Furnace slow-cooling area structure capable of shrinking cross-sectional temperature difference

A technology of slow cooling zone and cross-section, applied in the direction of furnace cooling, furnace, furnace components, etc., can solve problems such as temperature difference, cold cracking, and insufficient flexural strength of the kiln cross-section, and achieve the goal of reducing the temperature difference of the cross-section and avoiding defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

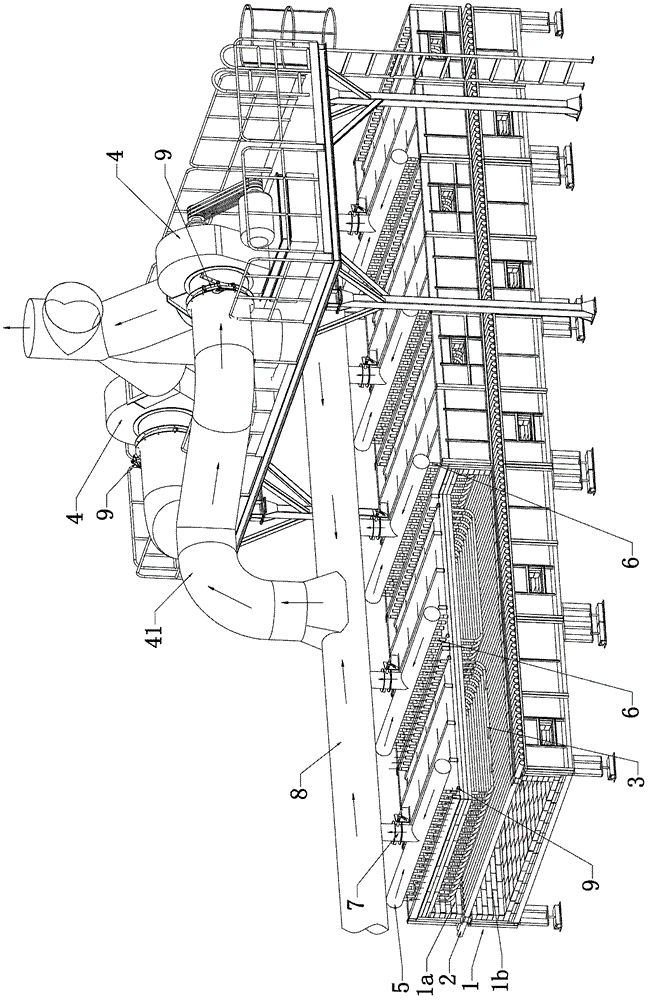

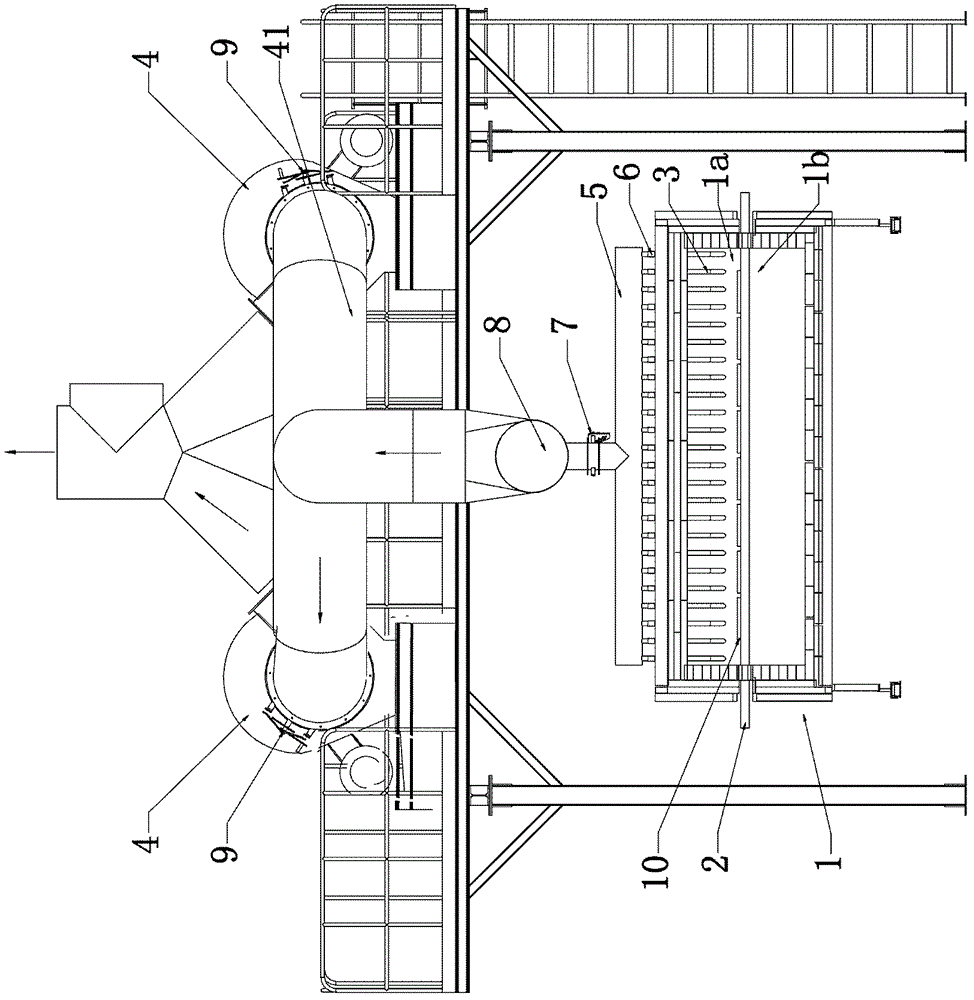

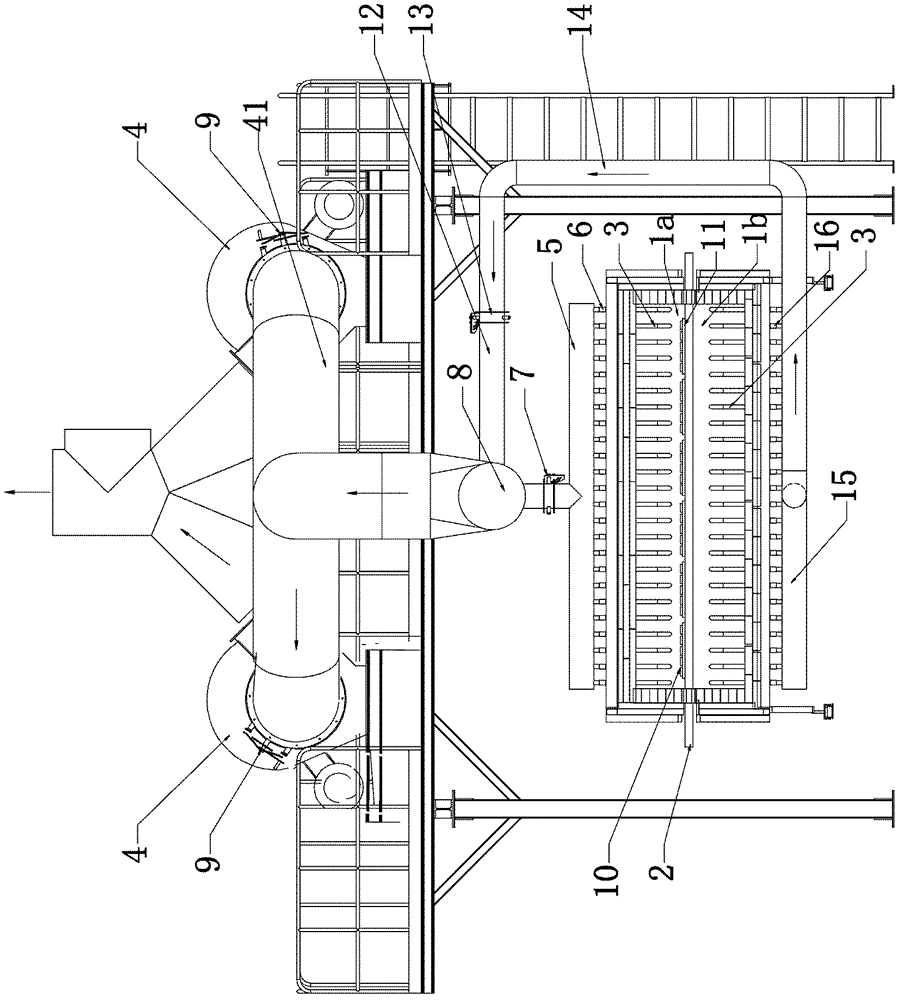

[0013] Now set forth the present invention in detail in conjunction with accompanying drawing:

[0014] See attached figure 1 And attached figure 2 As shown, it is the first embodiment of the present invention, including a slow cooling chamber 1, a plurality of conveying rollers 2, a "U"-shaped longitudinal heat exchange tube 3, an exhaust fan 4 and an exhaust branch pipe group 5, and the conveying rollers 2 move along the slow cooling chamber. 1 are arranged in sequence along the length direction, the slow cooling chamber 1 is divided into an upper passage 1a and a lower passage 1b by the conveying roller 2, and the "U"-shaped longitudinal heat exchange tube 3 is in the upper passage 1a in the length direction of the slow cooling chamber 1, and passes from the slow cooling chamber 1 The top of the cold room 1 protrudes, and one end of the "U"-shaped longitudinal heat exchange pipe 3 communicates with the workshop, and the other end is connected with the pipe joint of the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com