Cooling device

A heat dissipation device and heat dissipation fin technology, applied in indirect heat exchangers, heat exchange equipment, lighting and heating equipment, etc., can solve the problems of reducing the utilization rate of heat dissipation fins, small contact area, uneven temperature distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

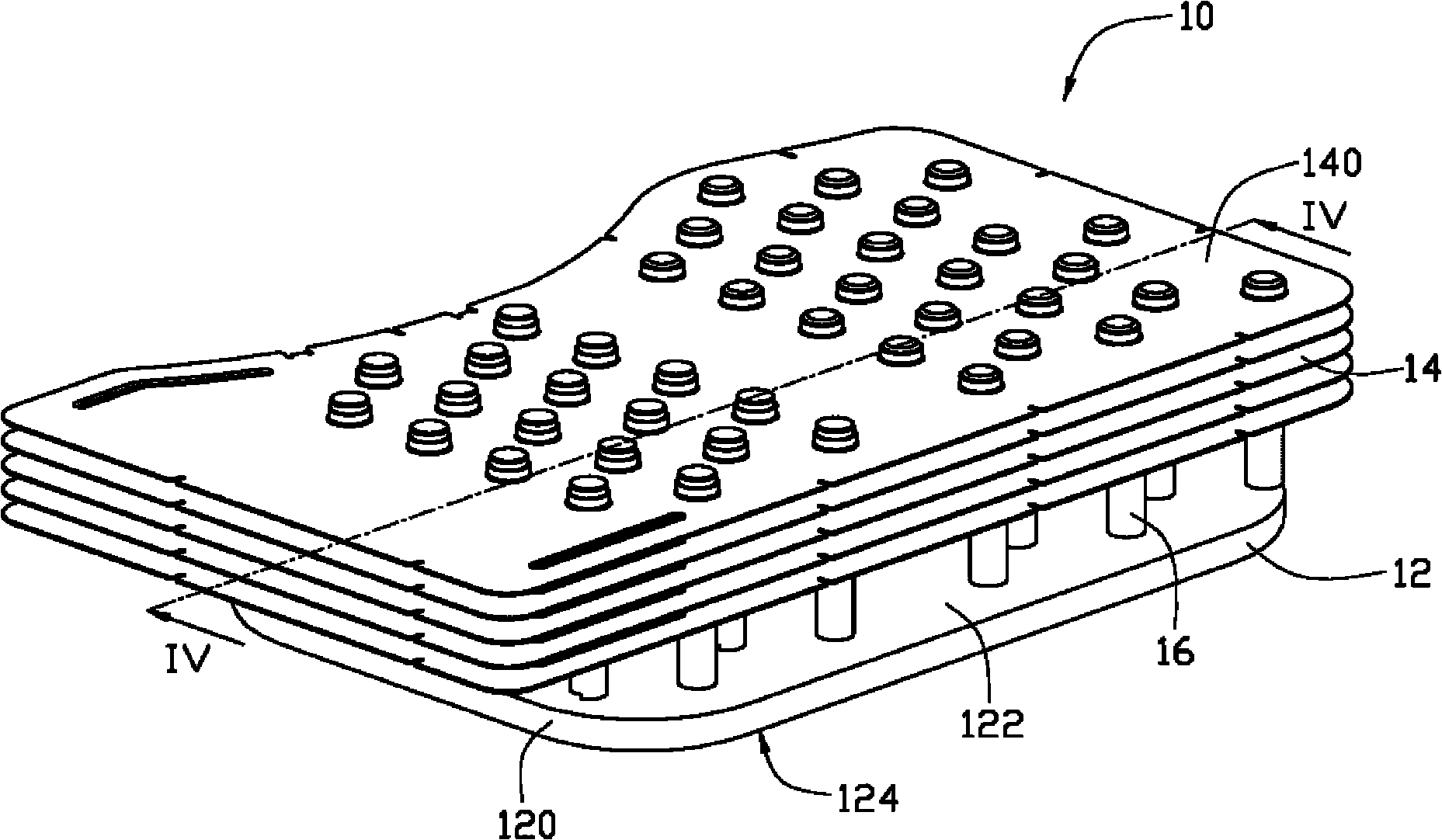

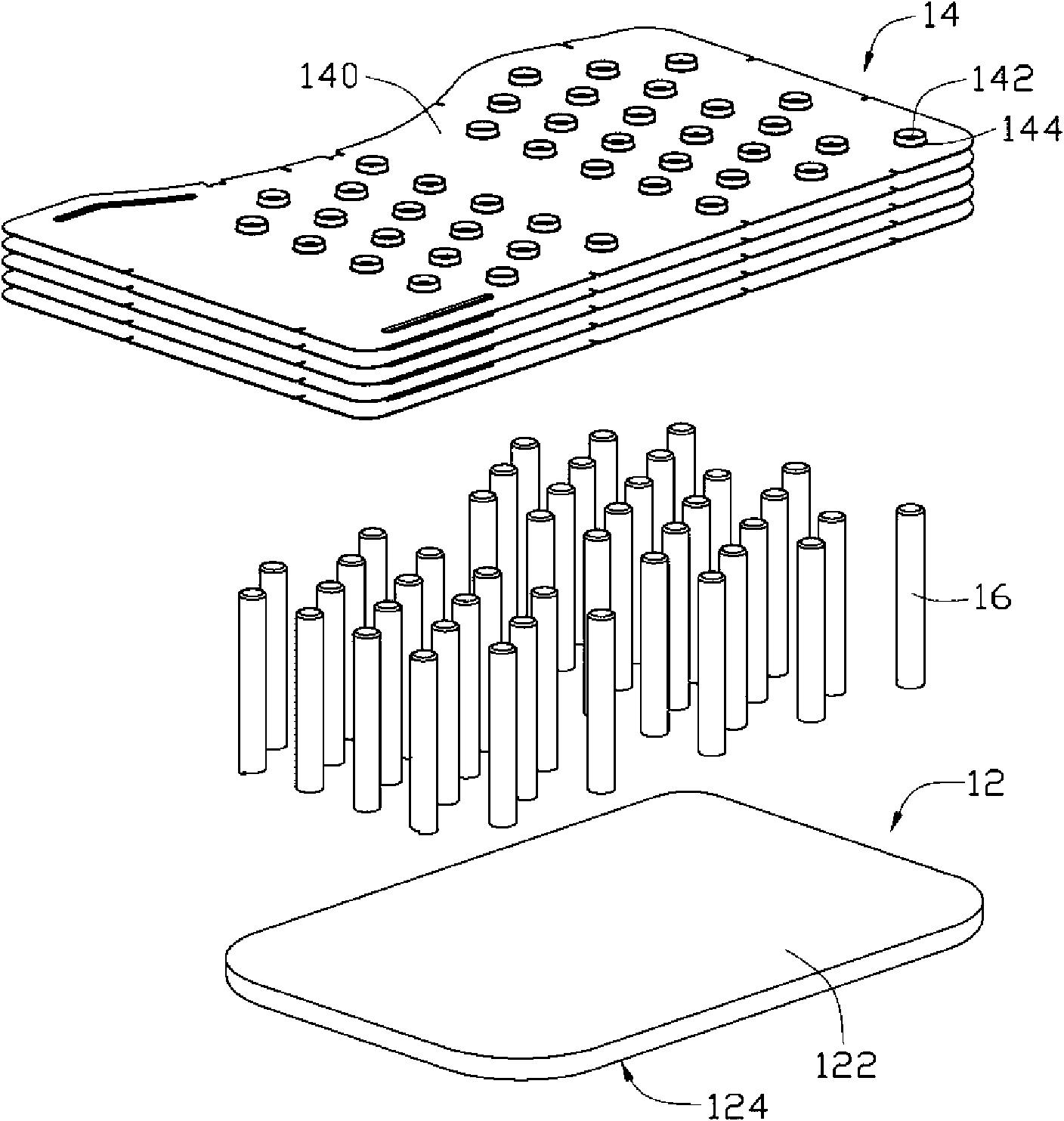

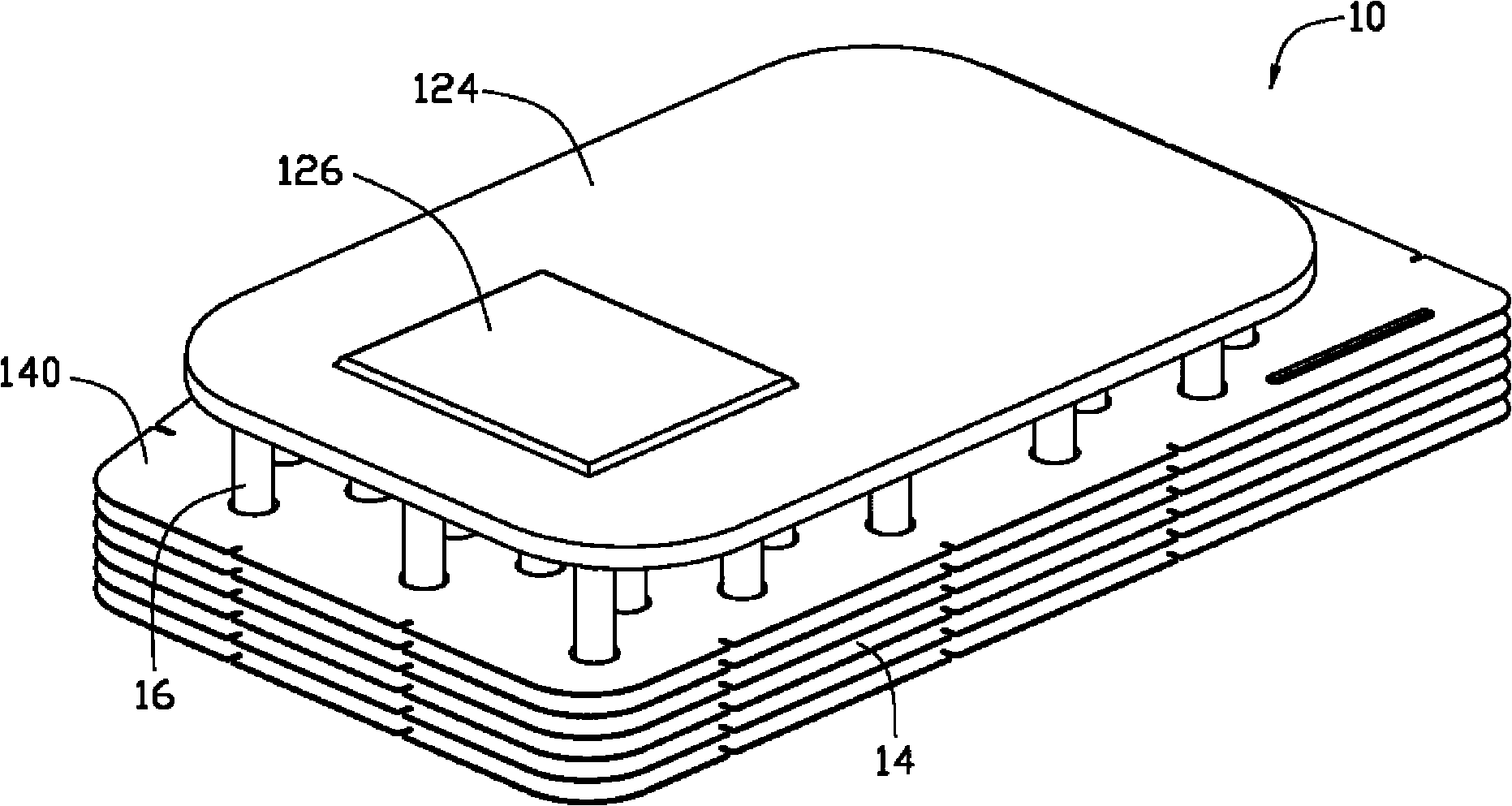

[0011] see Figure 1 to Figure 4 , the heat dissipation device 10 includes a plate-type heat pipe 12 , a heat dissipation fin set 14 and a plurality of heat transfer columns 16 .

[0012] The plate heat pipe 12 is flat and includes a shell 120 and a capillary structure 121 inside the shell 120 . The capillary structure 121 can be grooves, wire mesh, fibers or sintered powder. The casing 120 is made of a material with good thermal conductivity. The casing 120 encloses a hollow airtight chamber 125, and the chamber 125 contains a working medium (not shown in the figure) such as water, alcohol, and the like. The plate-type heat pipe 12 has a top surface 122 and a bottom surface 124 opposite thereto. The bottom surface 124 is used for contacting the heating electronic components to absorb heat generated by the heating electronic components. The bottom surface 124 protrudes outward to form a protruding portion 126 , and the protruding portion 126 is used for close contact with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com