High stability fuel assembly compacting system with variable rigidity and low radiation slack

A fuel assembly, high-stability technology, applied in the field of compression systems, can solve the problems of easy irradiation relaxation, insufficient compression force, reduced spring compression force, etc., to reduce structural materials, reduce axial loads and stress levels , reduce the effect of bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

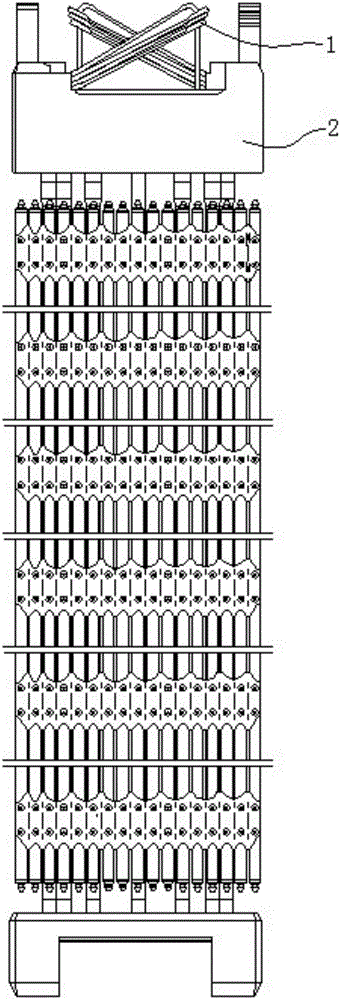

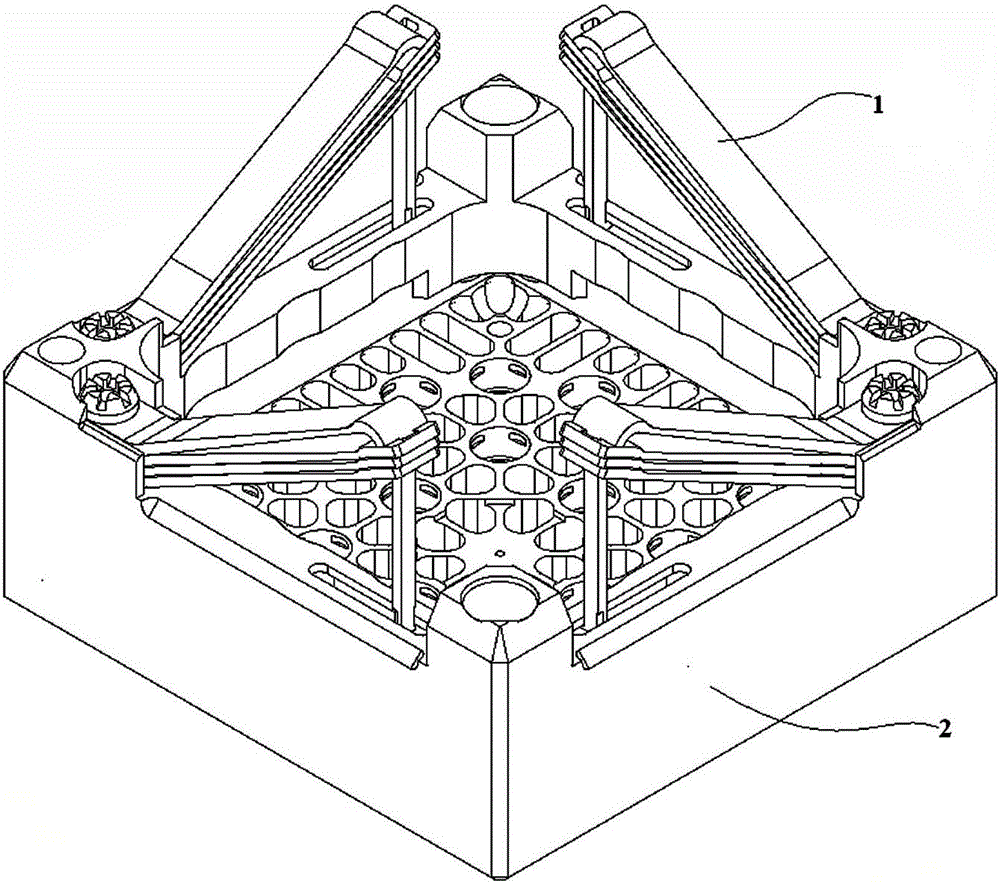

[0039] A high-stability fuel assembly compression system with variable stiffness and low radiation relaxation, such as figure 1 , figure 2 and image 3 As shown, it includes a leaf spring set 1 installed on the tube base 2 and a coil spring set 3 installed in the tube base 2 . In the present invention, the leaf spring assembly 1 is installed on the fuel assembly socket 2, which can be the upper socket at the upper end of the fuel assembly, or the lower socket at the lower end. In this embodiment, the above socket is taken as an example.

