Patents

Literature

58results about How to "Same cooling effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

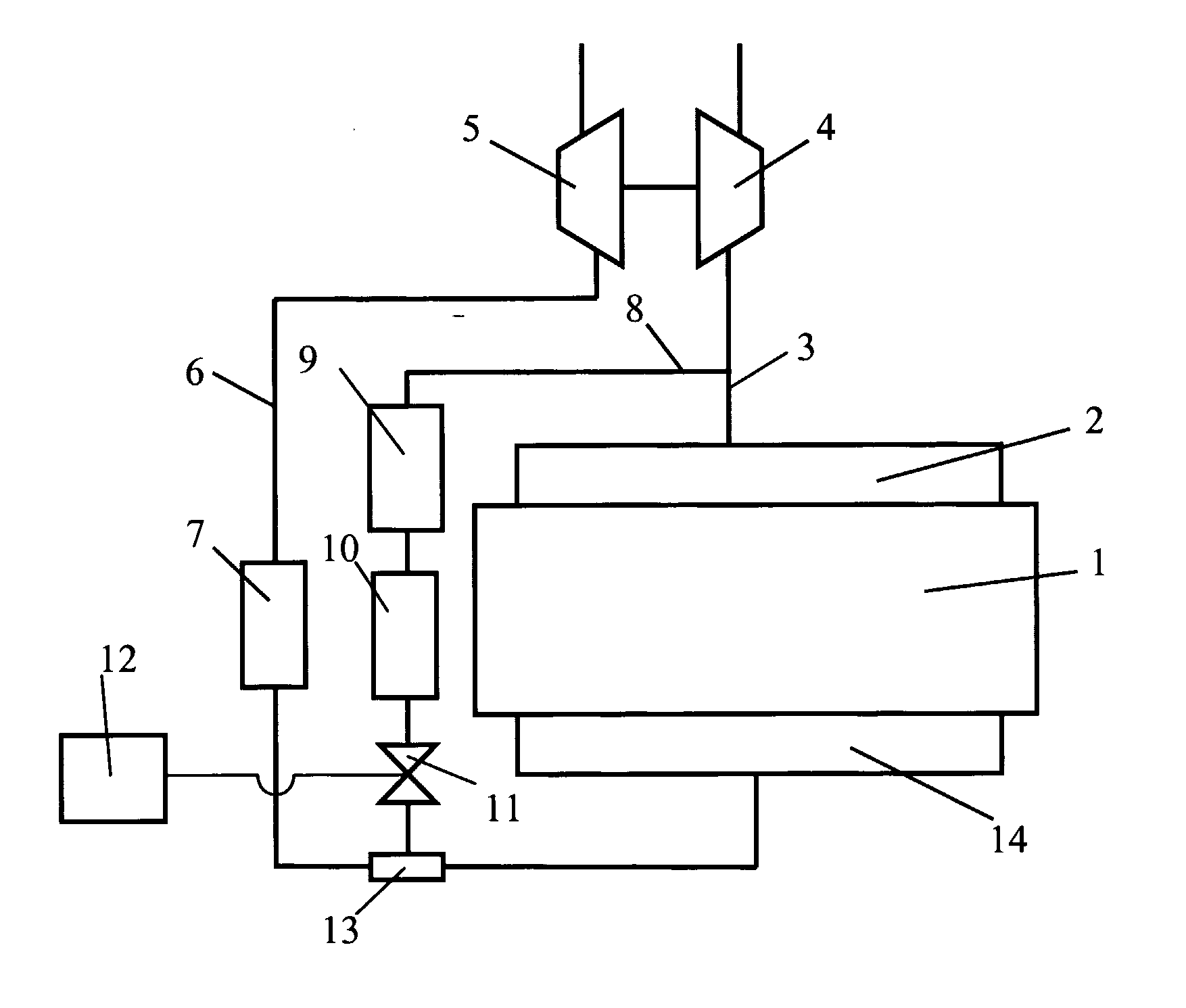

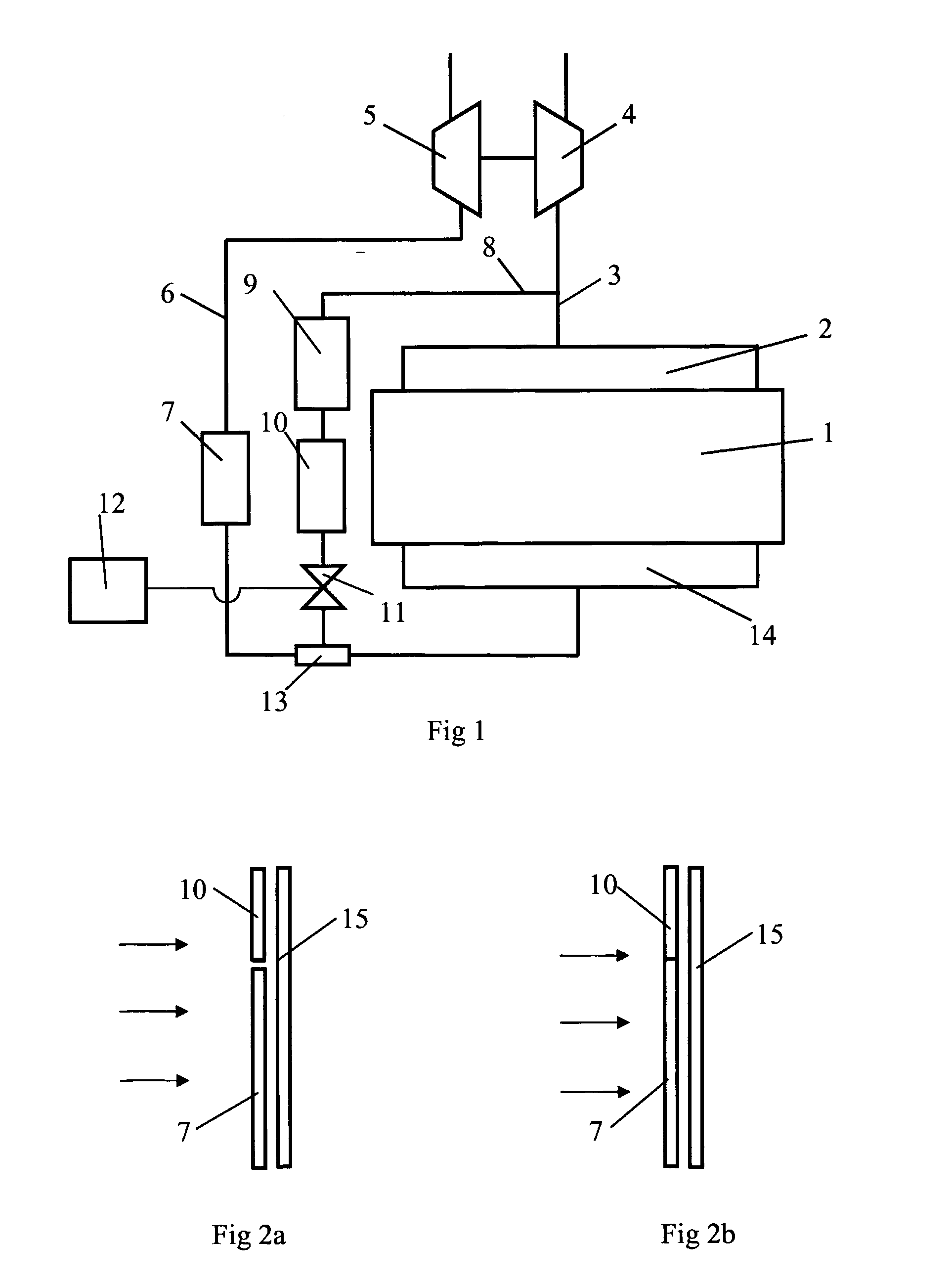

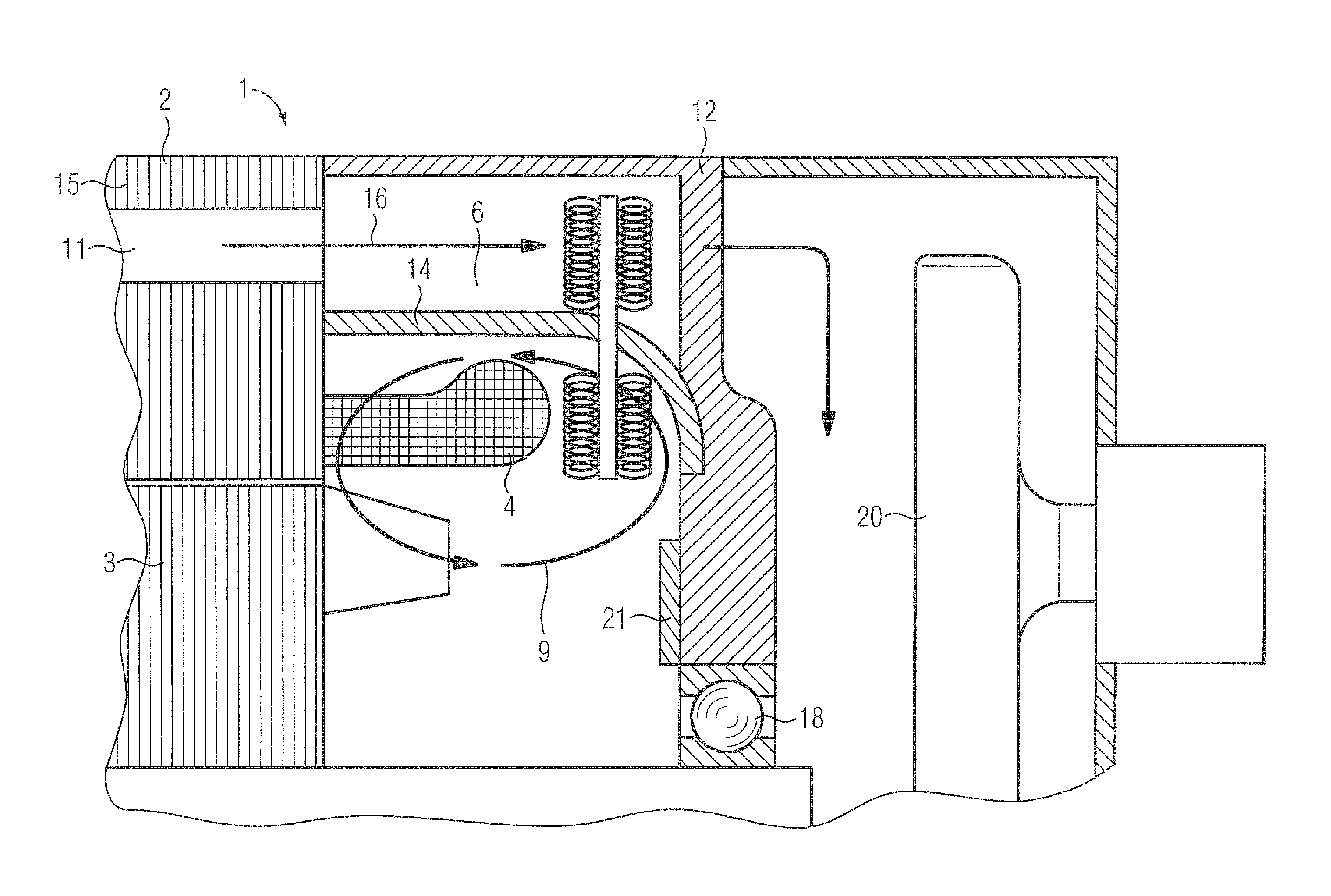

Arrangement for recirculation of exhaust gases of a super-charged internal combustion engine

InactiveUS20070204619A1Guaranteed airflowSame cooling effectNon-fuel substance addition to fuelInternal combustion piston enginesCombustionExternal combustion engine

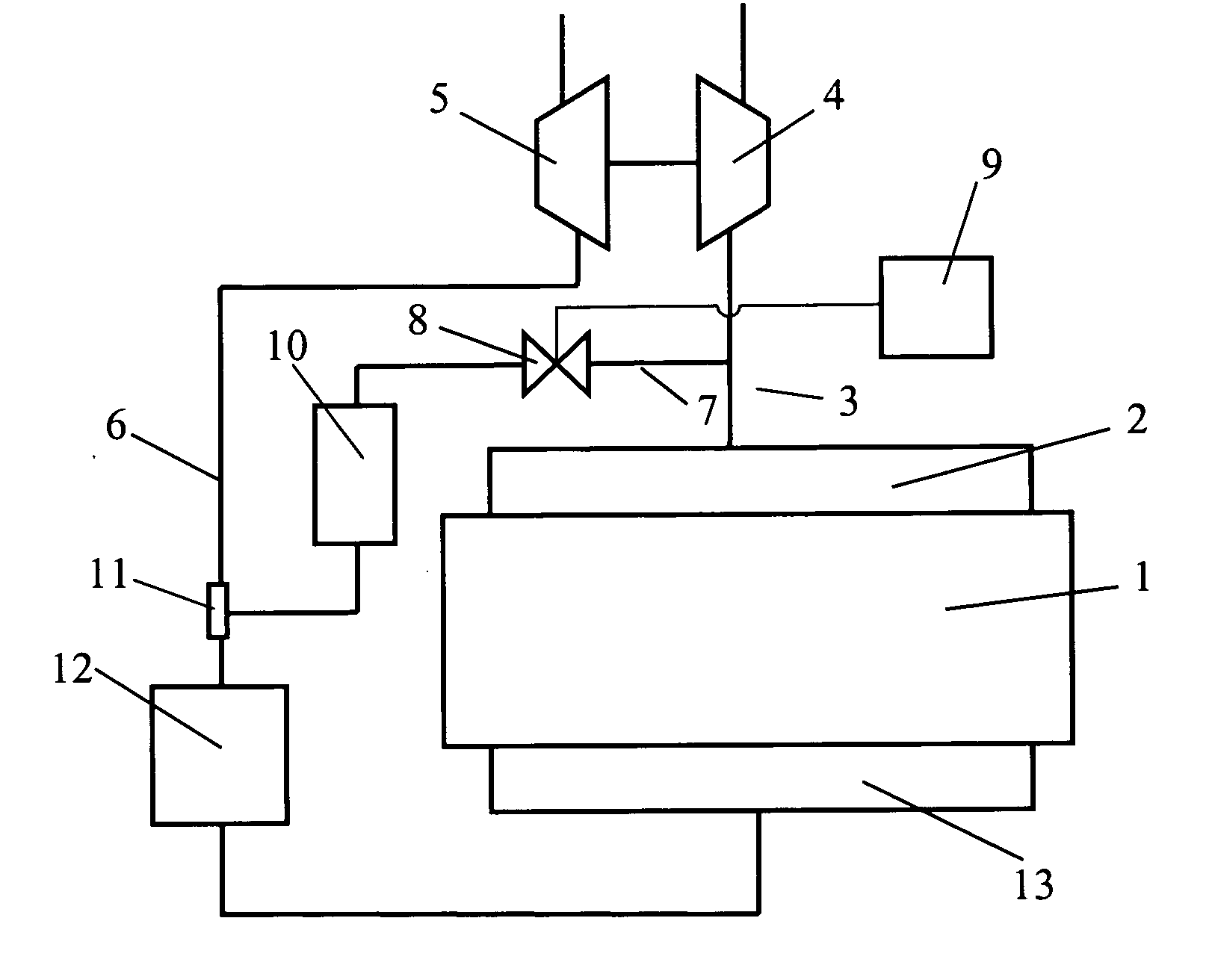

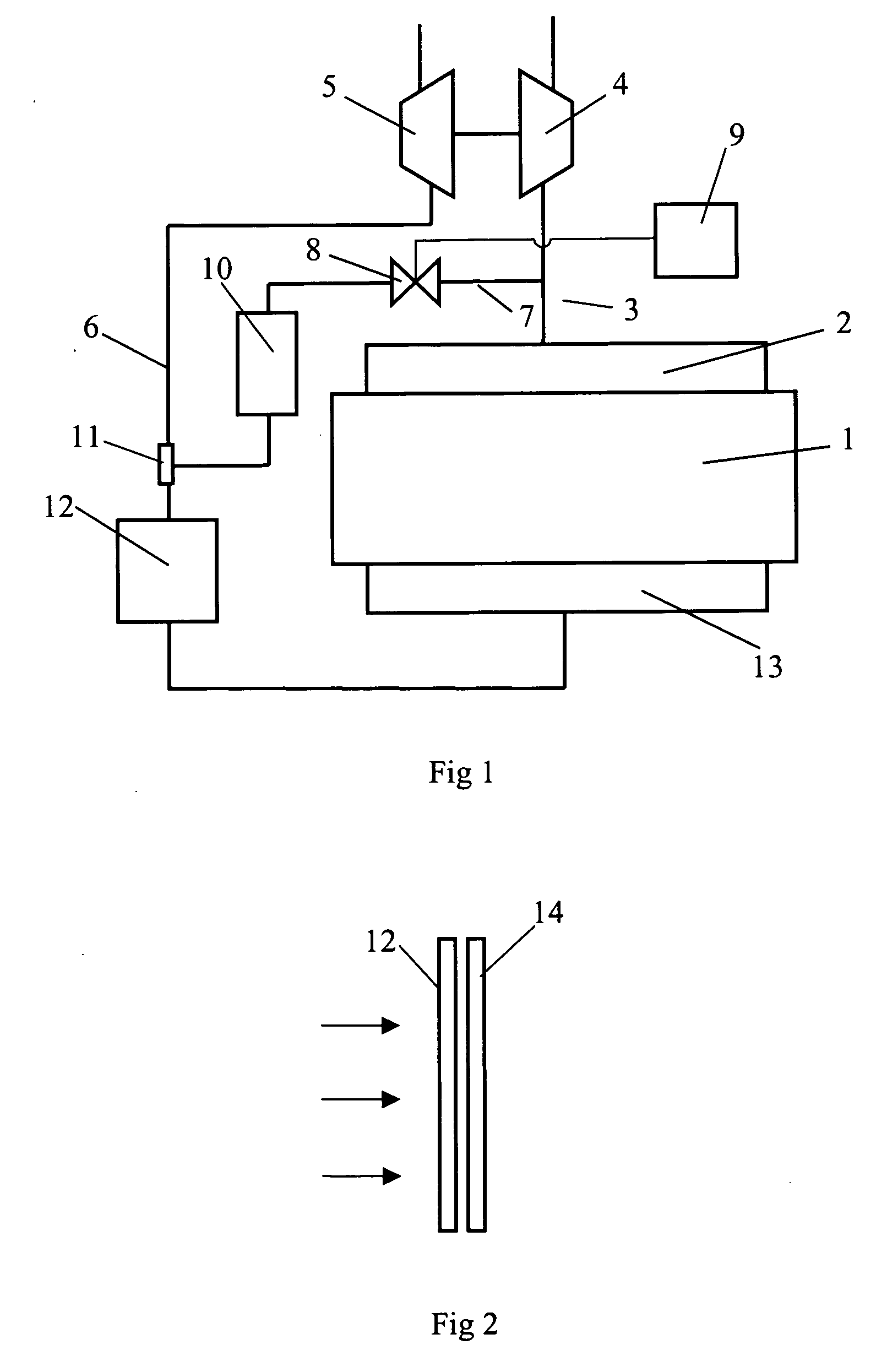

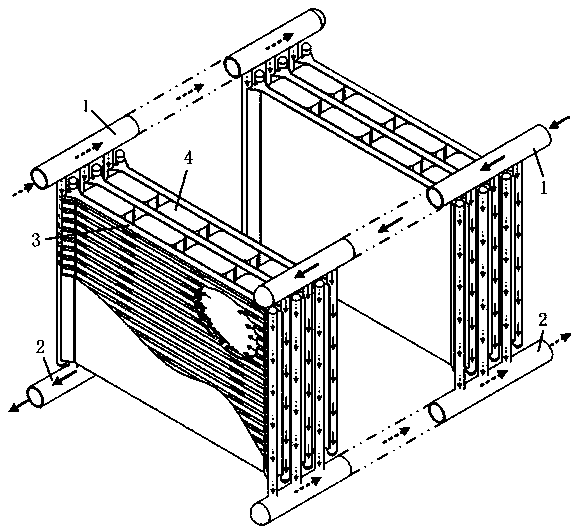

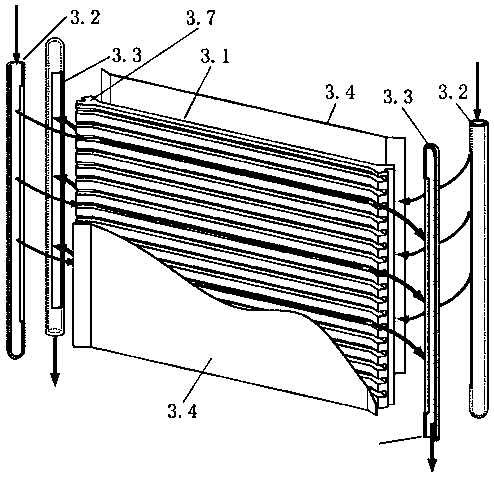

An arrangement for recirculation of exhaust gases in a supercharged combustion engine. The arrangement includes an exhaust line operable to lead exhaust gases out from the combustion engine, an inlet line operable to lead air at above atmospheric pressure to the combustion engine, a return line which comprises a connection to the exhaust line and a connection to the inlet line, so that via the return line it is possible to recirculate exhaust gases from the exhaust line to the inlet line. A first cooler incorporated in the return line for cooling the exhaust gases in the return line before they are mixed with the air in the inlet line. The exhaust gases in the first cooler are cooled by a first medium which is at a temperature substantially corresponding to the temperature of the surroundings.

