New parallel winding motor

A winding motor, a new type of technology, applied in the field of motors, can solve the problems of low utilization of winding space, complicated and complicated motor production process, etc., achieve high utilization of winding space, improve production and installation accuracy, and reduce noise and vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

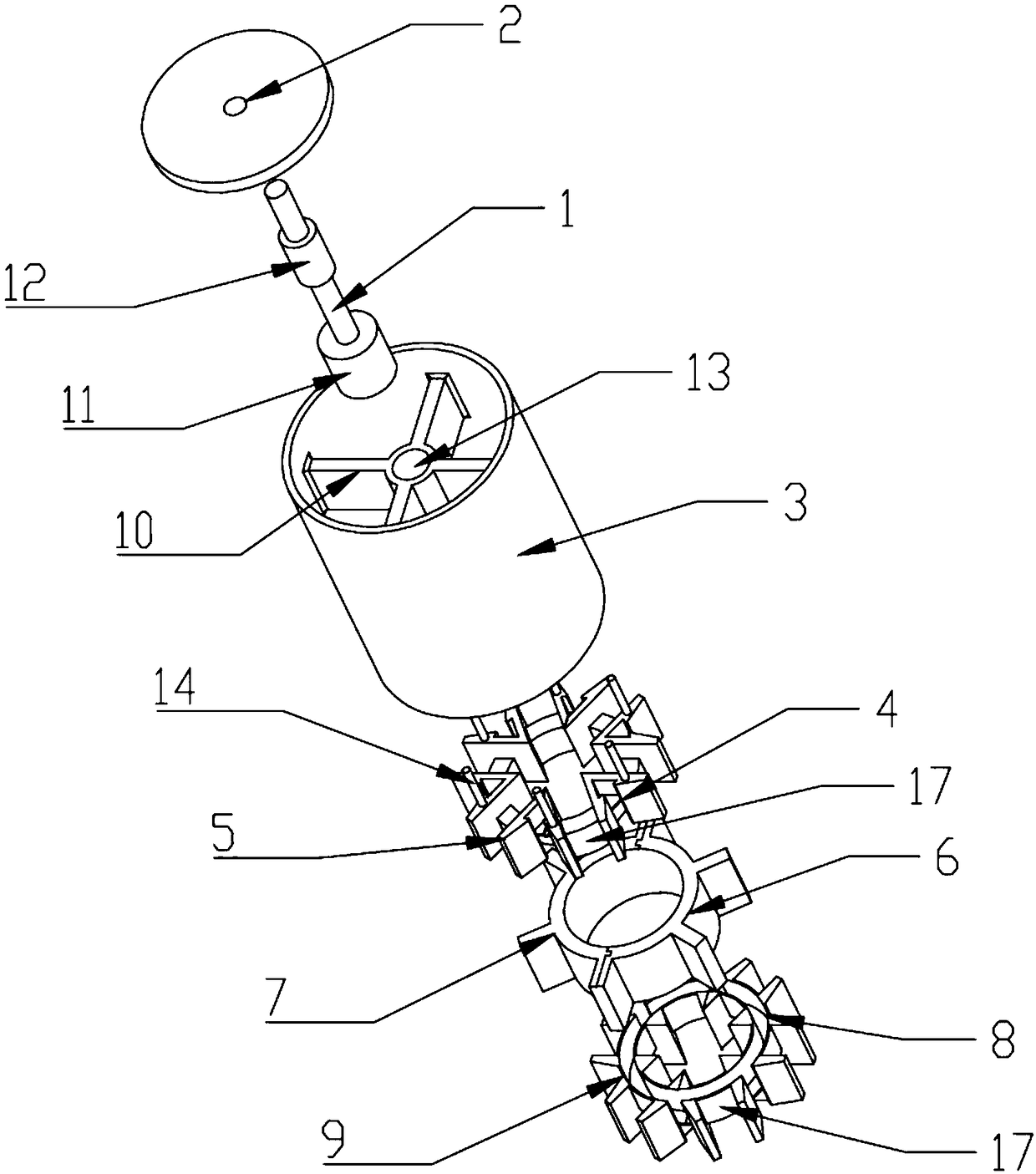

[0020] A novel parallel winding motor included in the present invention includes a stator, a rotor and a casing 3 .