[0040] Such as figure 2 As shown, the leaf spring group 1 includes an A leaf spring 11 stacked from top to bottom and more than one B leaf spring 12. The A leaf spring 11 consists of a horizontal section, an inclined arm and a vertical The B plate spring is composed of a horizontal section and an inclined arm. The end of the inclined arm of the B plate spring is provided with a window for the vertical arm to pass through. The horizontal ...

Embodiment 2

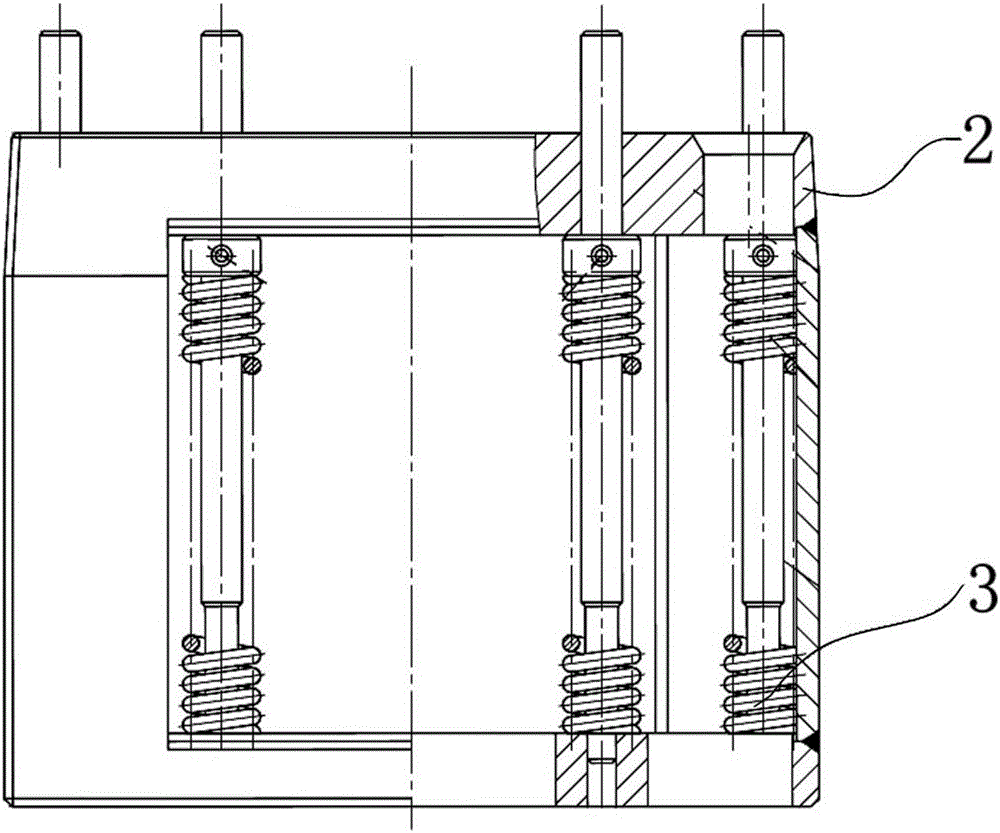

[0049] The difference between this embodiment and Embodiment 1 is that this embodiment optimizes the structure of the helical spring group 3, and the specific settings are as follows:

[0050] The coil spring group 3 includes a compression rod 31 that runs through the tube base 2 , a compression cap 32 that is arranged on the compression rod 31 and is located at the top end of the tube base 2 , and is sleeved on the compression rod 31 and is located inside the tube base 2 . The spiral outer spring 33 below the pressure cap 32; the pressure rod 31 below the pressure cap 32 in the tube seat 2 is also provided with a step, and the preset inner spring 34 is arranged between the step and the pressure cap 32, and the preset inner The spring is located inside the helical outer spring 33 . In this embodiment, the preset inner spring 34 is a helical spring, such as Figure 5 shown.

Embodiment 3

[0052] The difference between this embodiment and Embodiment 2 is that the setting of the preset inner spring 34 in this embodiment is different, and the preset inner spring 34 is a disc spring in this embodiment, such as Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com