Heat dissipation power device for power engineering

A technology of power engineering and power devices, applied in the field of electric power, can solve problems such as inability to dissipate heat, and achieve the effects of avoiding uneven heat dissipation, multiple heat dissipation spaces and heat dissipation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

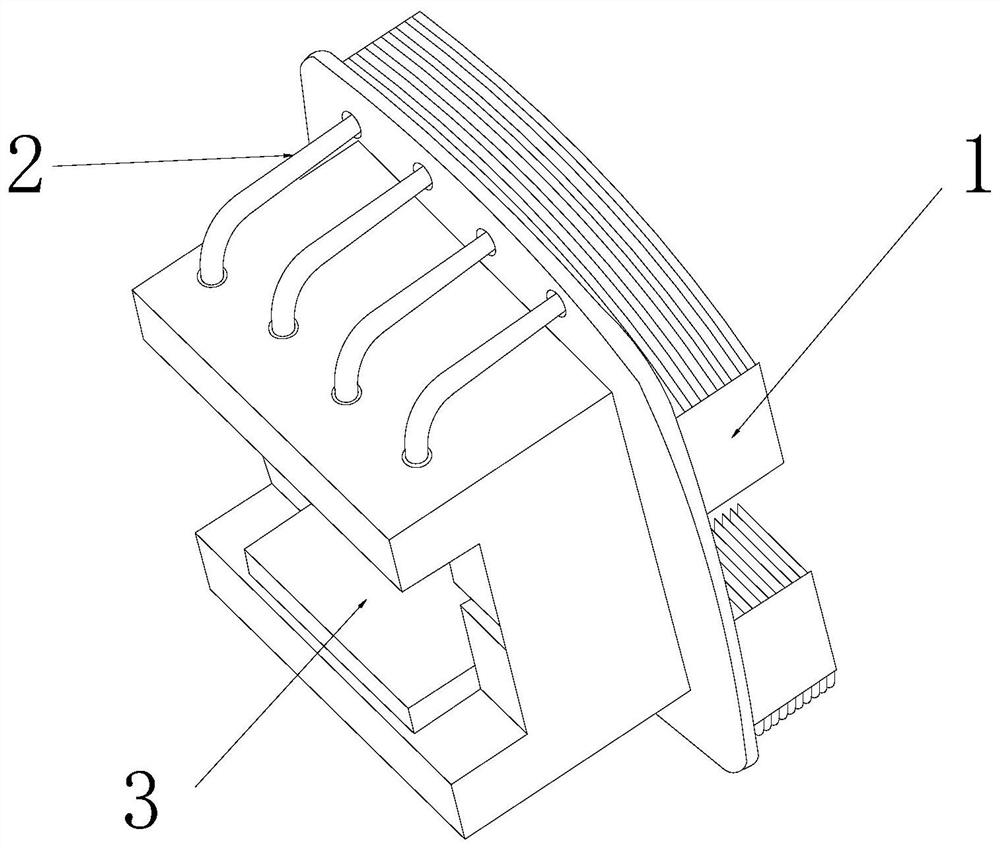

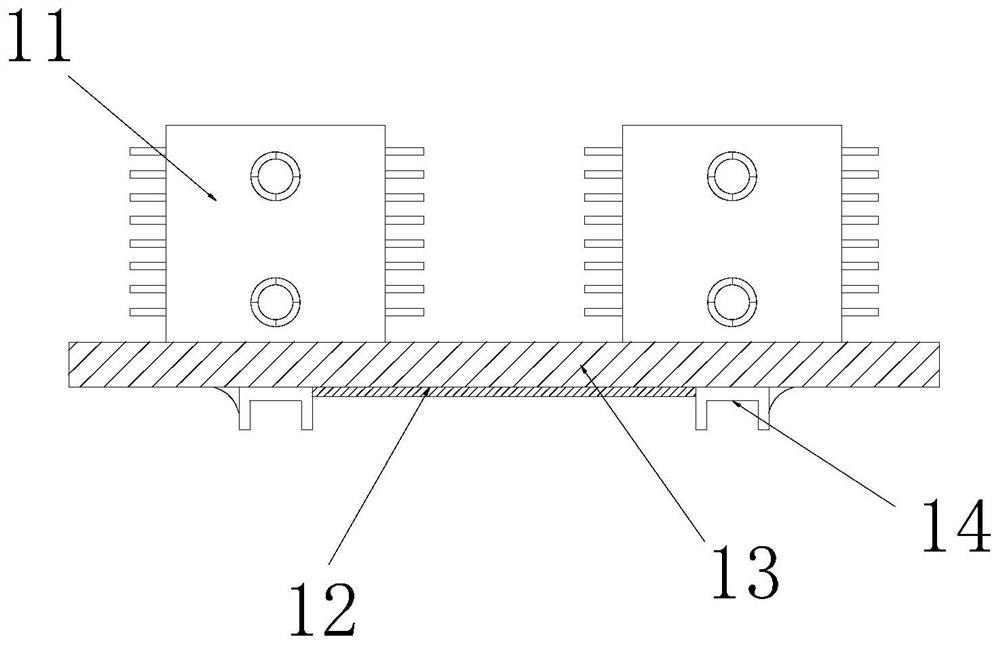

[0026] as attached figure 1 To attach Figure 5 Shown:

