Nuclear power plant fuel element cladding failure monitoring method and system

A technology for fuel elements and nuclear power plants, which is used in nuclear power generation, nuclear reactor monitoring, nuclear engineering, etc., and can solve the problems of inability to continuously monitor online and to accurately diagnose the damaged shape of fuel element cladding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] During the operation of a nuclear power plant (such as a pressurized water reactor nuclear power plant), when the fuel element cladding of the nuclear power plant is damaged, the characteristic nuclides produced by nuclear fuel fission, such as iodine (I), xenon (Xe) and other nuclides, in the primary circuit coolant Release, migration and deposition, and according to the size and location of the crack in the shell, and because of the different physical and chemical properties of each nuclide, the amount of the characteristic nuclide released from the crack is also different.

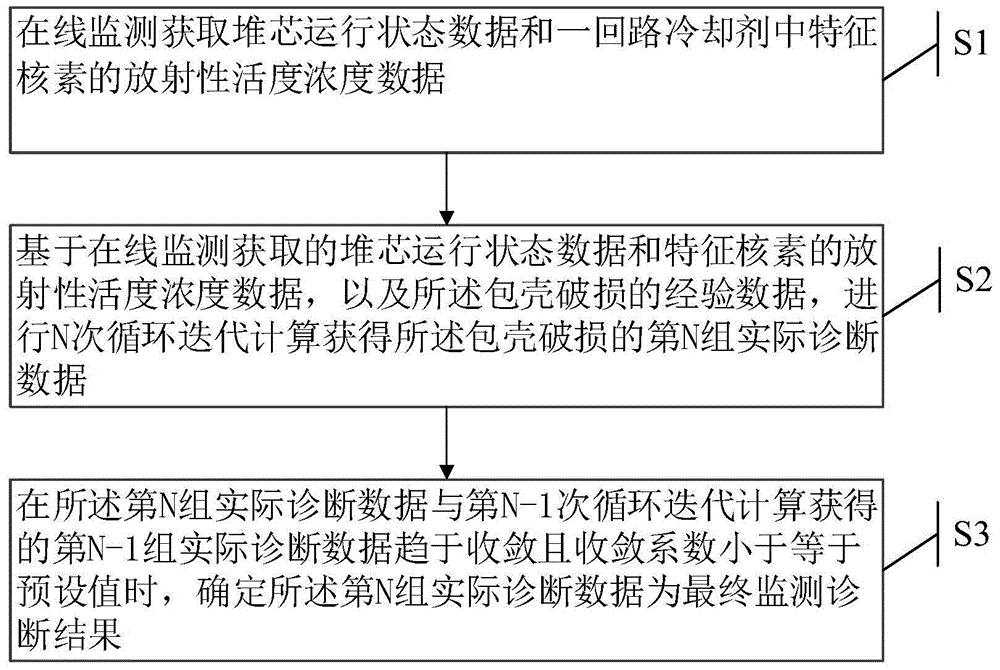

[0065] Please refer to figure 1 The embodiment of the present application provides a nuclear power plant fuel element cladding damage monitoring method, which is used for monitoring and diagnosing the number of damaged fuel element claddings, the damaged size and the burnup area of the damaged component when the nuclear power plant fuel element cladding is damaged. The monitoring method compris...

