Nuclear fuel rod with ceramic cladding and metallic pellet

A technology of nuclear fuel rods and metal fuels, which is applied in the fields of reactor fuel material, nuclear power generation, surveying and navigation, etc., can solve the problem that the cladding and fuel neutronics, mechanical properties have not been improved, and the thermal conductivity cannot be fundamentally improved. Thermal conductivity, poor mechanical properties and other problems, to achieve the effect of improving mechanical properties, high temperature resistance, and increasing working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

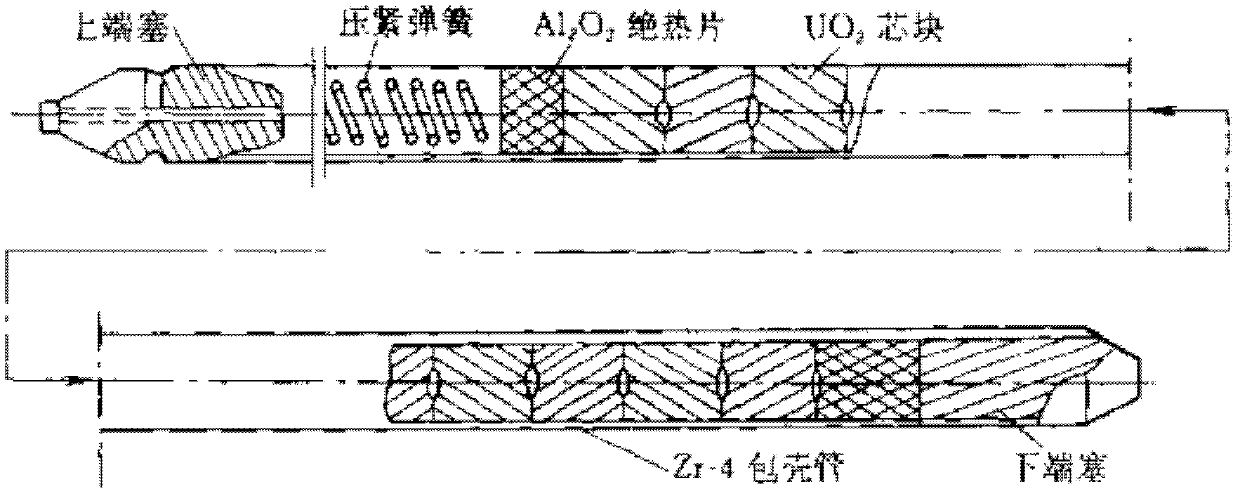

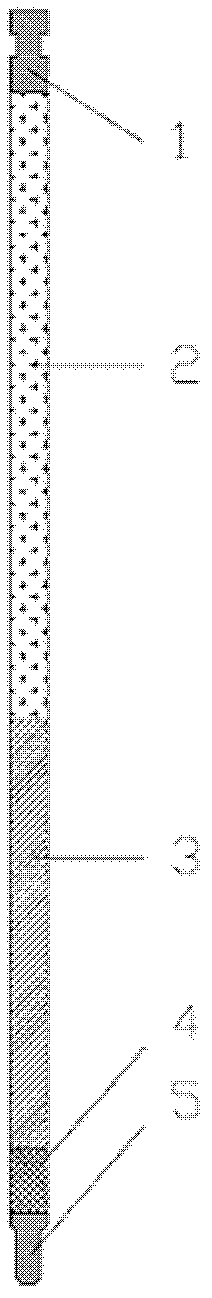

[0031] Such as image 3 As shown, the nuclear fuel rod of the present invention is provided with the lower end plug 5, the shielding area 4 adjacent to the lower end plug 5, the active fuel area 3 adjacent to the shielding area 4, and the extension above the active fuel area 3 in the axial direction. The air cavity 2 and the upper end plug 1 adjacent to the upper end of the elongated air cavity 2 . The length of the extended air chamber 2 is much longer than that of the existing PWR fuel rod air chamber, and is also longer than that of the existing fast reactor fuel rod air chamber, and its length is about 1 to 1.5 times the length of the fuel rod active area 3 .

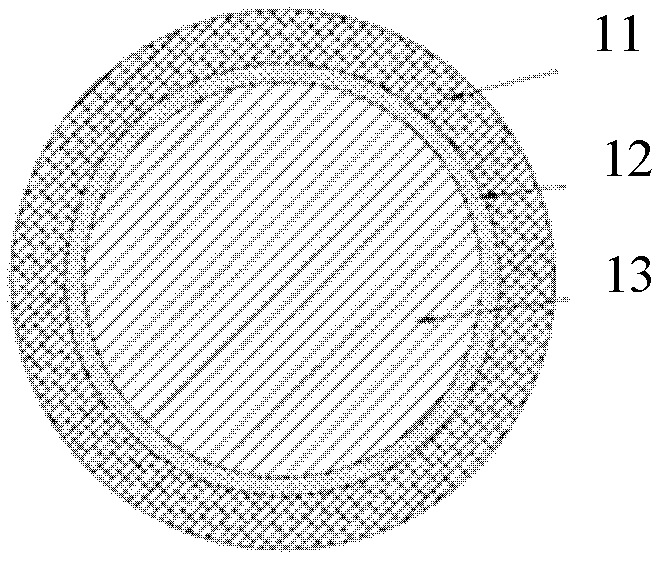

[0032] figure 2 is a cross-sectional view of the active fuel zone 3 . Such as figure 2 and image 3 In the shown embodiment, the elongated gas cavity 2 is elongated relative to the gas cavity of the existing fuel rod, so as to provide sufficient containment capacity of fission gas.

[0033] Such as image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com