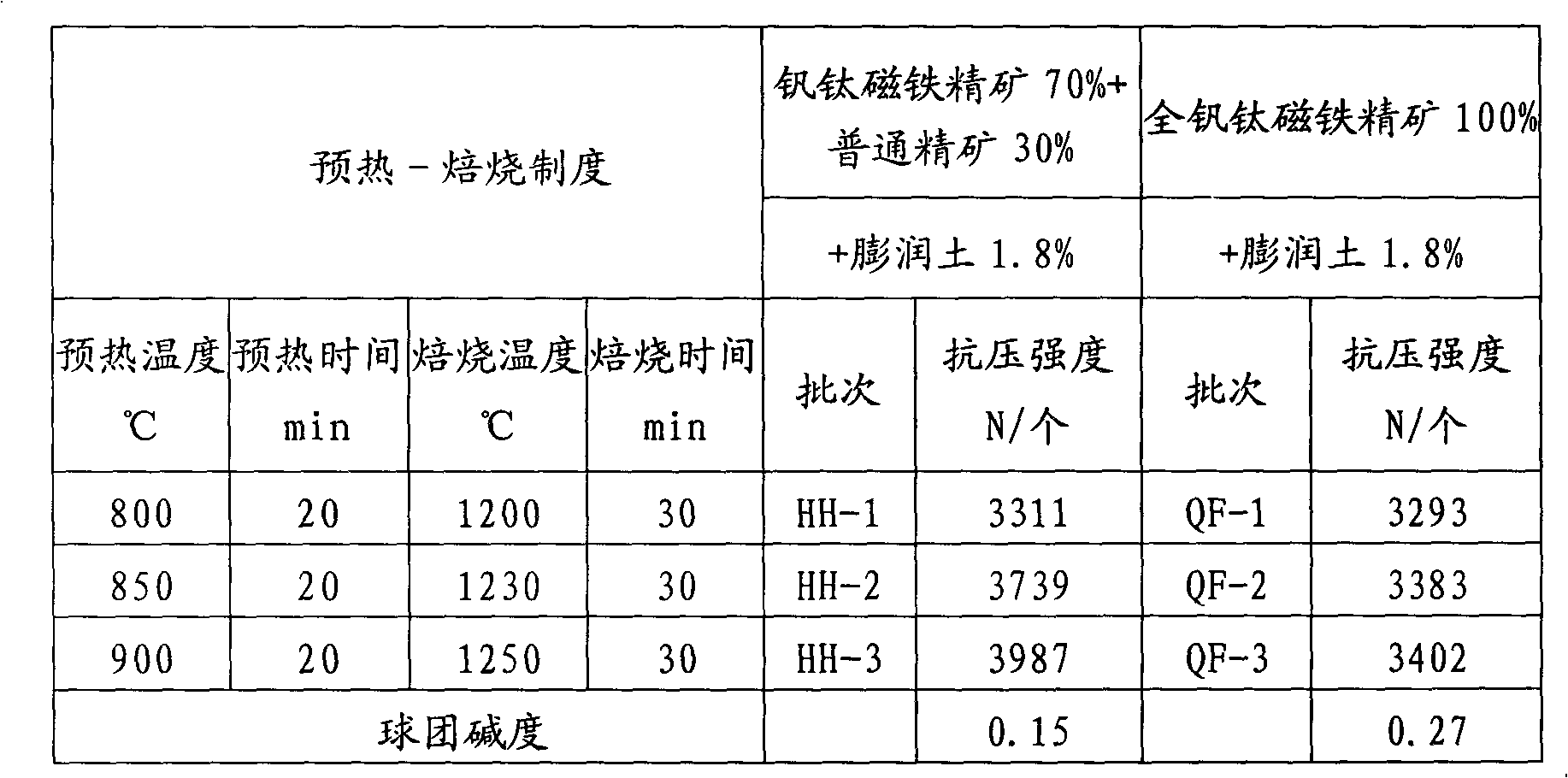

[0030] Take 5 kg of vanadium-titanium magnetite concentrate raw material according to the above-men...

Embodiment 2

[0036] This embodiment is the acidic all-vanadium-titanium pellets produced in actual industry. The composition of the vanadium-titanium magnetite concentrate used is shown in Table 4.

[0037] Table 4 raw material composition (%)

[0038] raw material name

TF

Fe 2 o 3

FeO

SiO 2

CaO

MgO

Al 2 o 3

V 2 o 5

TiO 2

S

P

Vanadium Titanium Magnetite Concentrate

56.5

48.5

31

2.55

1.55

2.84

3.65

0.65

10.5

0.41

0.001

[0039] The main equipment is a grate machine-rotary kiln, which produces qualified pellets through batching, mixing, pelletizing, preheating-roasting and other processes.

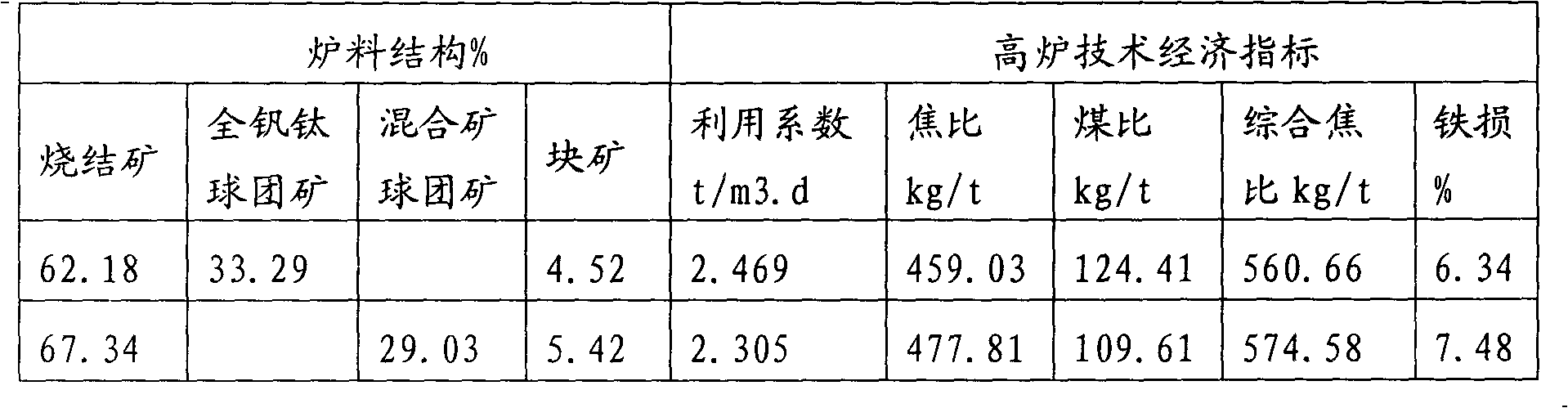

[0040] A, the proportioning of the all-vanadium-titanium magnetite concentrate of the above-mentioned table 2 content is 100%, is mixed and dried with 1.5% external bentonite, the moisture of the dry mixture is 6.5%, and its natural alkalinity is detected to be 0.26...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com