Patents

Literature

284results about "Processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

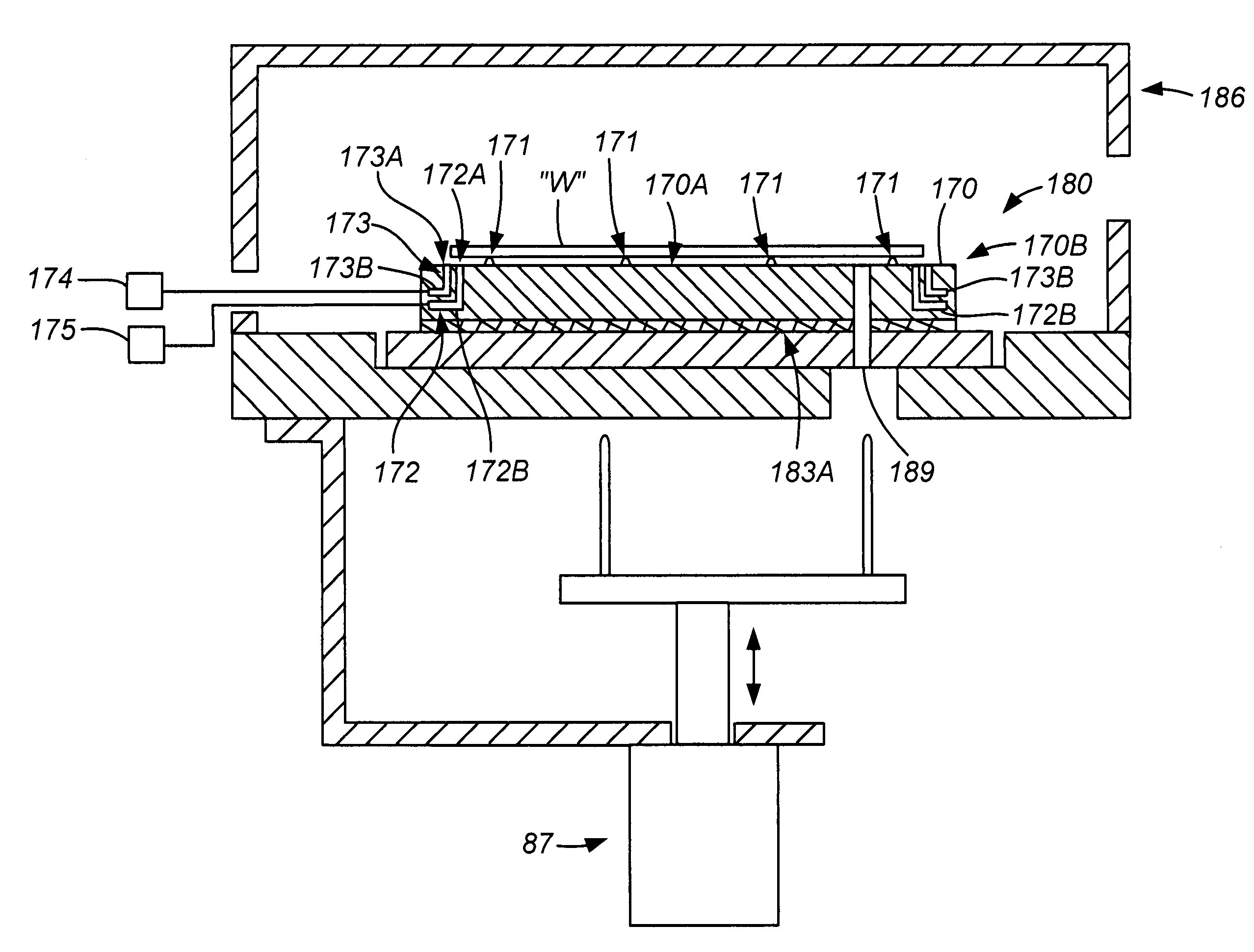

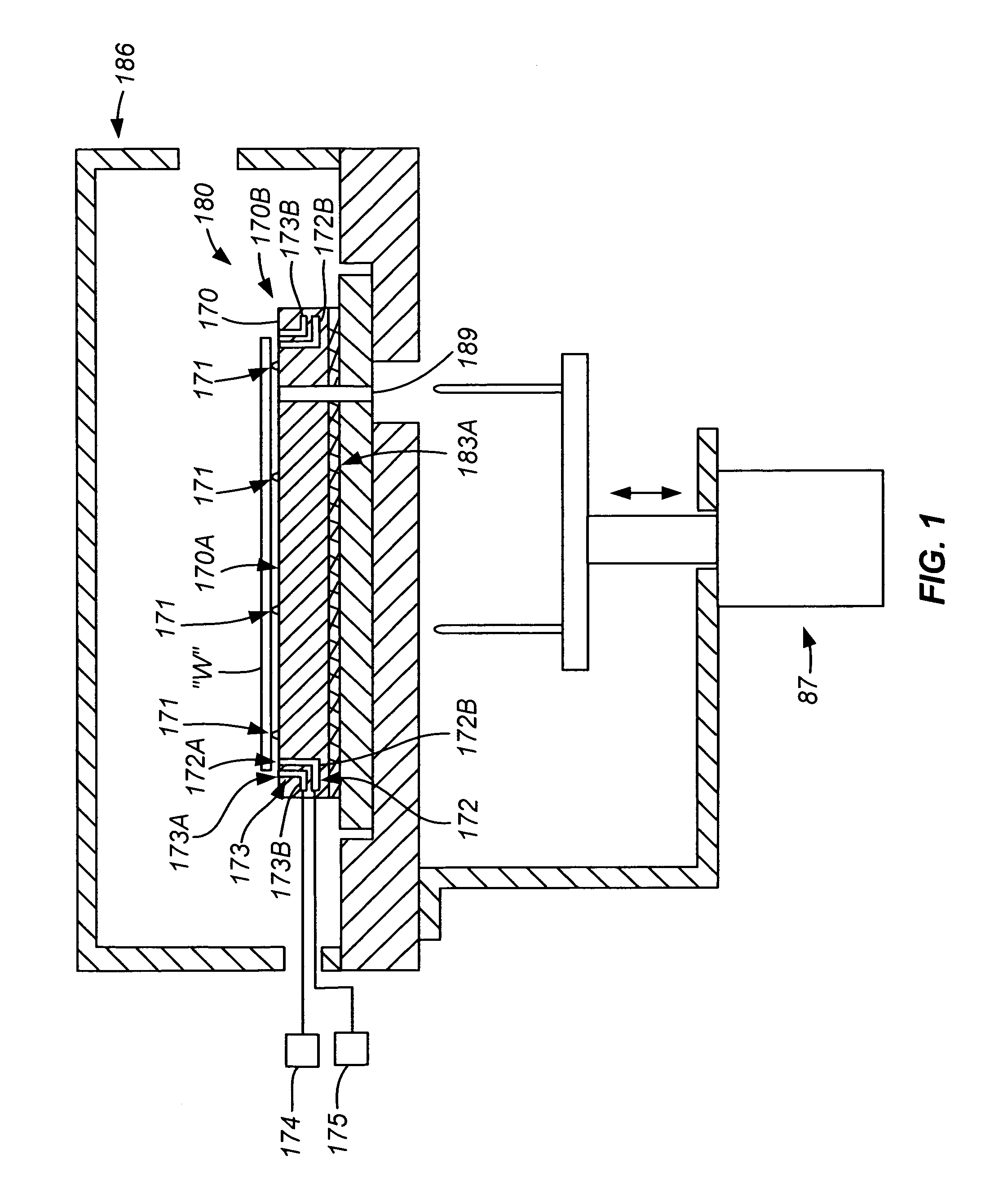

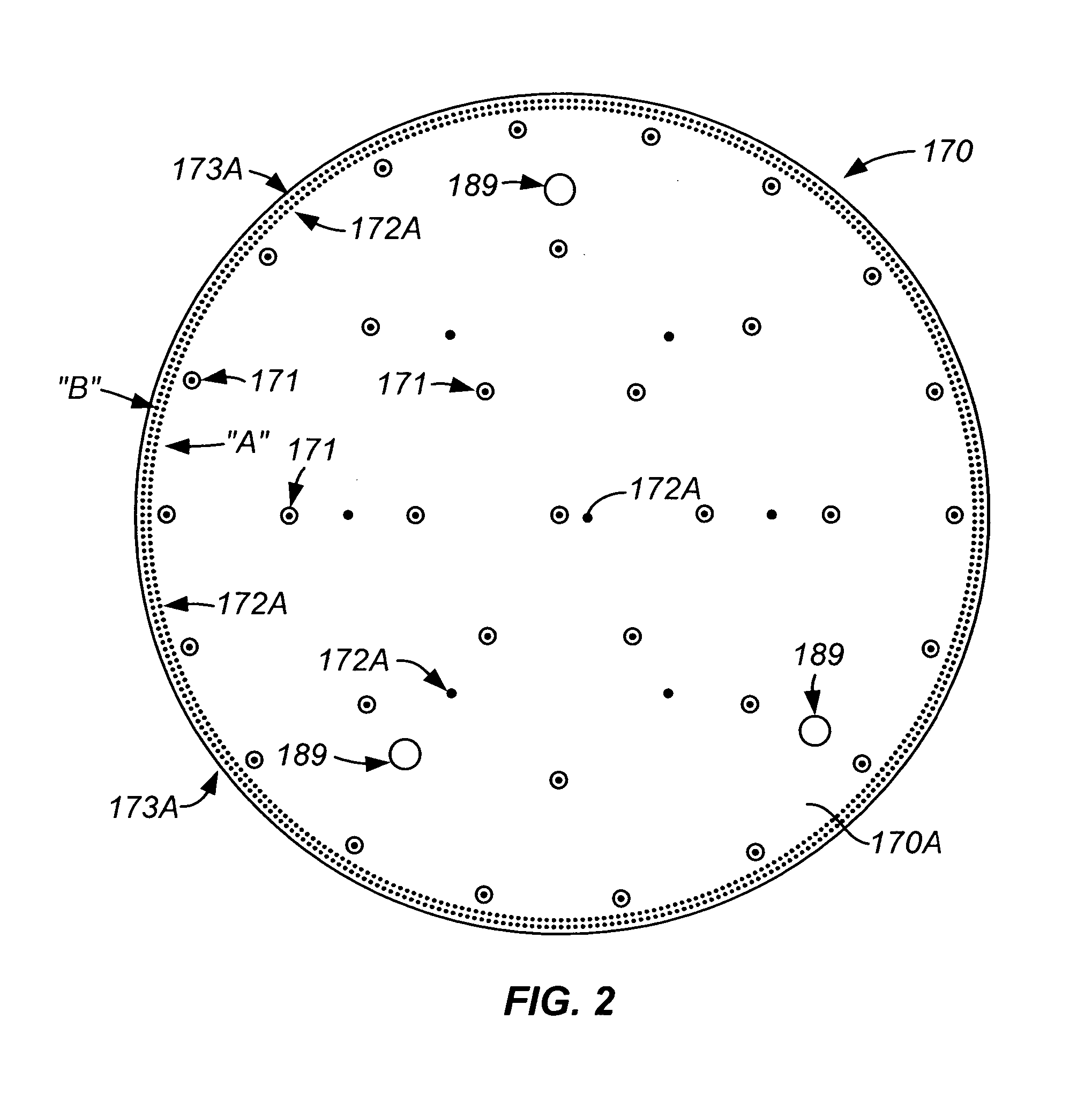

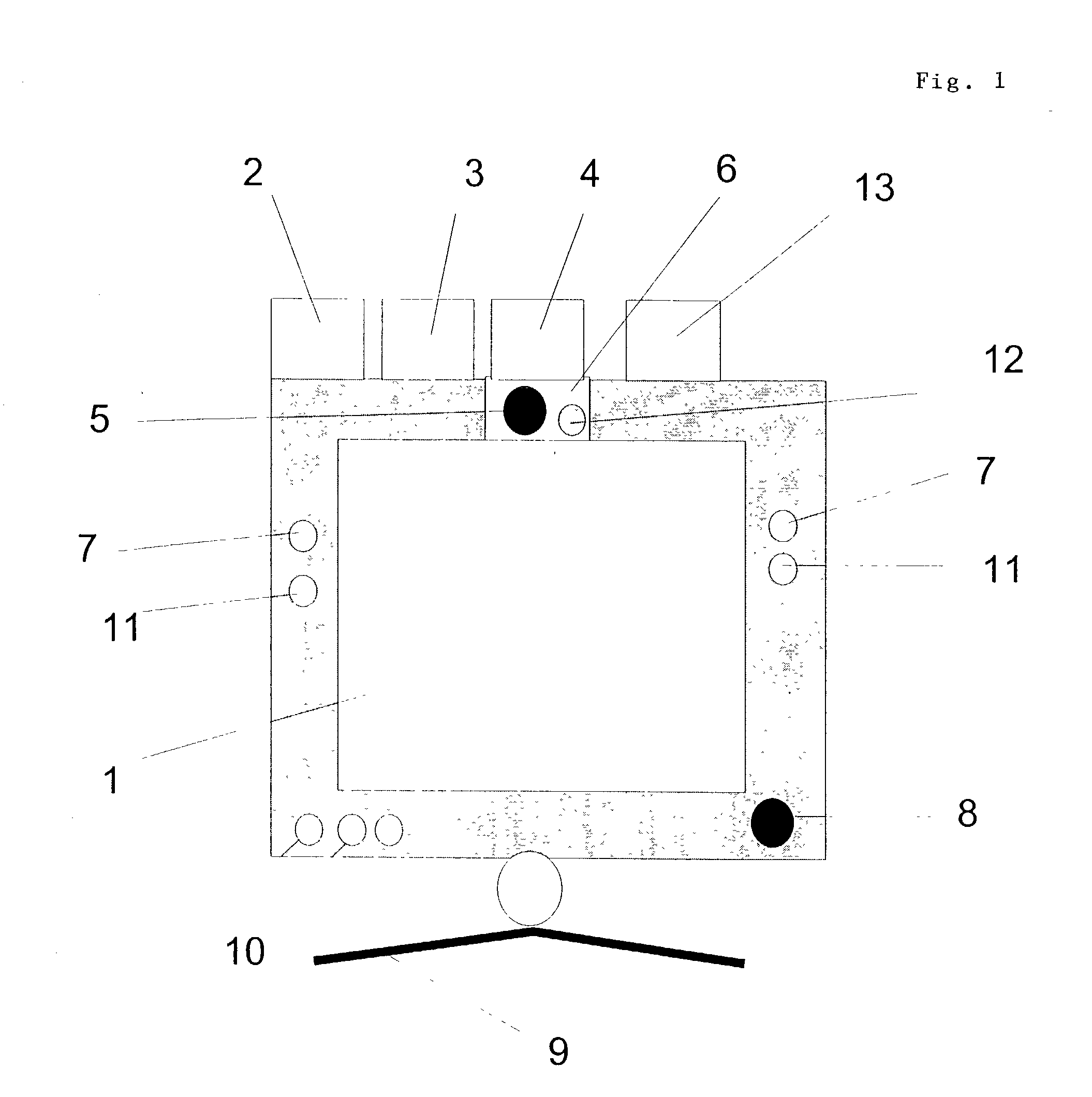

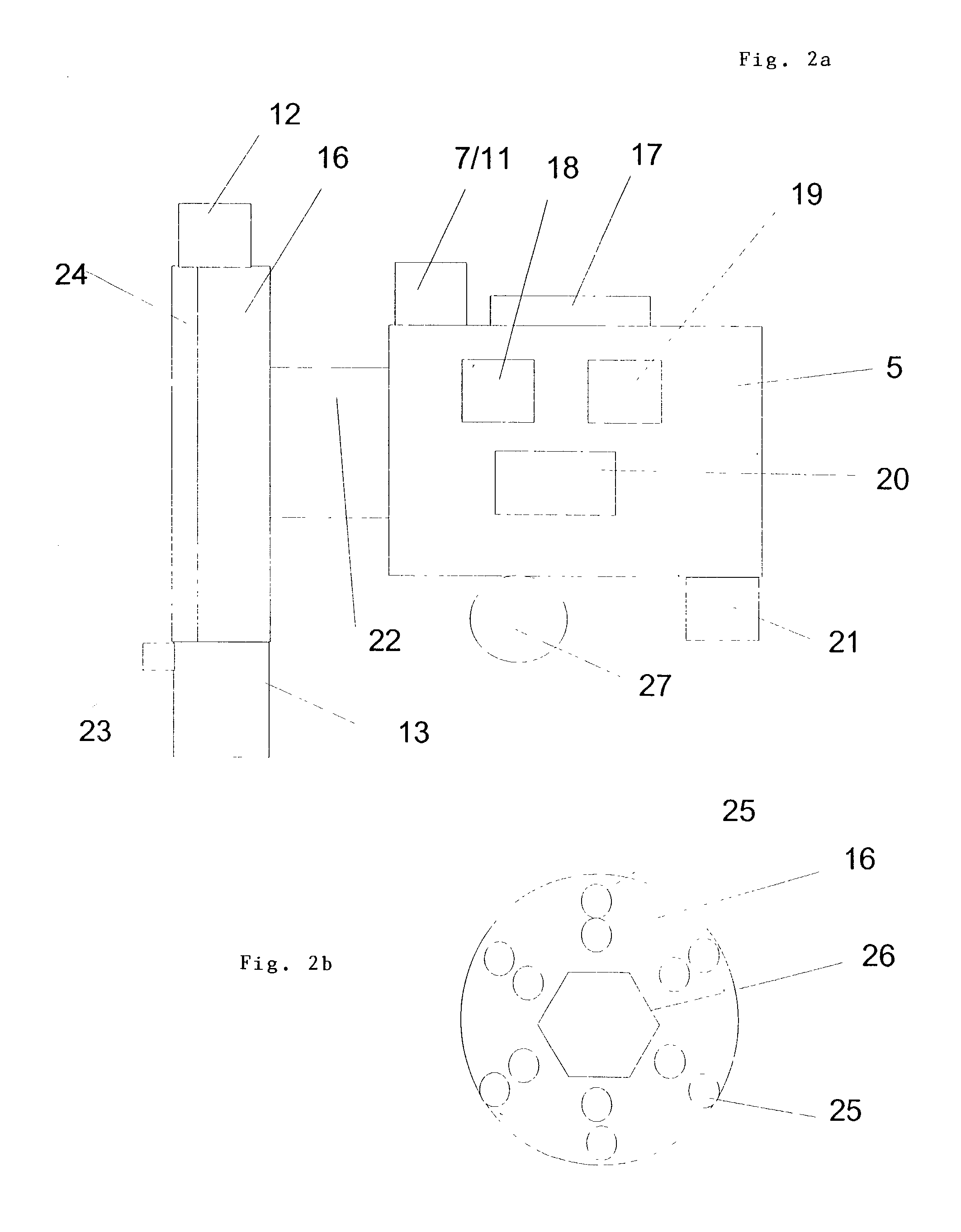

Purged vacuum chuck with proximity pins

InactiveUS20060130767A1Reduce the overall heightImprove heat transfer rateProgramme controlSemiconductor/solid-state device testing/measurementEngineeringFree space

A substrate support structure comprising a first surface and a second surface opposite the first surface. The substrate support structure also comprises a plurality of proximity pins projecting to a first height above the first surface, the first height being less than 100 μm. In addition, the substrate support structure further comprises a plurality of purge ports passing from the second surface to the first surface and a plurality of vacuum ports passing from the second surface to the first surface. In one embodiment, the plurality of purge ports are arranged in a first circular pattern, the first circular pattern having a first radial dimension less than the radius of the substrate support, and the plurality of vacuum ports are arranged in a second circular pattern, the second circular pattern having a second radial dimension less than the first radial dimension.