Embodiment 2

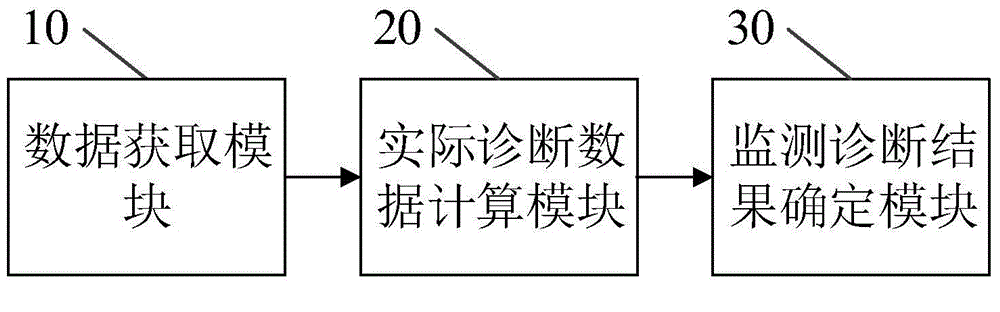

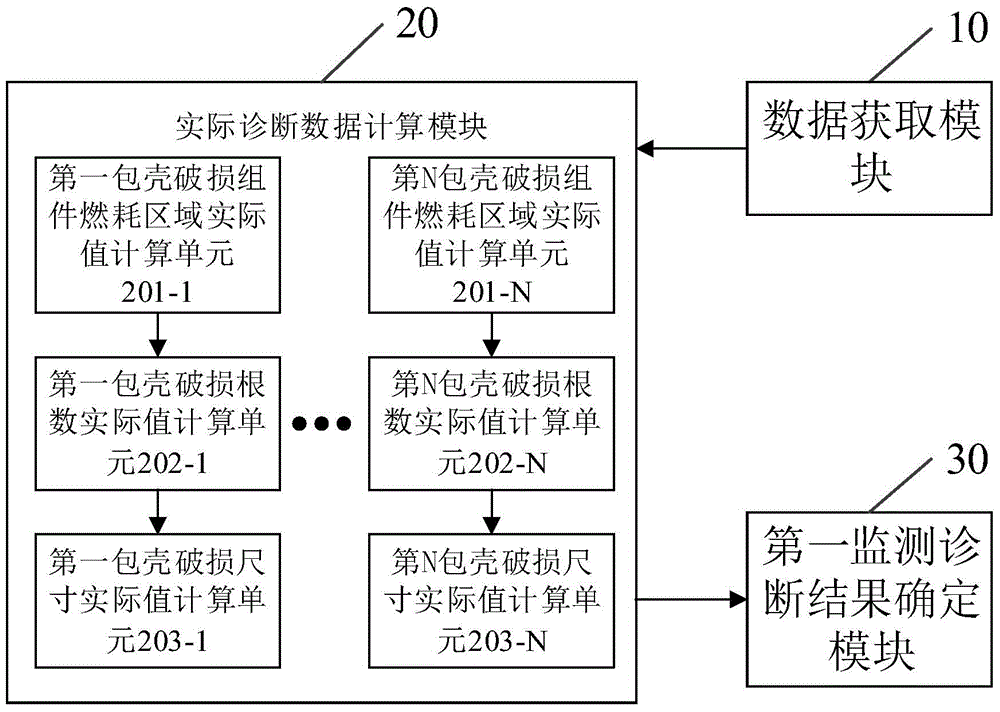

[0099] Based on the same inventive concept, please refer to figure 2, the embodiment of the present invention also provides a nuclear power plant fuel element cladding damage monitoring system, which is used for monitoring and diagnosing the number of damaged fuel element claddings, the size of the damage and the burnup area of the damaged component when the nuclear power plant fuel element cladding is damaged , when the nuclear power plant fuel element cladding is damaged, the characteristic nuclides produced by nuclear fuel fission are released, migrated and deposited in the primary coolant, and the monitoring system includes:

[0100] The data acquisition module 10 is used for online monitoring and acquisition of core operating status data and radioactivity concentration data of characteristic nuclides in the primary coolant;

[0101] The actual diagnostic data calculation module 20 is used to perform N cycles of iterative calculations to obtain the cladding based on the...

Embodiment 3

[0122] Please refer to Figure 4 According to the fuel cladding damage diagnosis model described in Embodiment 1 and the properties of radionuclides in the primary circuit coolant of the nuclear power plant, the embodiment of the present invention also proposes another nuclear power plant fuel element cladding damage monitoring system, including: A data acquisition module 41 for detecting radionuclides in the chemical and volume control system (RCV) pipeline in the primary circuit coolant, and a data processing module 42 connected with the data acquisition module 41 . The data acquisition module 41 is composed of a detection component unit 411 (such as a GEM P-type coaxial HPGe detector), a gamma spectrometer 412, a probe cooler 413 and a 4π lead shield (not shown in the figure). Specifically, the detection component unit 411 includes a detection pipeline and a gamma spectrum probe (not shown in the figure), considering reducing the interference of the surrounding environment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com