Online measuring method for burn-up level of fuel element of sphere type modular high-temperature gas-cooling reactor

A technology of high-temperature gas-cooled reactors and fuel elements, which is applied in the fields of reducing greenhouse gases, reactors, and nuclear reactor monitoring, and can solve problems such as difficult to meet timely and accurate basic requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

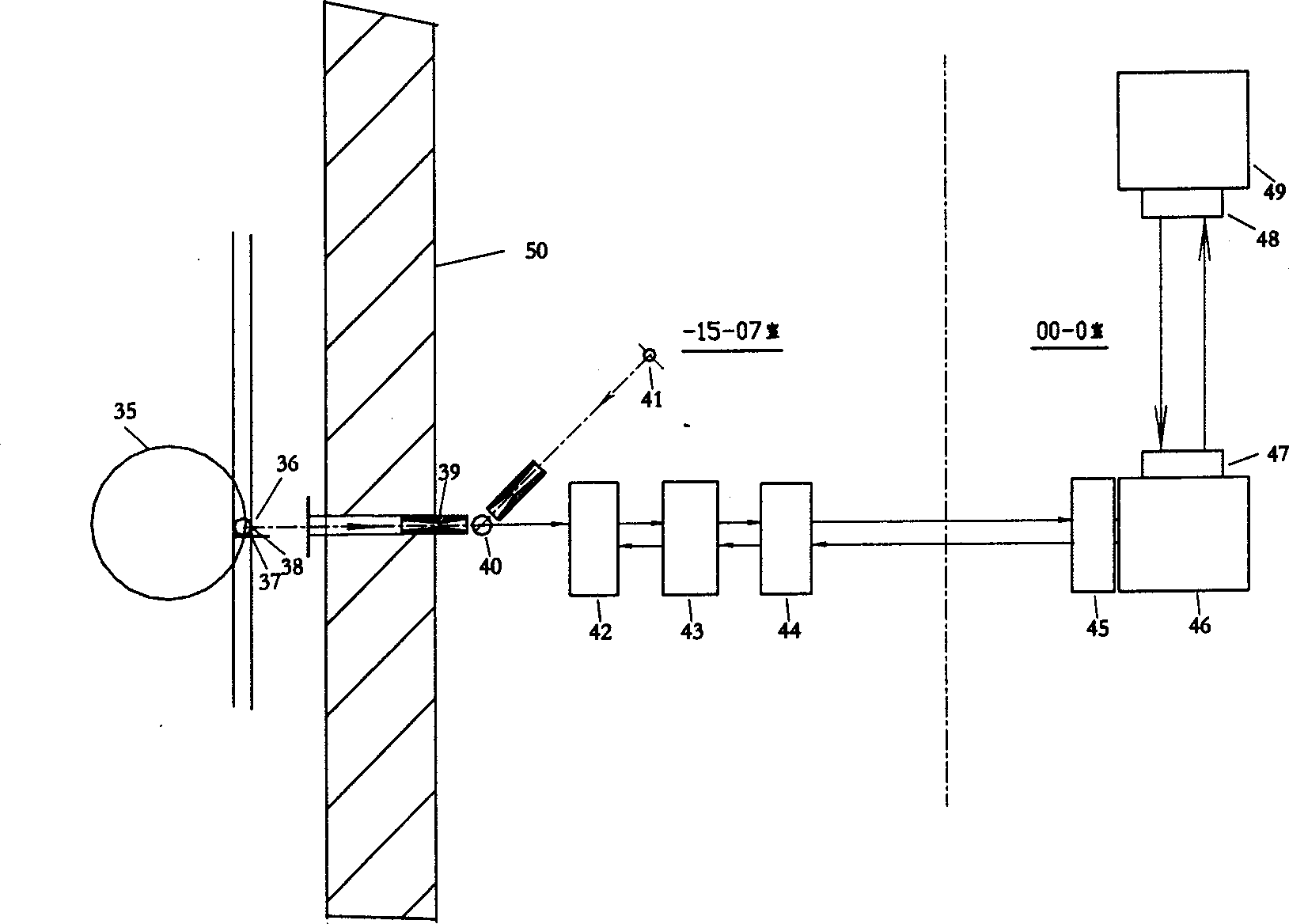

[0104] In order to realize the above-mentioned burnup depth measurement process, the FCA system of HTR-10 is equipped with three core system equipments: high-purity germanium gamma energy spectrometer, tungsten collimator, and programmable controller (OMRON C200HS):

[0105] (1) High-purity germanium gamma energy spectrometer: fission products emit relatively 137 The γ-rays that are nearly a hundred times stronger than Cs have extremely complex components, and some γ-rays have the same energy as 137 The Cs spectral lines are very close, so this method adopts a high-resolution high-purity germanium gamma energy spectrometer to separate 137 The gamma line of Cs. The relevant parameters are designed as follows:

[0106] i) Detector

[0107] P-type high-purity germanium detector, placed vertically, allowing temperature cycle, detection efficiency 19-20%, energy range for gamma-ray detection: 40KeV-10MeV;

[0108] Energy resolution: 1.8KeV~1.75KeV for γ of 1.33MeV;

[0109] Ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com