Owner:SOKUDO CO LTD

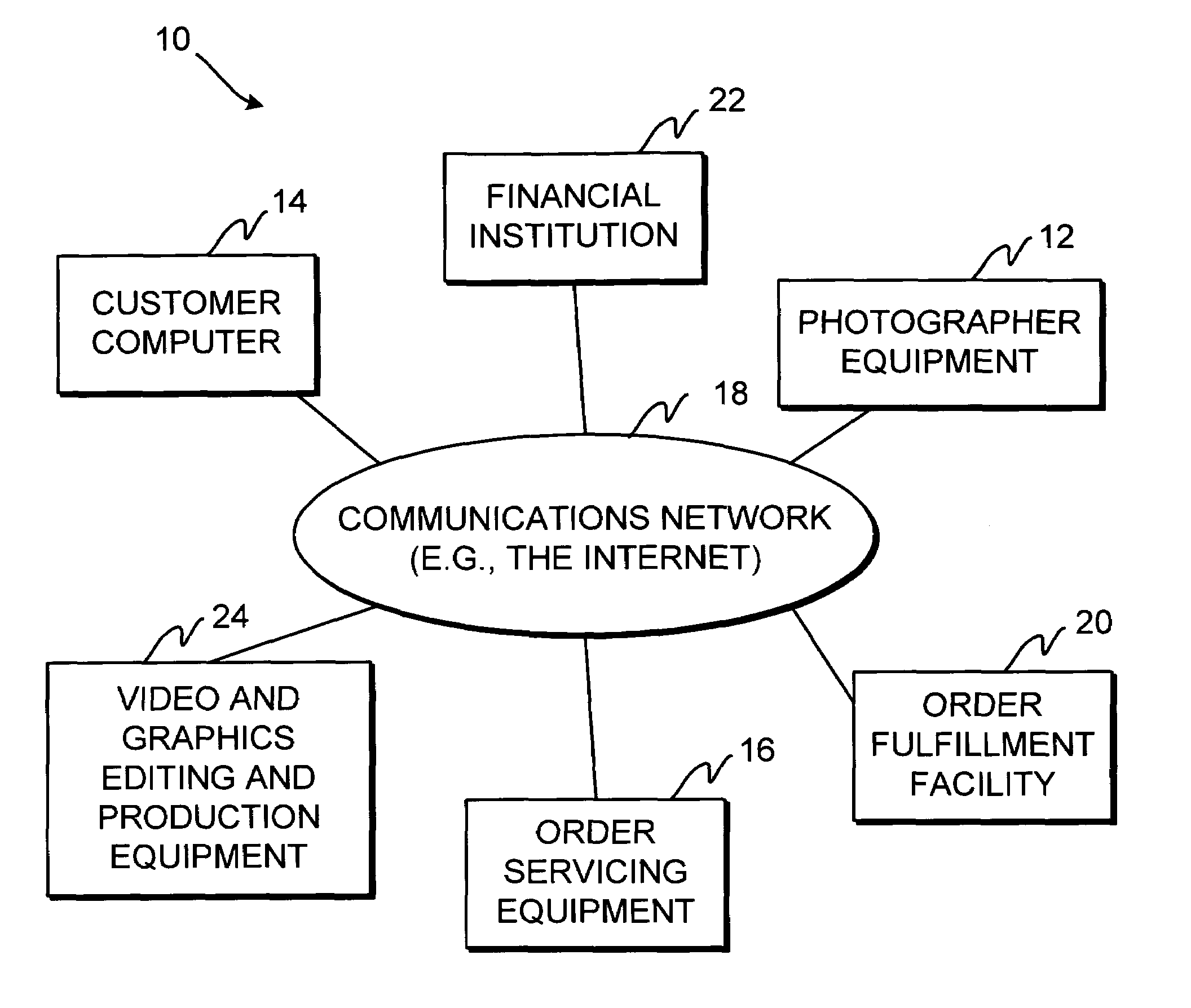

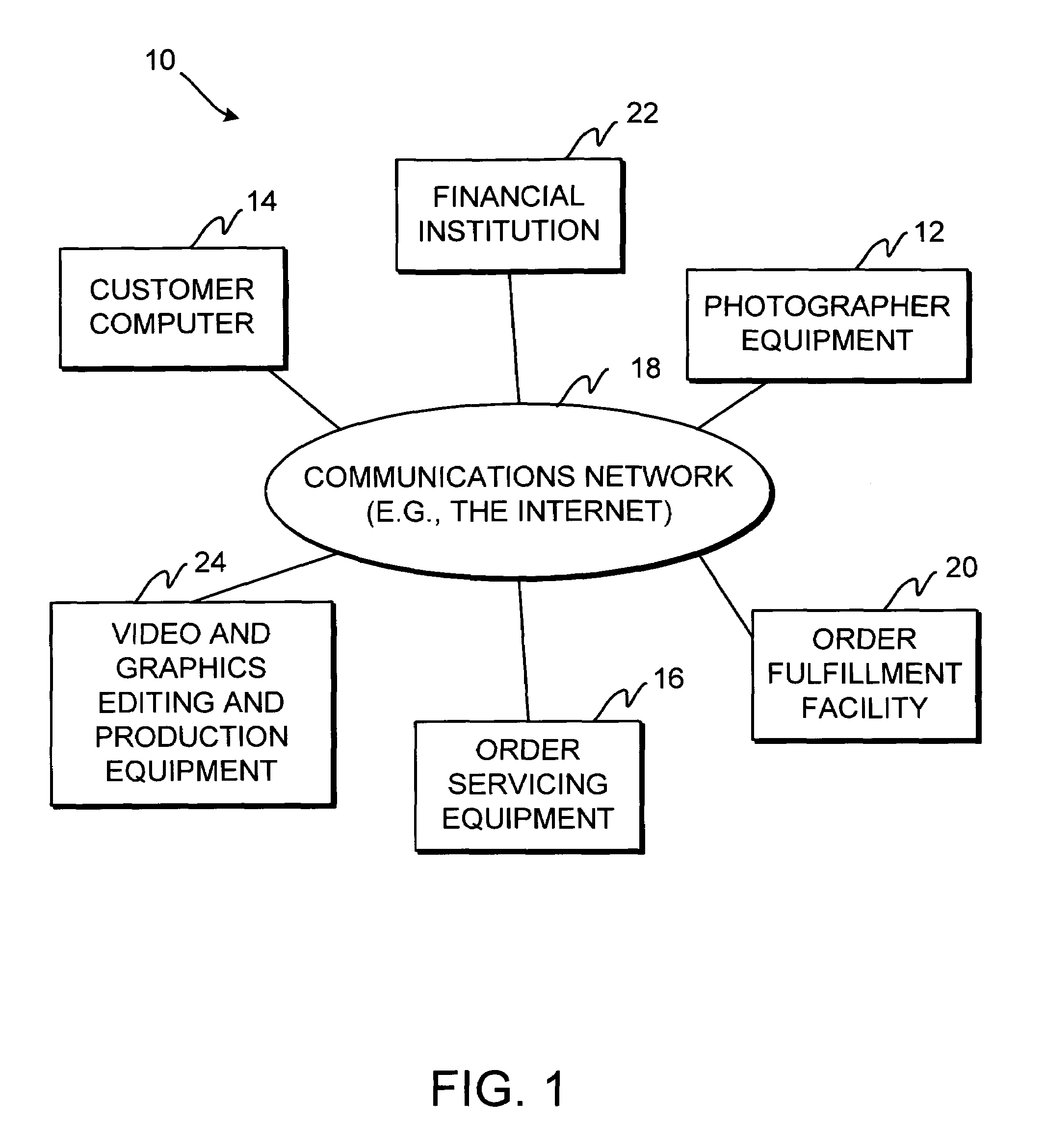

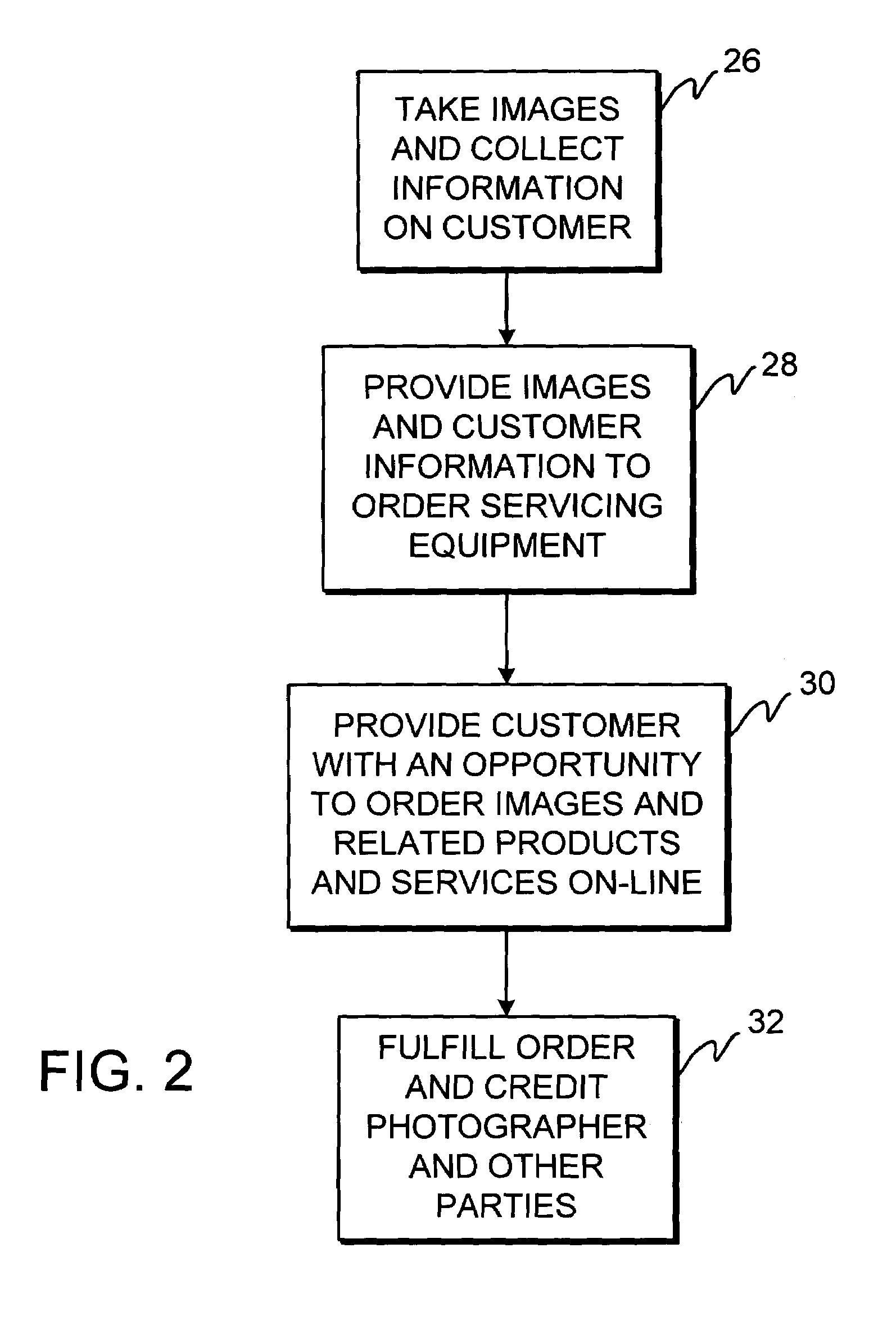

Online digital image-based product ordering system

InactiveUS7343320B1Image changeProcessingVisual presentationServicing equipmentComputer graphics (images)

A system is provided that allows a photographer to take images for a customer and provide those images to order servicing equipment with which the images are placed on-line for the customer to view. The customer may place orders for the images and products and services related to the images. The order servicing equipment may credit the photographer when the customer orders images, products, or services. Images may be manipulated before images, products, or services are ordered. Images may be taken using film-based cameras or digital image acquisition equipment. Image presentation options may be selected. Content may be appended to the images. Web sites and digital albums may be created using the images. The photographer may check the status of assignments that have been submitted to the order servicing equipment and may check on account status. Different rights levels may be established for different parties. Loyalty rewards may be awarded for frequent use of the system.

