Method for building tailings dam through adoption of mine dumping

A technology for tailings dams and mines, which is applied in the field of tailings dams using mine dumps, which can solve the problems of large land occupation of mine dumps and tailings ponds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

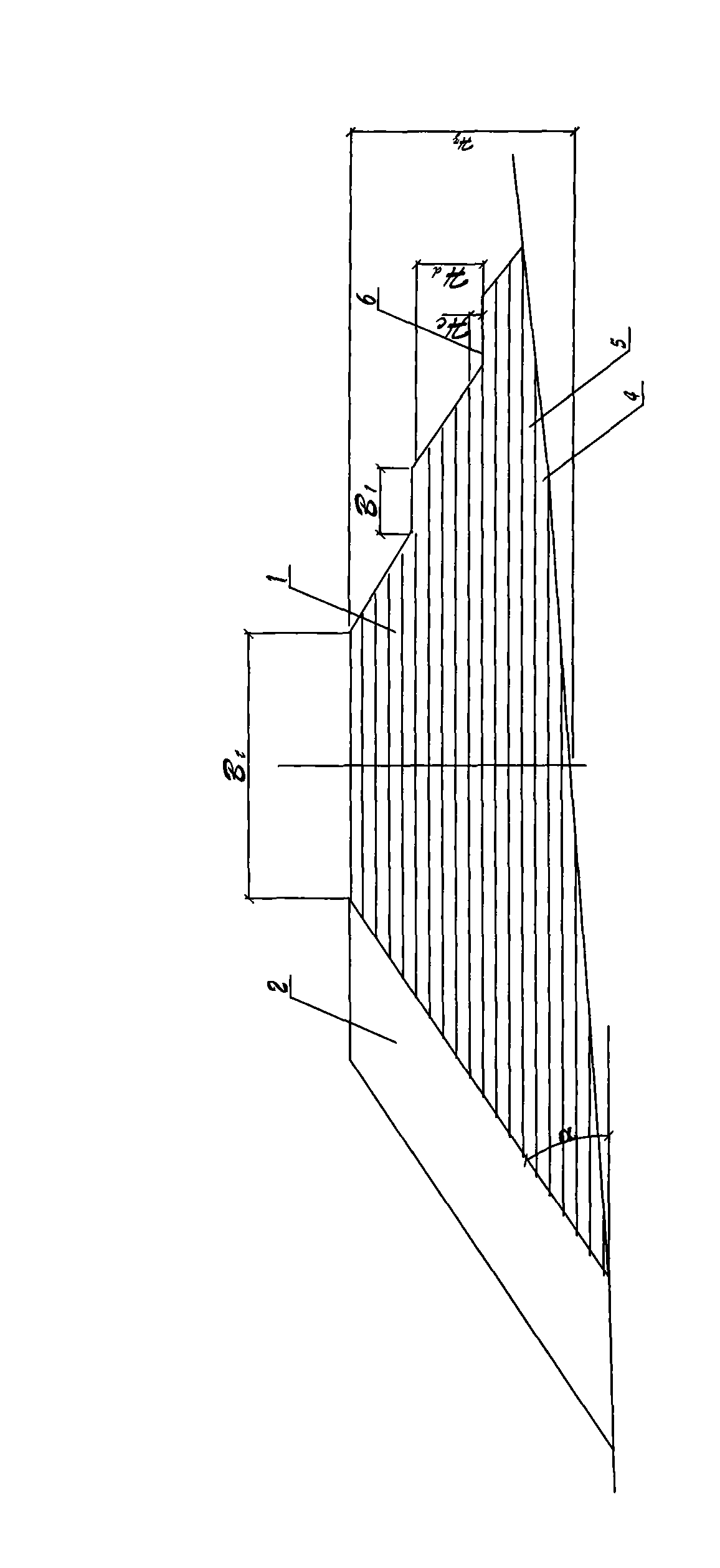

[0081] Such as figure 2 As shown, when the mine is excavated by trucks, the layered dam construction method is implemented, the tailings dam is divided into several layers in the height direction, and the tailings dams are piled up layer by layer by automobiles. The waste rocks are dumped directly on the ground to form a soil pile, and the soil pile is flattened by a bulldozer to form the first layer 4 of the tailings dam body, and then a fully loaded vehicle is used to roll back and forth on the first layer to compress the first layer. Leveling and compacting, then continue to dump waste rocks on the first layer to build the second layer 5, set a tailings discharge pipeline platform 6 every few layers, and form tailings dam 1 repeatedly. After formation, the dump site 2 develops toward the outside of the tailings dam.

