Uniform heat radiation structure

A technology of uniform heat dissipation and heat dissipation fins, applied in heat exchange equipment, lighting and heating equipment, etc., can solve the problems of low heat dissipation efficiency, no space utilization, and reduced efficiency, and achieve uniform heat dissipation, improved heat dissipation efficiency, and multiple heat dissipation spaces Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

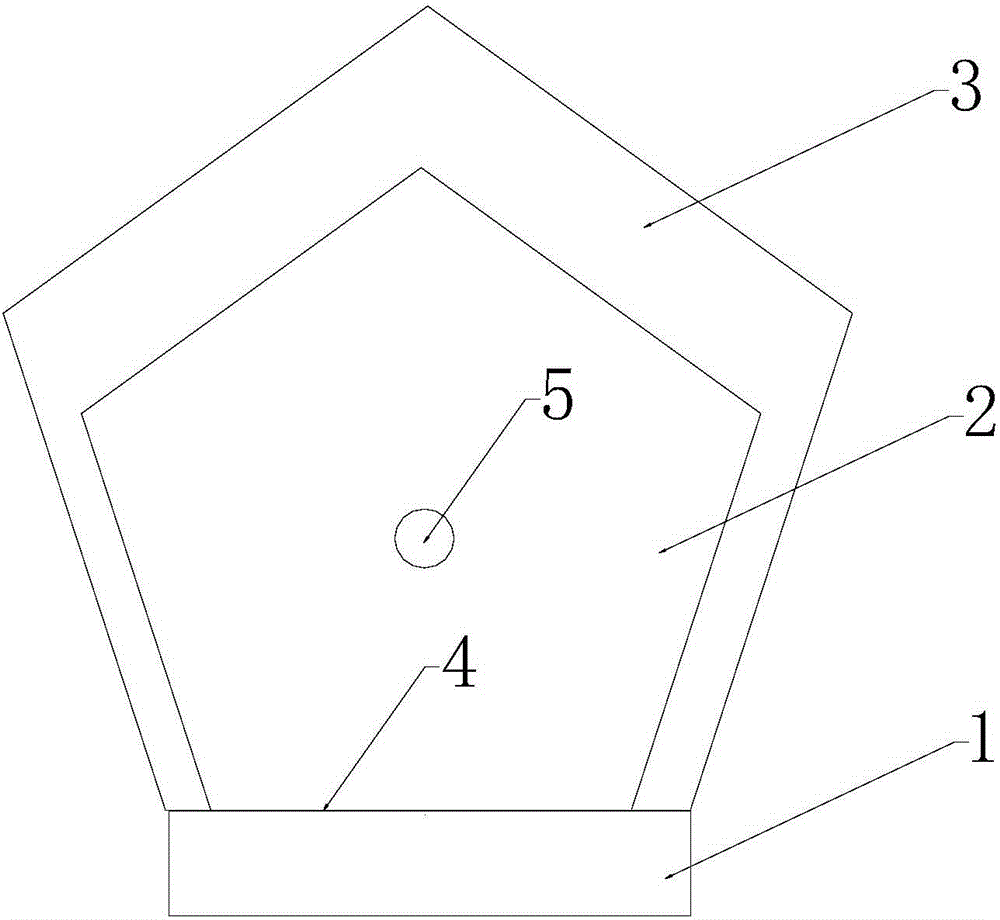

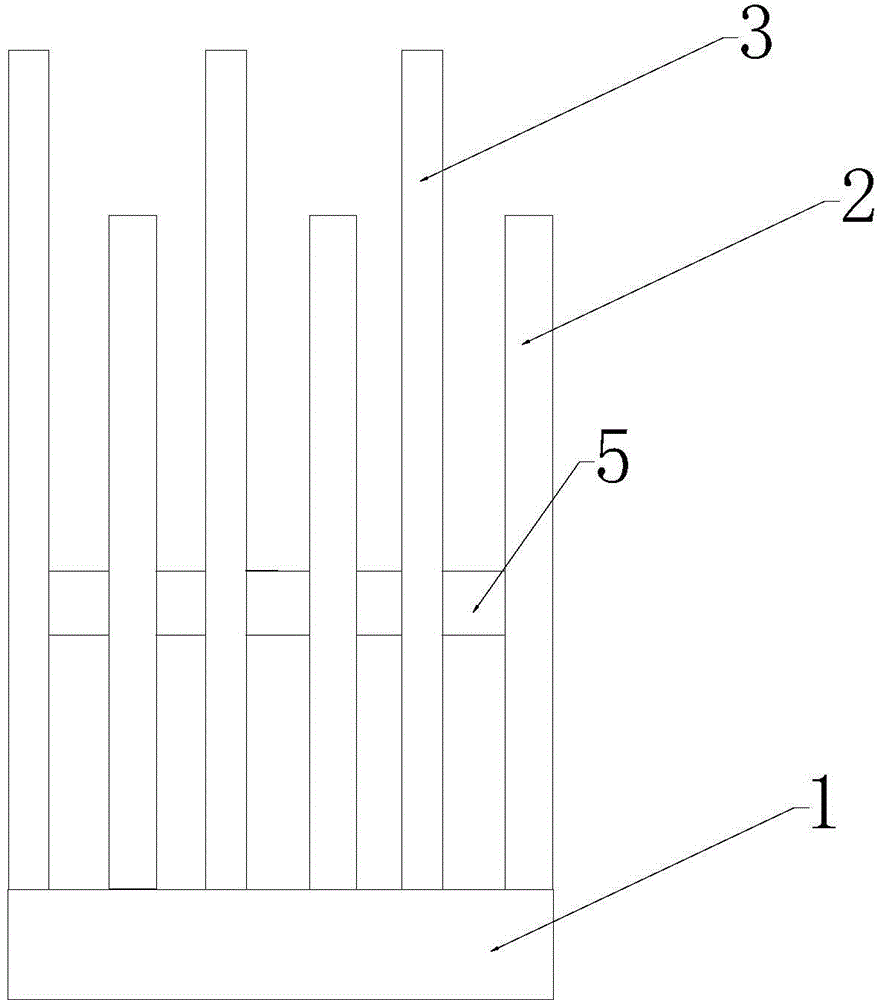

[0026] Such as Figure 1-Figure 3 As shown, it is a front view, a left view and a top view of the heat dissipation structure provided by Embodiment 1 of the present invention.

[0027] A uniform heat dissipation structure, including a heat sink 1 and a heat sink, the heat sink is vertically connected to the heat sink 1, and the heat sinks are distributed in parallel and kept at a certain distance, and the heat sink is divided into a first heat sink 2 and a second heat sink Two cooling fins 3, the shape of the first cooling fin 2 and the