Cooling system and cooling method for I-shaped steel

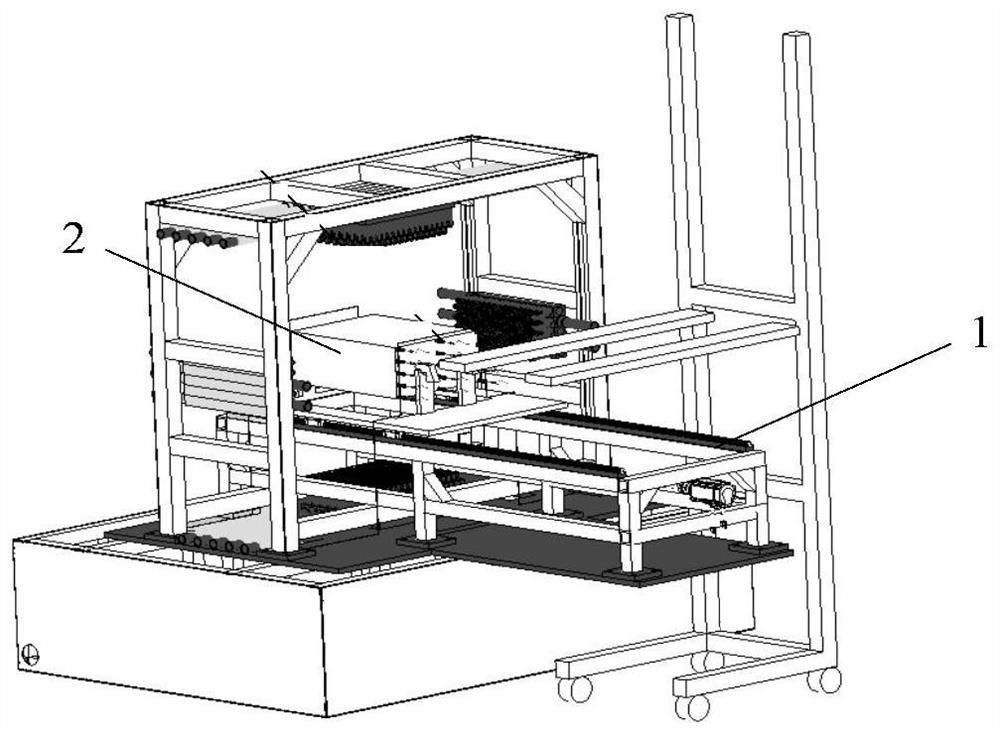

A technology of I-shaped steel and cooling system, applied in the direction of furnace types, manufacturing tools, furnaces, etc., can solve the problems of poor cross-section temperature uniformity affecting the stability of finished products, etc., to reduce temperature, improve lamellar spacing and shape, and accelerate cooling speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

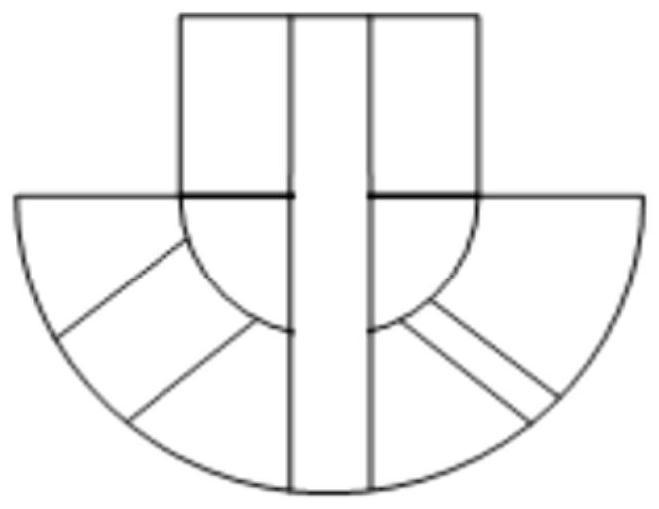

Method used

Image

Examples

Embodiment 1

[0075] The size of the I-shaped steel of the present embodiment is 165mm * 165mm * 10000mm, and its composition by weight percentage (wt%), comprises: C 0.15, Si 0.30, Mn 1.50, Nb 0.012, P≤0.015% and S≤0.015%, The rest is Fe, wherein the carbon equivalent CEV≤0.4%.