[0027] The invention provides a heat dissipation power device for electric power engineering, the structure of which includes a heat dissipation seat 1, a water guide pipe 2, and an embedded copper block 3. The water guide pipes 2 are evenly distributed on the left and right ends of the embedded copper block 3; the heat sink 1 includes a heat dissipation mechanism 11, a thermally conductive coating 12, an embedded solid block 13, and an inlay groove 14, and the heat dissipation mechanism 11 is symmetrically installed on the inlay On the left and right sides of the upper end of the groove 14, the thermally conductive coating 12 is evenly applied on the lower end surface of the embedding block 13 and fitted with the embedding groove 14, and the lower end surface of the embedding block 13 is embedded with the embedding groove 14, The inlay groove 14 is located right below the heat dissipation mechanism 11 .

[0028] Wher...

Embodiment 2

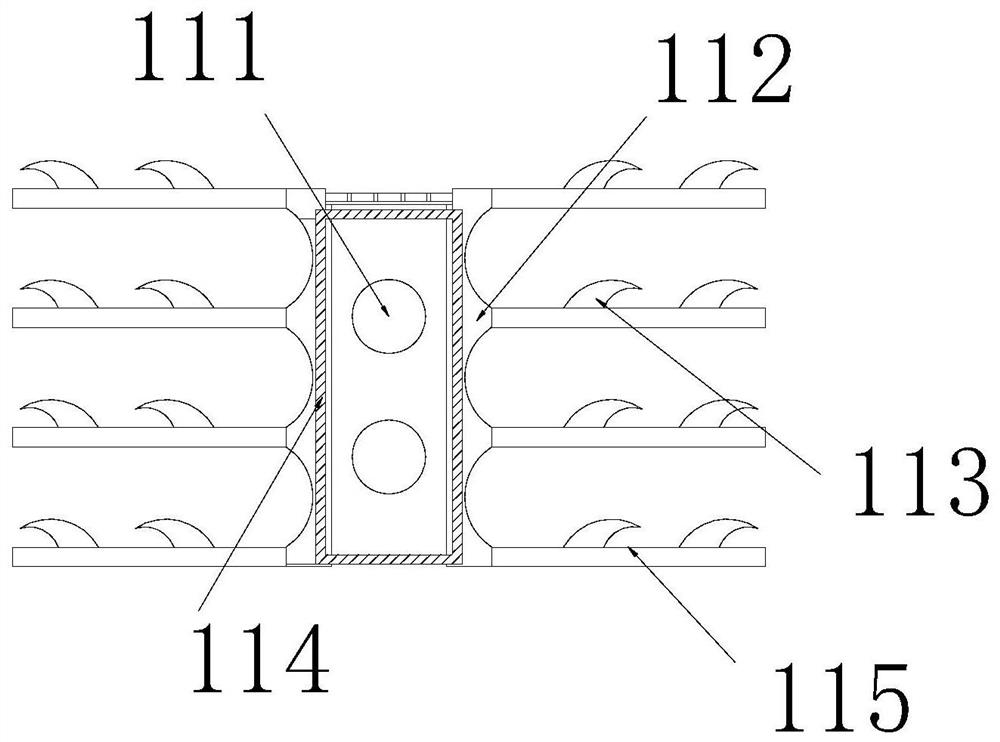

[0034] as attached Figure 6 To attach Figure 8 As shown: the heat dissipation pipe 111 includes a dispersion block 11a, a fitting groove 11b, a second heat dissipation port 11c, a connecting rod 11d, and a blocking block 11e, and the dispersion block 11a is symmetrically installed on the left and right sides of the heat dissipation pipe 111. The fitting groove 11b is inlaid and installed on the outer end surface of the heat dissipation pipe 111, the second cooling openings 11c are evenly distributed on the laterally outer end surface of the dispersing block 11a, and the connecting rod 11d is evenly inlaid and installed on the laterally outer end surface of the blocking block 11e and connected with The dispersing block 11a fits together, the barrier block 11e is located at the center of the dispersing block 11a, and the number of the second cooling openings 11c just matches the number of connecting plates 115, which can evenly conduct heat to the connecting plate 115 in vivo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com