Solar cell irradiation annealing furnace capable of uniformly and efficiently annealing

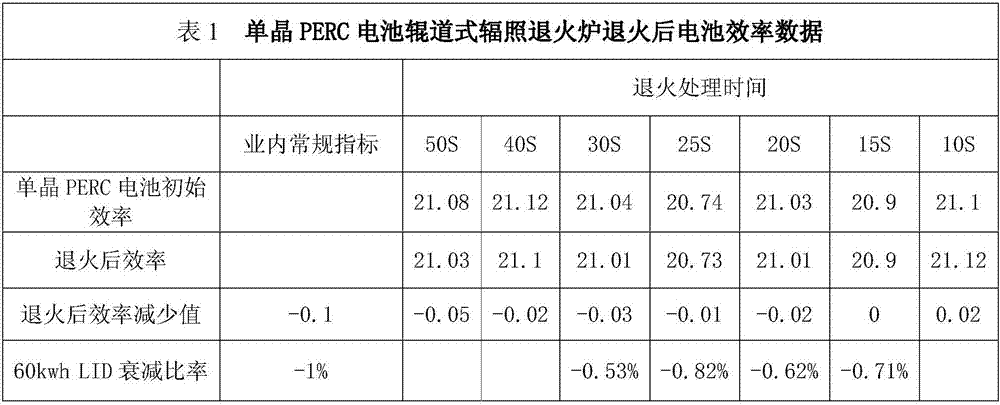

A solar cell and annealing furnace technology, which is applied in the field of irradiation annealing treatment of solar cells, can solve the problems of uneven cooling effect of cells, affecting cell treatment effects, and high temperature, and achieves enhanced cooling effect and uniformity of temperature control, Solve the problem of cooling and uniform temperature control, with the same cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

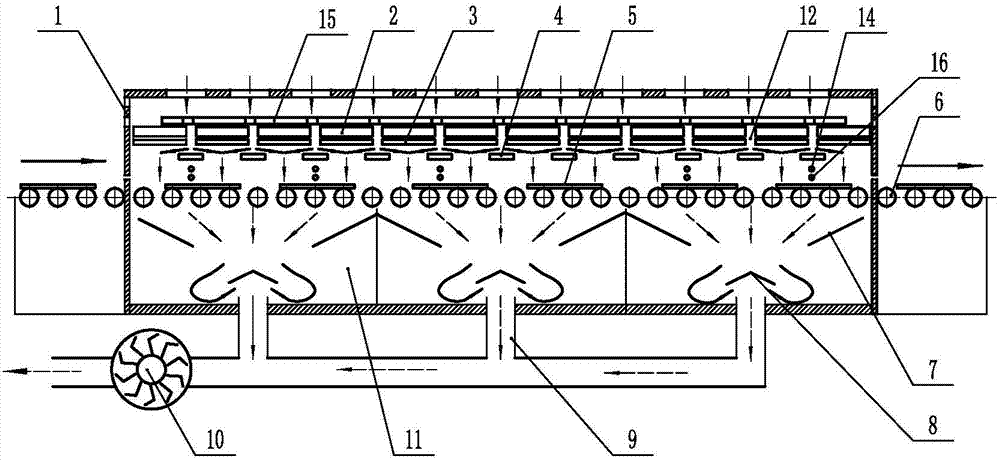

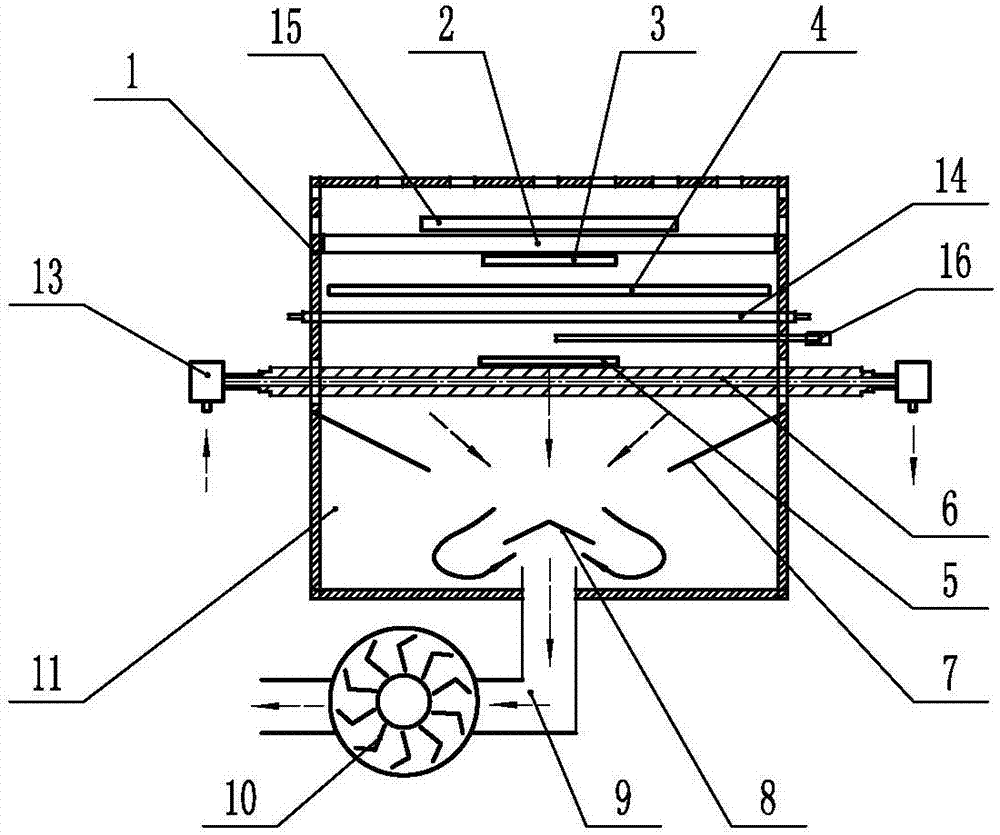

[0026] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0027] like Figure 1-2As shown, the uniform and high-efficiency annealing solar cell irradiation annealing furnace of the present invention includes a furnace body, the furnace body includes an upper furnace body 1 and a lower furnace body 11, and at least one group of light sources 3 are arranged in the upper furnace body 1, and the light source 3 Installed on the light source cooling device 2 and irradiate downward, an air inlet 12 is arranged between two adjacent groups of light sources 3 or between the light source 3 and the upper furnace body frame, and an air volume adjustment device 15 is arranged above the corresponding air inlet 12, corresponding to The air inlet 12 is provided with an upper deflector 4 below it, and a cell transfer device 6 is provided in the lower furnace body 11. The cell 5 is horizontally transferred on the cell transfer device 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com