Embodiment 2

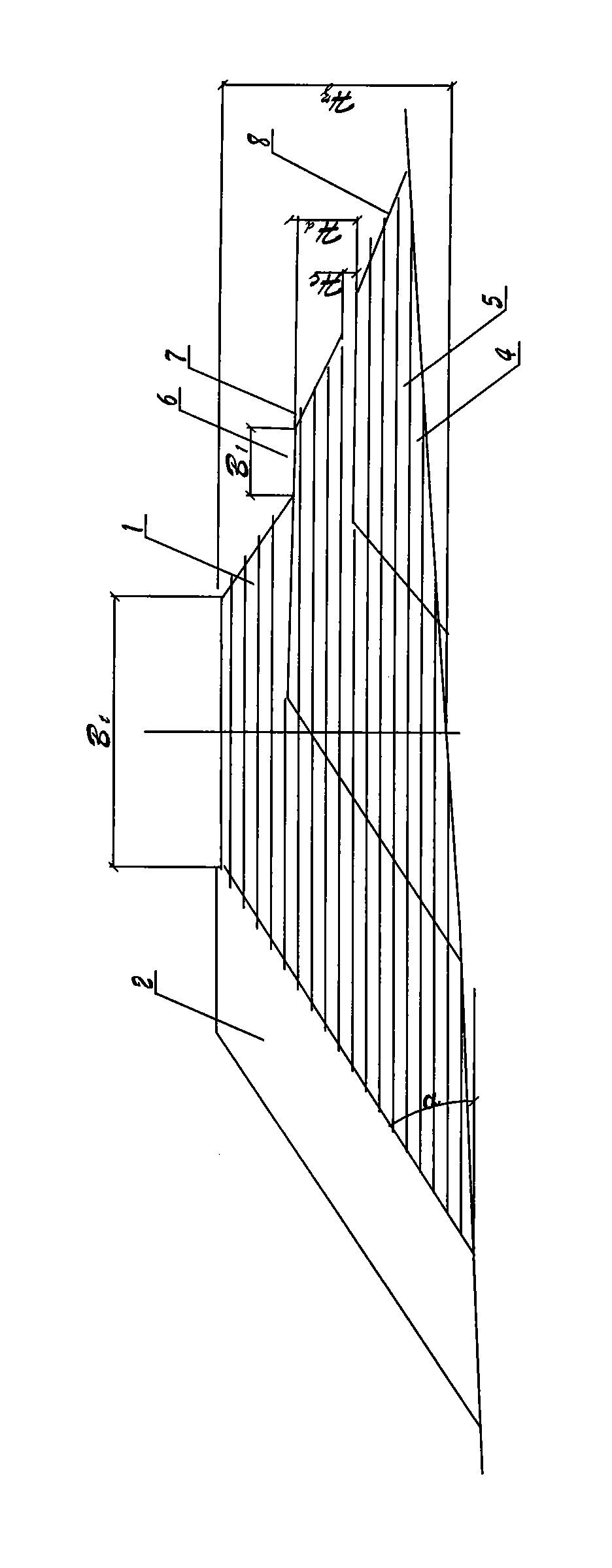

[0083] Such as image 3 As shown, when the mine discharge is carried out by automobiles, the dams are constructed in strips, and the tailings dams are divided into several strips in the width direction, which are piled up one by one by automobiles, and each tailings dam is A tailings discharge pipeline interval height is set higher than the previous tailings dam, and a tailings discharge pipeline platform 6 is set between the two tailings dams. First, the waste rocks are directly dumped by the car on the spot to form a mound, and the bulldozer will The soil mound is flattened to form the first layer 4 of the tailings dam body, and then a fully loaded vehicle is used to roll back and forth on the first layer to flatten and compact the first layer, and then continue on the first layer Turn over and unload waste rocks and build the second layer 5 to form the first tailings dam 8 repeatedly, and then build the second tailings dam 7 toward the outside of the tailings pond by the ab...

Embodiment 3

[0108] Such as Figure 4 As shown, when the mine discharge method adopts the railway discharge method, the tailings dam is directly piled up by using the railway discharge electric shovel pile or inverted pile. At first utilize electric shovel or bulldozer to form the initial embankment 9 of railway discharge, lay the railway on the initial embankment 9, utilize electric shovel to form initial stage dam 10 by piling up or inversion mode, lay railway on initial stage dam 10 after, utilize electric shovel to press The platform 11 is formed by stacking or inverting the soil toward the downstream of the tailings pond, and the second tailings dam 12 is formed on the platform in the direction of the downstream of the tailings pond by using an electric shovel. A tailings discharge pipeline platform 6 is set between the first tailings dams, and then a railway is laid on the second tailings dam 12, and the soil is discharged to the downstream of the tailings pond to form a platform 13,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com