Owner:SCANIA CV AB

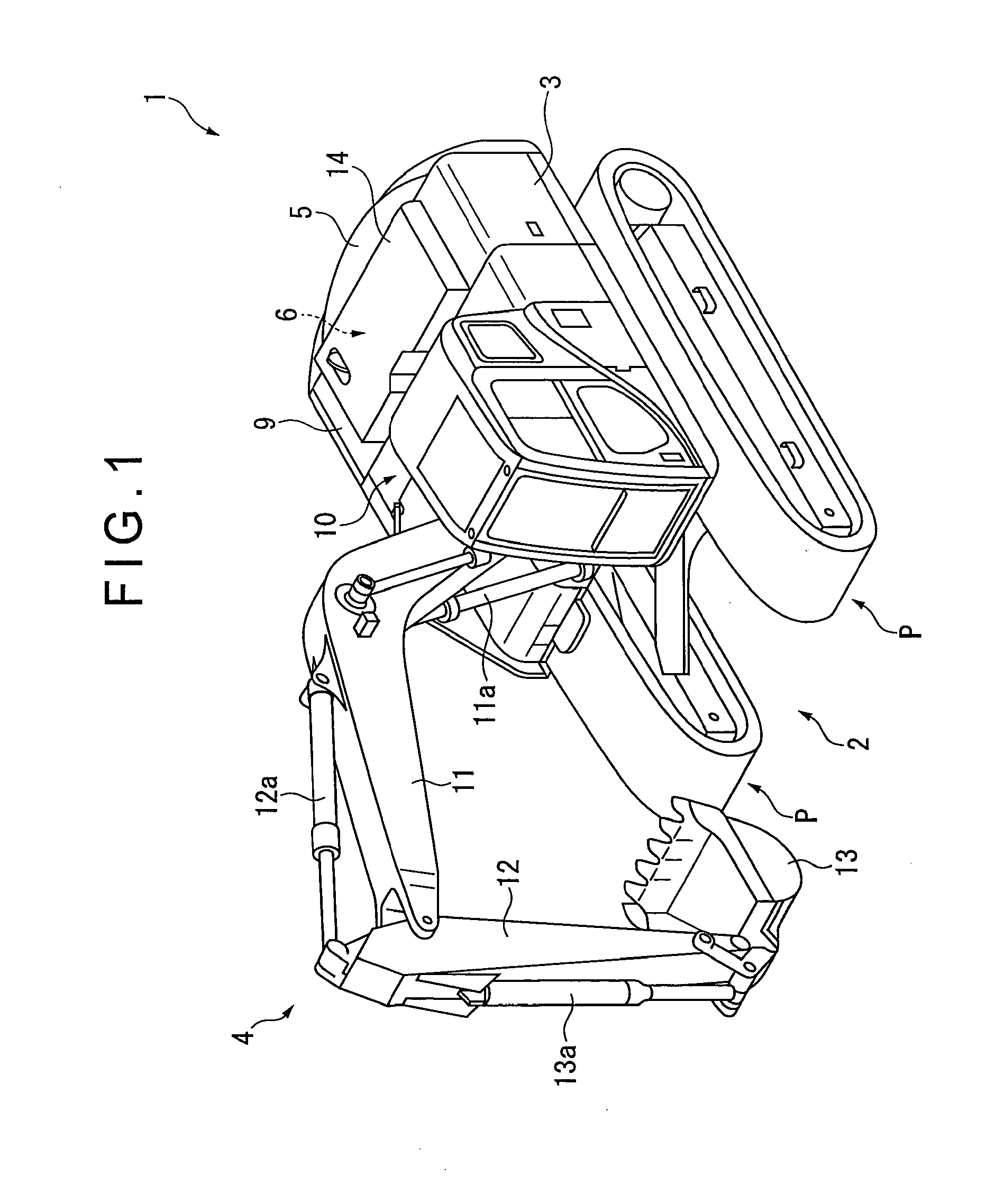

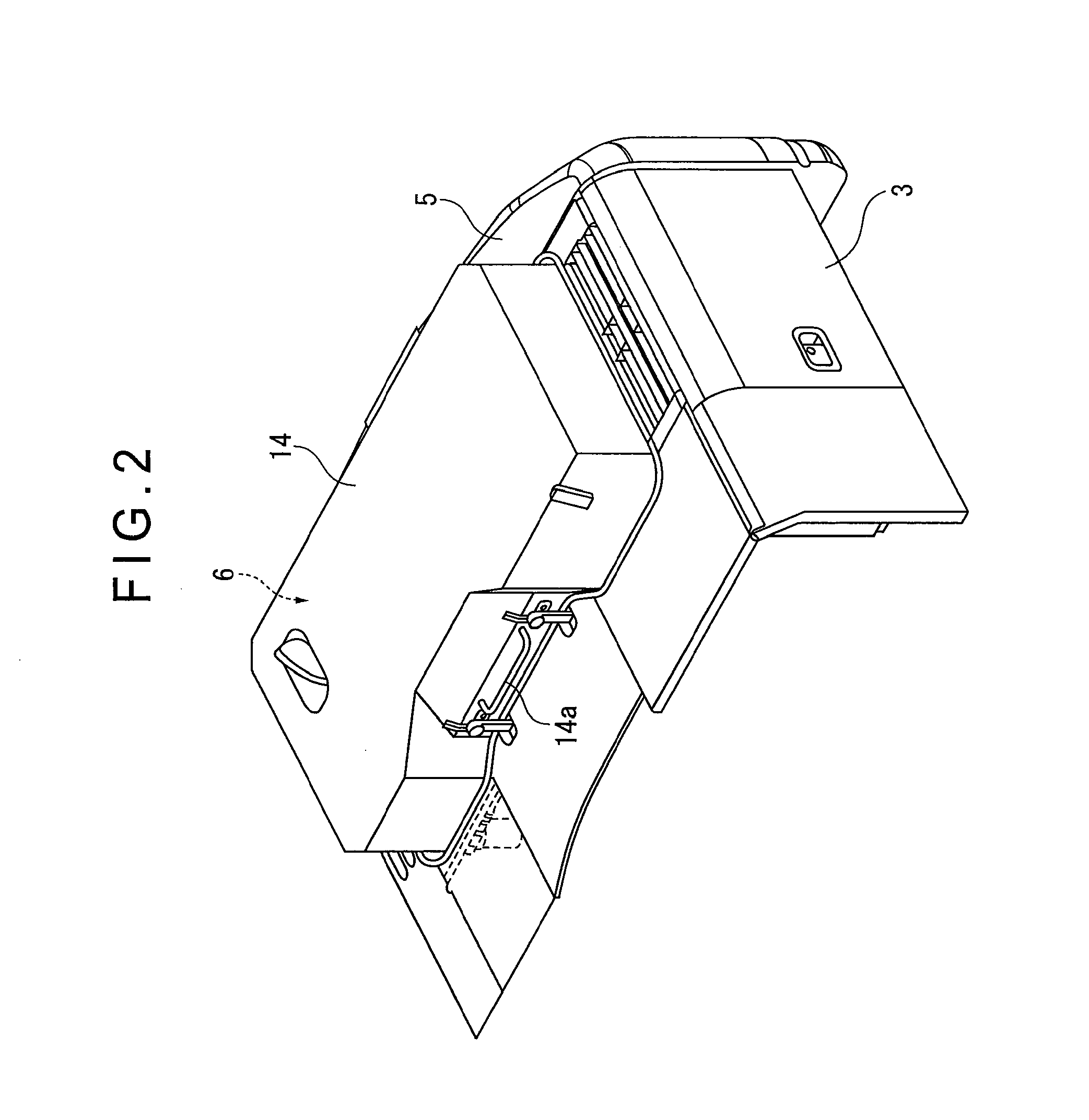

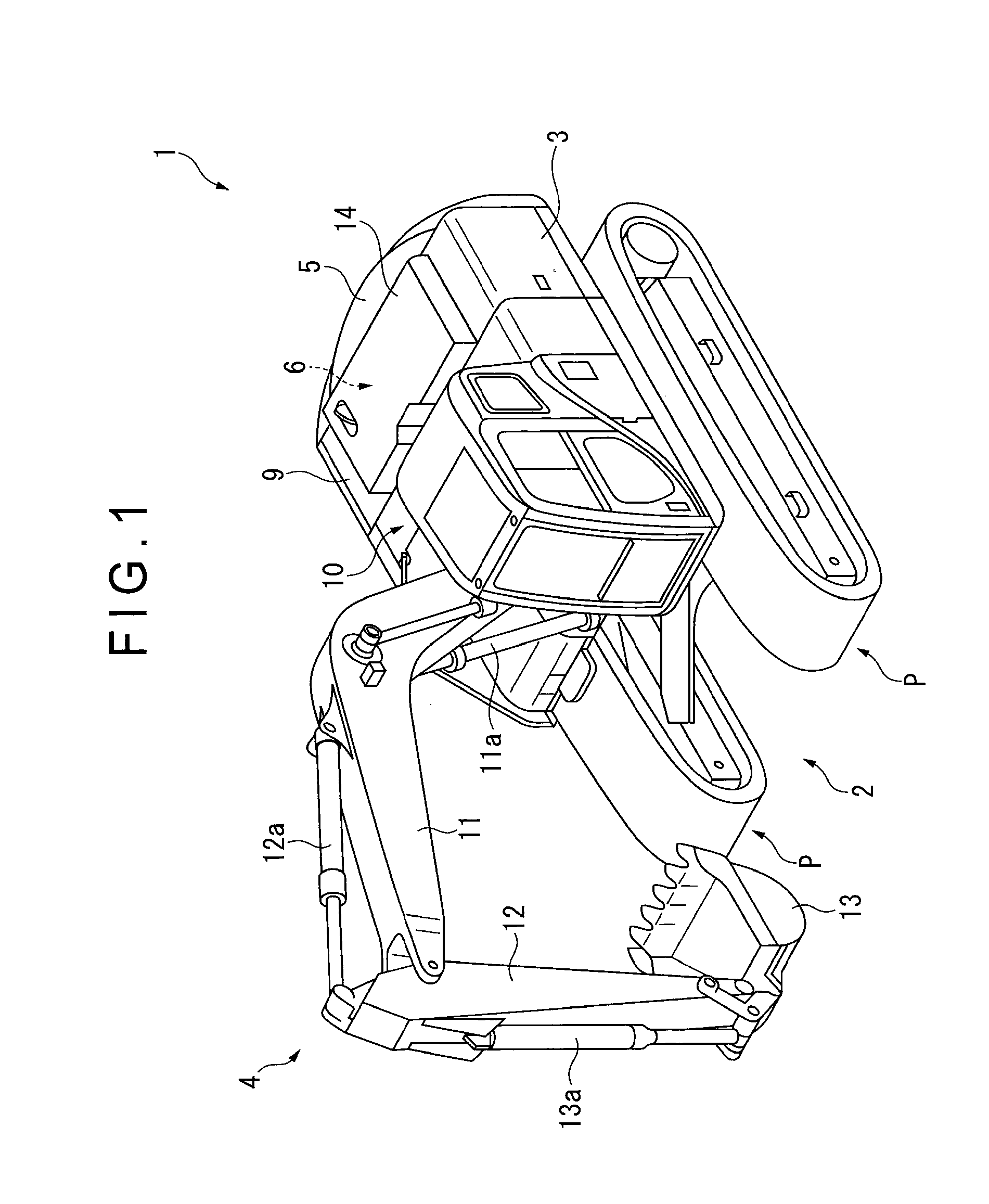

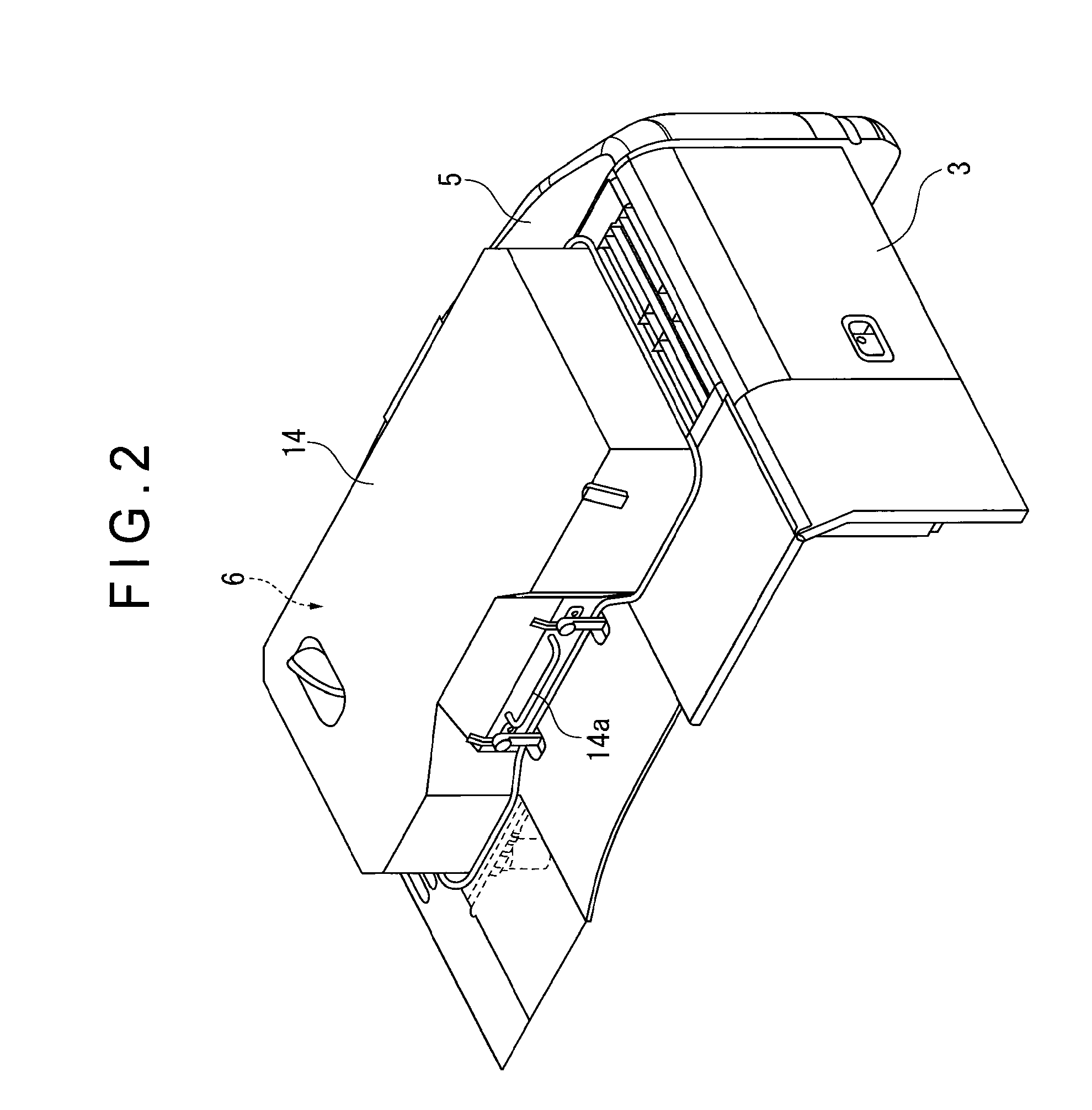

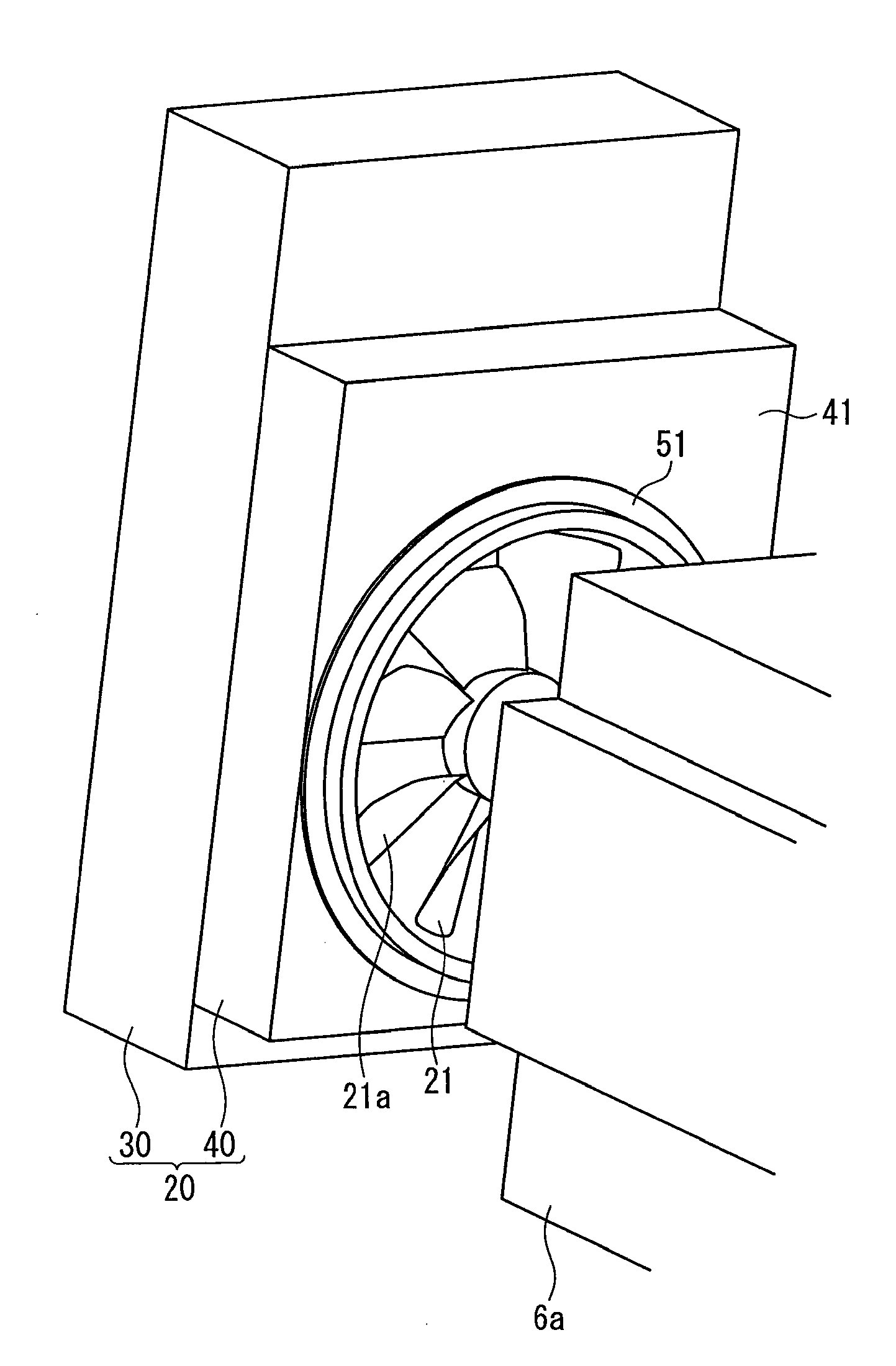

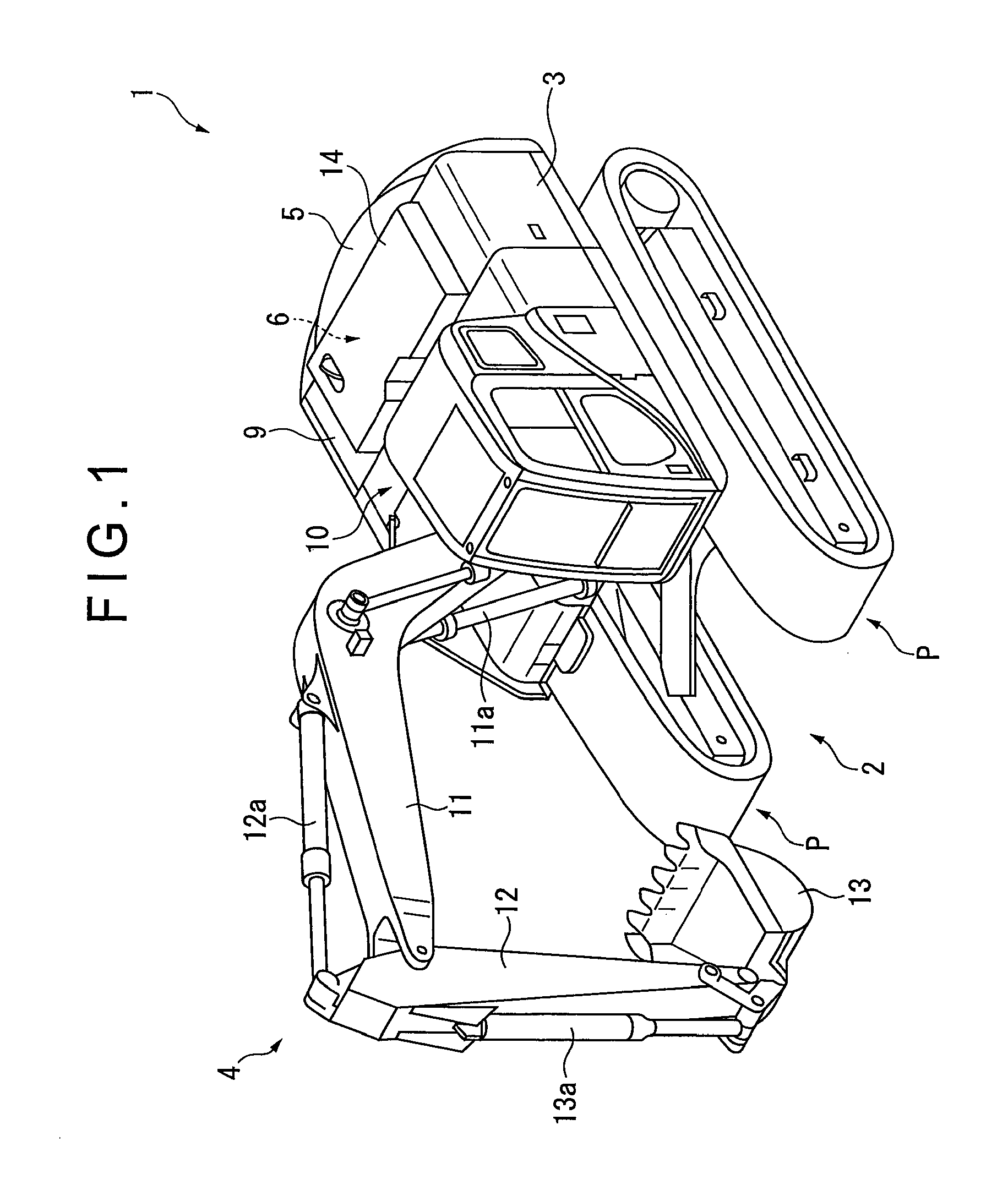

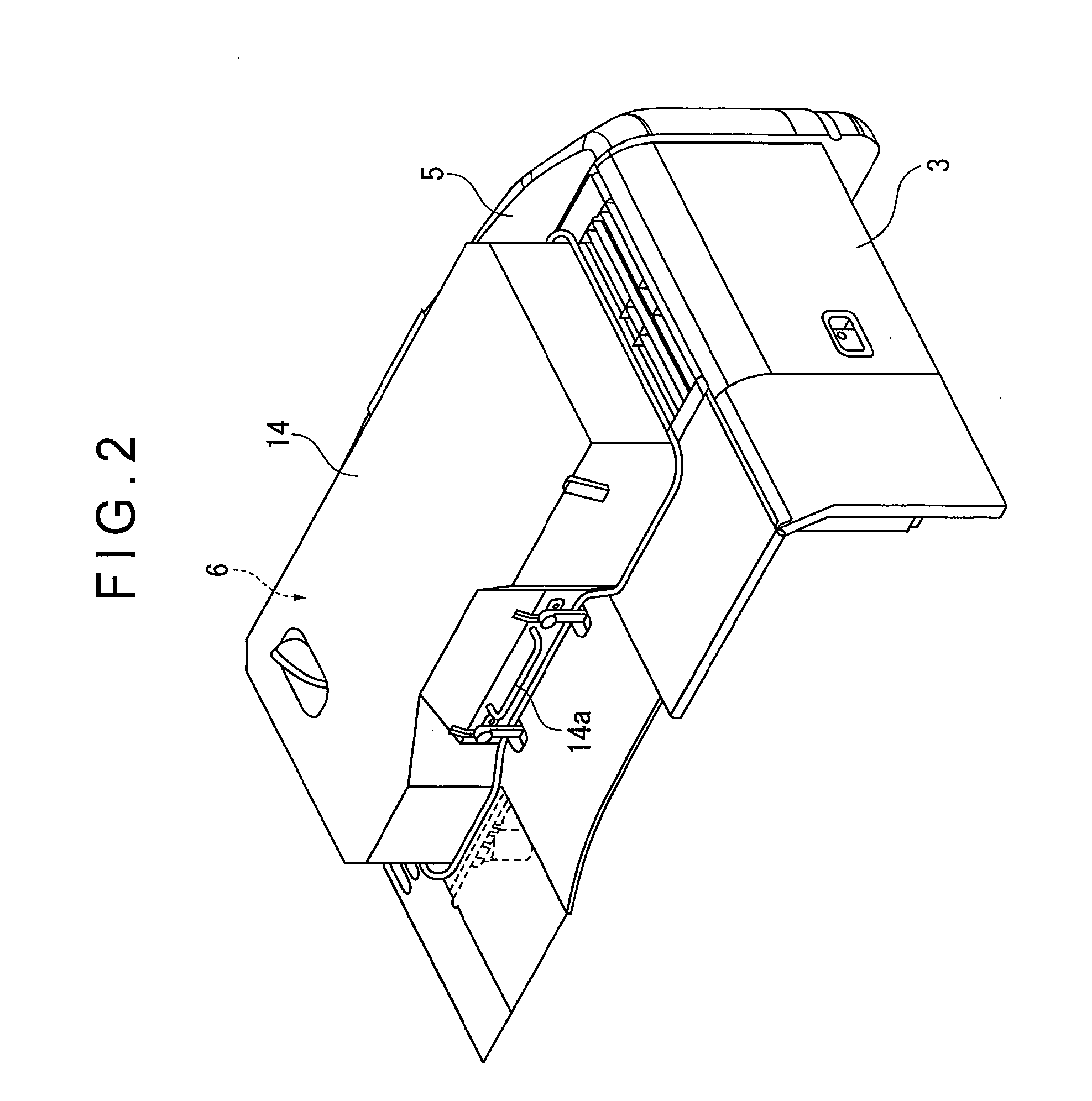

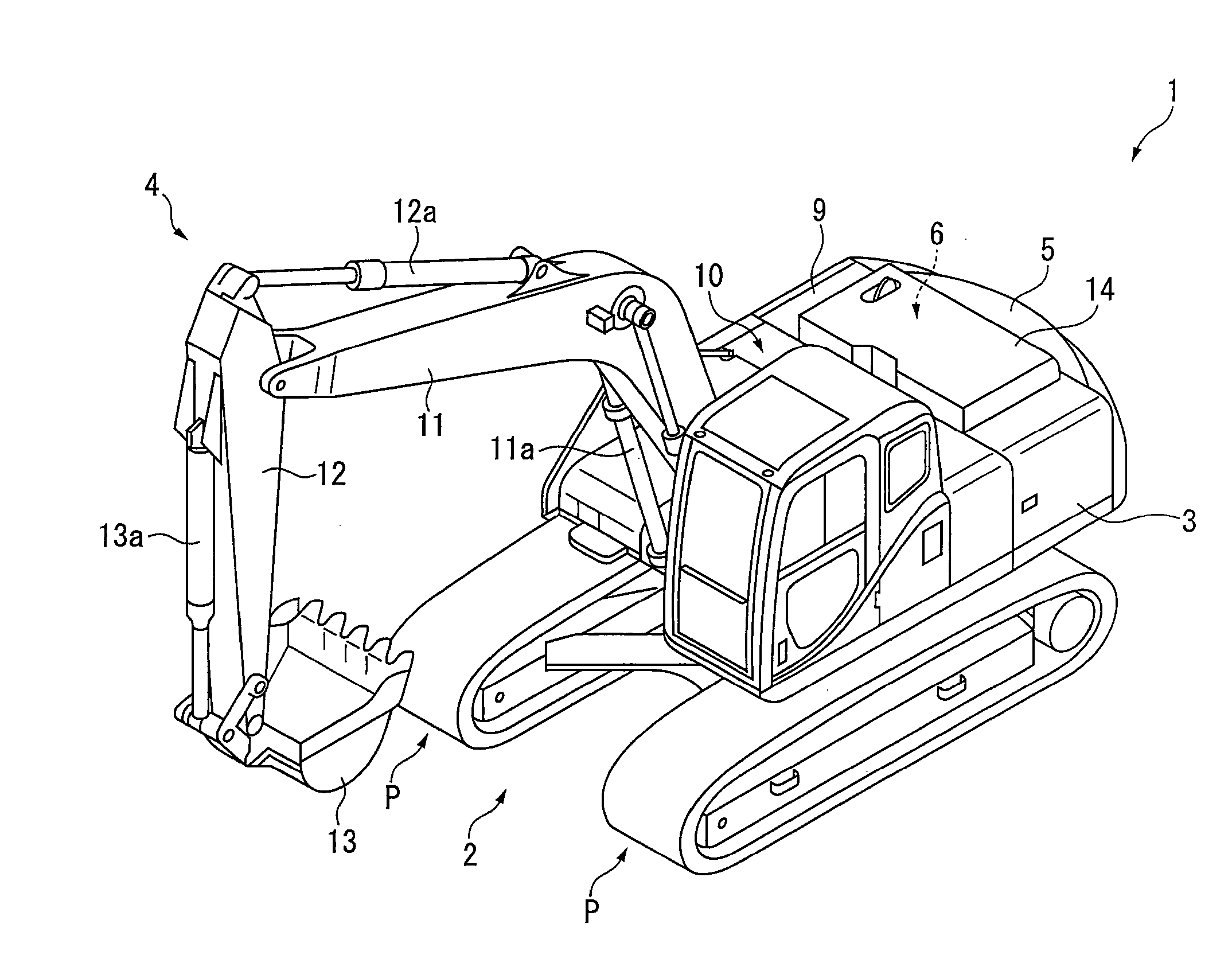

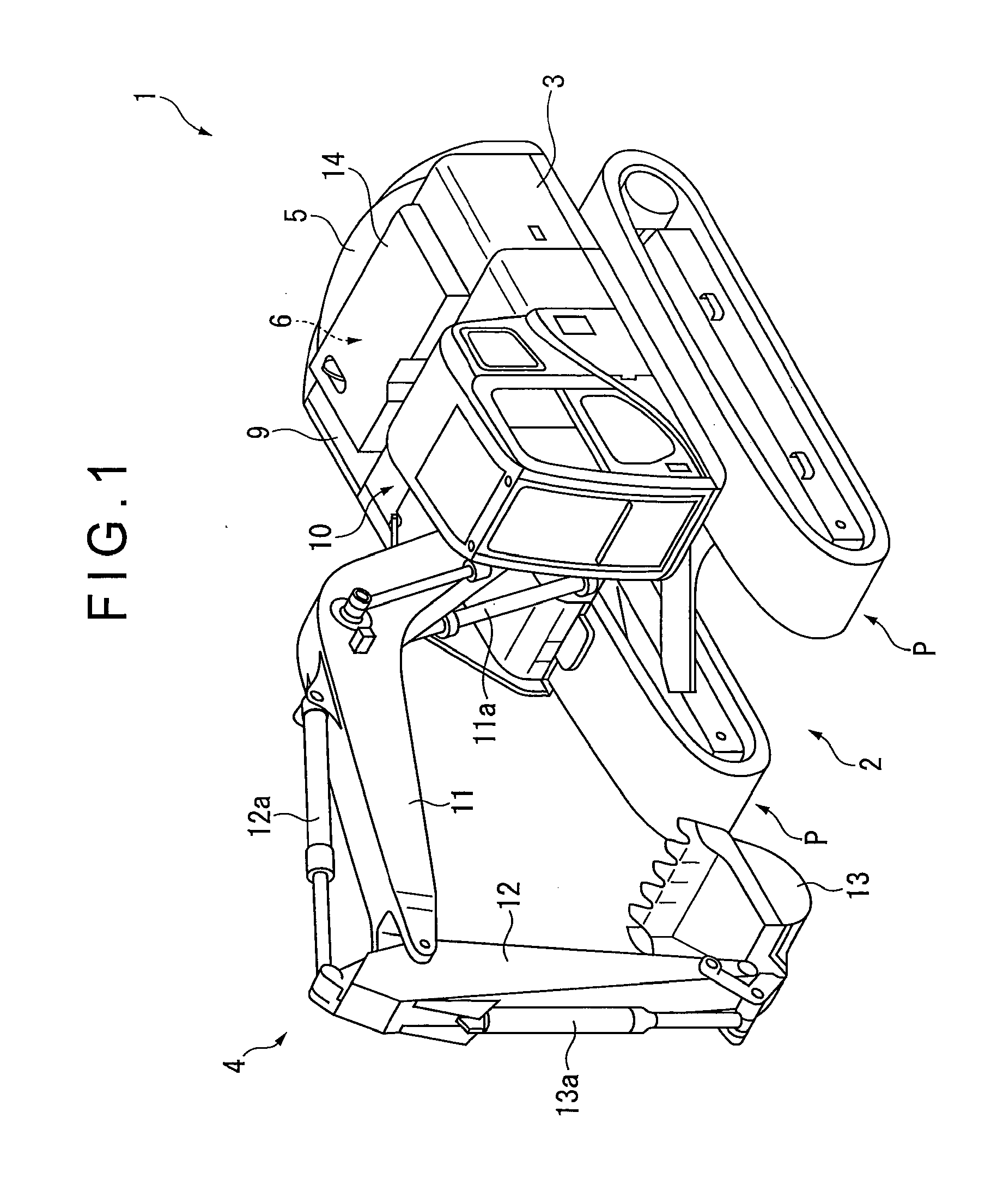

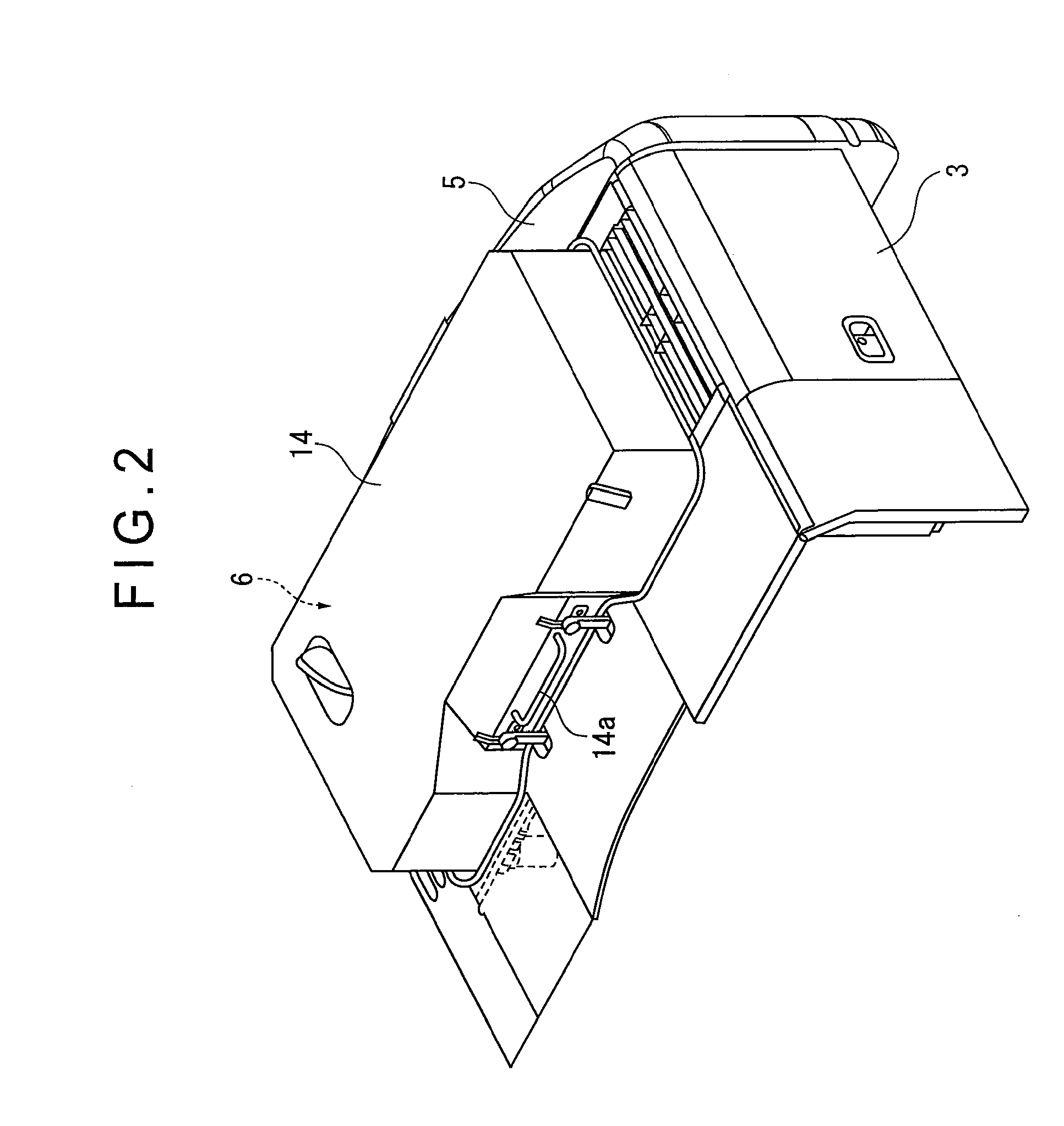

Cooling device and construction machine or working machine equipped with the same

ActiveUS20100200193A1Cool efficiency be enhanceHigh operatingPump componentsDigital data processing detailsAerospace engineering

