Roller shell roller capable of heating with heat conducting oil

A technology of heat-conducting oil and rolls, which is applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of high difficulty, difficulty in manufacturing and installing connectors, and complicated process of processing inclined holes, so as to reduce processing costs and achieve uniformity The effect of controlling temperature and reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

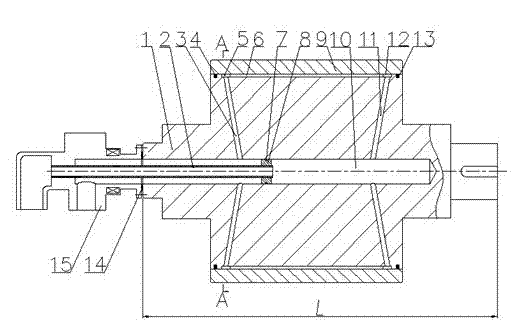

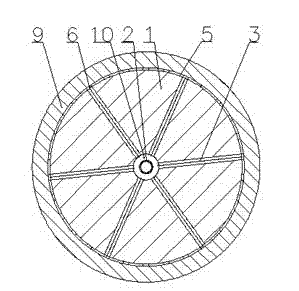

[0020] The utility model relates to a sleeved roller heated by heat conduction oil. The sleeved roll such as figure 1 and figure 2 Shown: including roll body 1, oil guide pipe 2, oil blocking ring 8, roll sleeve 9 and double-channel rotary joint 15.

[0021] Such as figure 1 As shown, the middle cylinder of the roll body 1 is the roll body, and the driven end of the roll body 1 is processed with a central oil passage 10 along the center line. The cylindrical surface of the roll body is symmetrically processed with a left annular oil groove 5 and a right annular oil groove 12, the left annular oil groove 5 is close to the left end of the roll body, the right annular oil groove 12 is close to the right end of the roll body, the left annular oil groove 5 and the left end of the roll body The cylindrical surface between is processed with left sealing groove, and left sealing ring 4 is housed in the left sealing groove. The right sealing groove and the left sealing groove are ...

Embodiment 2

[0025] The utility model relates to a sleeved roller heated by heat conduction oil. Except following technical parameter, all the other are with embodiment 1:

[0026] The left inclined oil passage 3 is inclined to the middle of the roll body, the inclination angle is 10°~15°, and the number of left inclined oil passages 3 is 5 or 7~12;

[0027] The length of the central oil passage 10 is the length of the roll body 1 L 80~90% of

[0028] The distance between the left annular oil groove 5 and the left end face of the roller body is 40-60mm.

[0029] This specific embodiment: after the roller sleeve 9 is fixedly covered on the surface of the roller body, the left annular oil groove 5, the right annular oil groove 12, the oil guide groove 6 and the inner wall of the roller sleeve 9 formed on the surface of the roller body correspondingly form a left annular oil passage , right annular oil passage and oil guide passage; The oil plug ring 8 divides the center oil passage 10 int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com