Self-circulation cooling loop of heavy current fixture wire

A cooling circuit, high-current technology, applied in the direction of transformer/inductor cooling, energy-saving heating/cooling, lighting and heating equipment, etc., to achieve the effect of simple lead structure, good fire protection, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

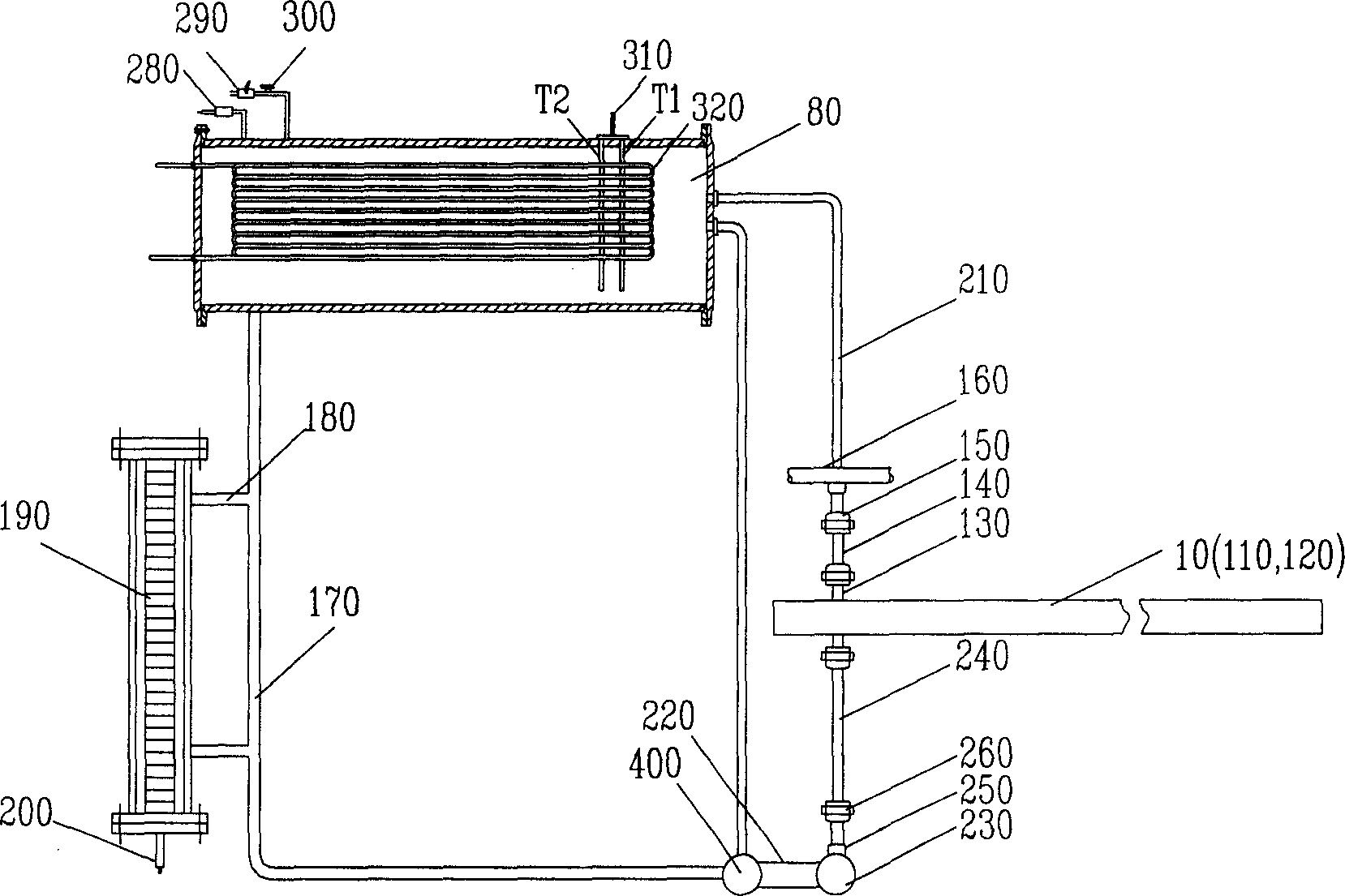

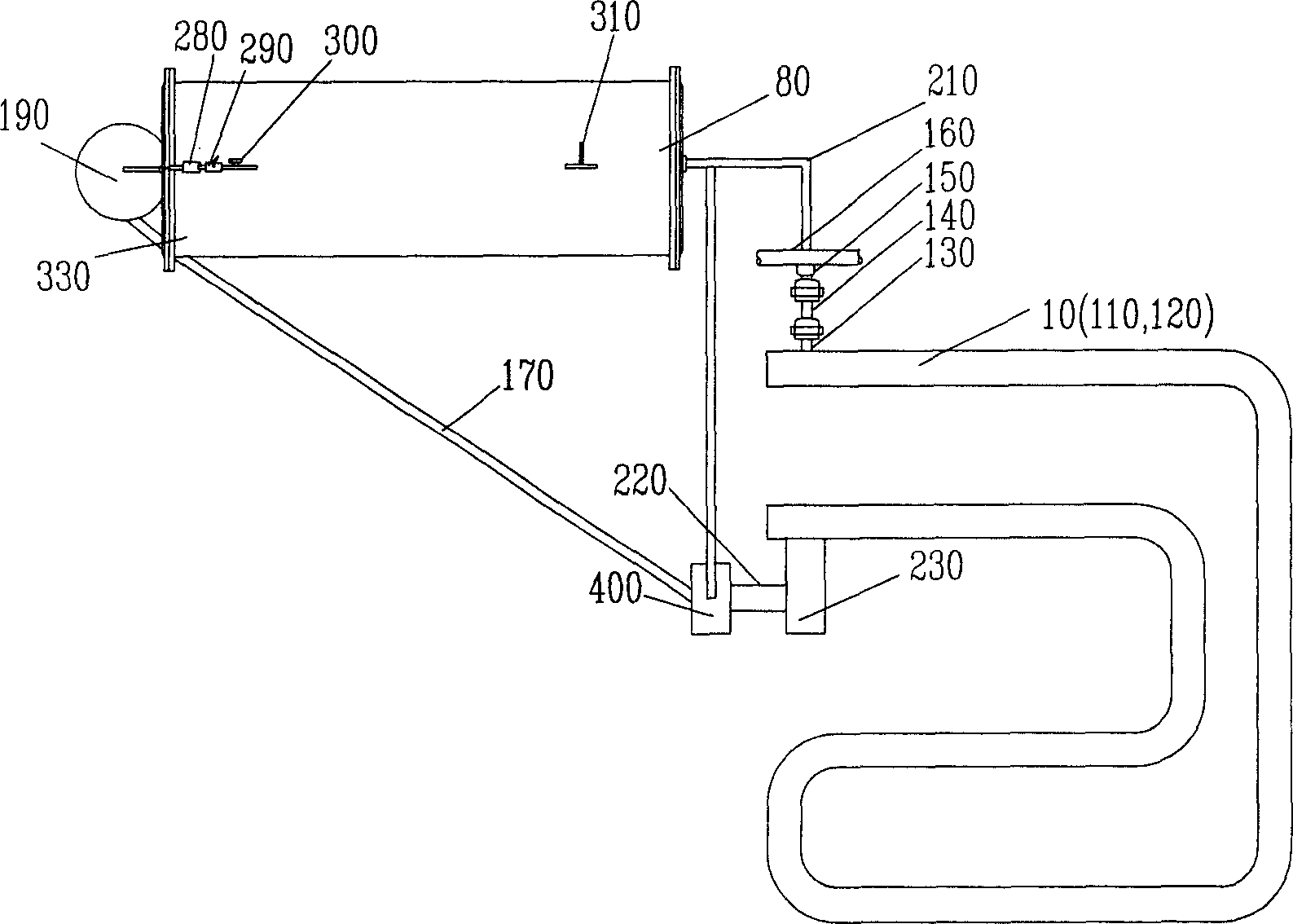

[0024] As shown in Figure 1, it is an embodiment of a hollow thick-walled tubular wire. The lead wire 10 of the large current equipment is composed of a thick-walled hollow pipeline 120 with a circular cross-section, which is placed horizontally. The outlet end is connected with the upper insulating lead pipe 140 through the upper electro-hydraulic separation joint 130 . The upper insulating lead pipe 140 is connected with the gas collecting pipe 160 through the sealing joint 150 . The air collecting pipe 160 enters the cooling space of the condenser 80 through the intake pipe 210 . The condenser 80 is connected to the liquid return pipe 170 . The magnetic float level gauge 190 is connected with the liquid return pipe 170 through the connection pipe 180 . A pressure sensor 200 is installed at the lower end of the liquid level gauge 190 , an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com