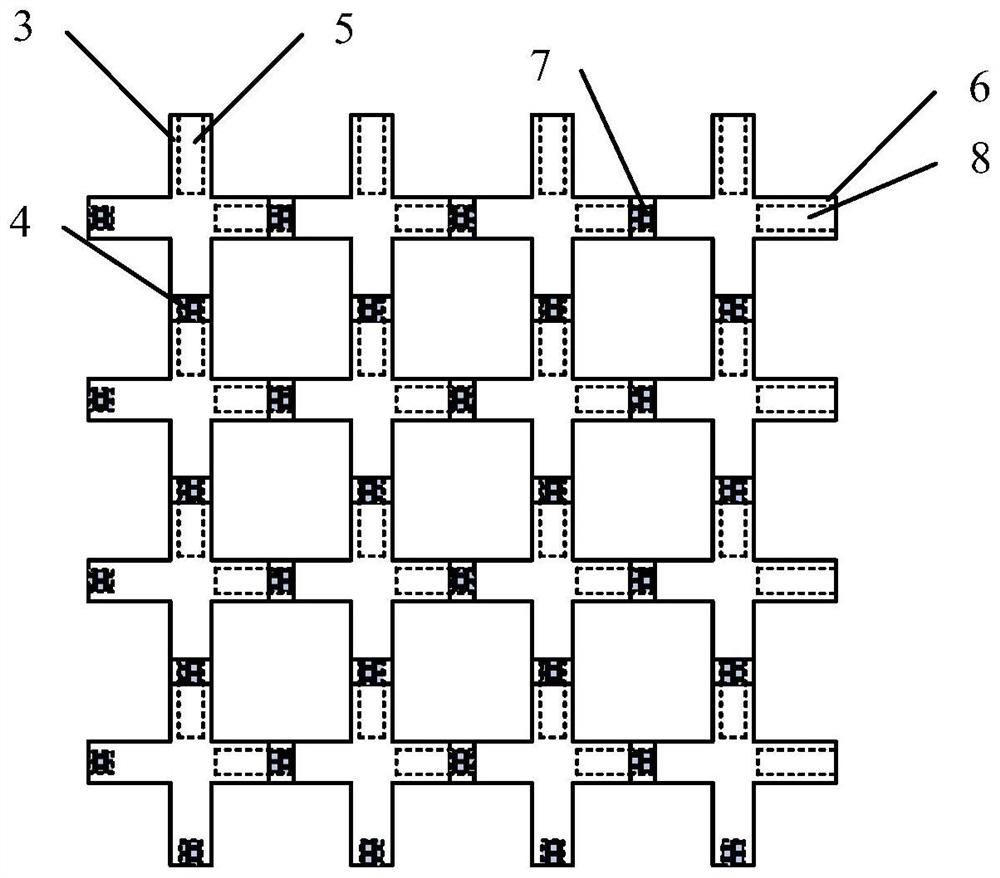

[0076] In each cycle, the length of a single nozzle group in the air mist mode (that is, the cooling path length of the air mist cooling) is 7m, the number of nozzles in the nozzle group in the air mist mode is 210, and the single nozzle in the air cooling mode The length of the group (that is, the length of the air-cooled cooling path) is 3m, and the number of nozzles in the nozzle group in the air-cooled mode is 90; a total of 8 groups are arranged, wherein, the first nozzle group is an air mist cooling nozzle group, and the second The nozzle group is an air-cooled nozzle group, the third nozzle group is an air-cooled nozzle group, the fourth nozzle group is an air-cooled nozzle group, the fifth nozzle group is ...

Embodiment 2

[0080] The size of the I-shaped steel in this embodiment is 150mm×150mm×9000mm, and its composition is by weight percentage (wt%), including: C 0.18, Si 0.40, Mn 1.35, Nb 0.045, P≤0.015% and S≤0.015% , and the rest is Fe, wherein the carbon equivalent CEV≤0.4%.

[0081] In each cycle, the length of a single nozzle group in the aerosol mode (that is, the cooling path length of the aerosol cooling) is 5.5m, the number of nozzles in the nozzle group in the aerosol mode is 165, and the single nozzle group in the air-cooling mode The length of the nozzle group (i.e. the length of the air-cooled cooling path) is 2.5m, and the number of nozzles in the nozzle group in the air-cooled mode is 75; a total of 10 groups are arranged, wherein the first nozzle group is an air mist cooling nozzle group, The second nozzle group is air-cooled nozzle group, the third nozzle group is air-cooled nozzle group, the fourth nozzle group is air-cooled nozzle group, the fifth nozzle group is air-cooled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com