second cooling fin 3 is a regular pentagon, the side lengths of the first cooling fin 2 and the second cooling fin 3 are different, and the first cooling fin 2 and the second cooling fin 3 have different side lengths. The fins 2 and the second fins 3 are arranged at intervals on the heat sink 1, the fins are provided with through holes, the through holes on the first fin 2 and the through holes on the second fin 3 are located On the same axis,...

Embodiment 2

[0038] Such as Figure 4 As shown, in this embodiment, more than two first heat sinks 2 are arranged between two adjacent second heat sinks 3 , which provides more heat dissipation space for the second heat sink 3 .

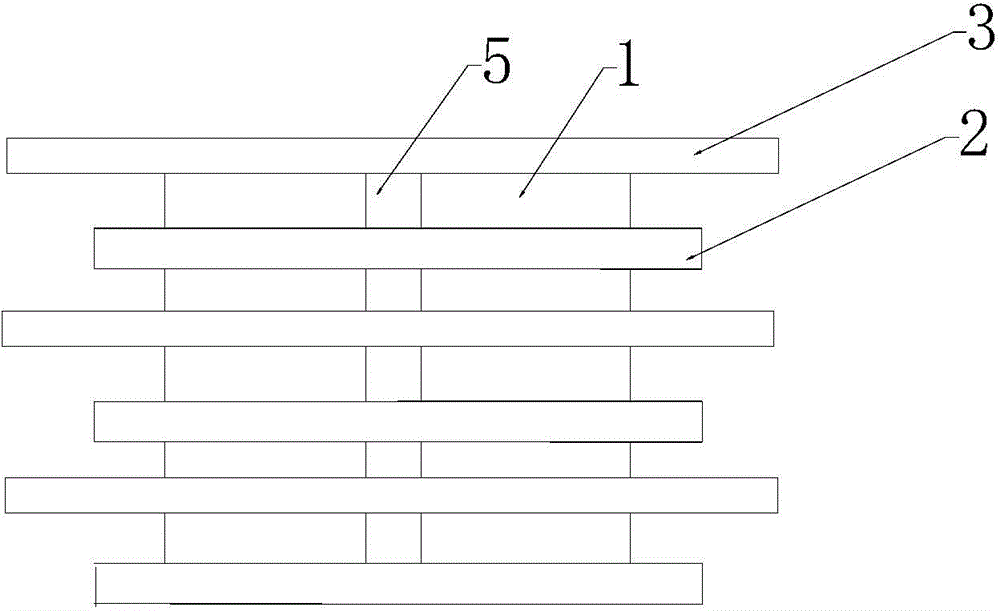

Embodiment 3

[0040] Such as Figure 5 As shown, in this embodiment, more than two second heat sinks 3 are arranged between two adjacent first heat sinks 2. Generally speaking, the number of second heat sinks 3 is relatively large. The heat dissipation area of the heat dissipation structure itself is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com