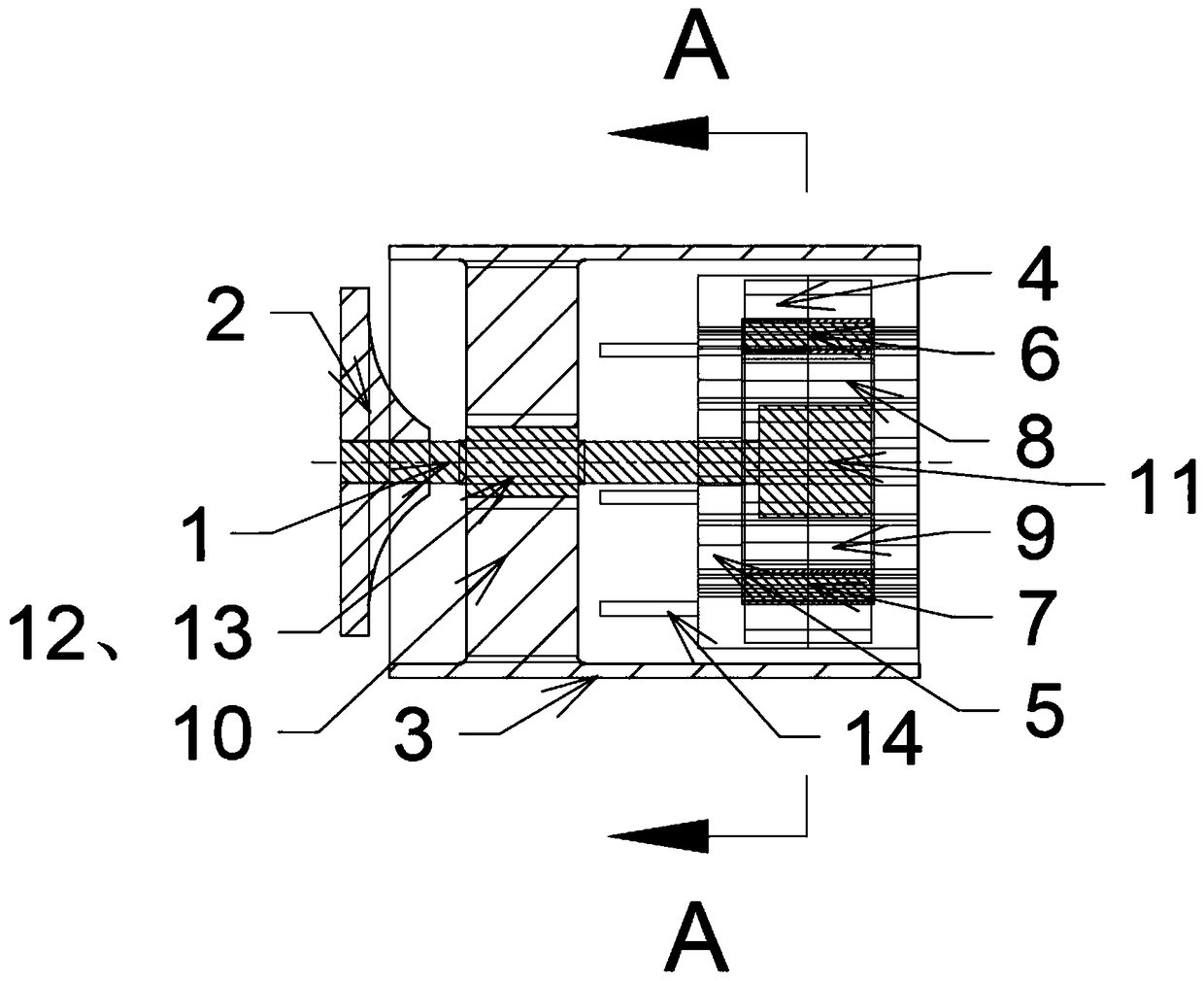

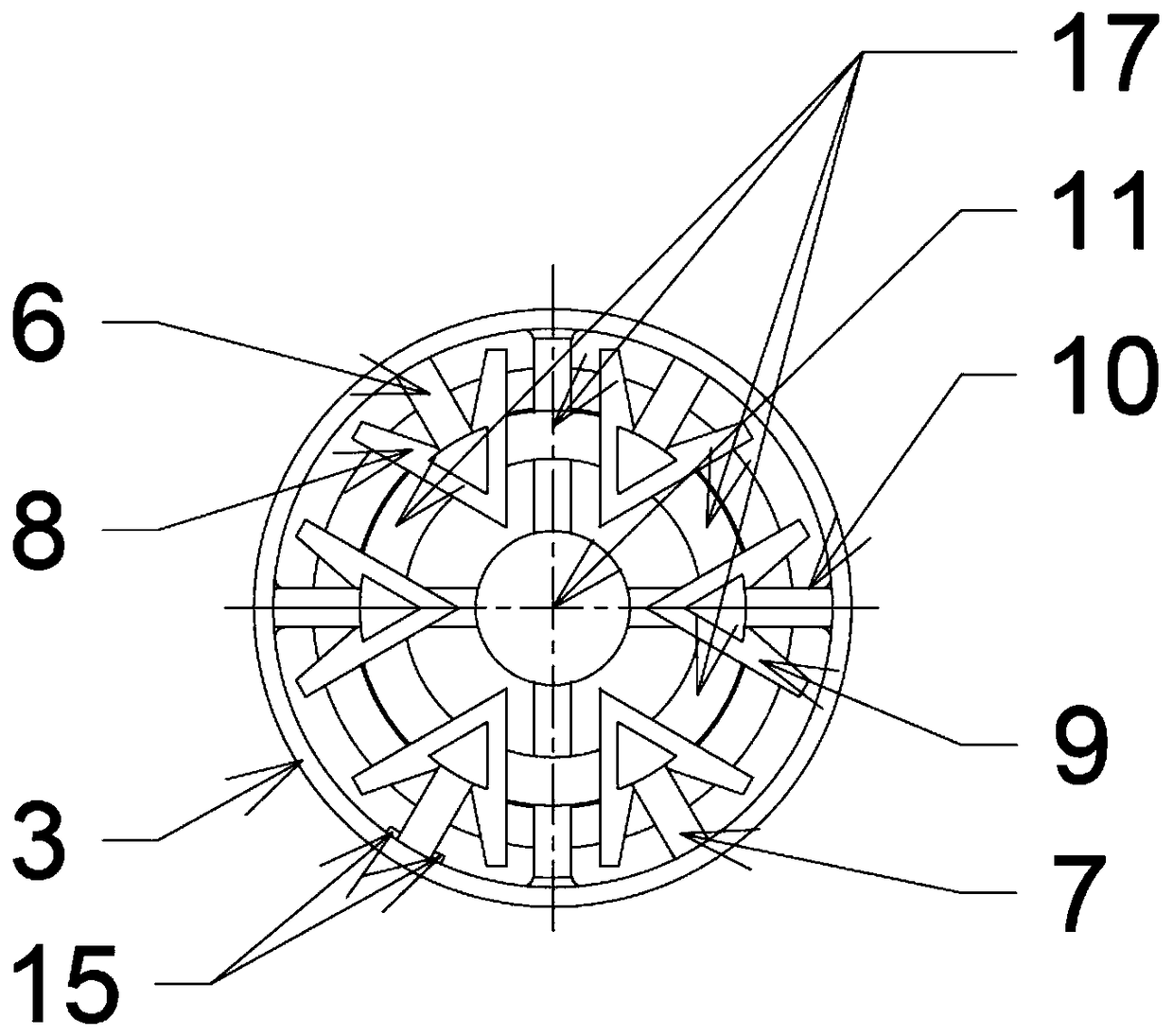

[0021] see Figure 4 The stator includes iron cores 6, 7 and stator windings 16. The iron cores 6 and 7 are identical integrally processed metal parts. A semi-circular iron core body 101, the outer side of the iron core body 101 is provided with a column 102 for supporting and fixing the stator, and the two ends of the iron core body 101 are provided with protrusions 104 and recesses 105 for fixing when combined, Half-width uprights 103 are provided on the outer sides of both ends of the iron core main body 101 .

[0022] see Figure 1 to Figure 3 , the stator is surrounded by an insulating frame wrapped around the core body 101 of the iron core 6, 7. The insulating frame includes an upper insulating frame 4, 5 and a lower insulating frame 8, 9, and the upper insulating frame 4, 5 is provided with a motor for supporting and fixing the motor. Circuit board su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com