Owner:KOMATSU LTD

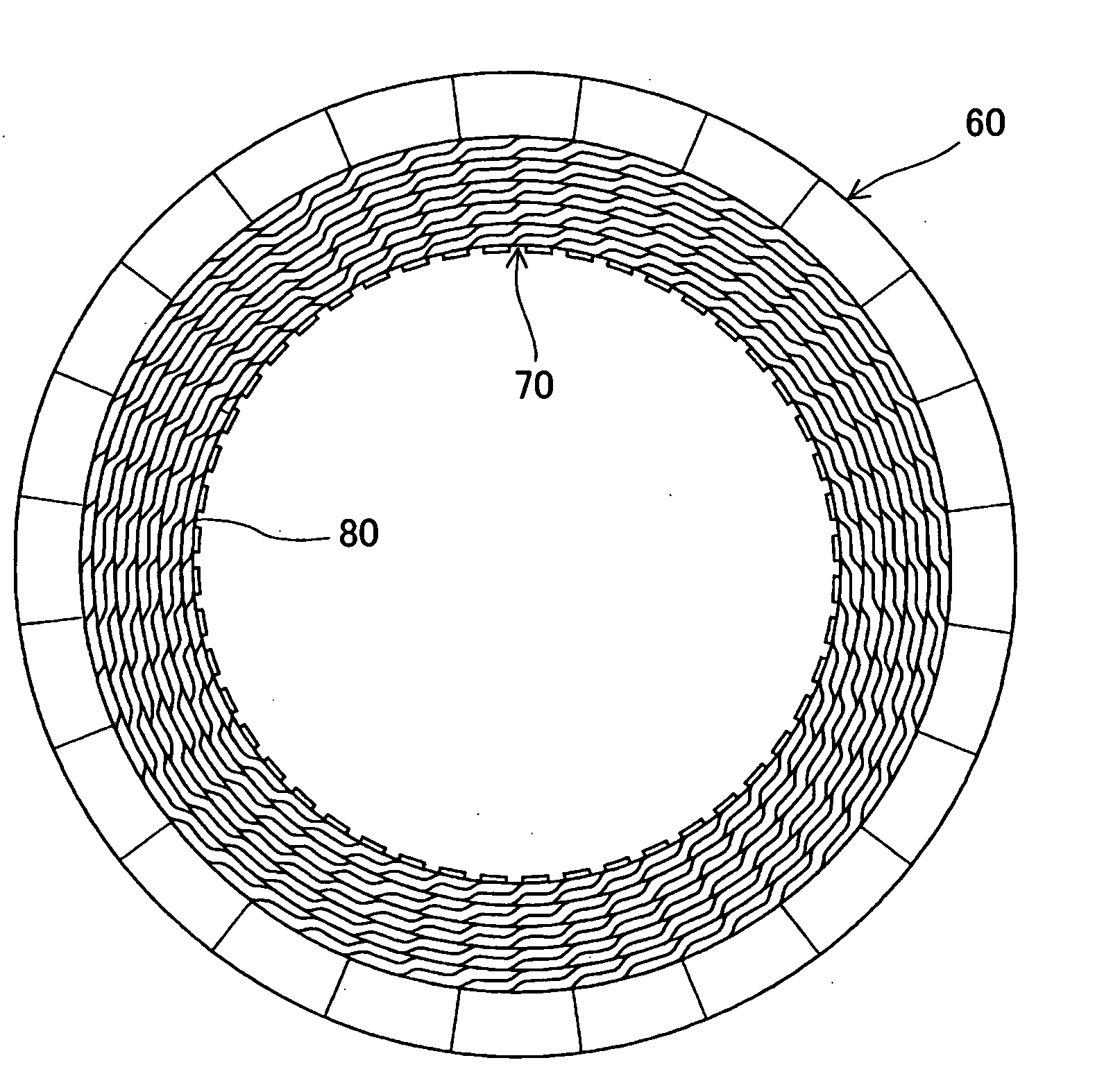

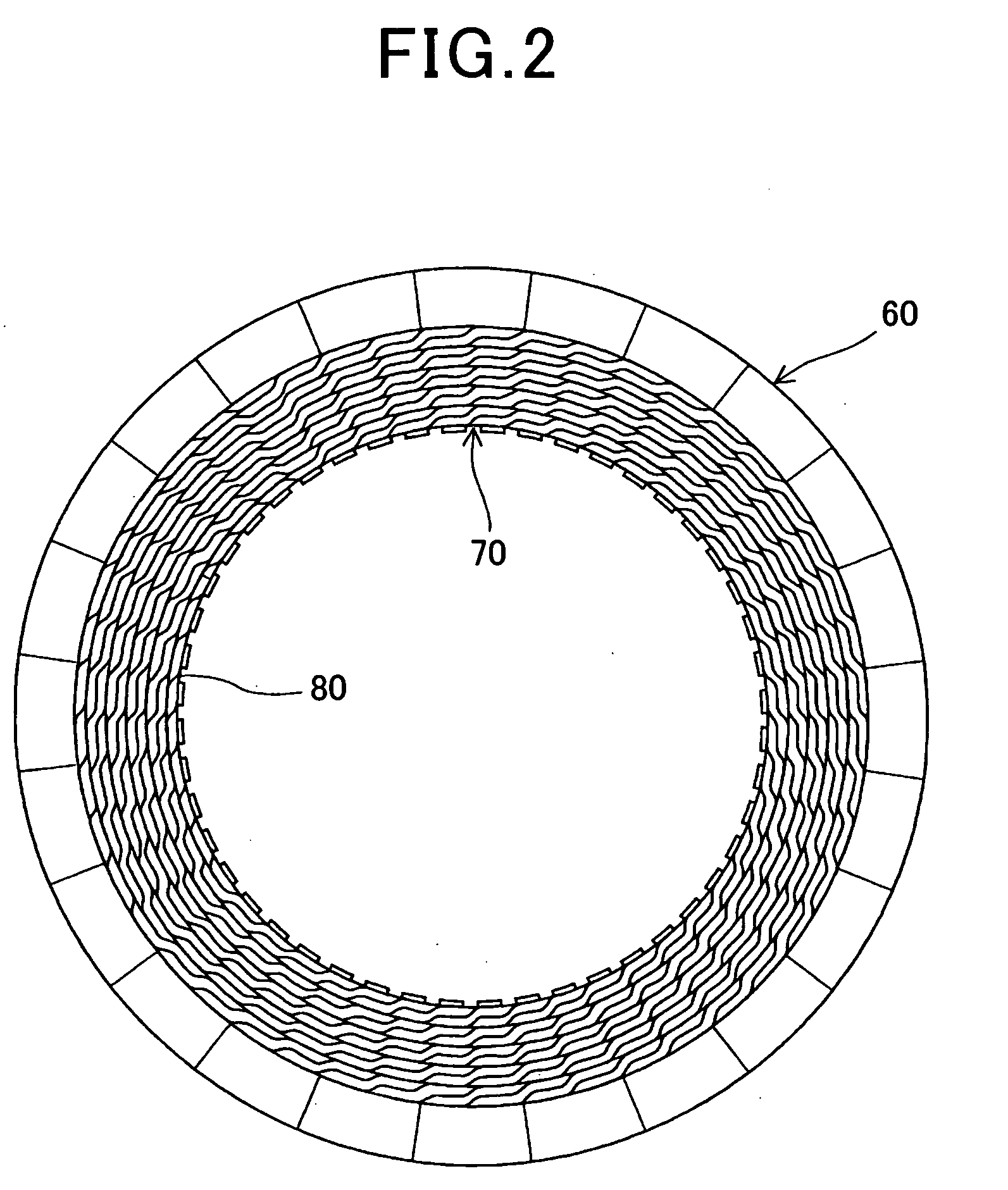

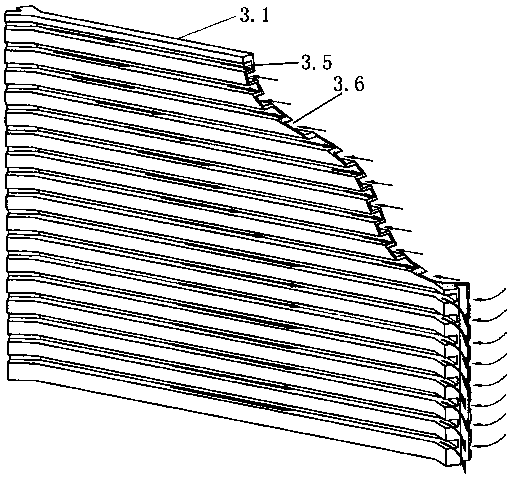

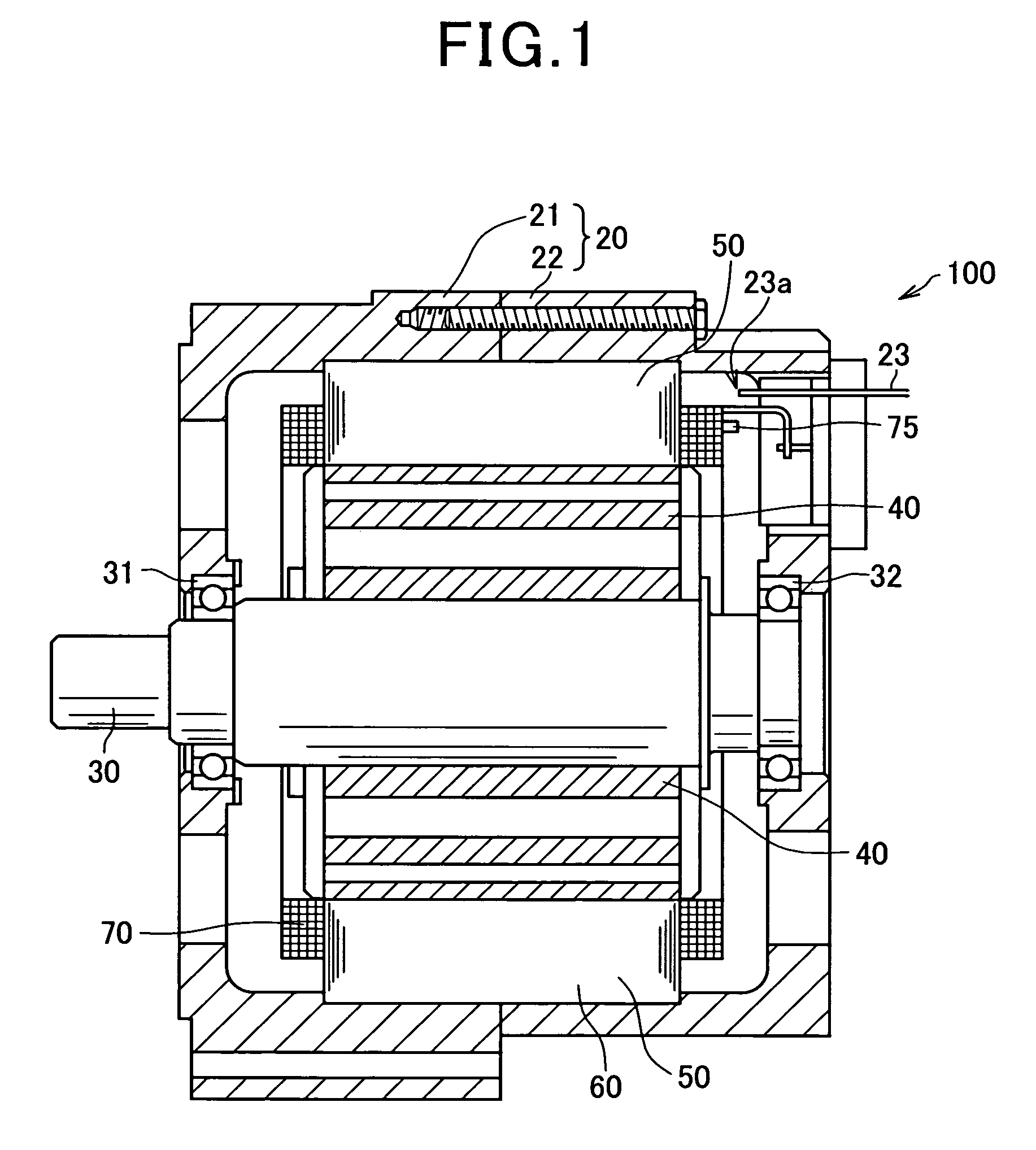

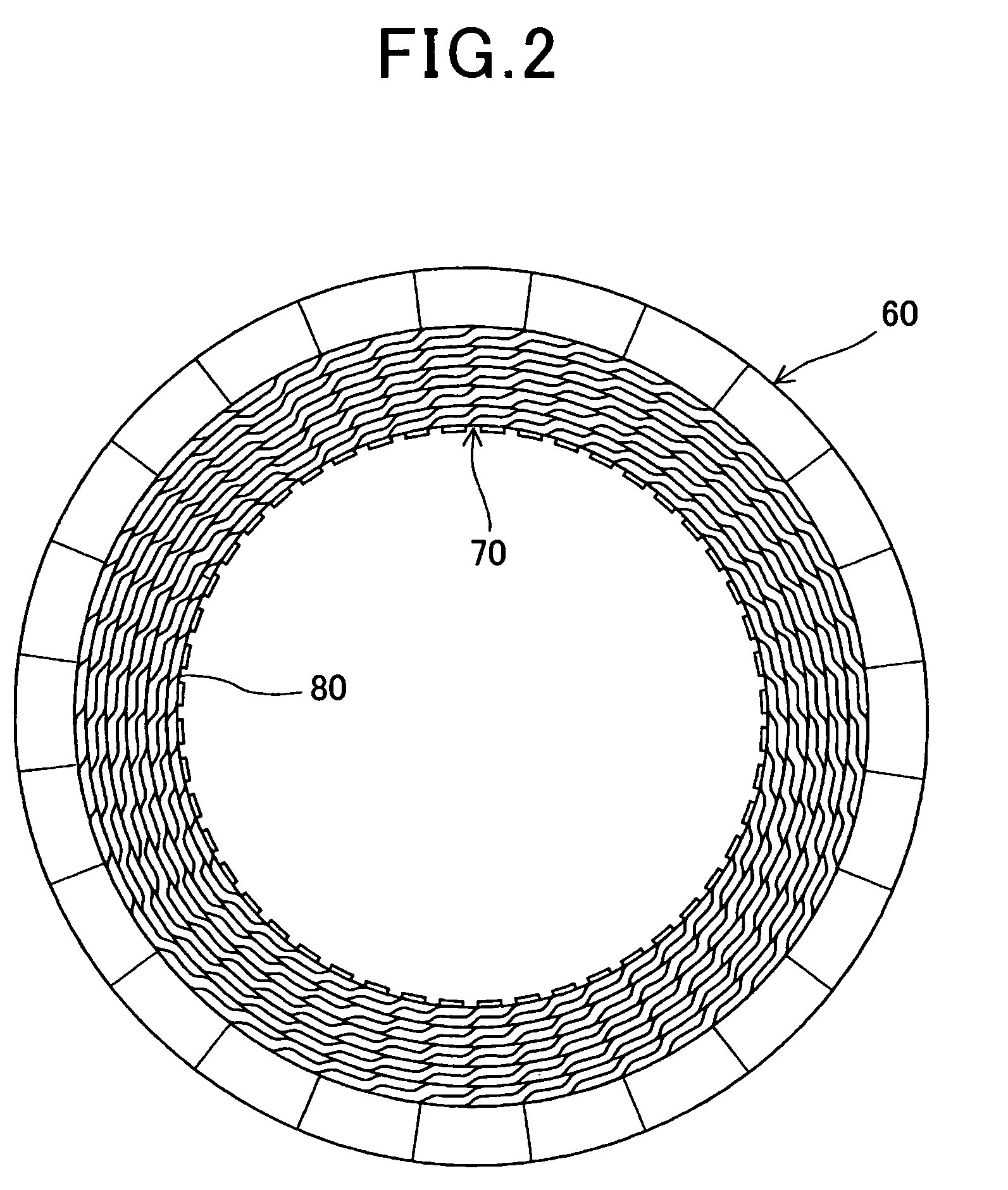

Stator for dynamoelectric machine and method of manufacturing same

ActiveUS20100117480A1Improve cooling effectSame cooling effectSynchronous machinesAsynchronous induction motorsWave shapeStator coil

A stator for a dynamoelectric machine includes a stator core and a stator coil. The stator coil is made up of wave-shaped electric wires mounted on the stator core. Each of the electric wires has in-slot portions, each of which is received in one of slots of the stator core, and connecting portions each of which is located outside of the slots to connect one adjacent pair of the in-slot portions. Each of the connecting portions includes an apex part that is located axially furthest in the connecting portion from the stator core and includes an oblique section extending obliquely with respect to the radial direction of the stator core. Further, the oblique sections of the electric wires on one side of the stator core in the axial direction of the stator core are oblique in the same direction as those on the other side of the stator core.

Owner:DENSO CORP

Maintaining method for blast furnace

InactiveCN101250598AImprove cooling effectStable at workBlast furnace componentsBlast furnace detailsRepair timeCooling effect

The invention provides a protection process of a blast furnace, which is a process which combines the furnace body grouting for the positions where furnace shell has high temperature, the installation of copper cooling sticks on cooling wall damaging positions, and the spraying lining for furnace body lining, wherein grouting adopts the way of indentation grouting, high aluminum fire-proof material is pressed into the furnace shell through a grouter, and furnace body damaging positions are sprayed after spraying lining and descending stock-line through damping down. Through the process of the invention, the copper cooling sticks are installed on burned-out cooling walls through damping out after the cooling wall is burned out, and thereby reaching the same cooling effect with the cooling walls, simultaneously cooling wall acid cleaning technology is adopted to conduct treatment, thereby increasing cooling effect. The process can significantly increase the cooling effect of the blast furnace cooling walls, thereby making the blast furnace working type basically stable, significantly delaying the damage of cooling walls and reducing blowing-out medium repair time, and obtaining excellent economical benefits.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

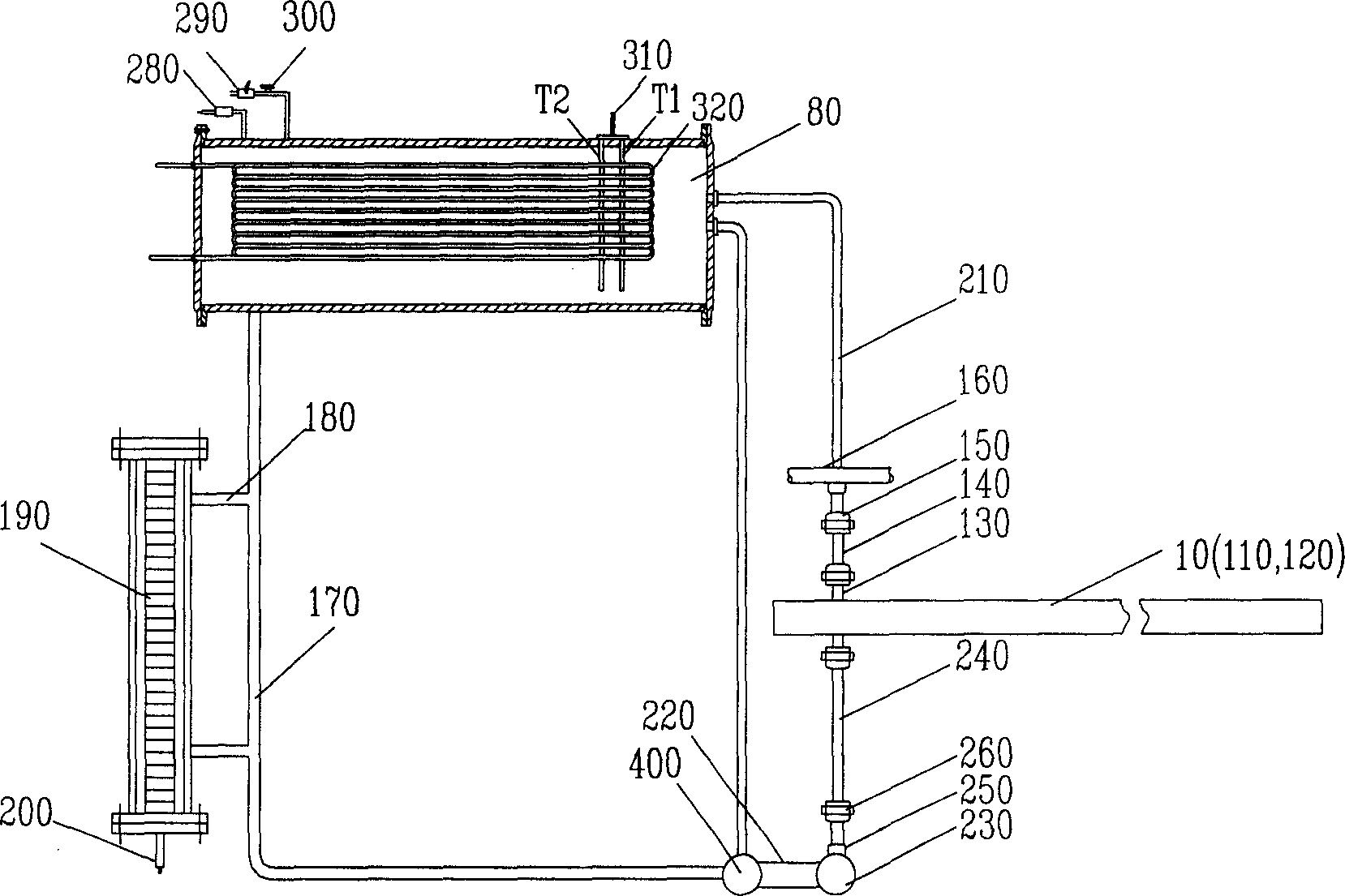

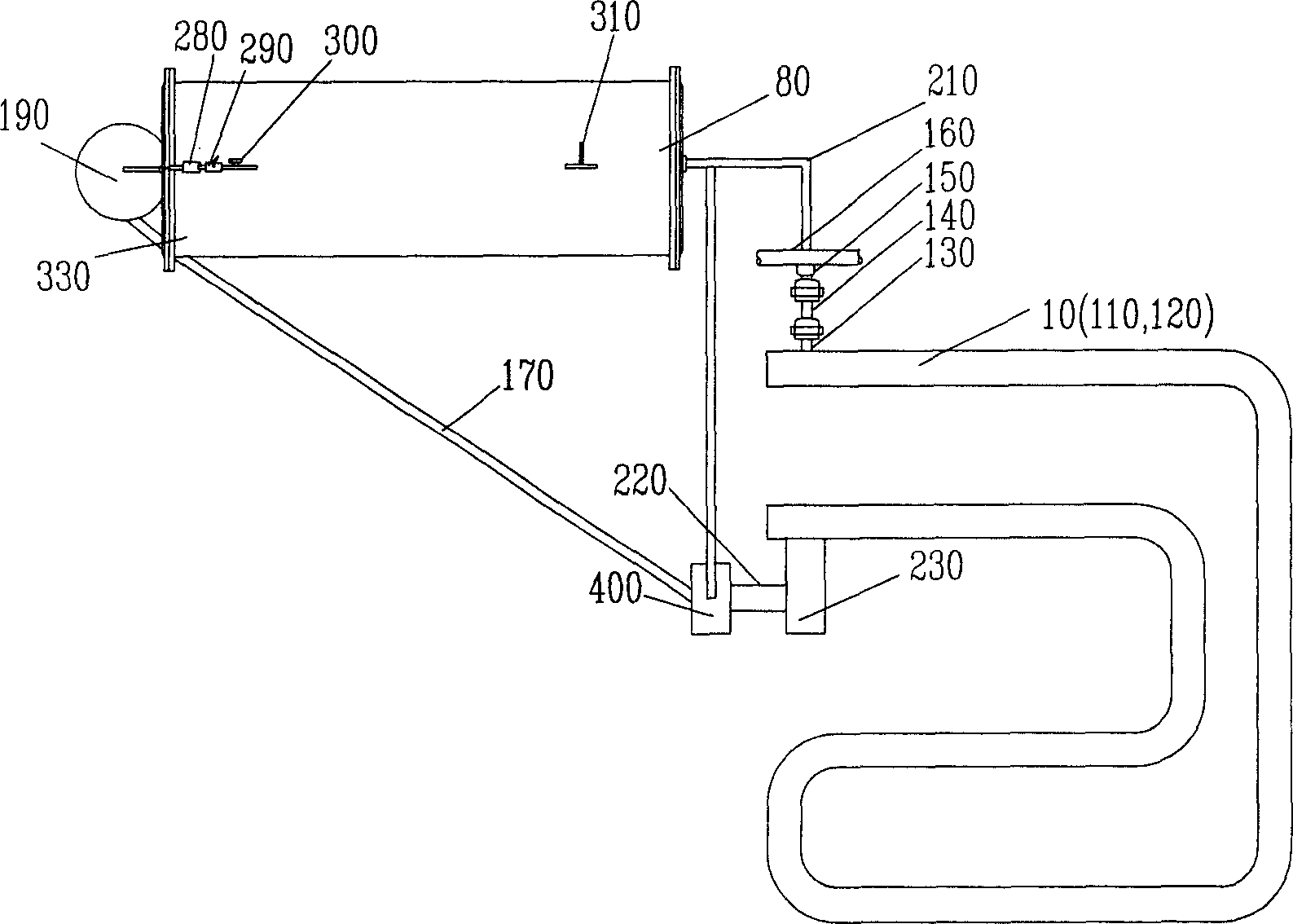

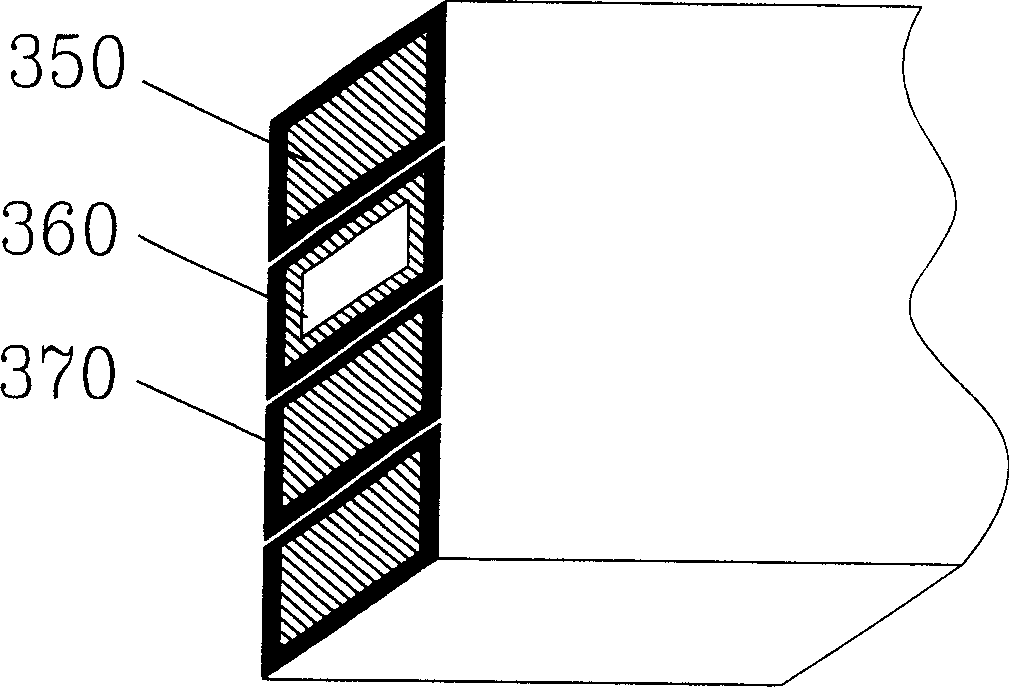

Self-circulation cooling loop of heavy current fixture wire

InactiveCN1841885AEliminate uneven temperature distributionRealize the purpose of self-circulation coolingTransformers/inductances coolingEnergy efficient heating/coolingInternal pressurePower flow

The invention relates to a large current equipment pin equipment cooler circuit. It is characterized in that it comprises a large current device pin (10) and an evaporative cooling circulation system; the large current device pin (10) is formed by a solid conductor and circular or polygonal hollow conductor or hollow pipe conductor; it injects the evaporative cooling media in the hollow conductor. The current can lead the loss and the winding heats whose heat transmits to the cooling media of the hollow conductor, when the temperature lifts to the corresponding saturation temperature; the winding inner hollow conductor evaporative cooling media evaporates to form boiling heat transfer and then uses cooler to be liquefied, and then cycles.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

