Grouped pneumatic lifting system and method for pebble-bed reactor fuel elements

A fuel element and lifting system technology, which is applied in the direction of reactor fuel elements, reactors, thermal reactors, etc., can solve problems such as high manufacturing, maintenance and use costs, complex systems, accuracy and economic limitations, and achieve optimized lifting capabilities and improved The effect of conveying efficiency and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

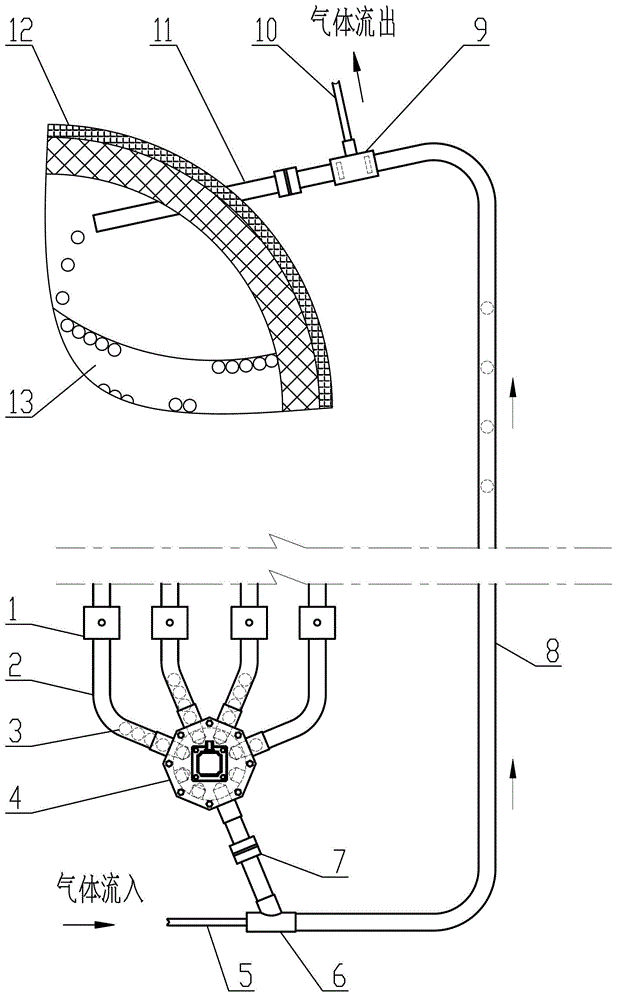

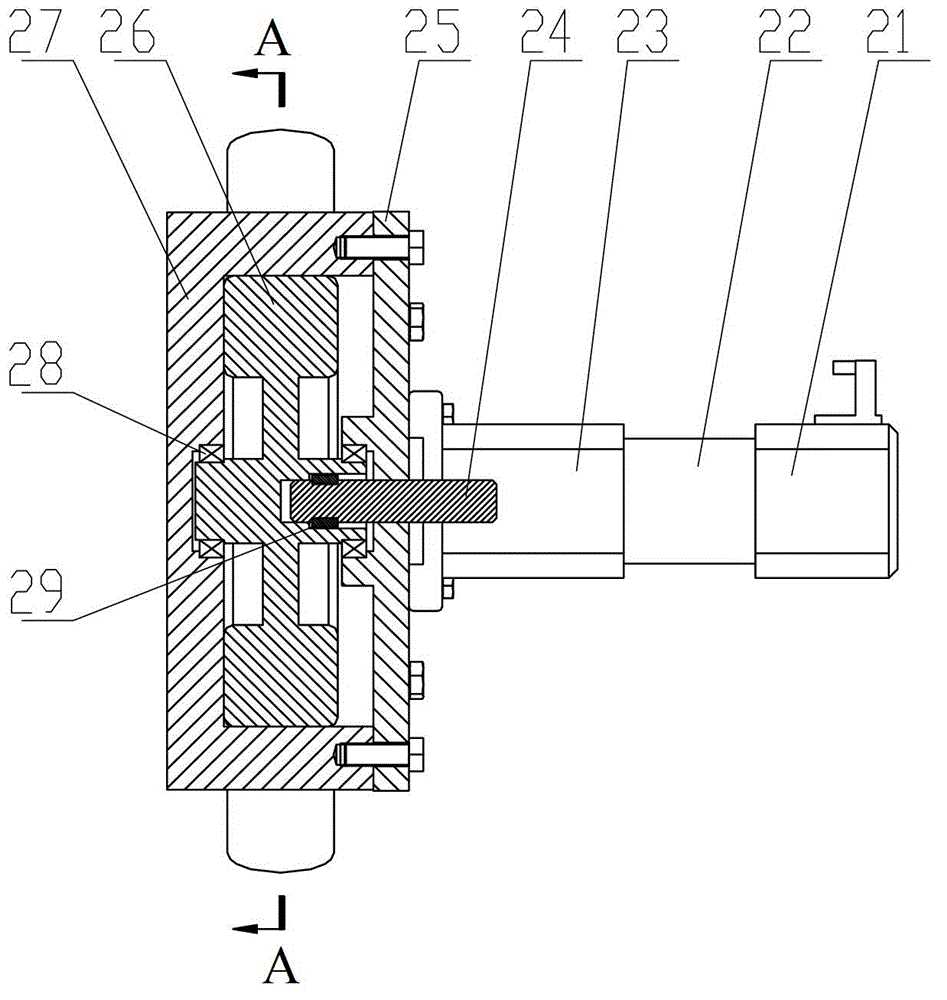

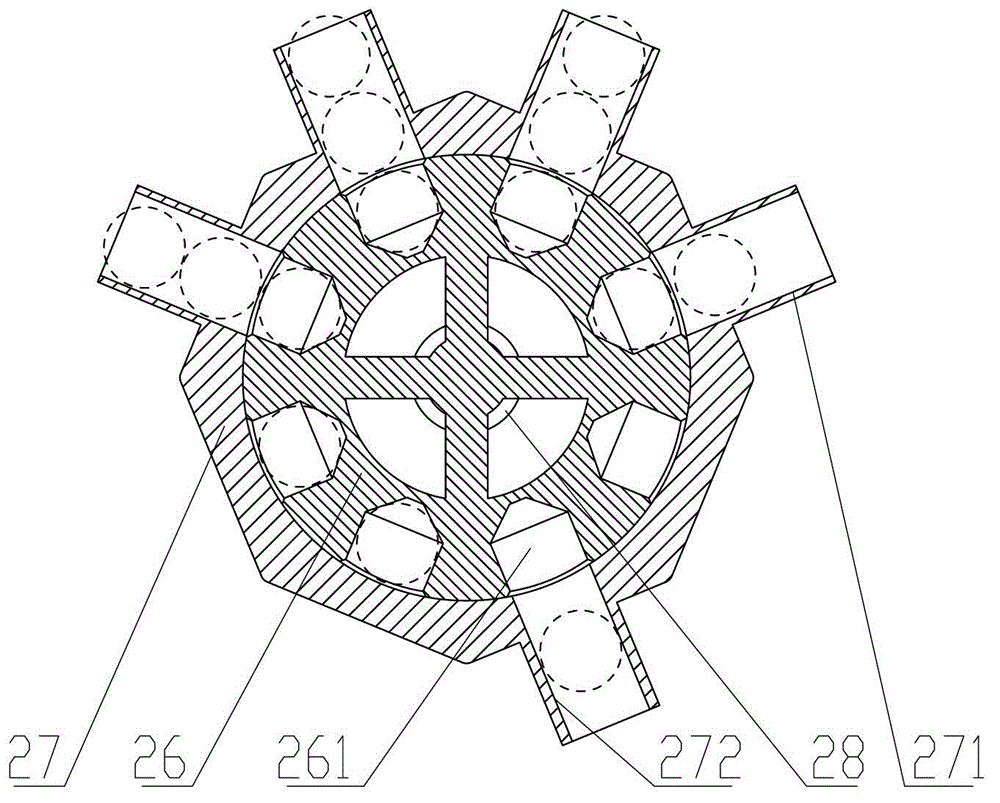

[0024] The structure, principle and working process of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] figure 1 It is a schematic structural diagram of an embodiment of a pebble bed reactor fuel element group pneumatic lifting system embodiment proposed by the present invention. Power equipment and at least two sets of fuel consumption detection assemblies, four sets of fuel consumption detection assemblies are used in this embodiment; the feeder has the same number of inlets and one outlet as the fuel consumption detection assemblies; each set of fuel consumption detection assemblies includes a Consumption detector 1 and a buffer pipeline 2, one end of each buffer pipeline is connected with the outlet of the burnup detector 1, and the other end is connected with one of the inlets of the feeder 4; the fluid power device includes a high-pressure gas chamber and a Low-pressure air chamber; a tee 6 is provided at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com