Electric vehicle annular forced air-cooled heat dissipation parallel battery module and application thereof

A battery module and forced air cooling technology, which is applied to electric vehicles, battery pack components, batteries, etc., can solve the problems of low edge temperature and high temperature of battery modules, achieve effective heat dissipation, ensure normal operation, and avoid heat dissipation. balanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

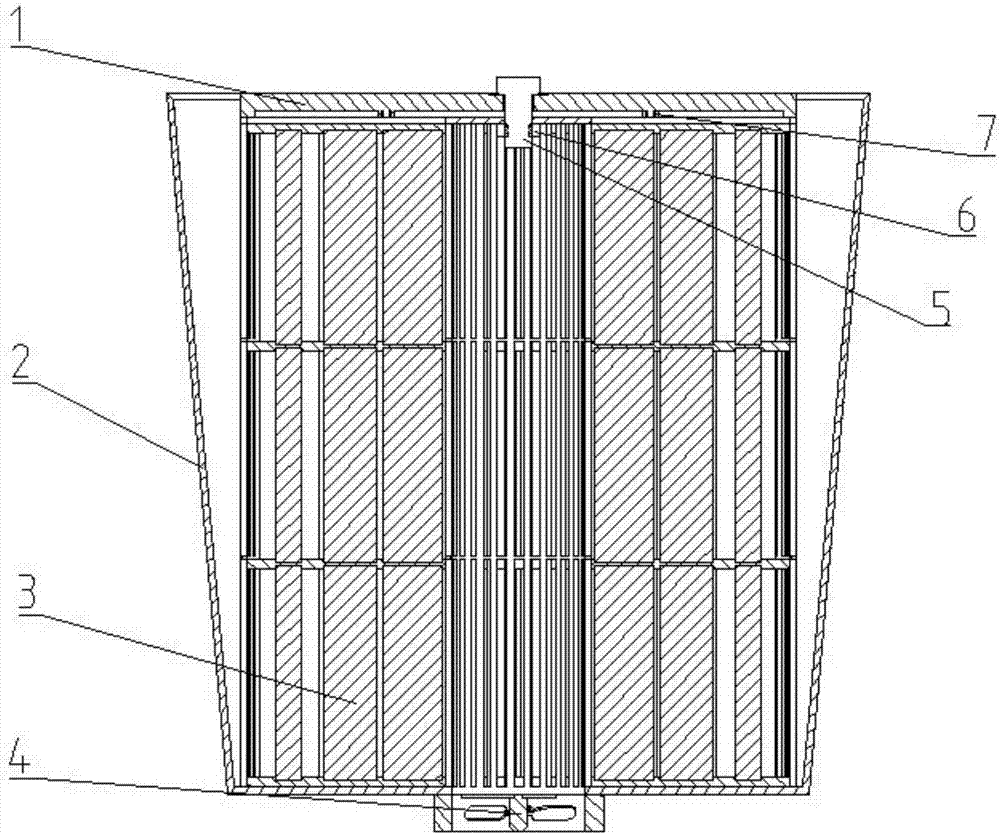

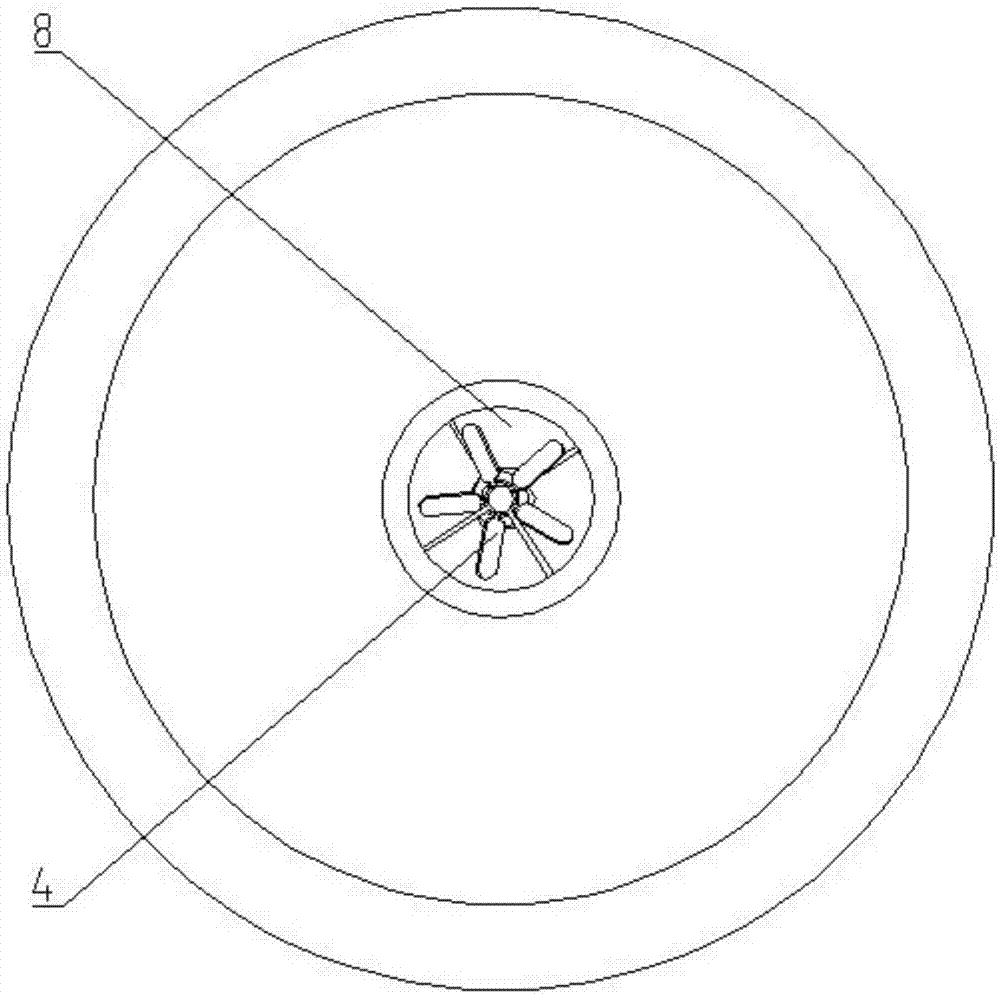

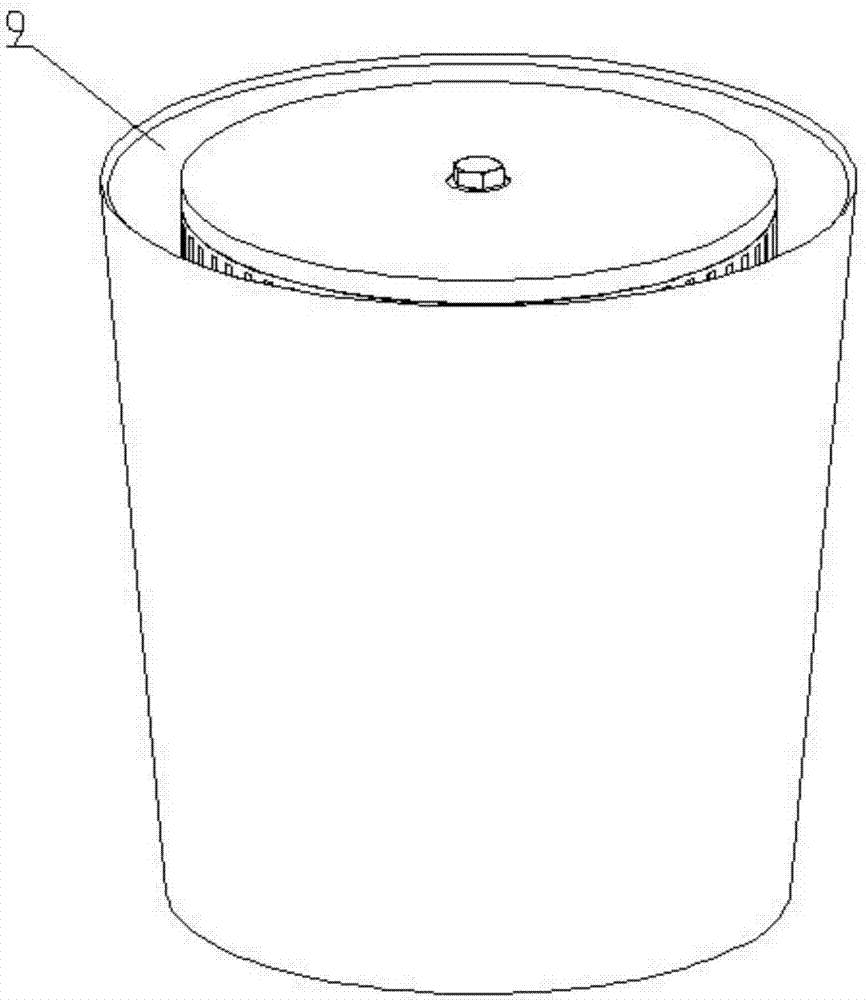

[0037] Such as Figure 1 to Figure 9 As shown, this embodiment provides an electric vehicle circular forced air-cooled heat dissipation parallel battery module, the battery module includes a battery module box 2, a battery module box cover 1 and a battery module core 3, the battery module box The body 2 is provided with a No. 1 air duct wall 202 and a No. 2 air duct wall 203. A number of ventilation holes are provided on the No. 1 air duct wall 202 and No. 2 air duct wall 203. The battery module core 3 is placed on the No. 1 air duct wall. Between the channel wall 202 and the No. 2 air channel wall 203, the space between the No. 1 air channel wall 202 and the inner wall of the battery module box casing 201 is the No. 1 air channel, and the space inside the No. 2 air channel wall 203 is two. No. 1 air duct, the top of No. 2 air duct is connected to the battery module box cover 1, and the bottom end is provided with a cooling fan 4. The battery module box cover 1 is used to fix ...

Embodiment 2

[0042] An electric vehicle annular forced air-cooled heat dissipation parallel battery module, the structure is as described in Example 1, the difference is that: the angle between the rounded frustum-shaped bus bar and the vertical direction is 3°, that is, the battery module box The inner wall of 2 is an inclined surface, which has an inclined angle of 3° with the No. 1 air duct wall.

Embodiment 3

[0044]An electric vehicle annular forced air-cooled heat dissipation parallel battery module, the structure is as described in Example 1, the difference is that the angle between the rounded frustum-shaped bus bar and the vertical direction is 8°, that is, the battery module box The inner wall of 2 is an inclined surface, which has an angle of inclination of 8° with the No. 1 air duct wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com