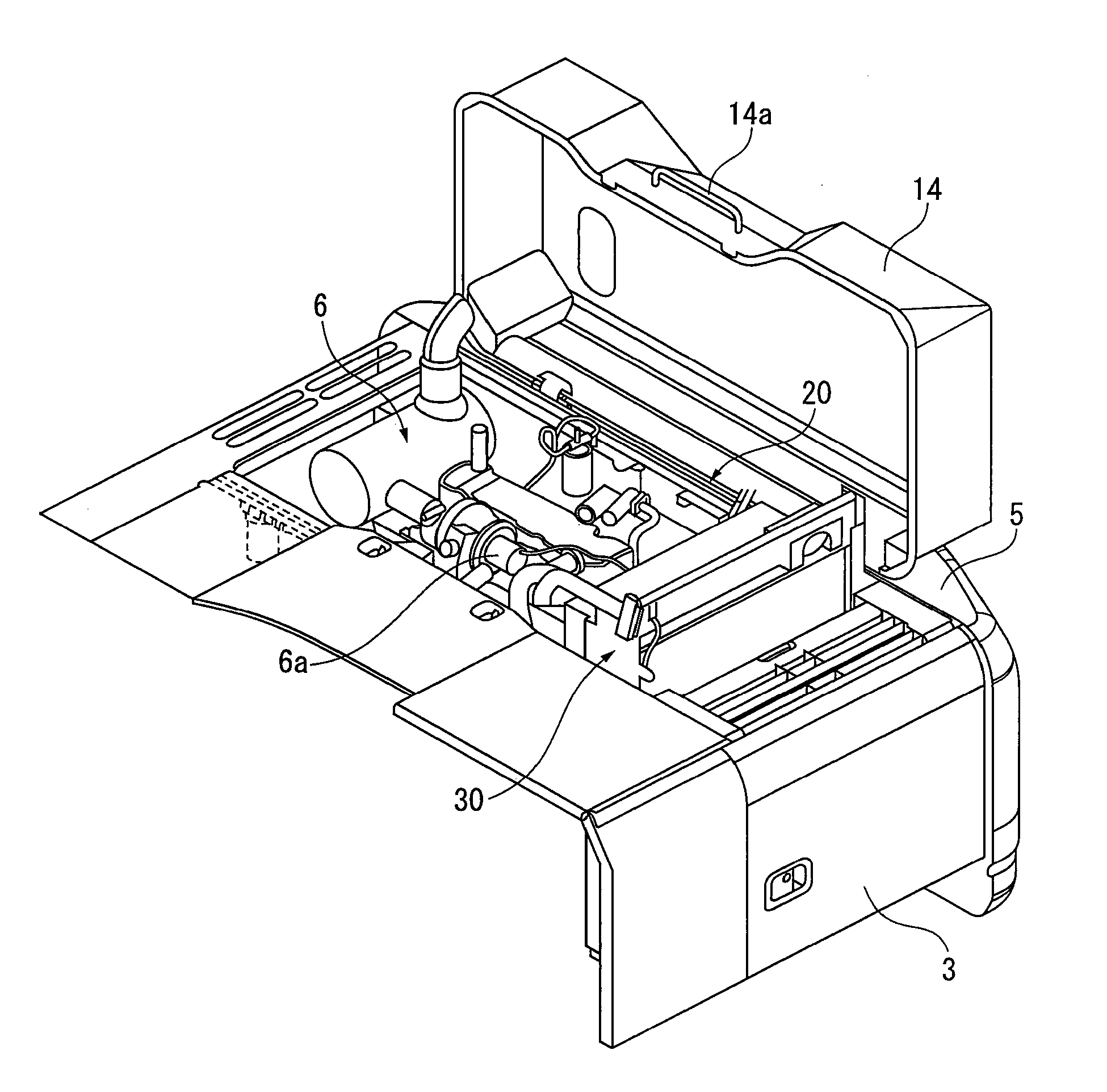

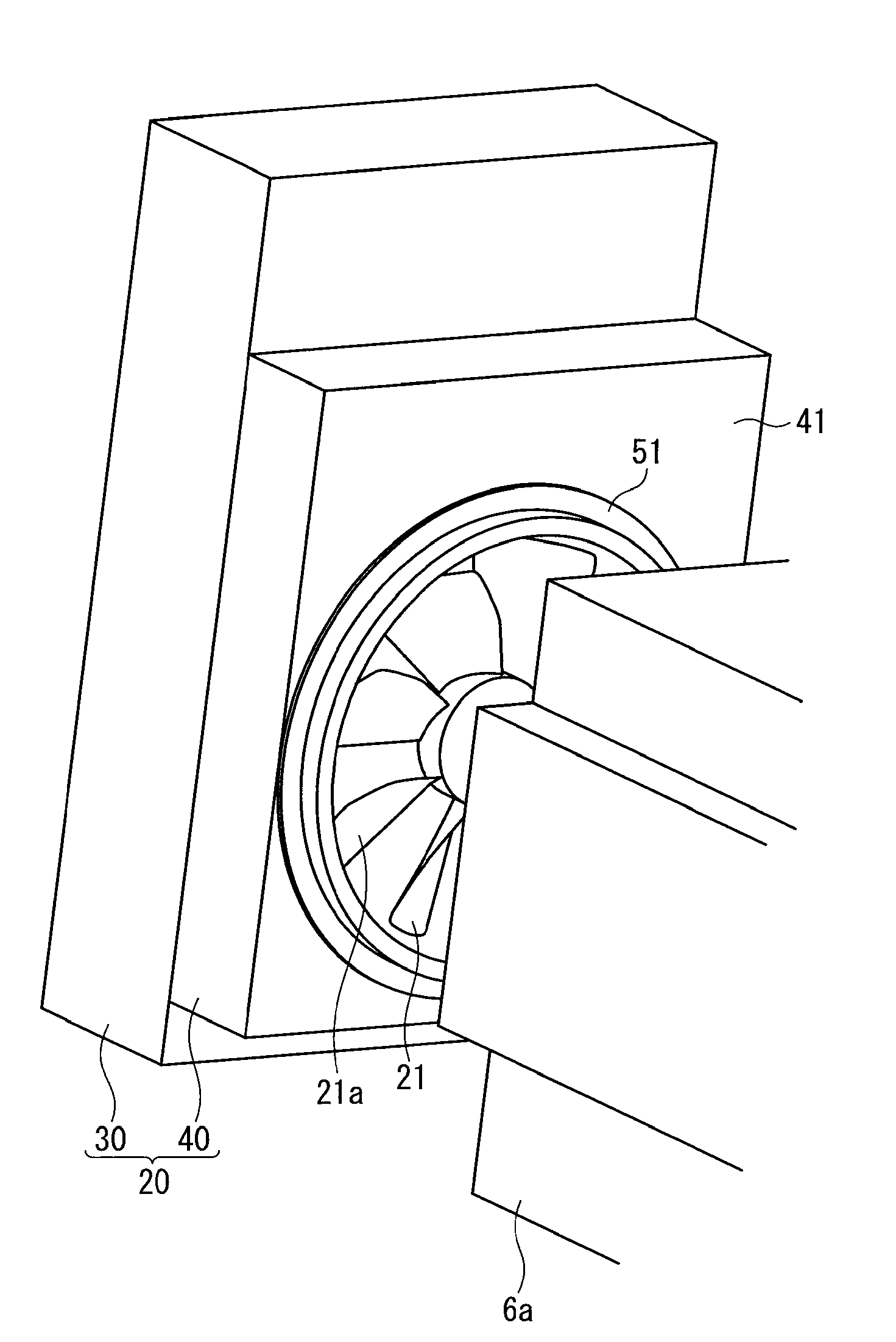

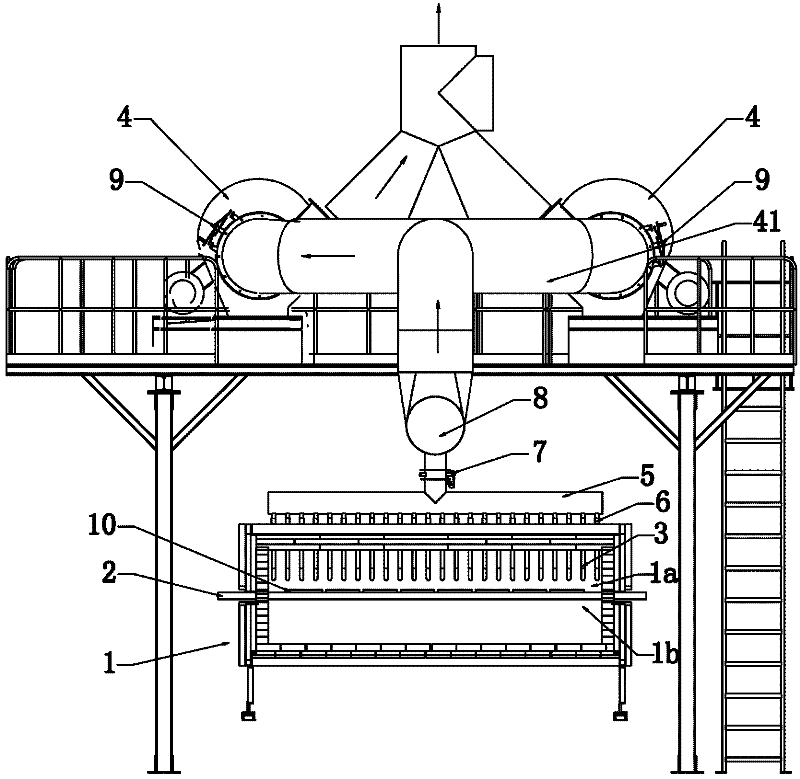

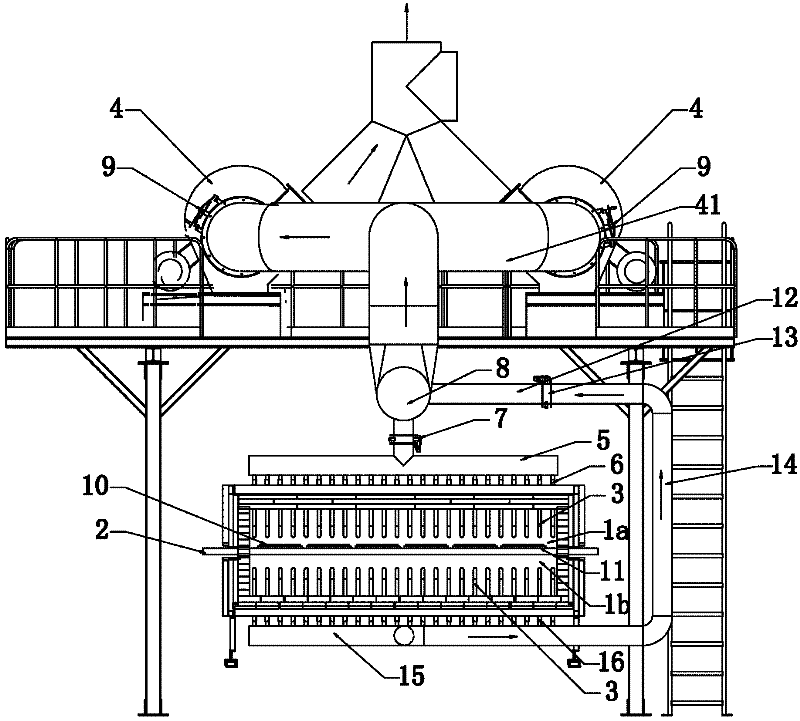

Cooling device and construction machine or working machine equipped with the same

ActiveUS20100206526A1Increase airflowImprove cooling effectPump componentsSemiconductor/solid-state device detailsAirflowAerospace engineering

Owner:KOMATSU LTD

Cooling device and construction machine or working machine equipped with the same

ActiveUS20100206525A1Highly quiet operationReduce running noisePump componentsSemiconductor/solid-state device detailsEngineeringAerospace engineering

Owner:KOMATSU LTD

Cooling device and construction machine or working machine equipped with the same

ActiveUS20100200194A1Highly quiet operationReduce operating noisePump componentsAir coolingEngineering

Owner:KOMATSU LTD

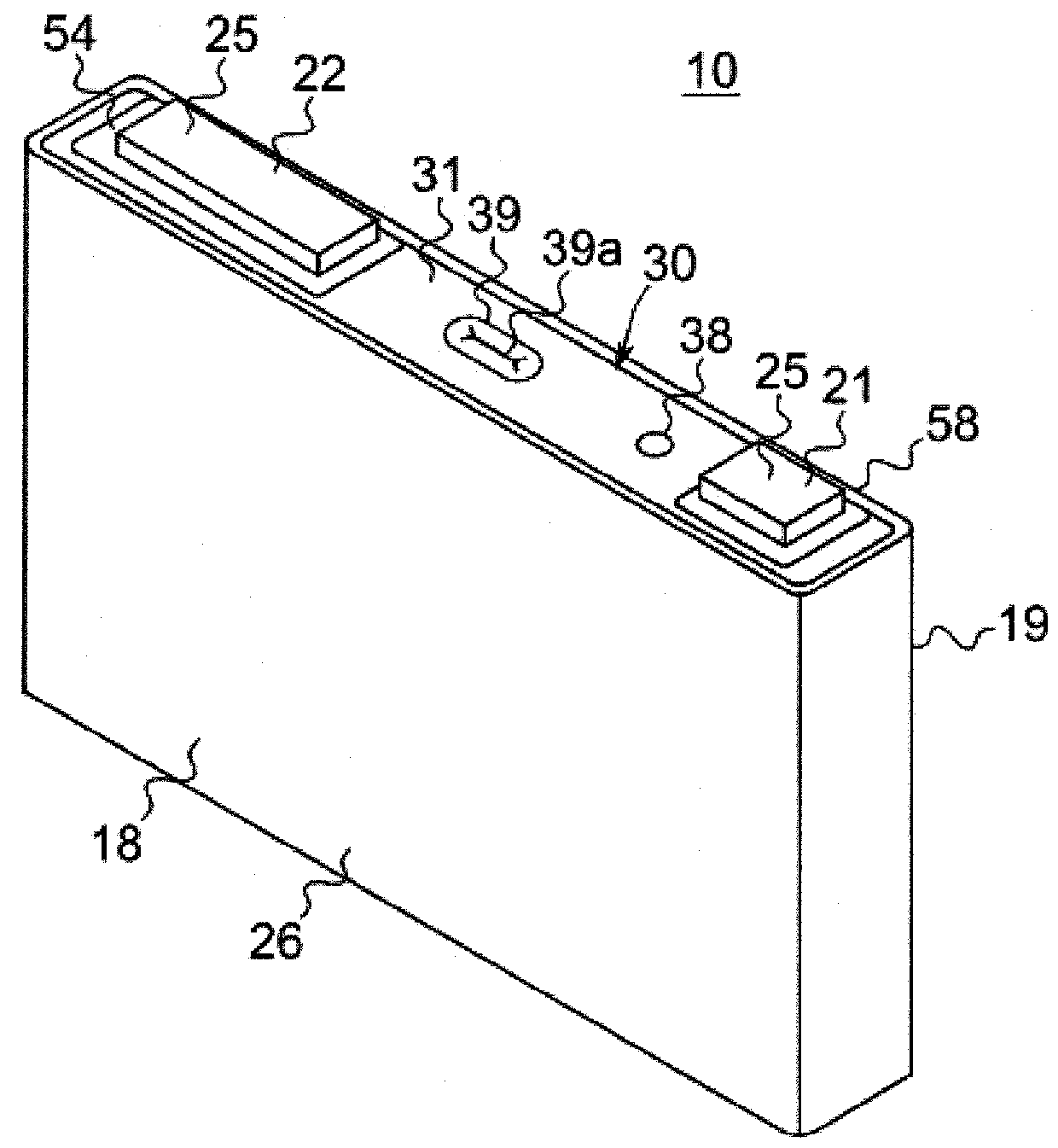

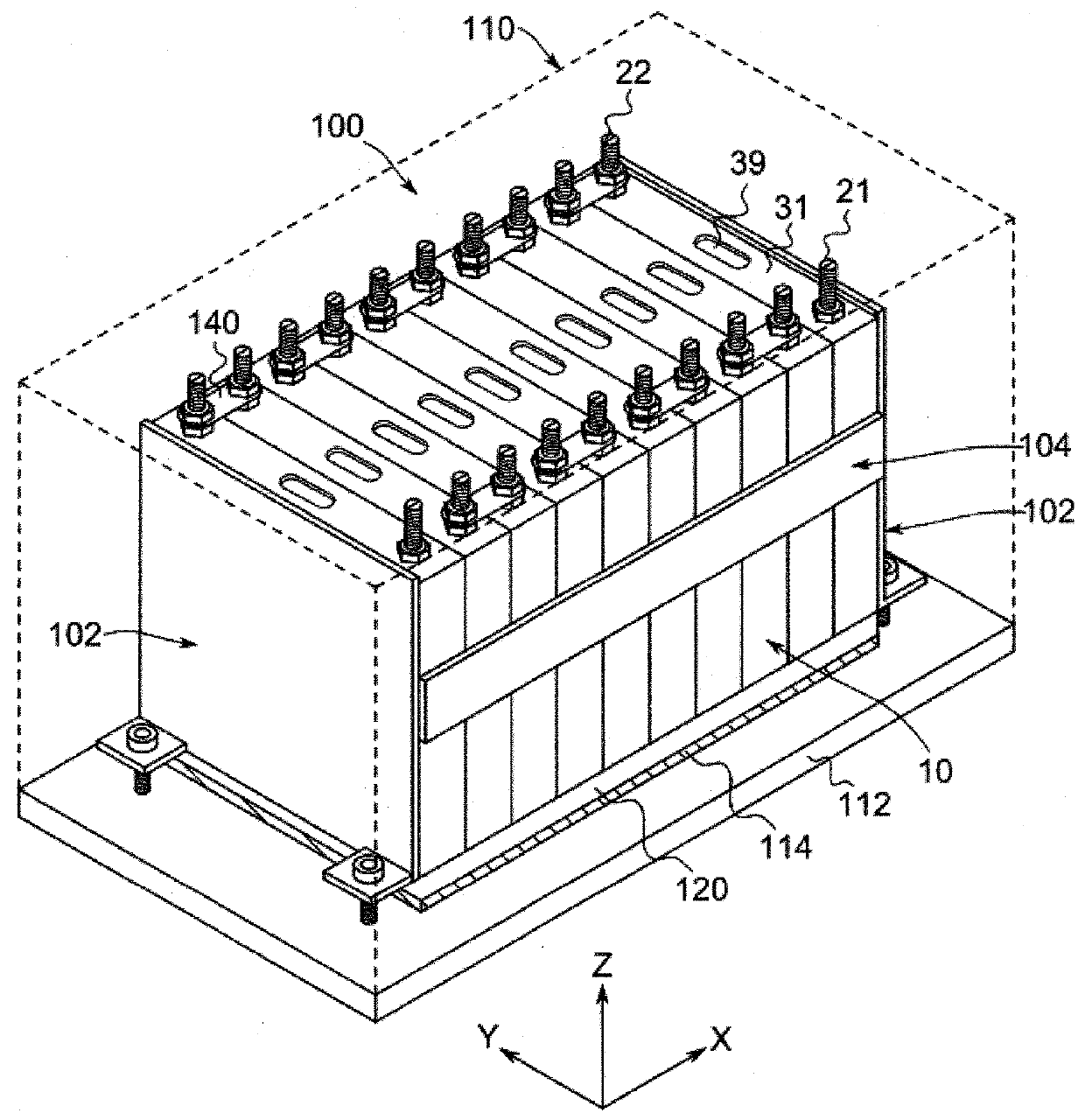

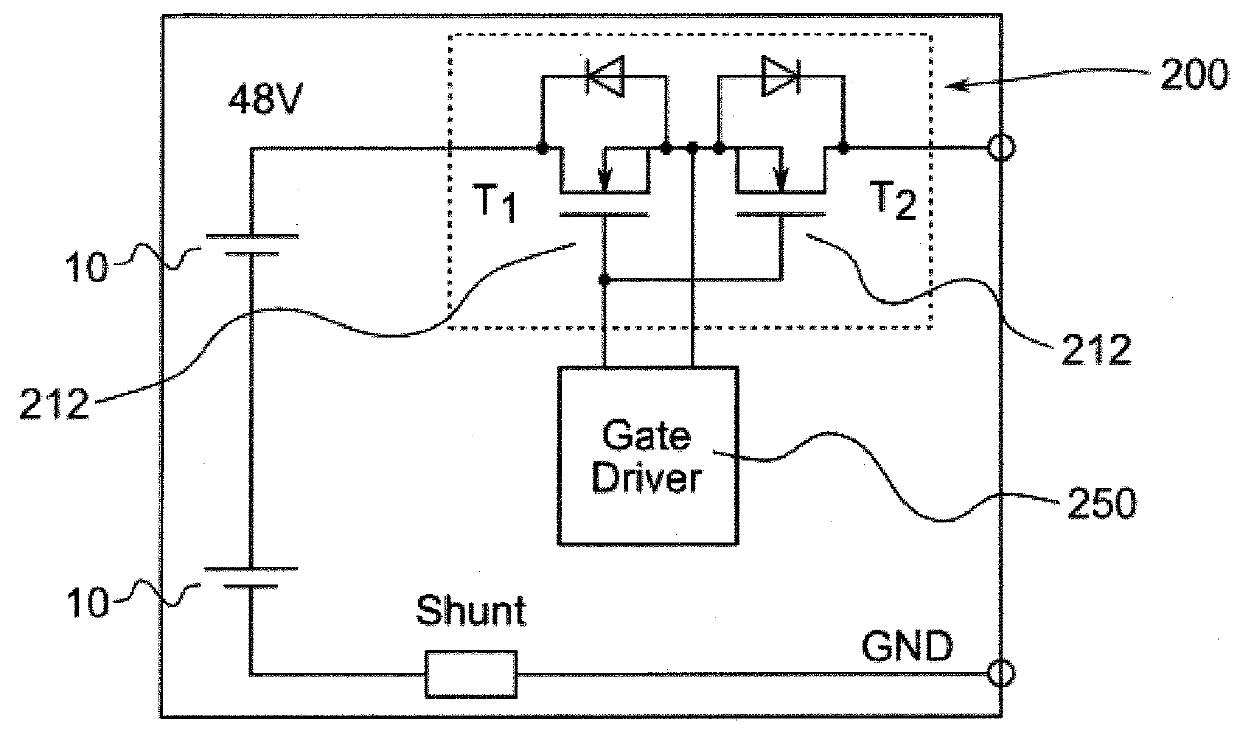

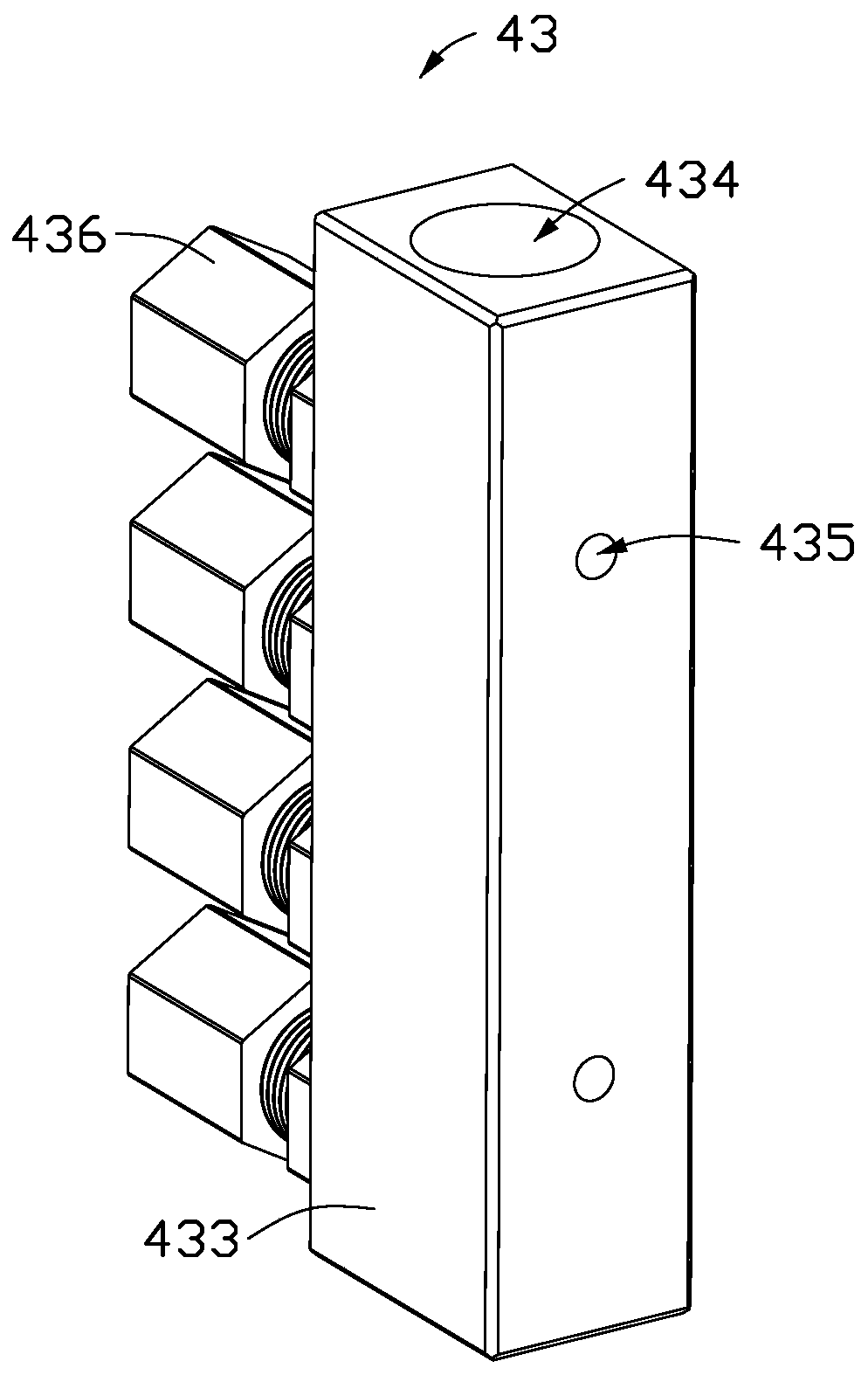

Switchable battery module

InactiveUS20190214606A1Increase expensesMeet the blocking requirementsFinal product manufactureSmall-sized cells cases/jacketsPower gridPower MOSFET

A plurality of battery cells arranged as a cell stack with adjacent lateral walls forming a row includes a case including two lateral walls from among the lateral walls, and a cap assembly capping the case, and including a positive terminal and a negative terminal, and a solid state switch arranged as an element in the cell stack of battery cells and for switchably connect the battery module with an external power grid, the solid state switch including a switch circuit board including a power MOSFET for providing a power stage for performing switching, a back cover and a front cover, the back and front covers forming a housing of the solid state switch and including lateral walls in the same size and shape as the lateral walls of the case of each battery cell.

Owner:SAMSUNG SDI CO LTD

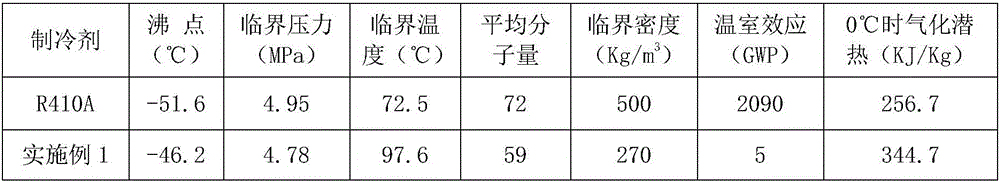

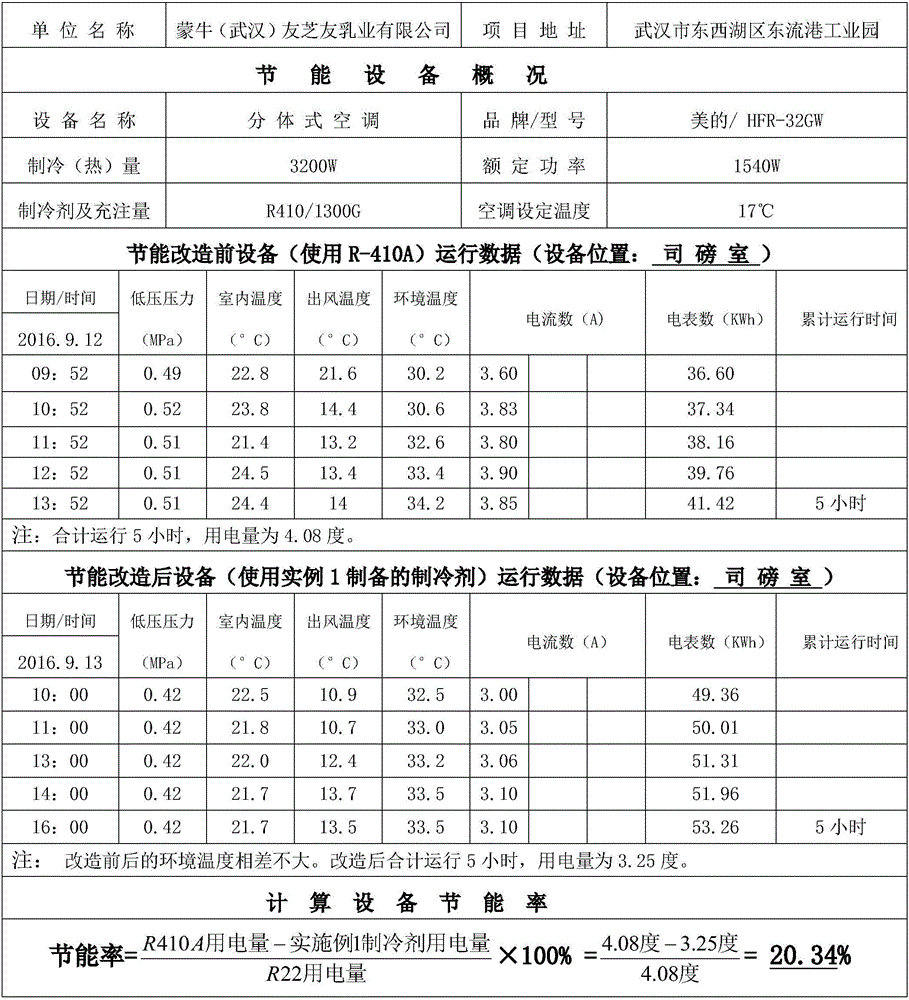

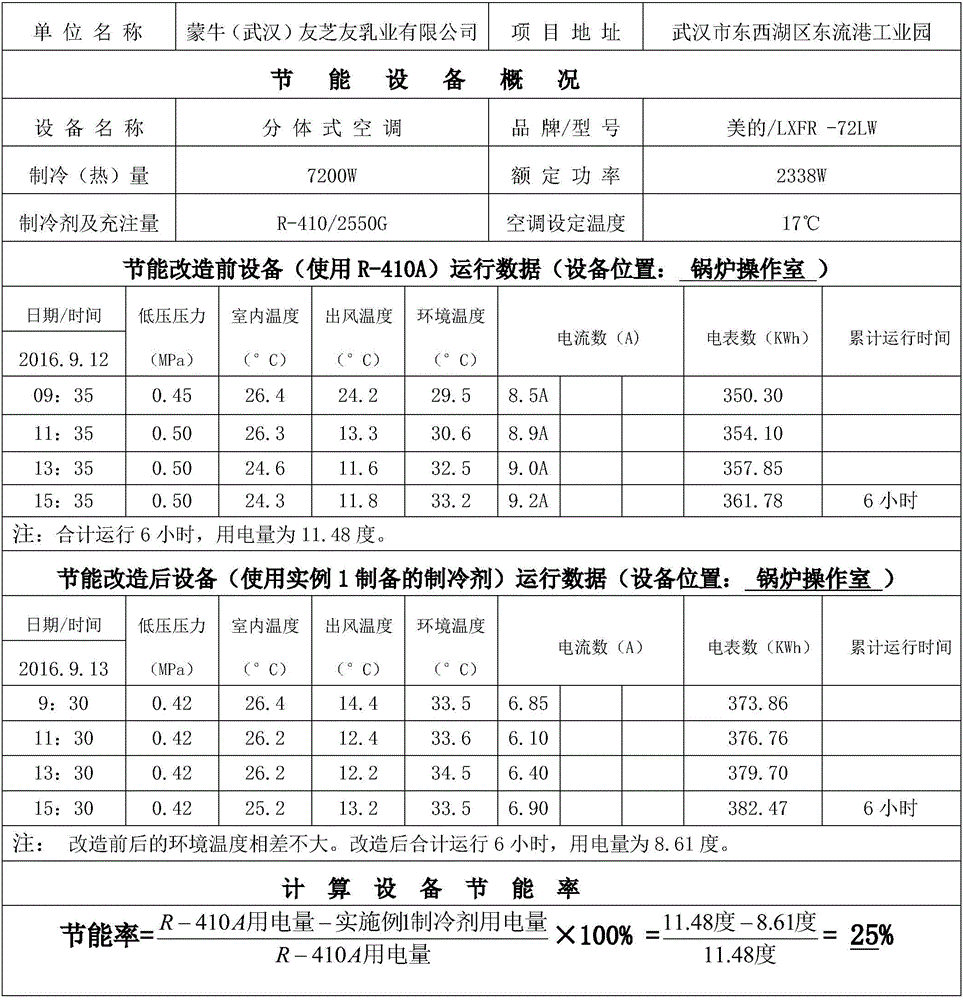

Refrigerant replacing R-410A and preparation method thereof

ActiveCN106543967ASolve substitution problemsGood energy saving effectChemical industryHeat-exchange elementsIodotrifluoromethaneR-410A

The invention belongs to the field of refrigerants, and particularly relates to a refrigerant replacing R-410A and a preparation method thereof. The refrigerant is formed by fully mixing the following raw materials including, by weight, 44-54 parts of propylene, 10-20 parts of iodotrifluoromethane and 30-40 parts of ethyl fluoride. The preparation method of the refrigerant comprises the following steps that S1, the purity of the raw materials are detected to ensure that the purity reaches the refrigerant-grade standard; S2, a cleaning reagent is used for cleaning a pressure vessel; S3, the cleaned pressure vessel is vacuumed; S4, the raw materials which reach the stand are added into the vacuumed pressure vessel according to the proportion of parts by weight and mixed to obtain a mixture; and S5, the mixture in the S4 is sampled, and whether all components in a sample meet the corresponding proportion of the parts by weight or not is detected. By adoption of the refrigerant replacing the R-410A, all original refrigeration equipment do not need to be replaced, the improvement cost is greatly reduced, and the refrigerant is good in energy saving effect and saves energy by 20-25% compared with the original refrigerant R-410A.

