Mutual inductor device for breaker

A technology of transformers and circuit breakers, which is applied in the field of electronic molded case circuit breakers, can solve the problems of inconvenient heat dissipation of transformers, cumbersome installation process, inconvenient installation, etc., and achieve labor cost saving, fast and convenient installation, and quick replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

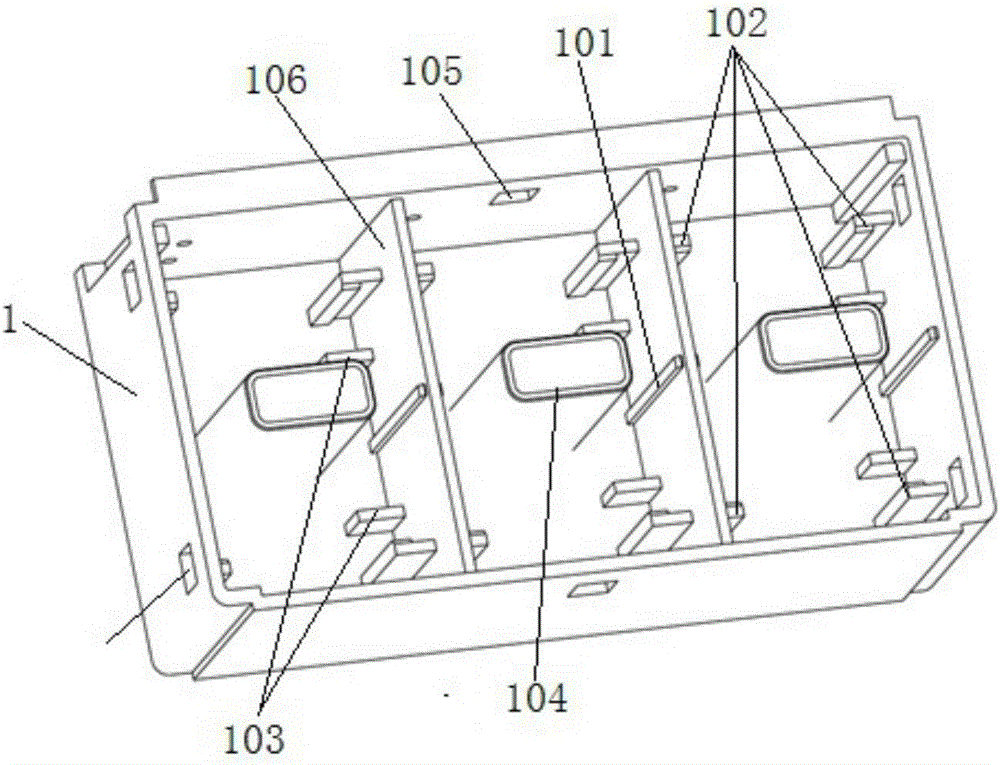

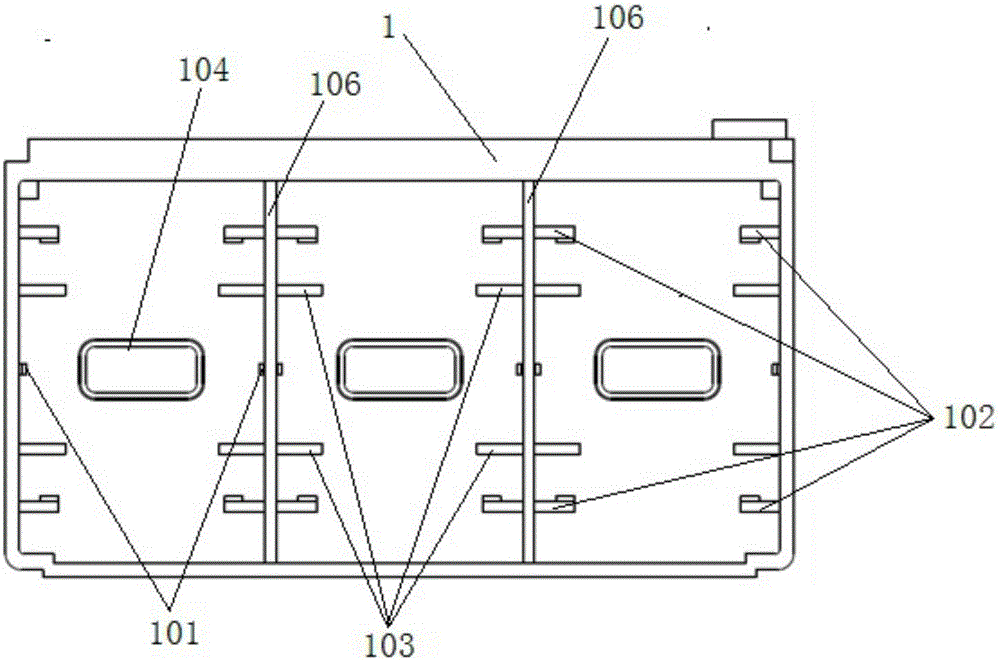

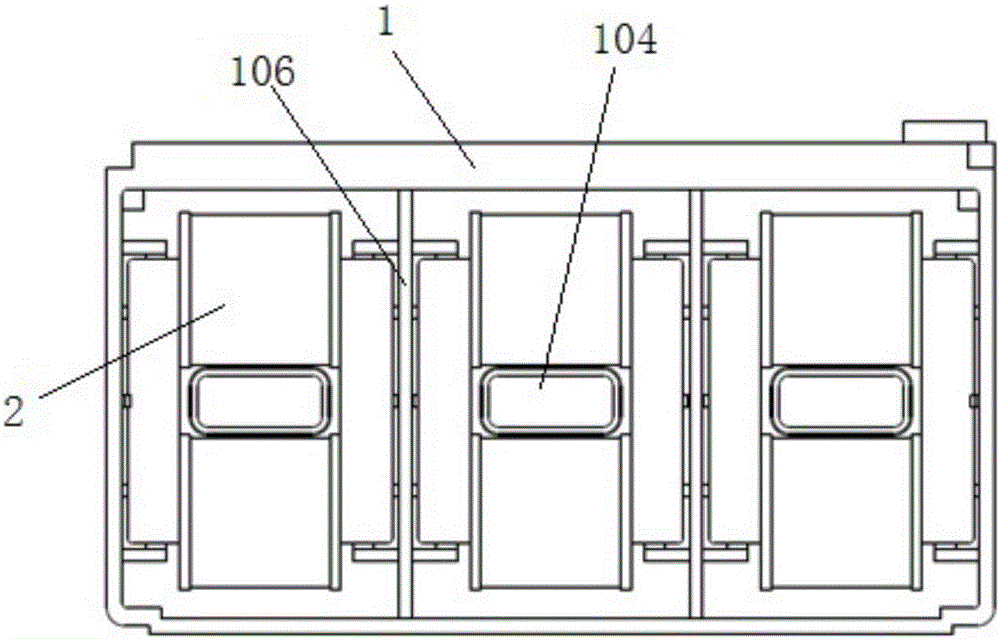

[0042] A transformer device for a circuit breaker, such as Figure 1-9 As shown, it includes a base 1 and a cover plate 3 that match each other. The top of the base 1 is open, and at least one chamber is provided in the base 1. In this embodiment, the base 1 is preferably divided into three chambers by two partitions 106. Each chamber is provided with a transformer 2, the transformer 2 has a mounting surface, and the inside of each chamber and the bottom of the cover plate 3 opposite to the chamber has a limit rib that cooperates with the mounting surface, and the limit rib and the mounting surface Cooperate to fix the transformer 2 in the base 1.

[0043] Such as Figure 5-6 As shown, the preferred transformer in this embodiment is composed of a coil 23 and an iron core, the iron core is a rectangular iron core, and the iron core part exposed outside the coil 23 is a first iron core subsection 21 and a second iron core subsection 22, Located on both sides of the coil 23 res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com