Owner:HUBEI GREEN COLD HI TECH ENERGY SAVING TECHCO

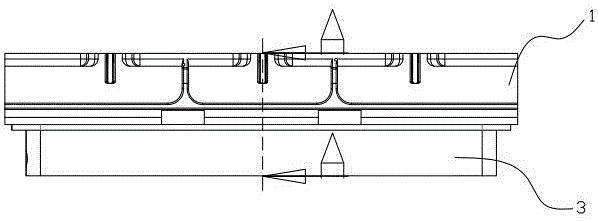

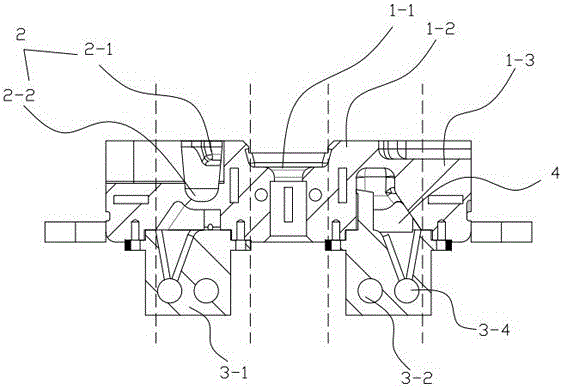

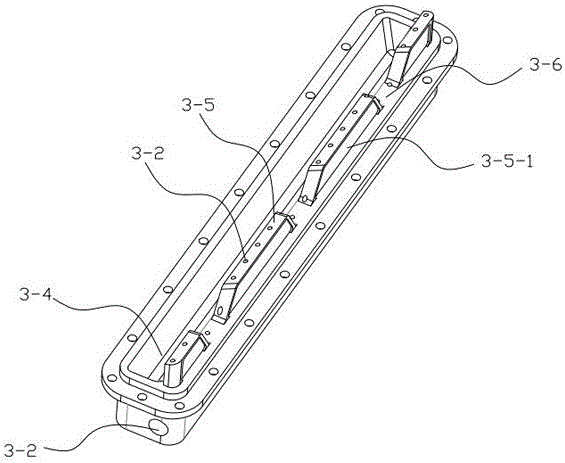

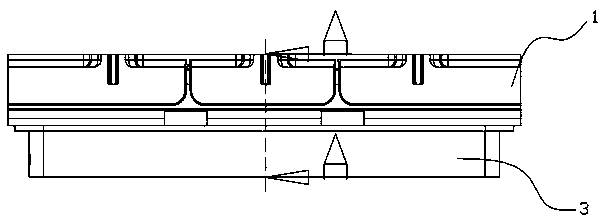

Cooling structure of busbar mold

The invention provides a cooling structure of a busbar mold. The cooling structure of the busbar mold comprises a mold body. A plurality of forming grooves are linearly formed in the mold body. Cooling devices are arranged below the forming grooves. The cooling structure of the busbar mold is characterized in that the mold body comprises a constant-temperature area, cast welding areas and heat preservation areas. The forming grooves are formed in the cast welding areas. One independent cooling device is correspondingly arranged in each cast welding area. Each cooling device comprises a cooling body which is arranged below the corresponding cast welding area and / or the corresponding heat preservation area, wherein a liquid inlet pipe is arranged on the cooling body in the arrangement direction of the corresponding forming groove, and a water injection nozzle is arranged on the liquid inlet pipe and faces the bottom of the corresponding forming groove; and a backflow groove is further formed in the cooling body, and the backflow groove is lower than the water injection nozzle. According to the cooling structure of the busbar mold, cooling systems independently correspond to the cast welding areas are arranged, so that cooling consistency of the different cast welding areas is ensured while the cooling efficiency is improved, constant-temperature control of the mold is facilitated, and thus the cast welding effect is improved.

Owner:ZHEJIANG HAIYUE AUTOMATIC MACHINERY

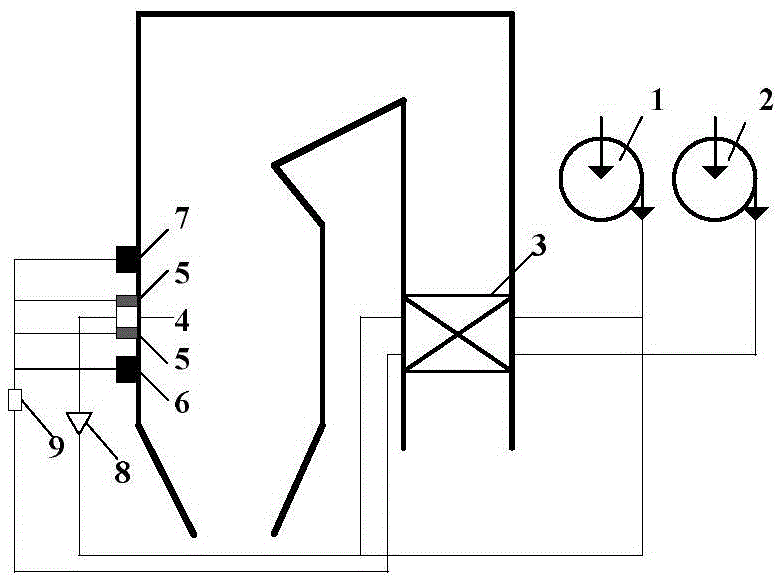

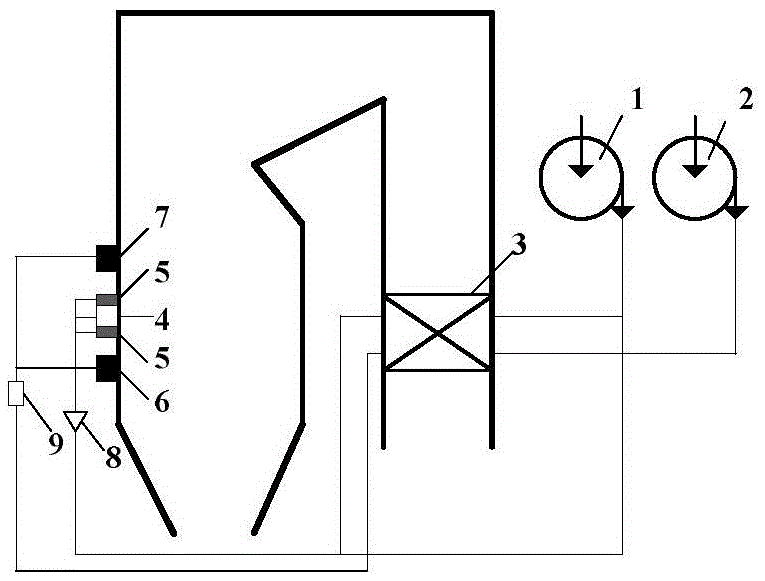

Surrounding air method for reducing NOx emission concentration of power station pulverized coal powder plant boiler

InactiveCN105605606AThe total air volume remains unchangedReduce Excess Air CoefficientFuel supply regulationAir supply regulationMomentumAir volume

The invention provides a surrounding air method for reducing the NOx emission concentration of a power station pulverized coal powder plant boiler. The method includes the specific step of replacing existing secondary air with primary air high in wind pressure under the condition that it is ensured that the total air volume of a hearth is not changed, wherein the primary air is used as surrounding air of a cooling pulverized coal spray nozzle. Because the wind pressure of primary air is higher than the wind pressure of secondary air, after the existing surrounding air is replaced with primary air, the flowing speed of surrounding air is increased. It is ensured that the momentum of surrounding air is constant before and after replacement, and therefore the mass flow rate of surrounding air is correspondingly decreased after replacement. Because the momentum of surrounding air is not changed, the cooling effect the same as that of a combustor can be achieved, and rigidity of the pulverized coal jet flow is also ensured. Meanwhile, the mass flow rate of surrounding air is decreased, and therefore the excess air coefficient of the initial combustion period of pulverized coal is decreased, NO generation in the initial period of combustion is restrained, and therefore the NO emission concentration during running of the boiler is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

Energy-saving air conditioner

InactiveCN101666528ATake advantage ofReduce consumptionLighting and heating apparatusAir conditioning systemsFresh airEngineering

The invention relates to an energy-saving air conditioner. Not a refrigerant but a rotor air compressor provided with an internal compression capability is used for compressing outdoor fresh air in asmall compression ratio (compressed air pressure is 1.1 to 1.3 times of atmospheric pressure), feeding the compressed air into a plate-type heat exchanger, and expanding and doing work on a pneumaticmachine after exchanging heat with indoor air to lower a temperature and reduce an air pressure to the atmospheric pressure, at the moment, the temperature and the flow rate of air can meet the requirement of indoor refrigeration and the air can be fed into a room directly. The indoor air entered the heat exchanger is discharged out of the room after heat exchange so as to achieve the aim of indoor and outdoor air exchange. The energy-saving air conditioner can achieve the same refrigeration effect as a common air conditioner in the situation of less energy consumption and achieves the aims ofenergy conservation, environment protection and the indoor and outdoor air exchange at the same time.

Owner:张桂伟

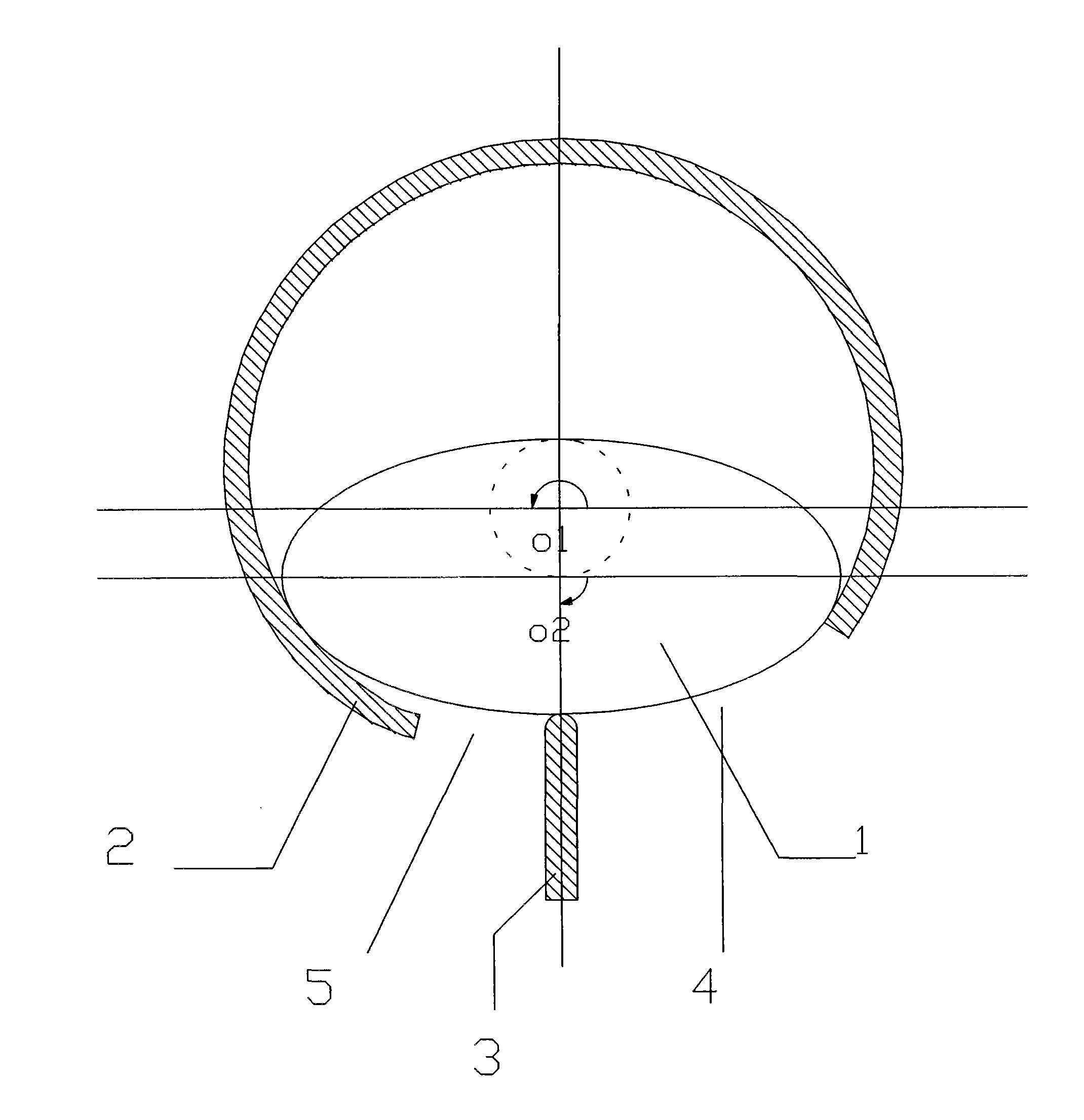

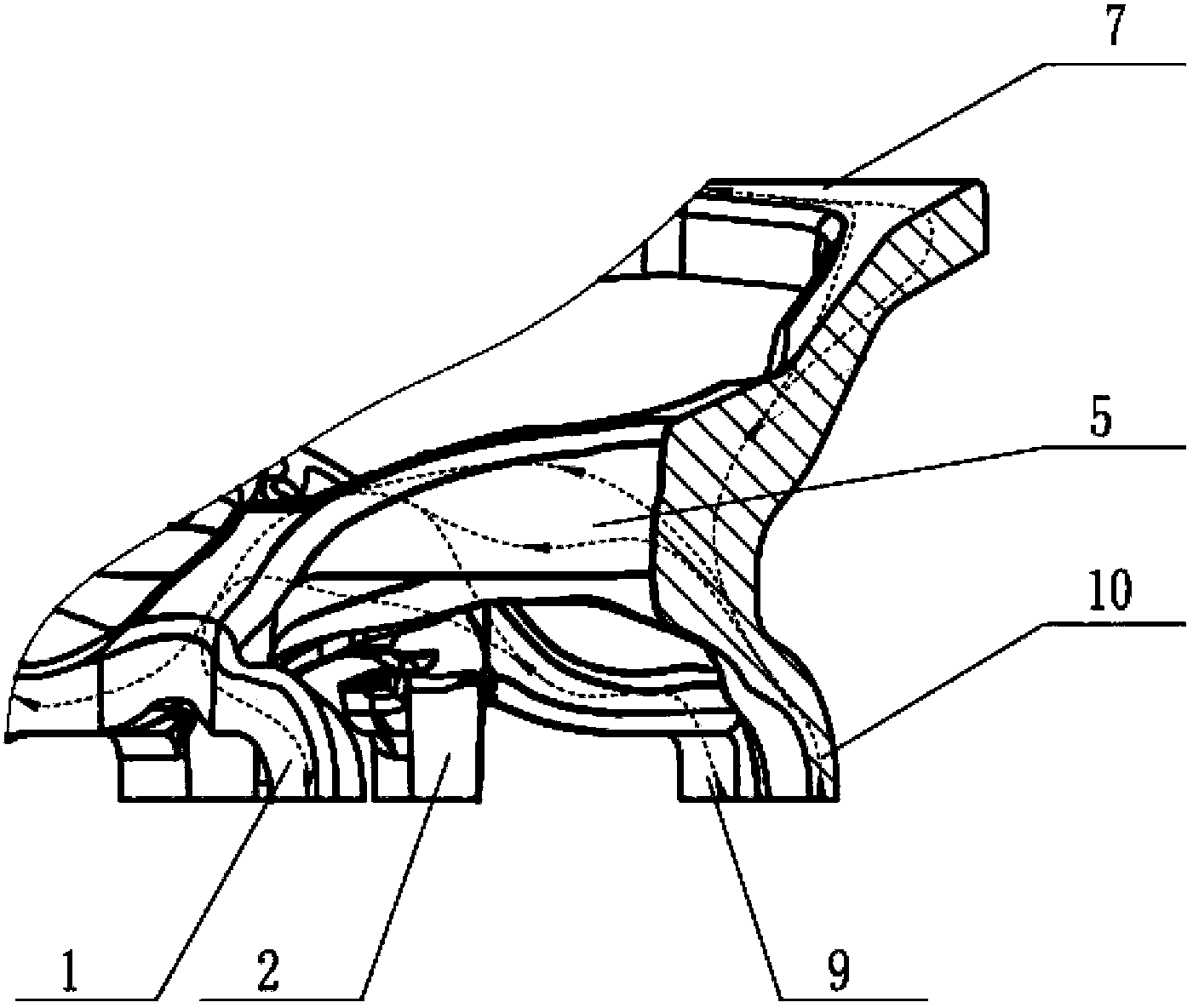

Cross type cooling water jacket of cylinder head of three-cylinder supercharged engine

ActiveCN103835830ASame cooling effectAvoid crackingCylinder headsCylindersForced inductionEngineering

The invention discloses a cross type cooling water jacket of a cylinder head of a three-cylinder supercharged engine. Three cooling liquid inlets of the cooling water jacket are formed in the exhaust side of the cylinder head, three cooling liquid outlets of the cooling water jacket body are formed in the air inlet side of the cylinder head, each cooling liquid inlet and the corresponding cooling liquid outlet correspond to an air cylinder, each air cylinder corresponds to a cylinder head exhaust channel area and a cylinder head air inlet channel area, a cooling water channel is formed in the nose bridge area in the middle of each cylinder head exhaust channel area, one end of each cooling water channel is communicated with the corresponding cooling liquid inlet, the other end of each cooling water channel is communicated with one side wall of an exhaust channel, and one end of each exhaust channel is connected with a cooling liquid inlet of a supercharger. According to the cross type cooling water jacket of the cylinder head of the three-cylinder supercharged engine, due to the fact that each set of the cooling liquid inlet and the cooling liquid outlet are formed in the portion, corresponding to the corresponding air cylinder, of the cylinder head, it is ensured that the cooling effects of the air cylinders are the same; due to the fact that the special cooling water channels are arranged in the nose bridge areas, the phenomenon that the nose bridge areas crack due to the overhigh temperature is avoided.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

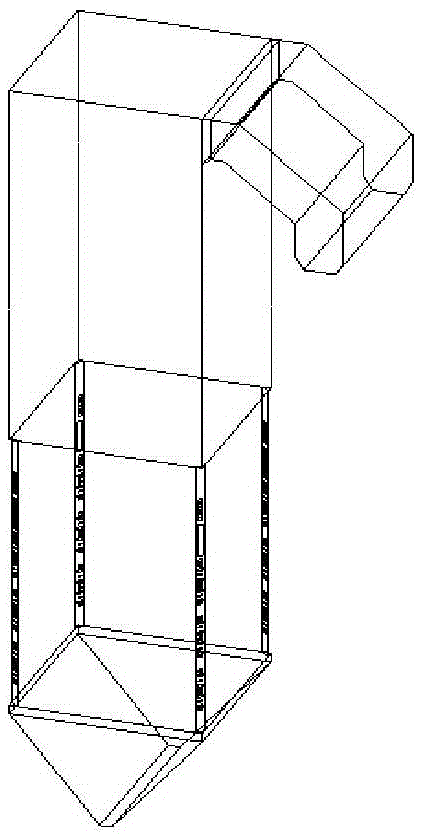

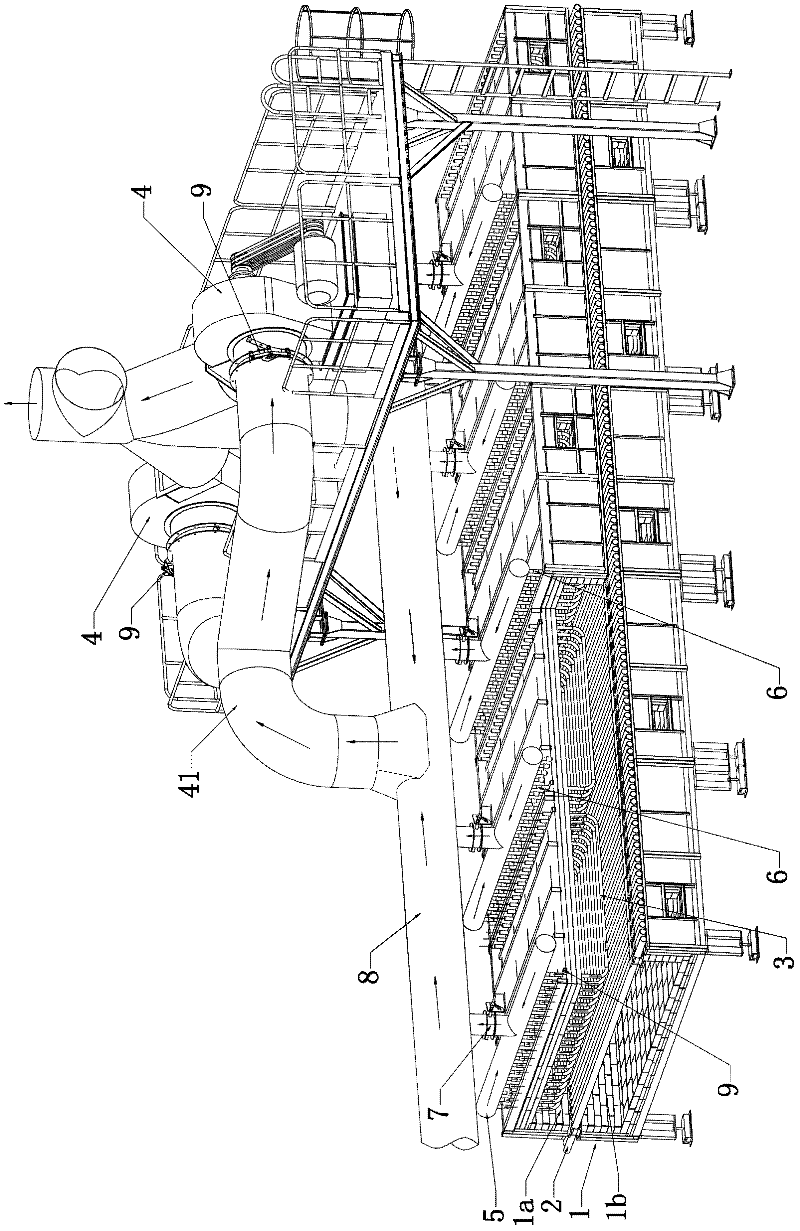

Furnace slow-cooling area structure capable of shrinking cross-sectional temperature difference

ActiveCN102374788AReduce cross-section temperature differenceSame cooling effectFurnace coolingTubular elementsCooling effectEngineering

The invention discloses a furnace slow-cooling area structure capable of shrinking cross-sectional temperature differences, which comprises a slow-cooling chamber, a plurality of conveying rollers, a large amount of heat-exchanging pipes and an exhausting mechanism, wherein the exhausting mechanism is communicated with the heat-exchanging pipes, the conveying rollers are sequentially arranged along the length direction of the slow-cooling chamber and are placed at the middle part of the slow-cooling chamber, the heat-exchanging pipes are arranged along the longitudinal direction of the slow-cooling chamber, each heat-exchanging pipe is a U-shaped steel pipe with two open ends, one end of each heat-exchanging pipe is communicated with a workshop, and the other end of each heat-exchanging pipe is communicated with the exhausting mechanism. The furnace slow-cooling area structure has the beneficial effects that the basic sameness of the temperatures of all points on the same cross section is realized; because a wind inlet and a wind outlet are positioned at different positions on the same section, the cooling effects can tend towards consistency under the conditions that the diameters of branched pipes are the same and the flow speeds of hot wind are the same, the cross-sectional temperature difference of a furnace-cooling passage is shrunk, the sameness of the cooling speeds of a product at the slow-cooling stage can be ensured, and the defects of the product caused by cooling temperature differences are avoided.

Owner:MODENA TECH LTD

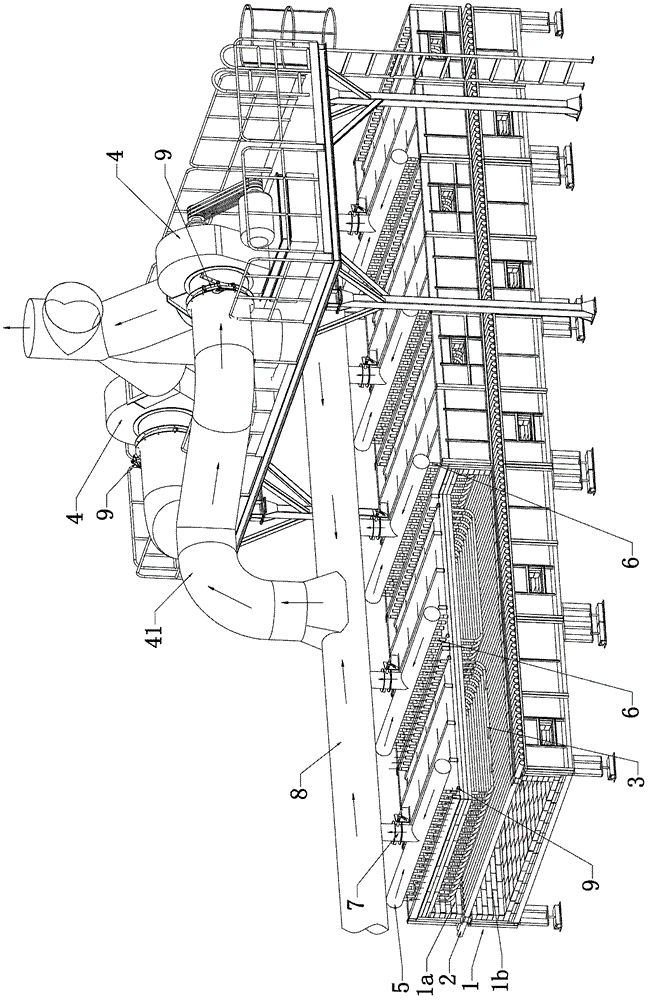

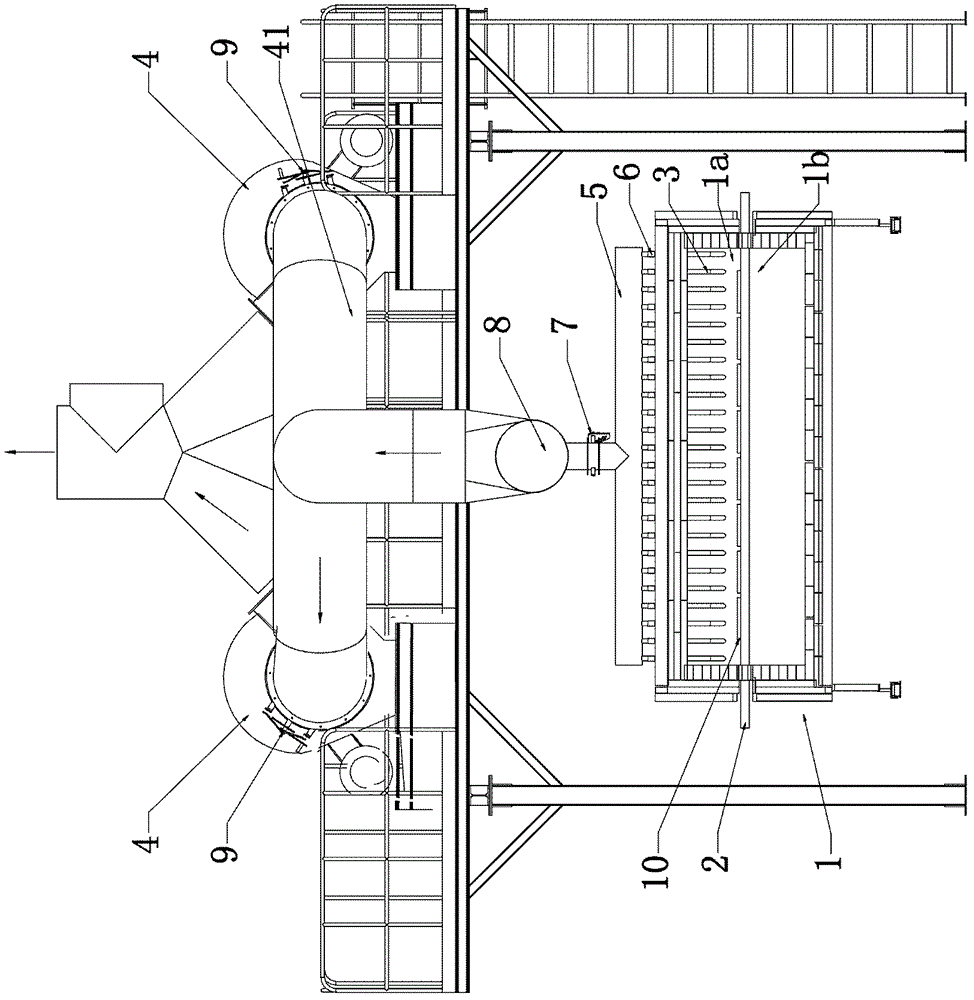

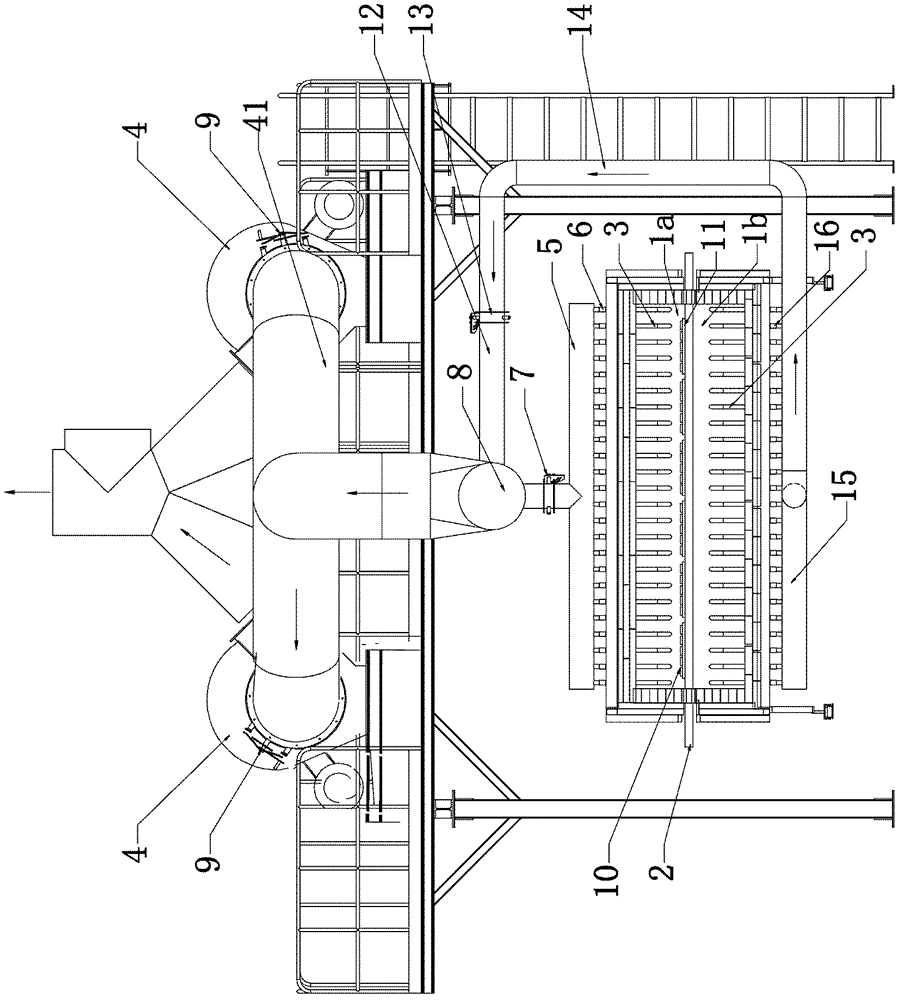

Arrangement for Recirculation of Exhaust Gases of a Super-Charged Internal Combustion Engine

InactiveUS20070199317A1Guaranteed airflowSame cooling effectNon-fuel substance addition to fuelInternal combustion piston enginesExhaust fumesEngineering

The present invention relates to an arrangement for recirculation of exhaust gases in a supercharged combustion engine. The arrangement comprises an exhaust line intended to lead exhaust gases out from the combustion engine, an inlet line intended to lead air at above atmospheric pressure to the combustion engine, a return line which comprises a connection to the exhaust line and a connection to the inlet line, so that via the return line it is possible to recirculate exhaust gases from the exhaust line to the inlet line. The arrangement comprises a charge cooler which is cooled by ambient air. The charge cooler is incorporated in the inlet line downstream from the connection of the return line to the inlet line so that, when the exhaust gases are returned via the return line, said charge cooler cools a mixture of exhaust gases and air before the mixture is led to the combustion engine.

Owner:SCANIA CV AB

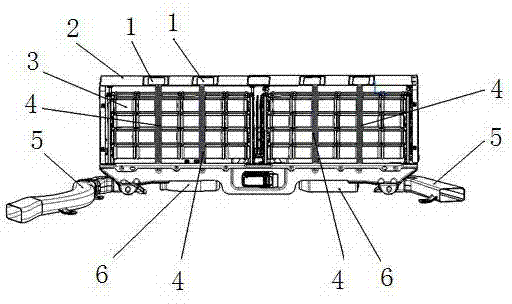

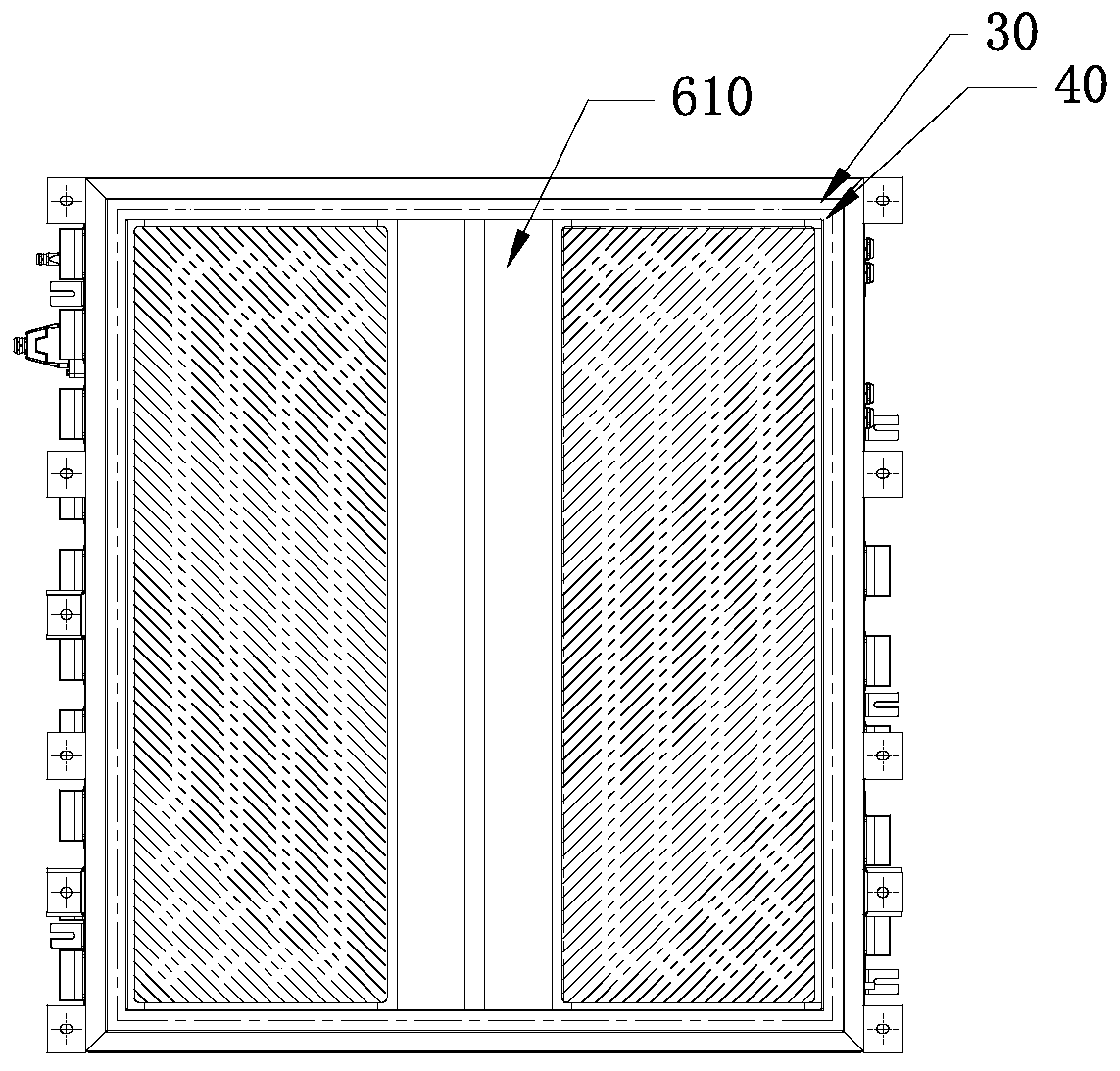

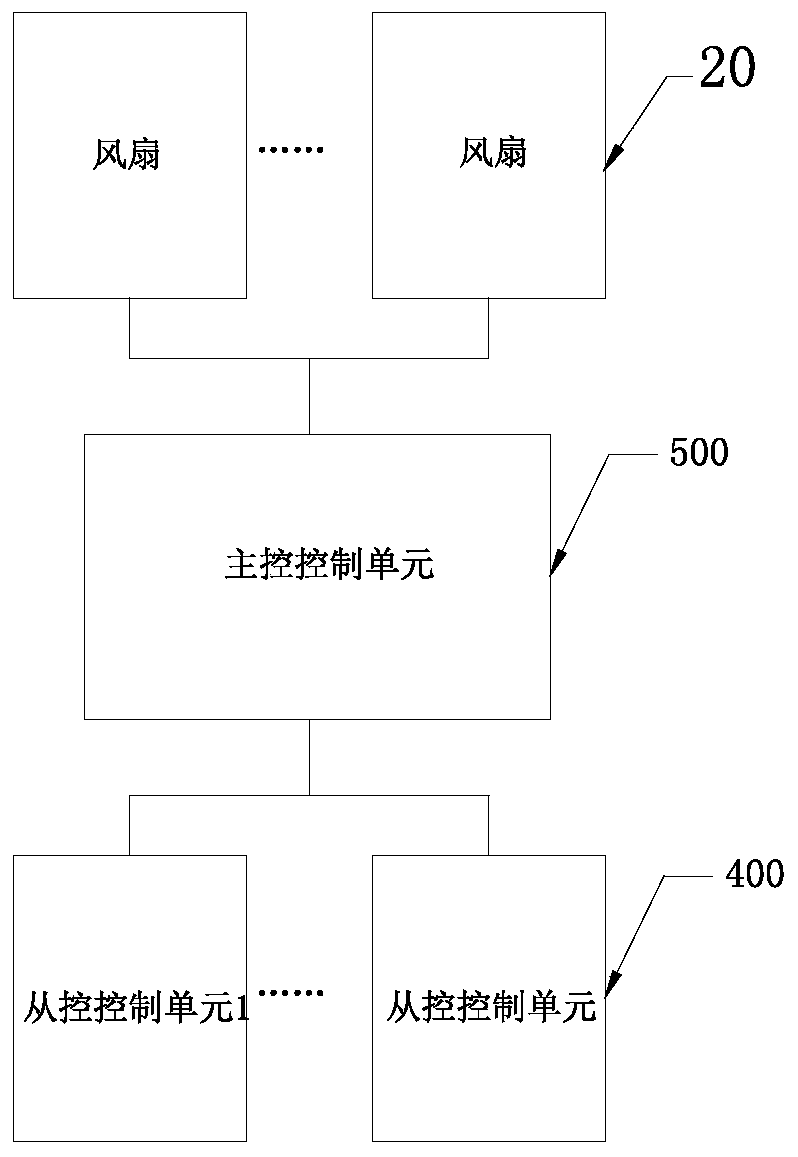

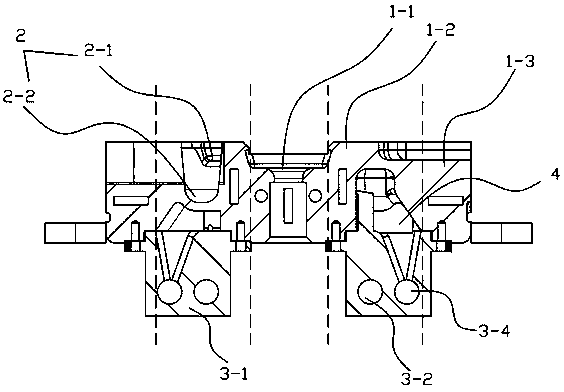

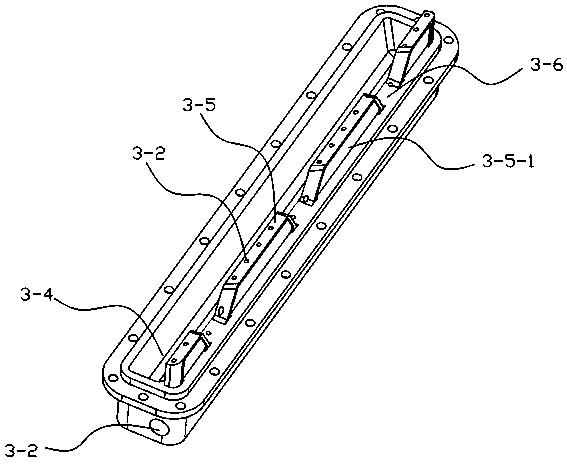

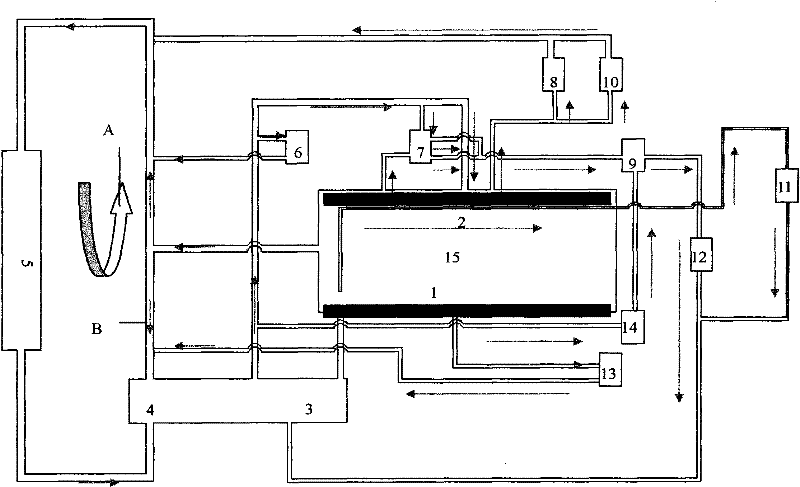

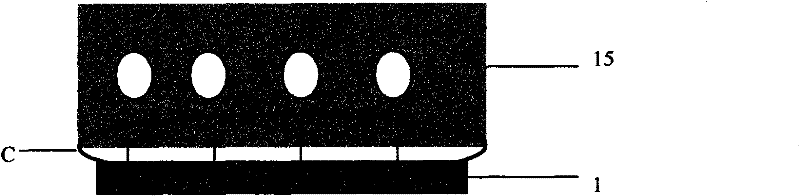

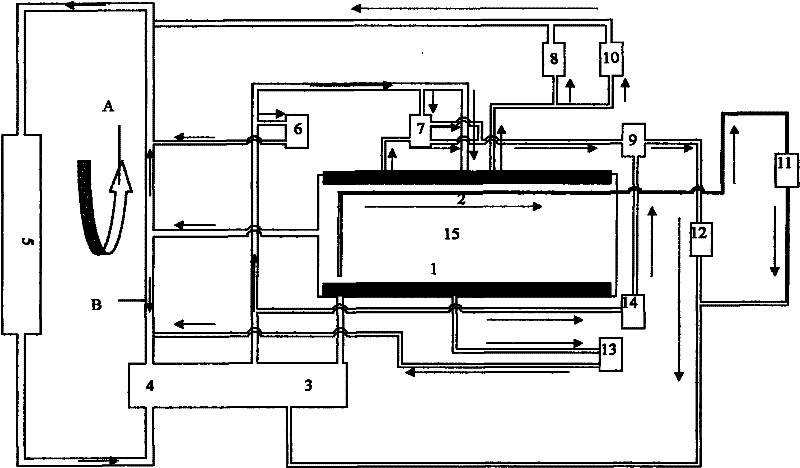

Reverse-flow cooling system for power battery pack and power battery pack

ActiveCN111490313AOvercoming the disadvantages of gradually increasing temperatureSame cooling effectSecondary cellsElectrical batteryProcess engineering

The embodiment of the invention relates to the technical field of batteries, and in particular relates to a reverse-flow cooling system for a power battery pack and the power battery pack. The coolingsystem comprises a plurality of cooling units which are arranged in parallel; two sets of cooling channels which are arranged in a staggered mode are arranged in each cooling unit, and the flowing directions of cooling media in the two sets of cooling channels which are arranged in the staggered mode are opposite. According to the invention, two sets of staggered cooling channels are arranged ineach cooling unit; the flowing directions of the cooling media in each set of cooling channels are opposite to form reverse flow, so that the cooling effects of the two ends of each cooling unit are the same, and the defect that the temperature of a battery is gradually increased due to gradual reduction of the cooling capacity in the flowing direction during one-way cooling is overcome; the powerbattery is cooled through the plurality of cooling units; and the plurality of cooling units are arranged in parallel, so that the overall arrangement has the characteristics of compactness and modularization.

Owner:SICHUAN UNIV

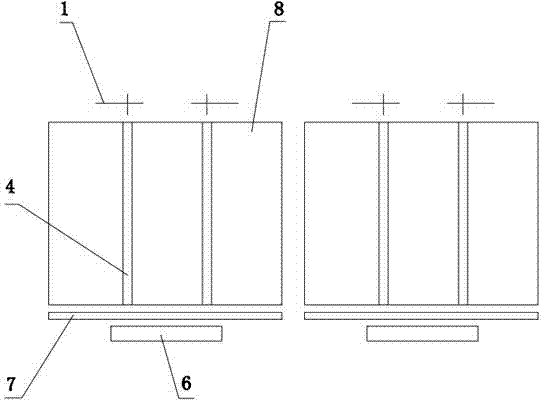

Power battery pack dissipation device for hybrid electric vehicle

ActiveCN103779633ADuct length is the sameKeep the temperature field uniformSecondary cellsBatteriesElectric vehicleEngineering

The invention relates to a power battery pack dissipation device for a hybrid electric vehicle and aims to overcome the defects that the position arrangement of the air inlet and the air outlet of the existing battery pack dissipation device is not reasonable, which causes that the lengths of air channels in the battery pack are not consistent, the deviation between the wind pressure and the flow rate is caused, the dissipation effect of the battery pack is not consistent, the temperature field part is not uniform, and the service life and the performance of the battery pack are influenced. The battery pack is placed in the space with air inlet windows; the volume of the space is greater than the size of the battery pack; the air inlets are directly communicated with the space; the number of the air inlets is the same as that of support frames in the battery pack, and the positions of the air inlets correspond to those of the support frames; a battery module in the battery pack is partitioned off into equant units; the area of each air inlet corresponding to each unit is the same; the air inlets are opposite to the air outlets, and the air inlets correspond to the support frames, so that the cooling air in the air inlets descends along the support frames and does not cause eddies at the support frames, the lengths in air channels of the battery pack are consistent, the temperature field in the battery pack keeps uniform, and the situation that the dissipation effect in the battery pack is the same is ensured.

Owner:科力远混合动力技术有限公司

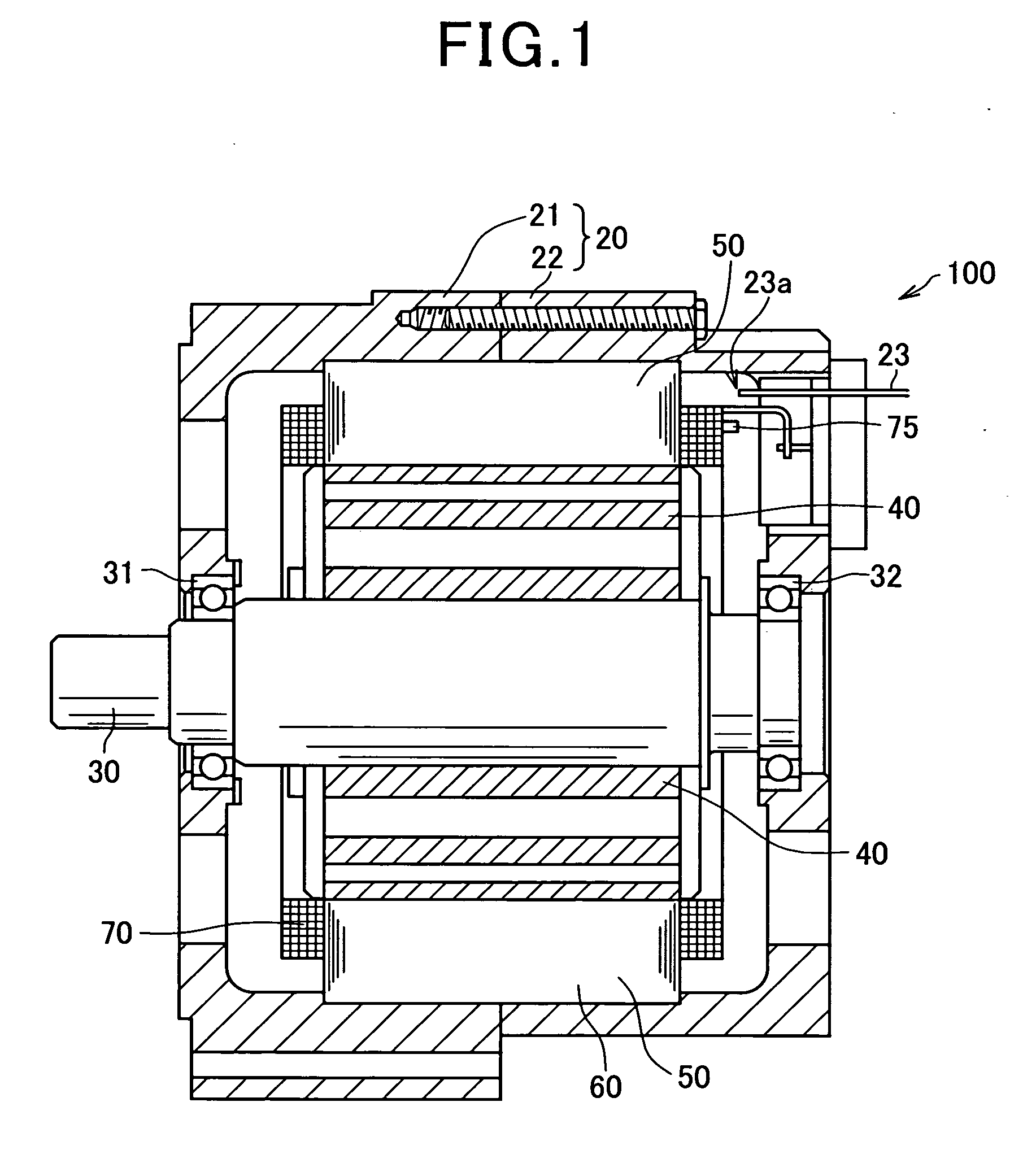

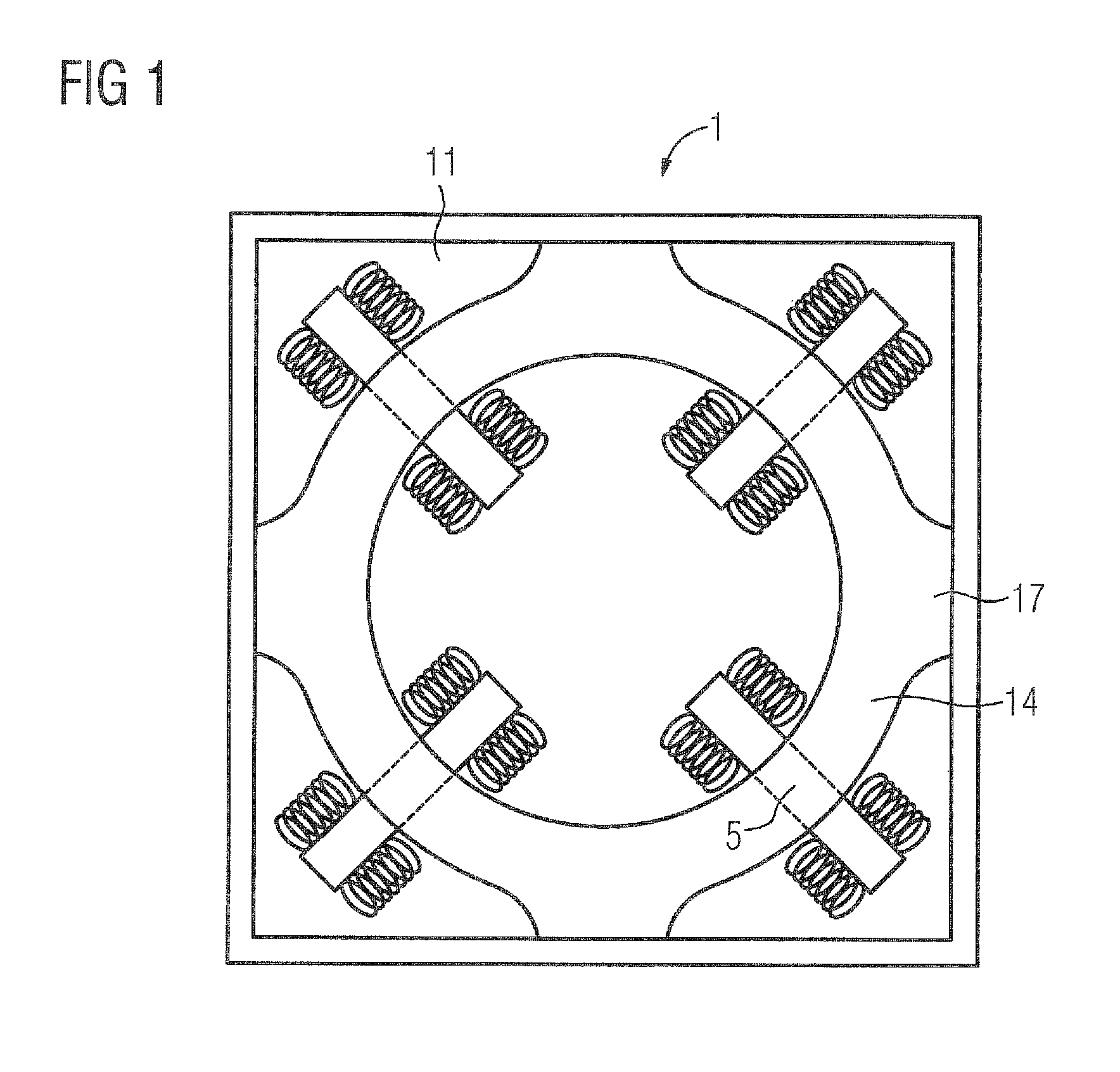

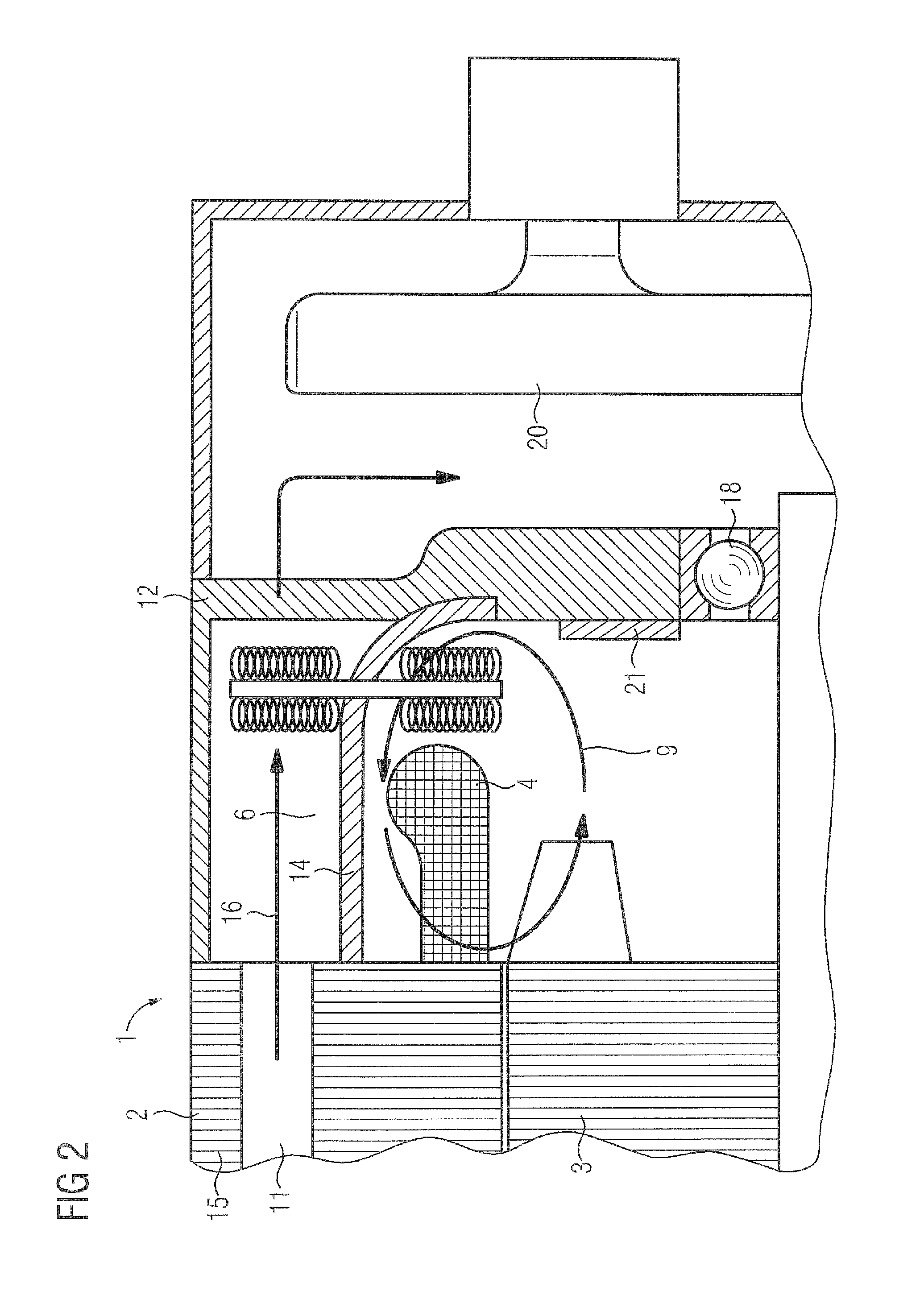

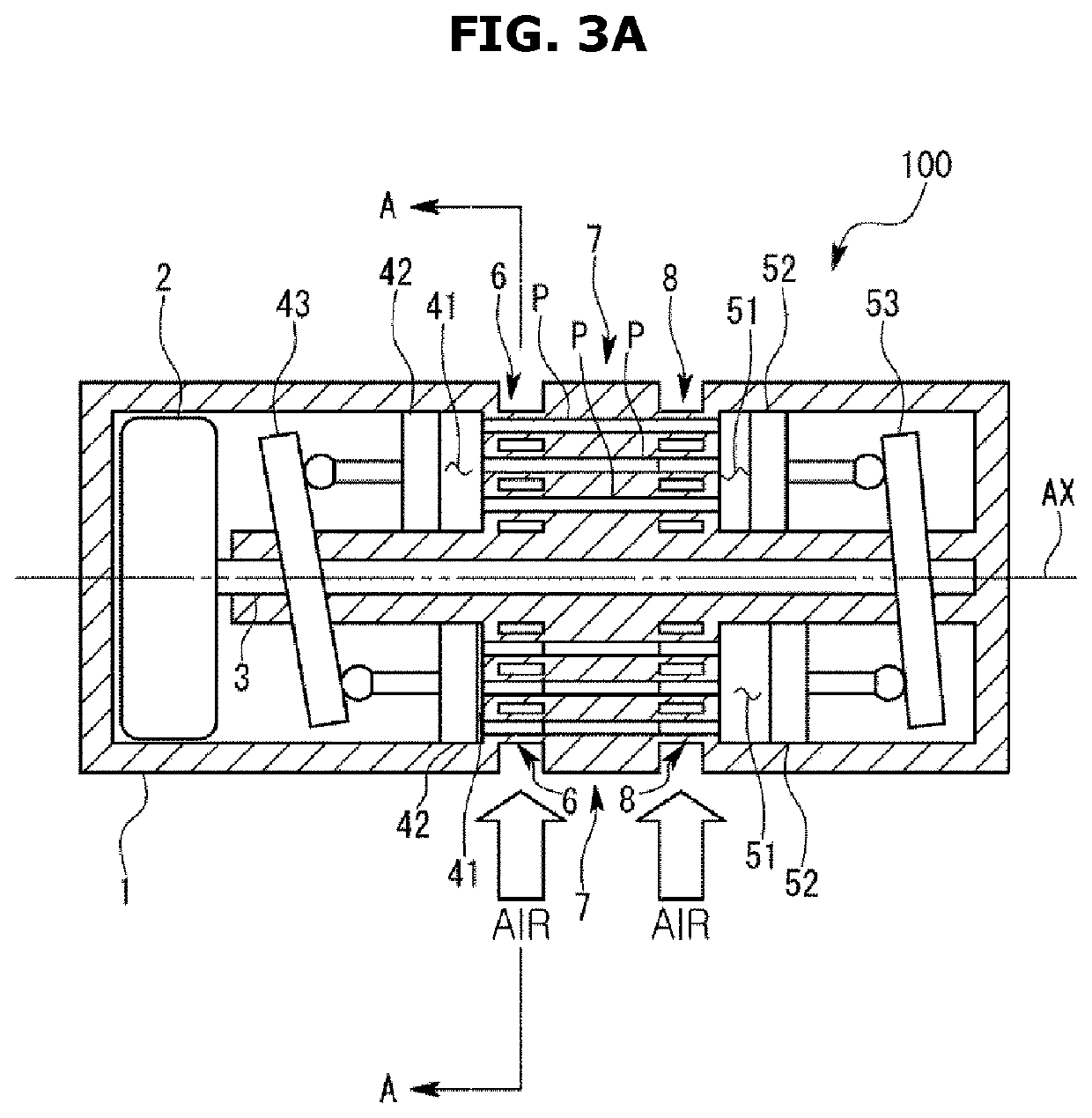

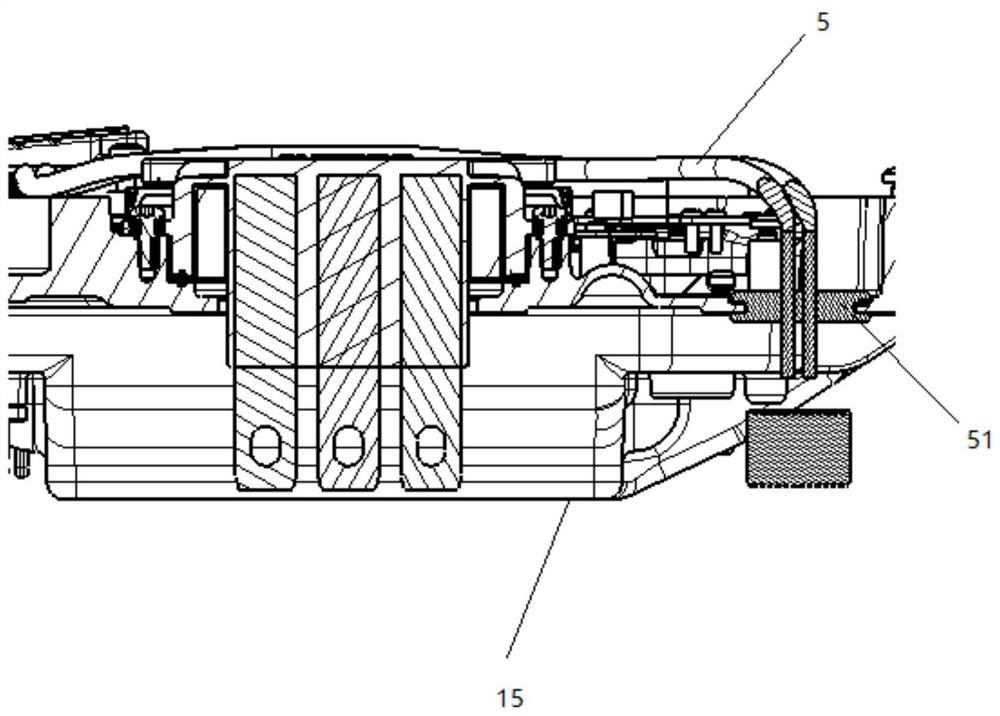

Dynamoelectric machine

InactiveUS8350424B2Increase surface areaImprove transferMagnetic circuit rotating partsIndirect heat exchangersStatorElectrical and Electronics engineering

The invention relates to a dynamoelectric machine (1) comprising a stator (2) and a rotor (3). At least the stator (2) has a winding system (4) which is arranged in grooves of the stator (2). Heat is transferred in a substantially radial direction on the front sides (6) of the stator (2) by means of heat pipes (5).

Owner:SIEMENS AG

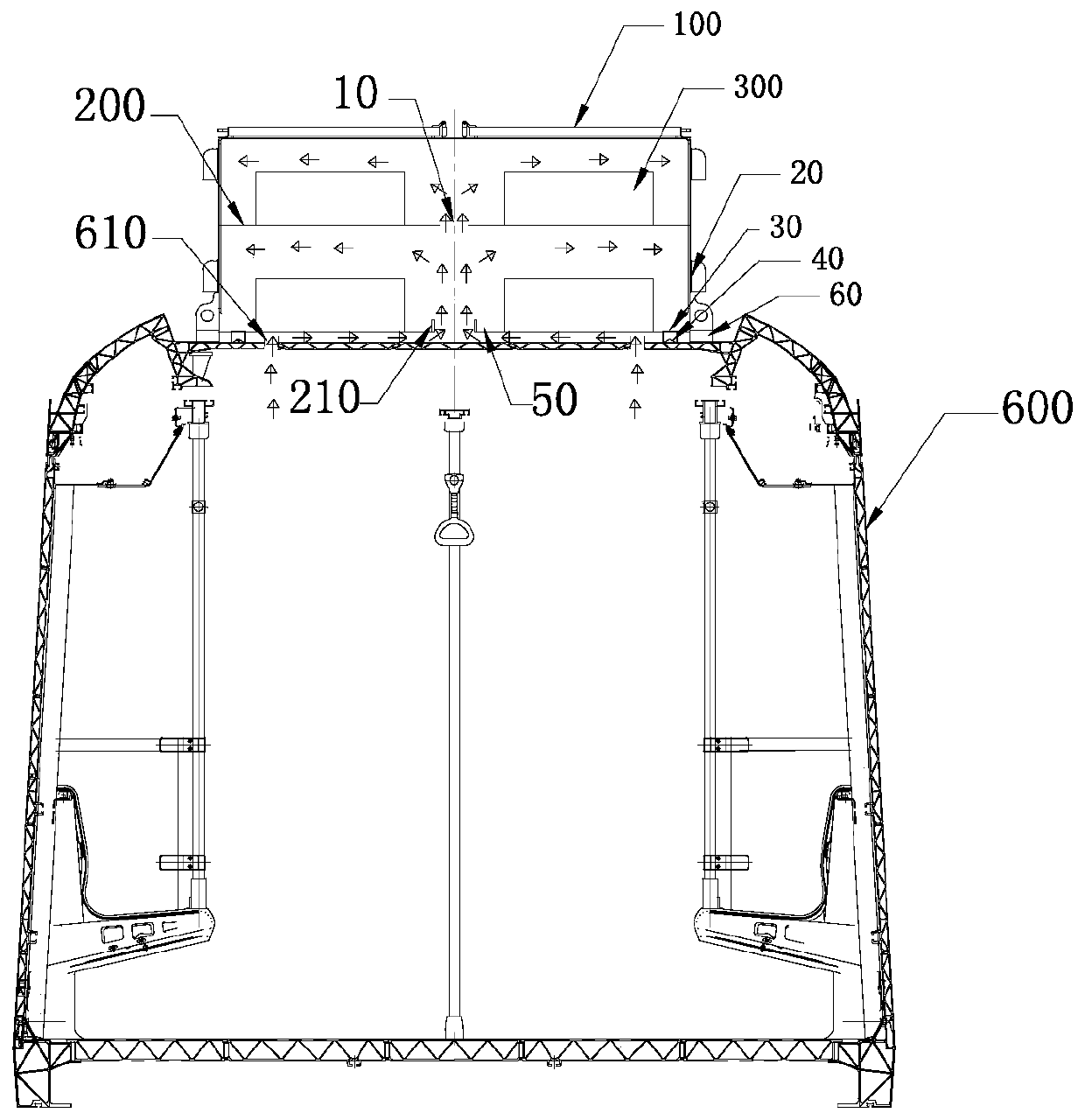

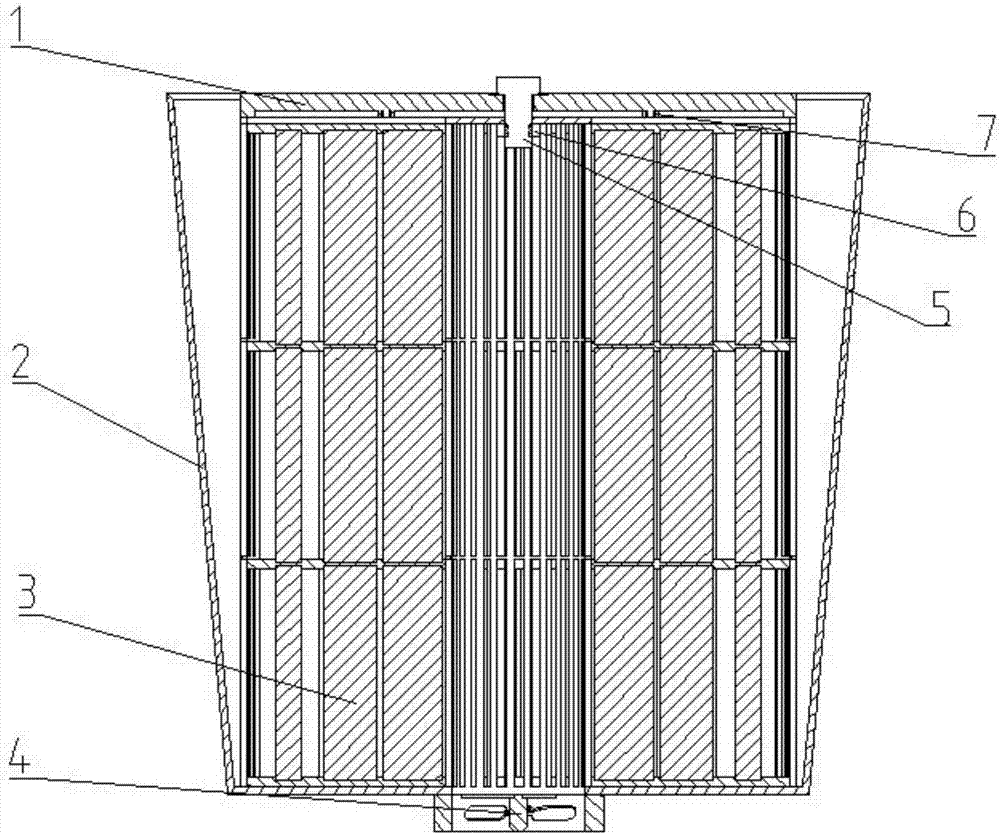

Super-capacitor energy storage system for vehicle, rail vehicle and cooling method of super-capacitor energy storage system for vehicle

ActiveCN111071069AEasy to installRealize dockingProtecting/adjusting hybrid/EDL capacitorPropulsion by capacitorsCapacitanceCooling effect

The invention discloses a super-capacitor energy storage system for a vehicle, a rail vehicle and a cooling method of the super-capacitor energy storage system for the vehicle, and belongs to the technical field of rail vehicles. The rail vehicle comprises the energy storage system and a carriage; an air outlet is formed in the top of the carriage; and the top of the carriage makes contact with asealing groove in an energy storage cabinet body, and a cavity is defined by the top of the carriage and the bottom layer of the energy storage cabinet body and communicated with the air outlet and anair duct at the same time. When super-capacitor modules in the energy storage cabinet body are cooled, cooling air is shunted from the air duct, and the super-capacitor modules located on the upper layer and the lower layer of the energy storage cabinet body are cooled at the same time, so that the super-capacitor modules on the upper layer and the lower layer in the energy storage cabinet body almost obtain the same cooling effect; and in the rail vehicle, the energy storage system is directly placed at the top of the carriage, the air outlet is located in the ring of the sealing groove, sobutt joint of the energy storage system and the air outlet of the carriage is achieved, and the structures of the air outlet and a butt joint opening in the energy storage system are greatly simplified.

Owner:NINGBO CRRC NEW ENERGY TECH CO LTD

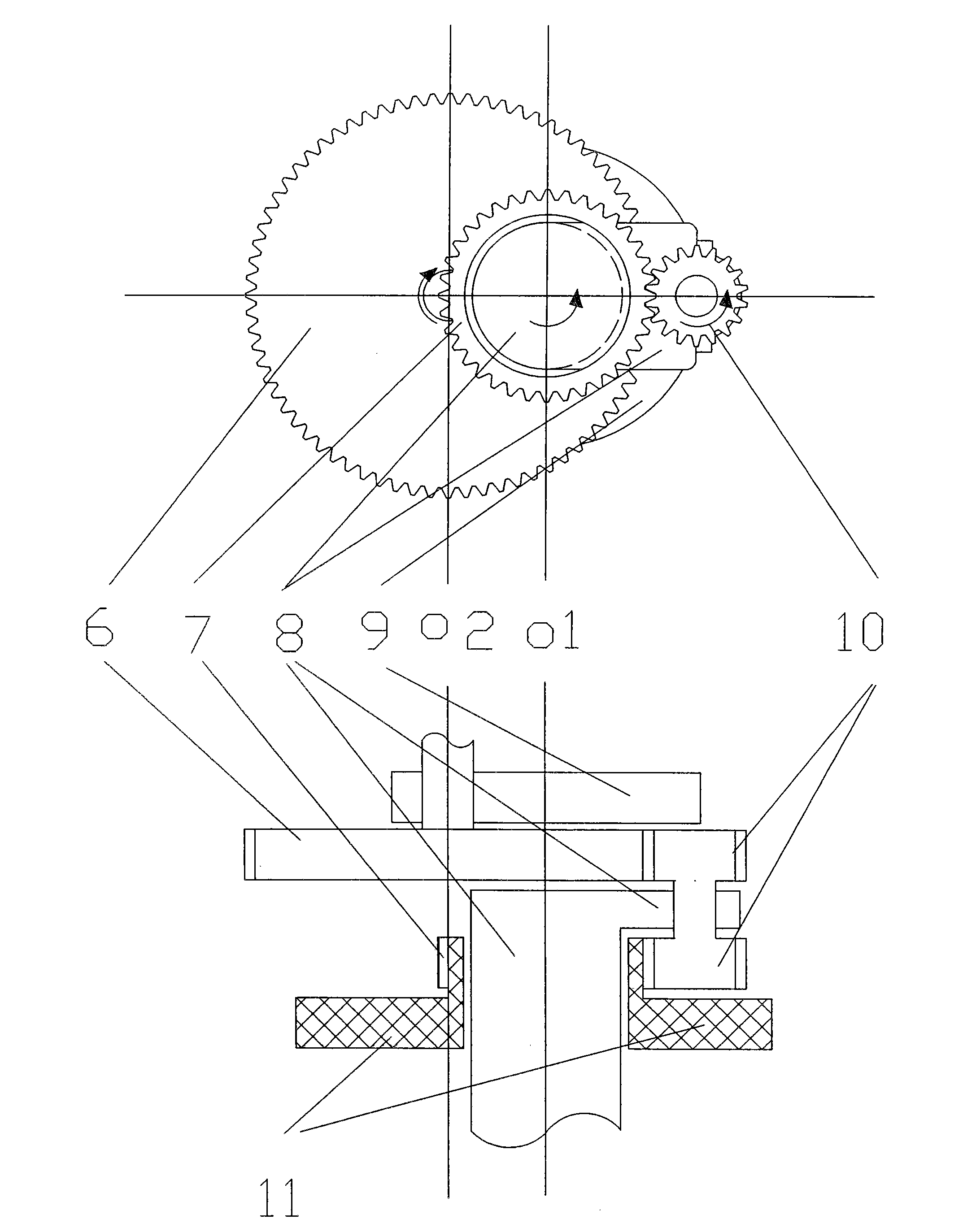

Cool air supplying apparatus and refrigerator having the same

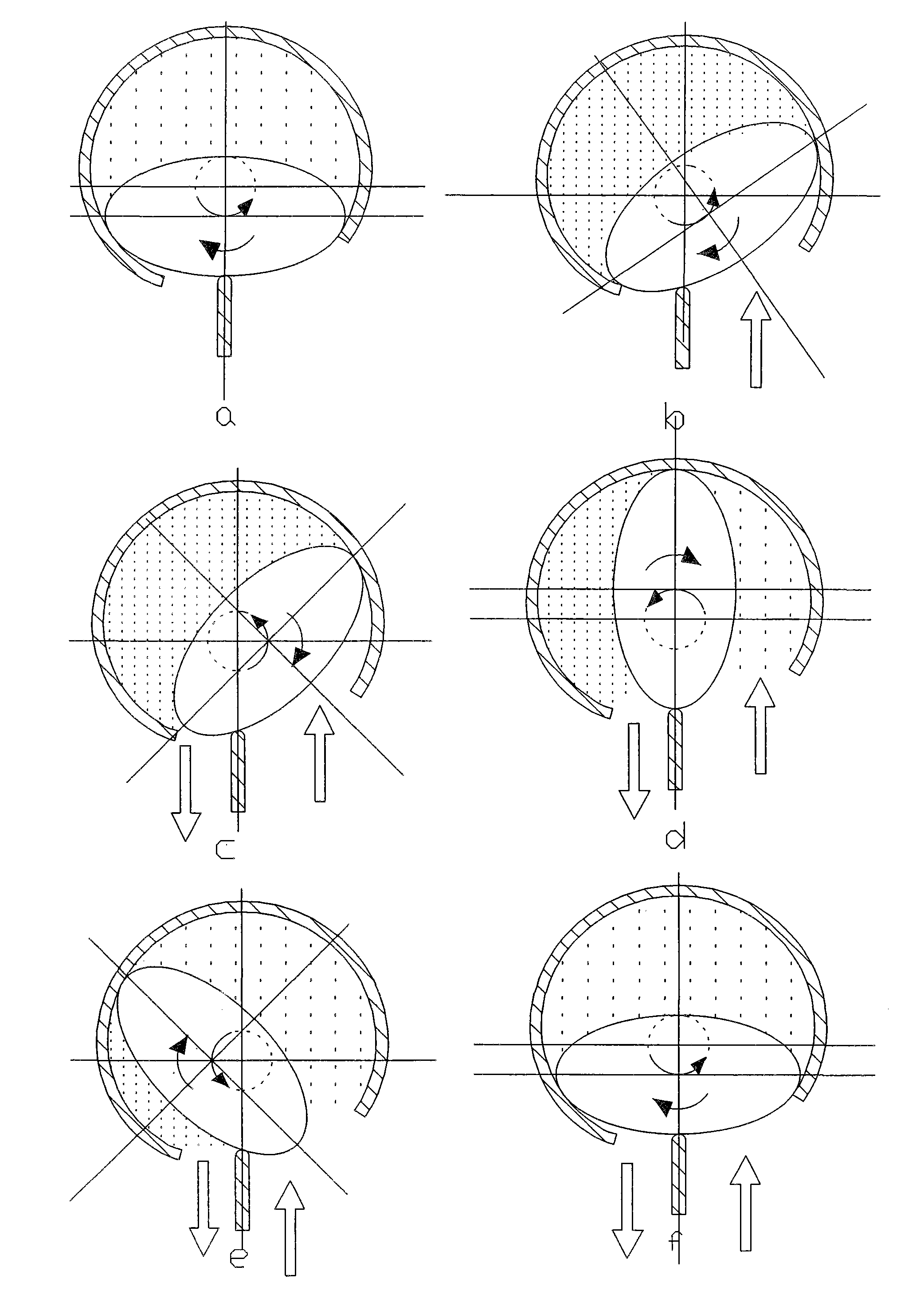

ActiveUS20200025420A1Improve heat transfer efficiencySame cooling effectCompression machinesMachines using electric/magnetic effectsWorking fluidReciprocating motion

A cool air supplying apparatus includes a swash plate shaft connected to a motor and extending in a predetermined axial direction; a compression swash plate obliquely coupled to the swash plate shaft; a compression piston configured to reciprocate in the axial direction by the rotation of the compression swash plate; a compression cylinder in which a working fluid is compressed by the compression piston, an expansion swash plate obliquely coupled to the swash plate shaft; an expansion piston configured to reciprocate in the axial direction by the rotation of the expansion swash plate; and an expansion cylinder arranged with the compression cylinder in the axial direction and configured to expand a working fluid compressed by the compression cylinder; and the compression swash plate and the expansion swash plate are installed in the swash plate shaft with a predetermined phase difference.

Owner:SAMSUNG ELECTRONICS CO LTD

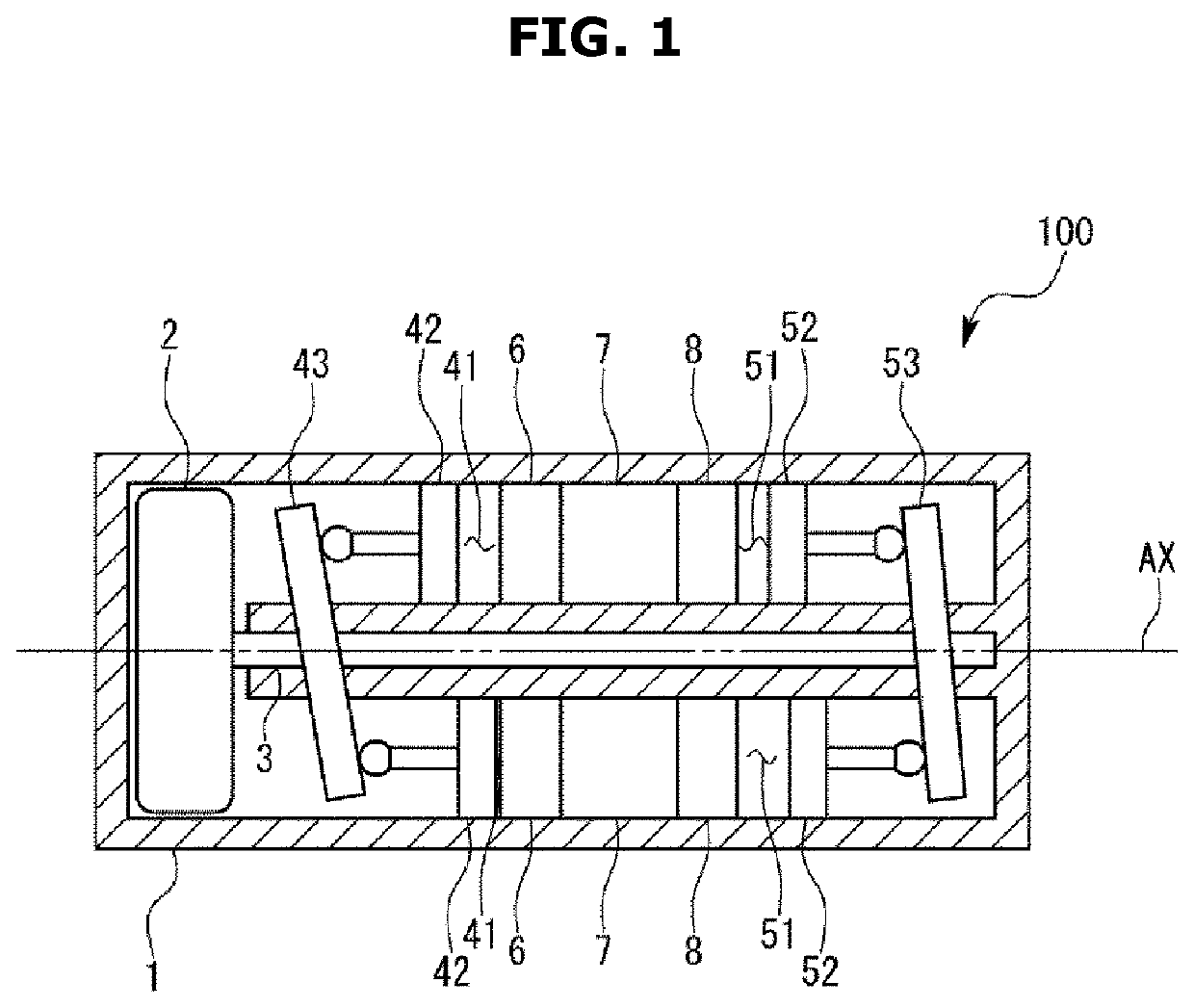

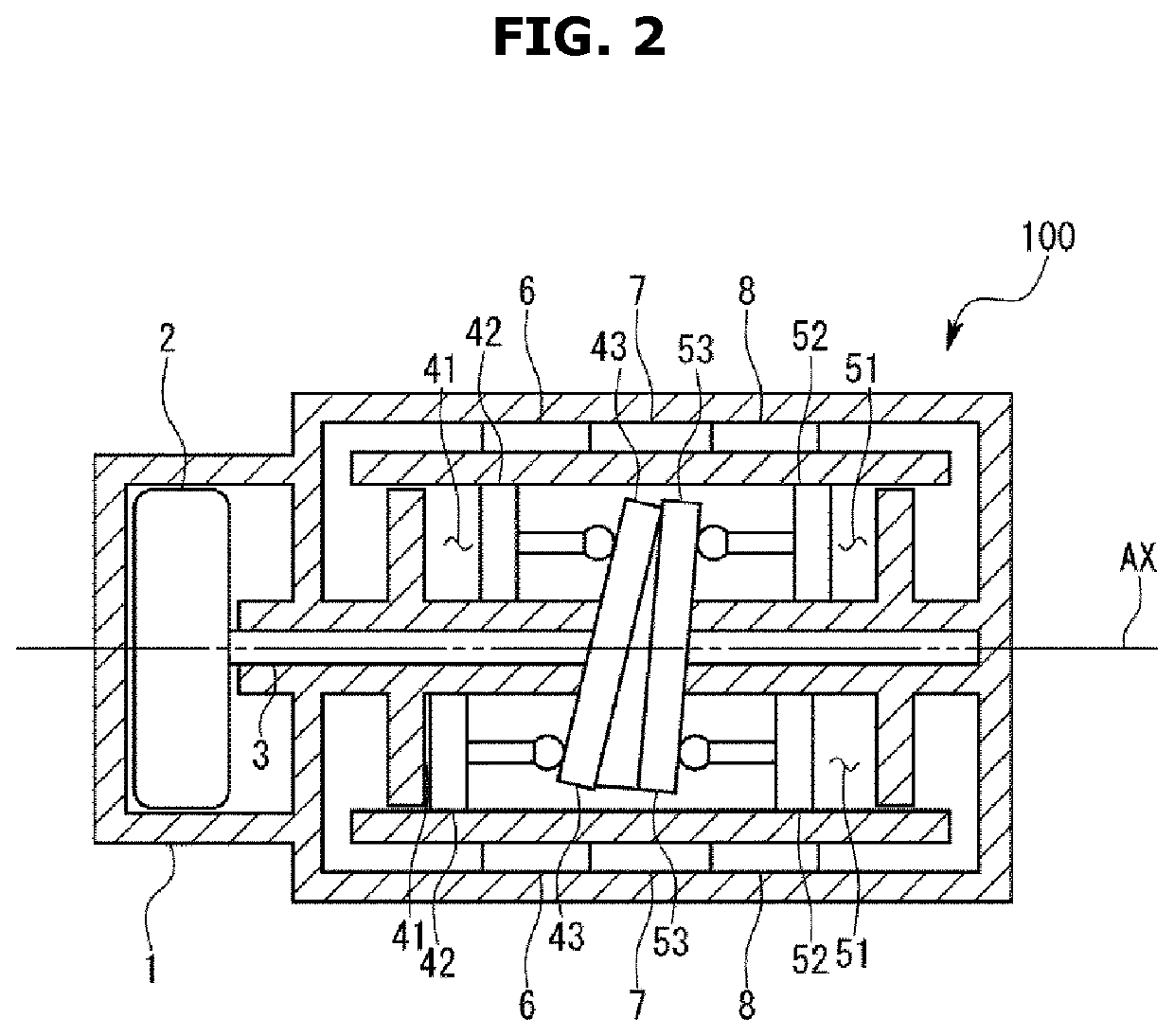

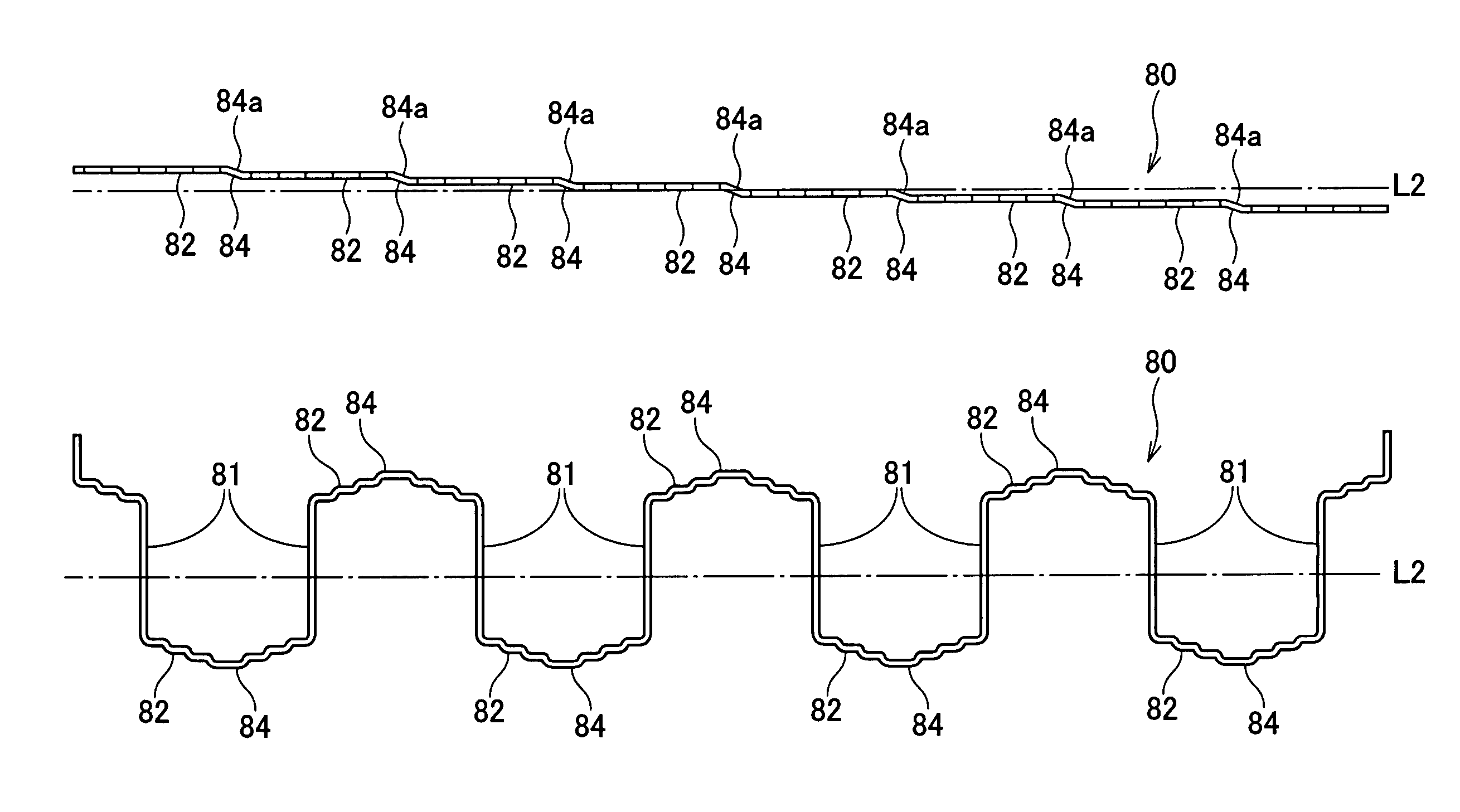

Stator for dynamoelectric machine and method of manufacturing same

ActiveUS8179013B2Improve cooling effectSame cooling effectSynchronous machinesAsynchronous induction motorsWave shapeStator coil

A stator for a dynamoelectric machine includes a stator core and a stator coil. The stator coil is made up of wave-shaped electric wires mounted on the stator core. Each of the electric wires has in-slot portions, each of which is received in one of slots of the stator core, and connecting portions each of which is located outside of the slots to connect one adjacent pair of the in-slot portions. Each of the connecting portions includes an apex part that is located axially furthest in the connecting portion from the stator core and includes an oblique section extending obliquely with respect to the radial direction of the stator core. Further, the oblique sections of the electric wires on one side of the stator core in the axial direction of the stator core are oblique in the same direction as those on the other side of the stator core.

Owner:DENSO CORP

A cooling structure for a busbar mold

The invention provides a cooling structure of a busbar mold. The cooling structure of the busbar mold comprises a mold body. A plurality of forming grooves are linearly formed in the mold body. Cooling devices are arranged below the forming grooves. The cooling structure of the busbar mold is characterized in that the mold body comprises a constant-temperature area, cast welding areas and heat preservation areas. The forming grooves are formed in the cast welding areas. One independent cooling device is correspondingly arranged in each cast welding area. Each cooling device comprises a cooling body which is arranged below the corresponding cast welding area and / or the corresponding heat preservation area, wherein a liquid inlet pipe is arranged on the cooling body in the arrangement direction of the corresponding forming groove, and a water injection nozzle is arranged on the liquid inlet pipe and faces the bottom of the corresponding forming groove; and a backflow groove is further formed in the cooling body, and the backflow groove is lower than the water injection nozzle. According to the cooling structure of the busbar mold, cooling systems independently correspond to the cast welding areas are arranged, so that cooling consistency of the different cast welding areas is ensured while the cooling efficiency is improved, constant-temperature control of the mold is facilitated, and thus the cast welding effect is improved.

Owner:ZHEJIANG HAIYUE AUTOMATIC MACHINERY

Quenching Fluid

InactiveUS20090308505A1Improve cooling effectHigh indexHydrocarbon by hydrogenationHydrocarbon purification/separationFluid compositionCentistokes

Quenching fluid composition comprising one or more additives and a saturated base oil having a kinematic viscosity at 100° C. “K” expressed in centistokes and a viscosity index “I” wherein I is greater than 120 and K greater than 2 cSt.

Owner:SHELL OIL CO

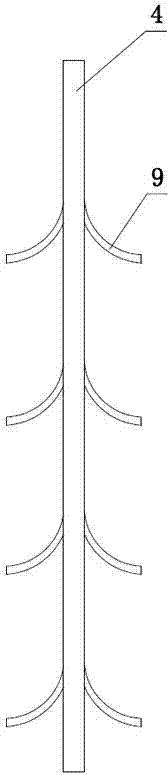

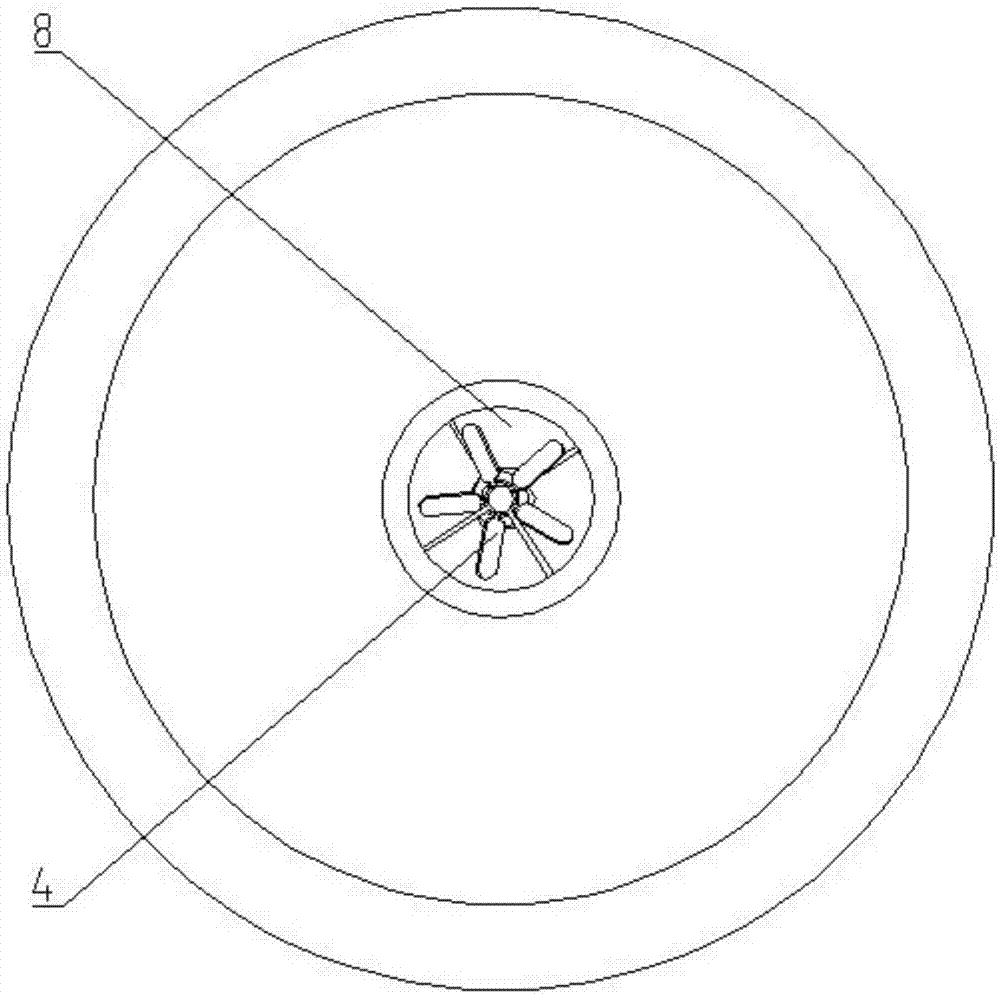

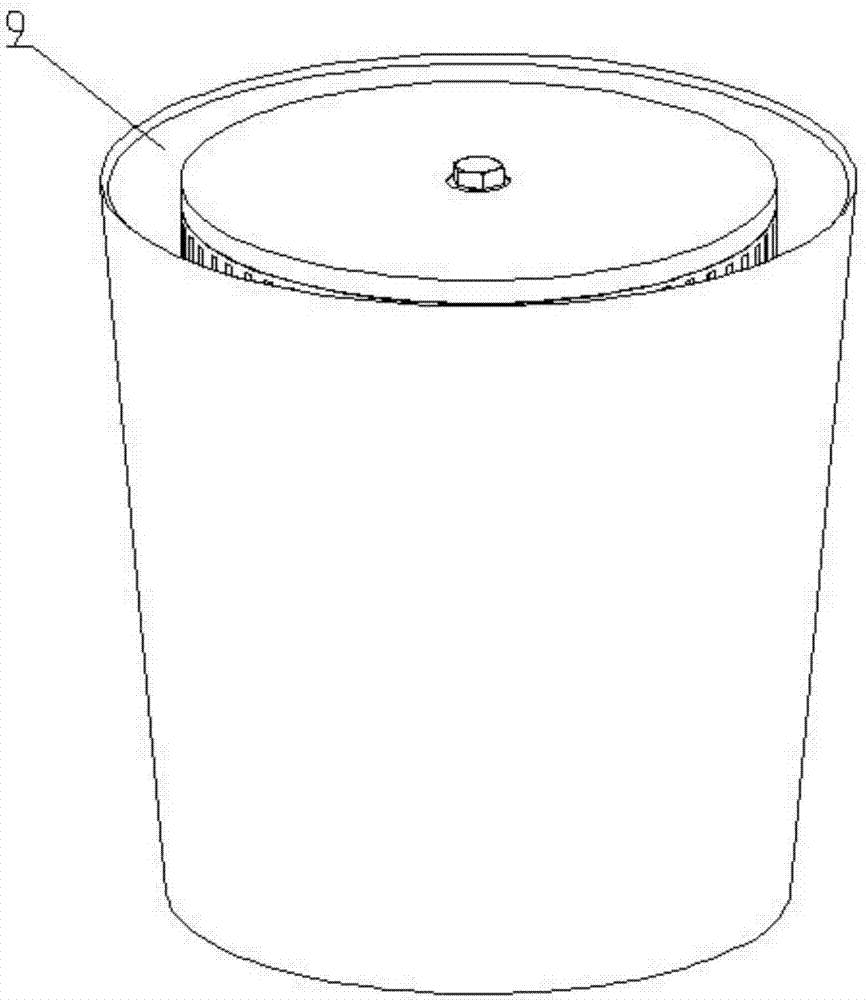

Electric vehicle annular forced air-cooled heat dissipation parallel battery module and application thereof

ActiveCN106876627AAvoid the problem of uneven heat dissipationGuaranteed uptimeSecondary cellsCell component detailsCooling effectEngineering

The invention relates to an electric vehicle annular forced air-cooled heat dissipation parallel battery module and application thereof. The electric vehicle annular forced air-cooled heat dissipation parallel battery module comprises a battery module box body, a battery module box cover and a battery module core; the battery module box body is internally provided with a first air duct wall and a second air duct wall; ventilation holes are formed in the first air duct wall and the second air duct wall respectively; the battery module core is arranged between the first air duct wall and the second air duct wall; a first air duct is arranged between the first air duct wall and the inner side wall of the battery module box body; the inner side wall of the second air duct wall is a second air duct; the top end of the second air duct is connected with the battery module box cover; the bottom end of the second air duct is provided with a heat dissipation fan; and a plurality of standard electrical cores are arranged on the battery module core. The electric vehicle annular forced air-cooled heat dissipation parallel battery module changes the traditional battery module layout mode, adopts a novel layout mode to carry out mounting, improves the forced air cooling effect and ensures each single standard electrical core to have the same heat dissipation effect, so that the purpose of effectively dissipating heat is reached, the problem of uneven heat dissipation of the battery module is also solved, and normal running of the battery module is effectively guaranteed.

Owner:SHANDONG UNIV OF SCI & TECH

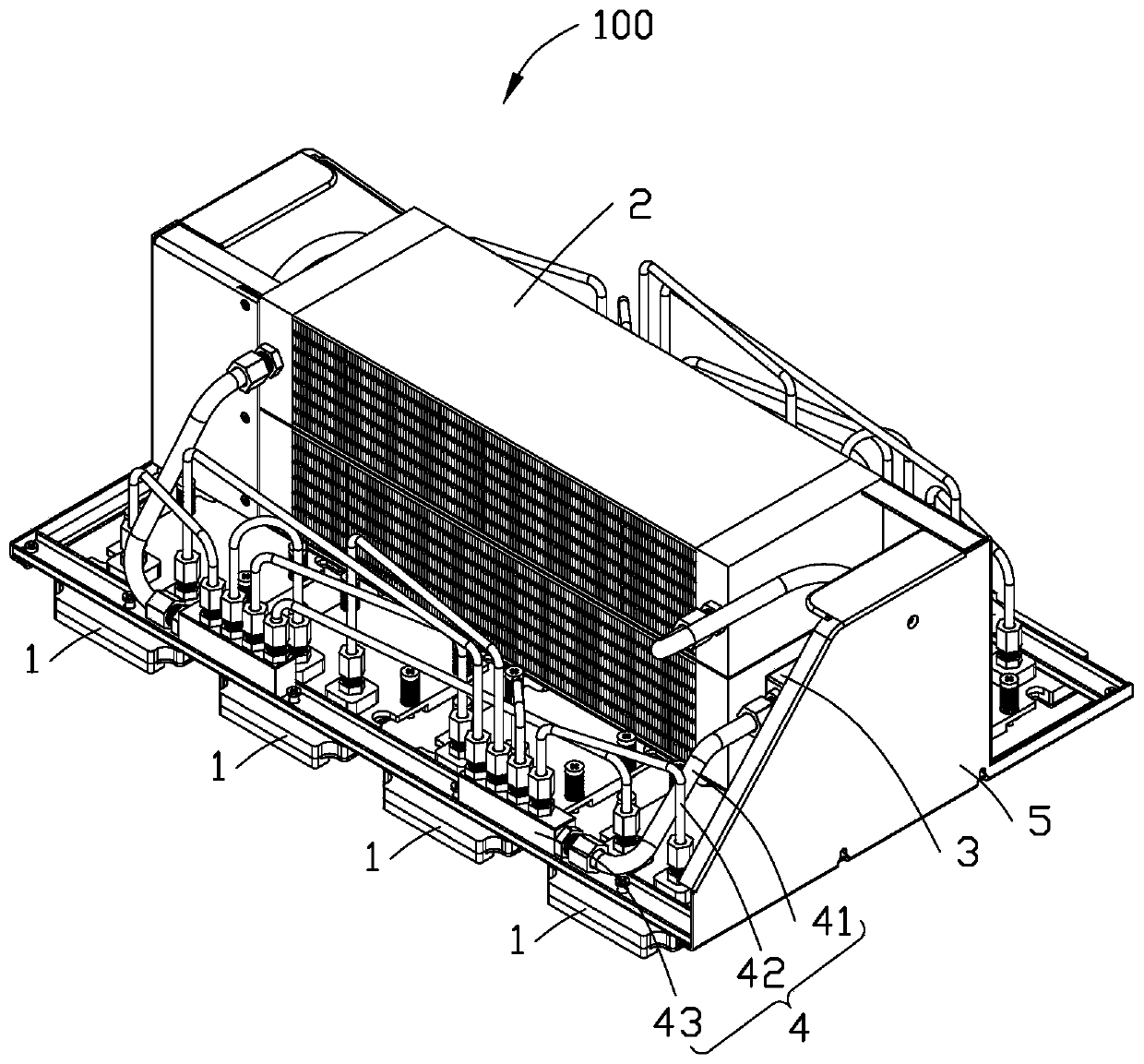

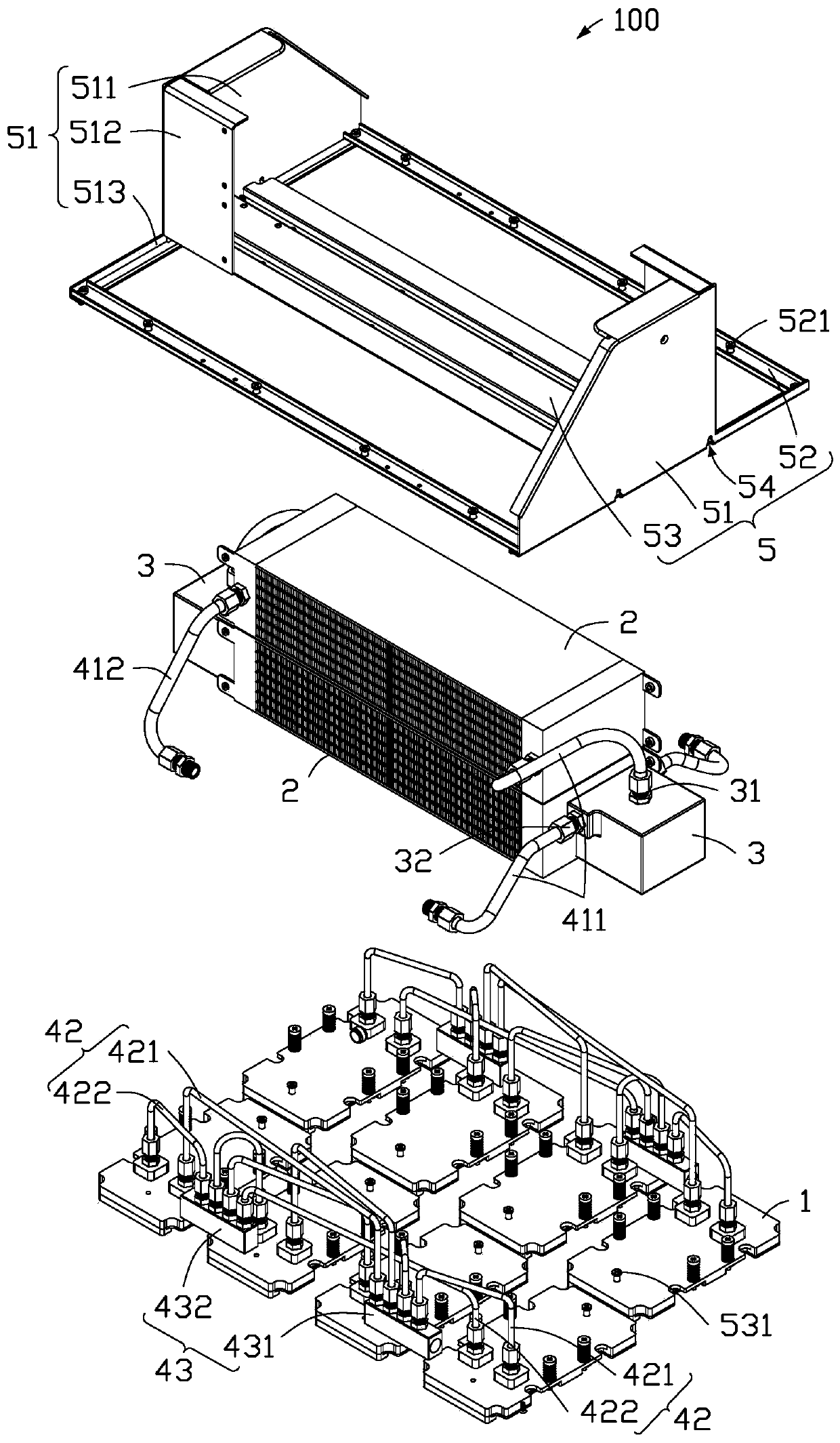

Liquid cooling radiators and server system

ActiveCN109743869AImprove performanceSame cooling effectDigital data processing detailsStationary conduit assembliesServer systemWater cool

The invention discloses liquid cooling radiators. A liquid cooling radiator comprises a plurality of water cooling plates, condensers, drivers, cooling liquid pipeline assemblies and a mounting bracket. The plurality of water cooling plates and the condensers are fixedly set on the mounting bracket. The cooling liquid pipeline assemblies comprise main pipelines, shunt blocks and branch pipelines.The shunt blocks are also fixedly set on the mounting bracket. The plurality of water cooling plates are connected with the shunt blocks in parallel through utilization of the branch pipelines. The condensers, the drivers and the shunt blocks are connected through utilization of the main pipelines. The drivers are used for providing working power. Through utilization of the shunt blocks and the branch pipelines, cooling liquid in the condensers is shunted to the plurality of water cooling plates, then the cooling liquid flows back to the condensers for cooling through utilization of the branchpipelines, the shunt blocks and the main pipelines, and the condensers send the cooled cooling liquid to the drivers through utilization of the main pipelines, thereby forming a loop system.

Owner:CHAMP TECH OPTICAL FOSHAN

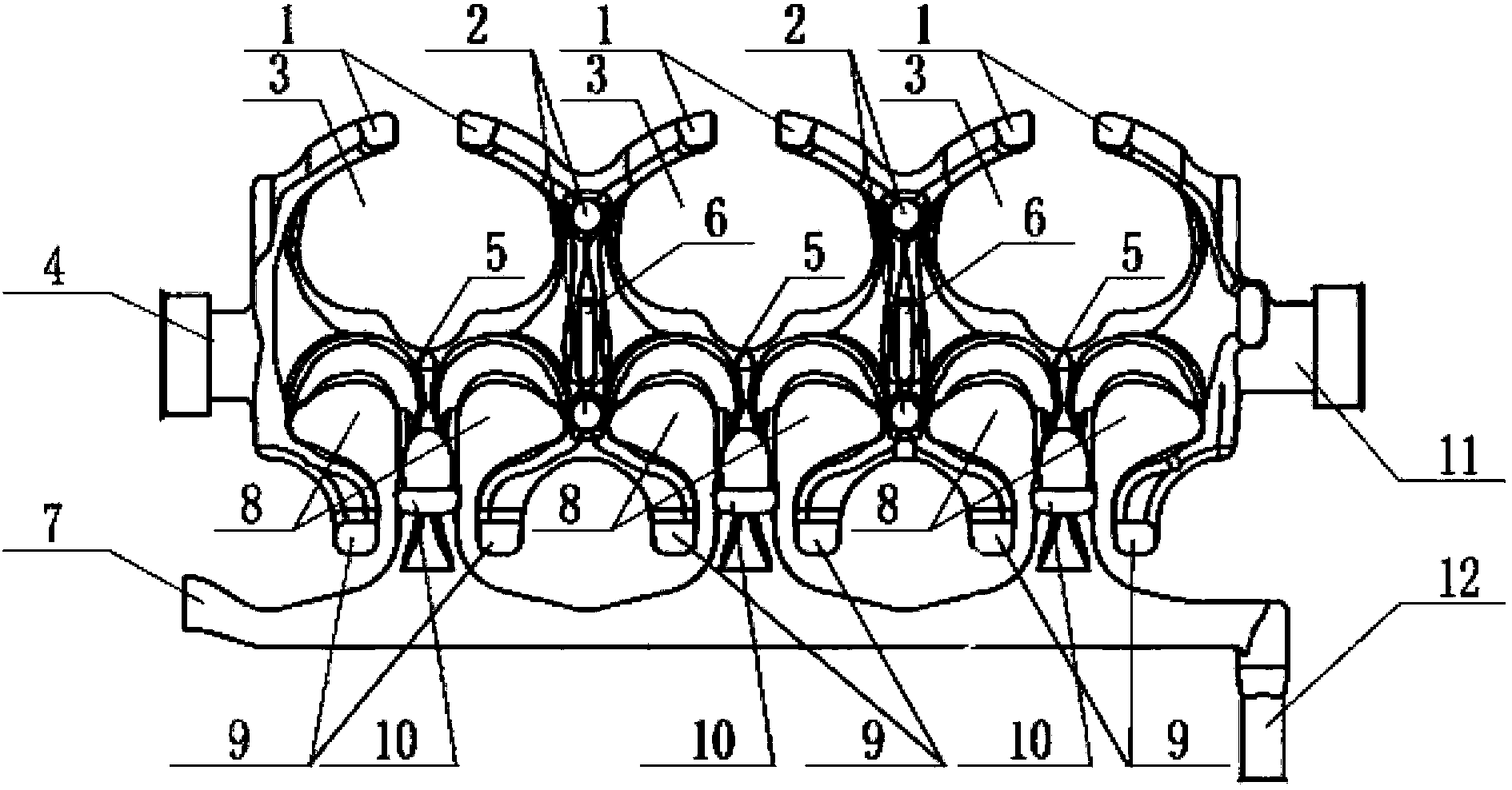

an engine cooling system

ActiveCN101644201BSame cooling effectImprove cooling effectLiquid coolingCoolant flow controlWater velocityCylinder head

The invention discloses an engine cooling system, which is characterized in that: a cooling water distribution pipe is installed on the engine block, and the distribution pipe has a plurality of passages, and one passage corresponds to one cylinder. The cooling water enters the engine block through each channel to cool the engine, and then the coolant enters the cylinder head through the cylinder block to cool the engine cylinder head, and then the coolant returns to the water collector through the cylinder head, and then returns to the thermostat. Eventually back to the water pump. The present invention installs a water distribution pipe under the ordinary engine cylinder, so that each cylinder corresponds to each channel of a water distribution pipe, so that the water intake of each cylinder is the same, and the water intake pressure and water intake speed are the same. In this way, the cooling effect of all the cylinders is guaranteed to be the same, which improves the cooling effect of the engine, and the uniformity of the coolant distribution in the engine block is also improved. The fuel economy of the engine has been improved, and the emission of the engine has been optimized.

Owner:CHERY AUTOMOBILE CO LTD

Cooling device and construction machine or working machine equipped with the same

ActiveUS9228318B2Increase airflowImprove cooling effectPump componentsSemiconductor/solid-state device detailsAerospace engineeringEngineering

Owner:KOMATSU LTD

Furnace slow-cooling area structure capable of shrinking cross-sectional temperature difference

ActiveCN102374788BReduce cross-section temperature differenceSame cooling effectFurnace coolingTubular elementsCooling effectEngineering

The invention discloses a furnace slow-cooling area structure capable of shrinking cross-sectional temperature differences, which comprises a slow-cooling chamber, a plurality of conveying rollers, a large amount of heat-exchanging pipes and an exhausting mechanism, wherein the exhausting mechanism is communicated with the heat-exchanging pipes, the conveying rollers are sequentially arranged along the length direction of the slow-cooling chamber and are placed at the middle part of the slow-cooling chamber, the heat-exchanging pipes are arranged along the longitudinal direction of the slow-cooling chamber, each heat-exchanging pipe is a U-shaped steel pipe with two open ends, one end of each heat-exchanging pipe is communicated with a workshop, and the other end of each heat-exchanging pipe is communicated with the exhausting mechanism. The furnace slow-cooling area structure has the beneficial effects that the basic sameness of the temperatures of all points on the same cross section is realized; because a wind inlet and a wind outlet are positioned at different positions on the same section, the cooling effects can tend towards consistency under the conditions that the diameters of branched pipes are the same and the flow speeds of hot wind are the same, the cross-sectional temperature difference of a furnace-cooling passage is shrunk, the sameness of the cooling speeds of a product at the slow-cooling stage can be ensured, and the defects of the product caused by cooling temperature differences are avoided.

Owner:MODENA TECH LTD

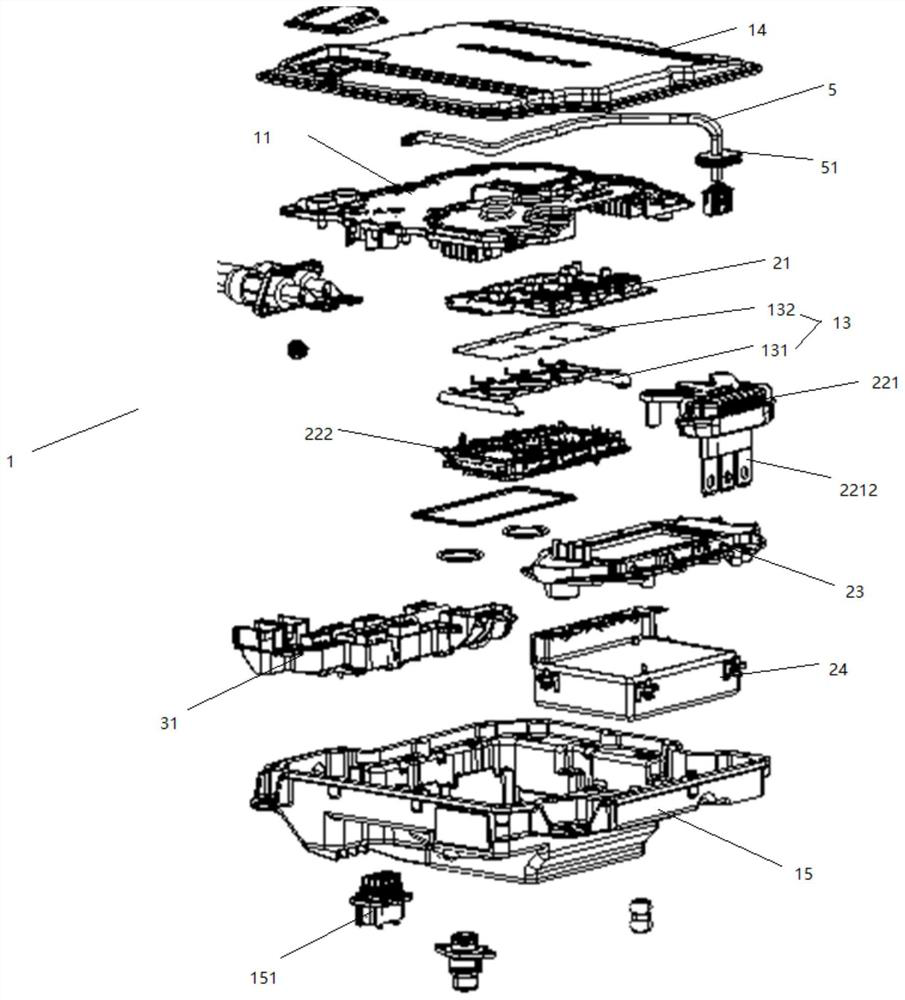

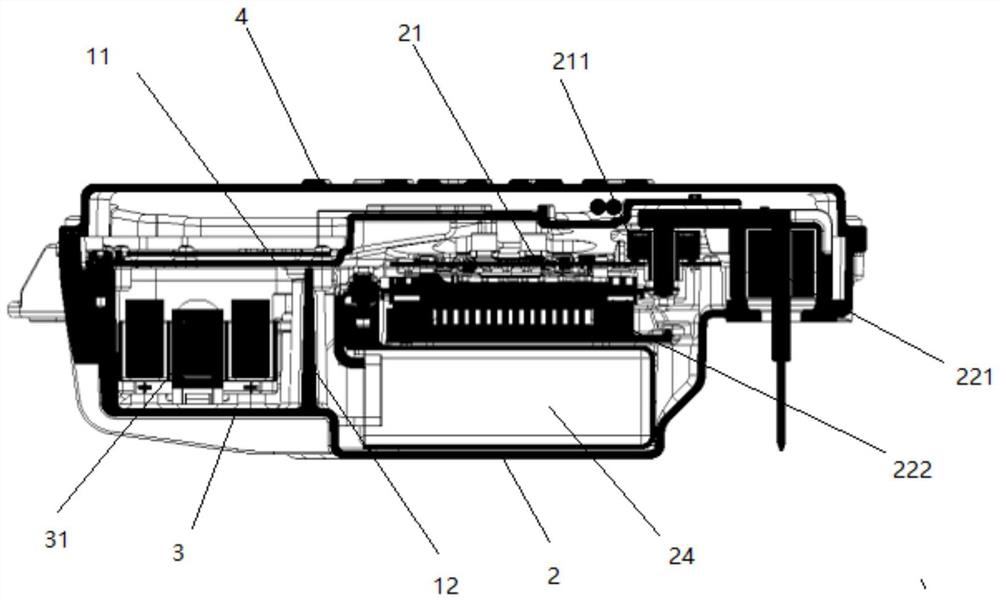

Motor controller shell, motor controller and vehicle

PendingCN114126336ASame cooling effectGuaranteed cooling effectMagnetic/electric field screeningCasings/cabinets/drawers detailsElectric machineryCooling effect

The embodiment of the invention provides a motor controller shell, a motor controller and a vehicle, and belongs to the technical field of controllers. Comprising a plurality of device placing grooves which are at least used for placing a first device and a second device; wherein a cooling part is arranged between the first device and the second device; when cooling liquid circulates in the cooling part, the cooling part is used for cooling the first device and the second device at the same time. By using the motor controller shell, the motor controller and the vehicle provided by the invention, the cooling effect of the cooling component on the second device can be improved.

Owner:HYCET TRANSMISSION SYST (JIANGSU) CO LTD BAODING RES & DEV BRANCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com