Owner:LG ELECTRONICS INC

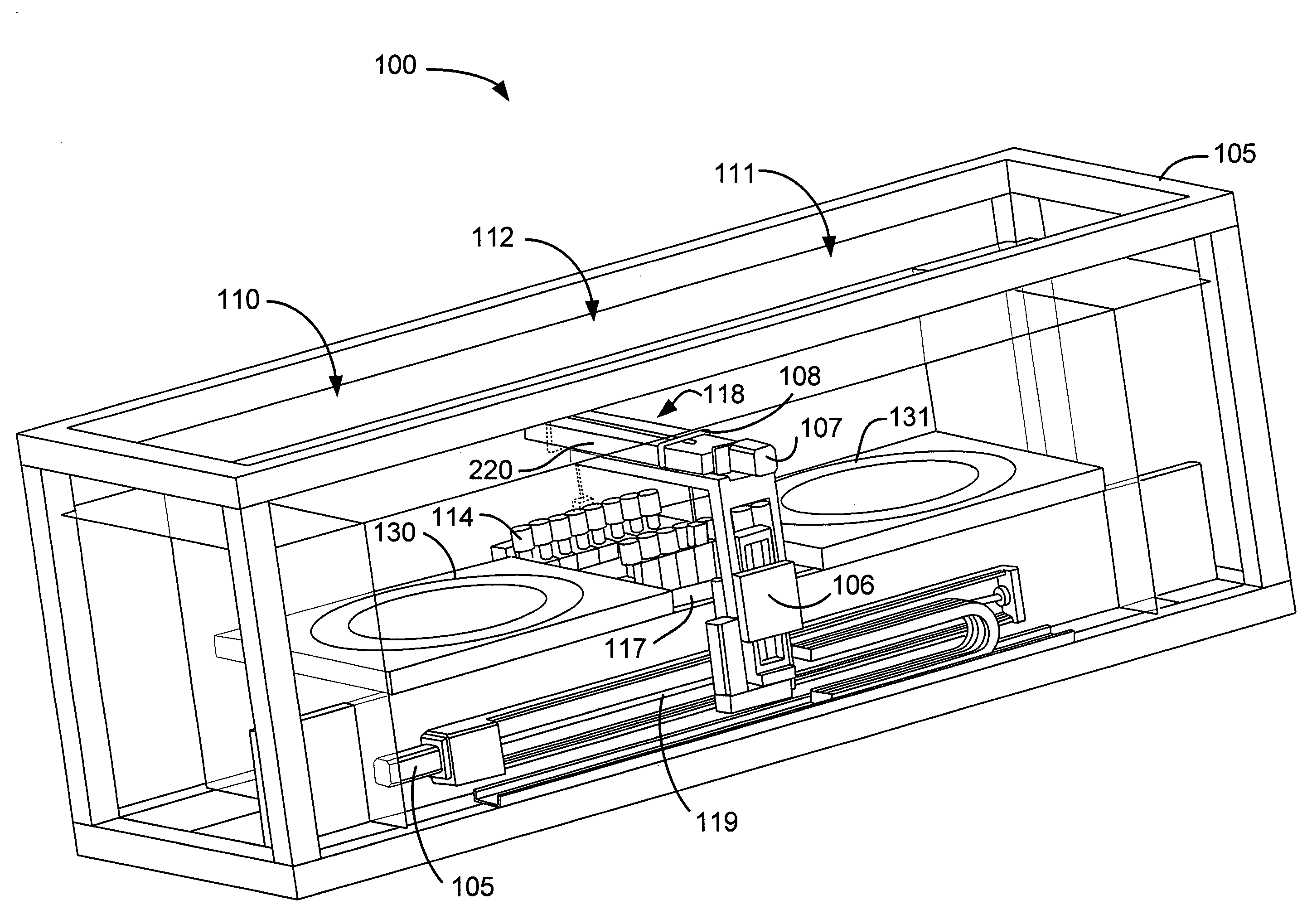

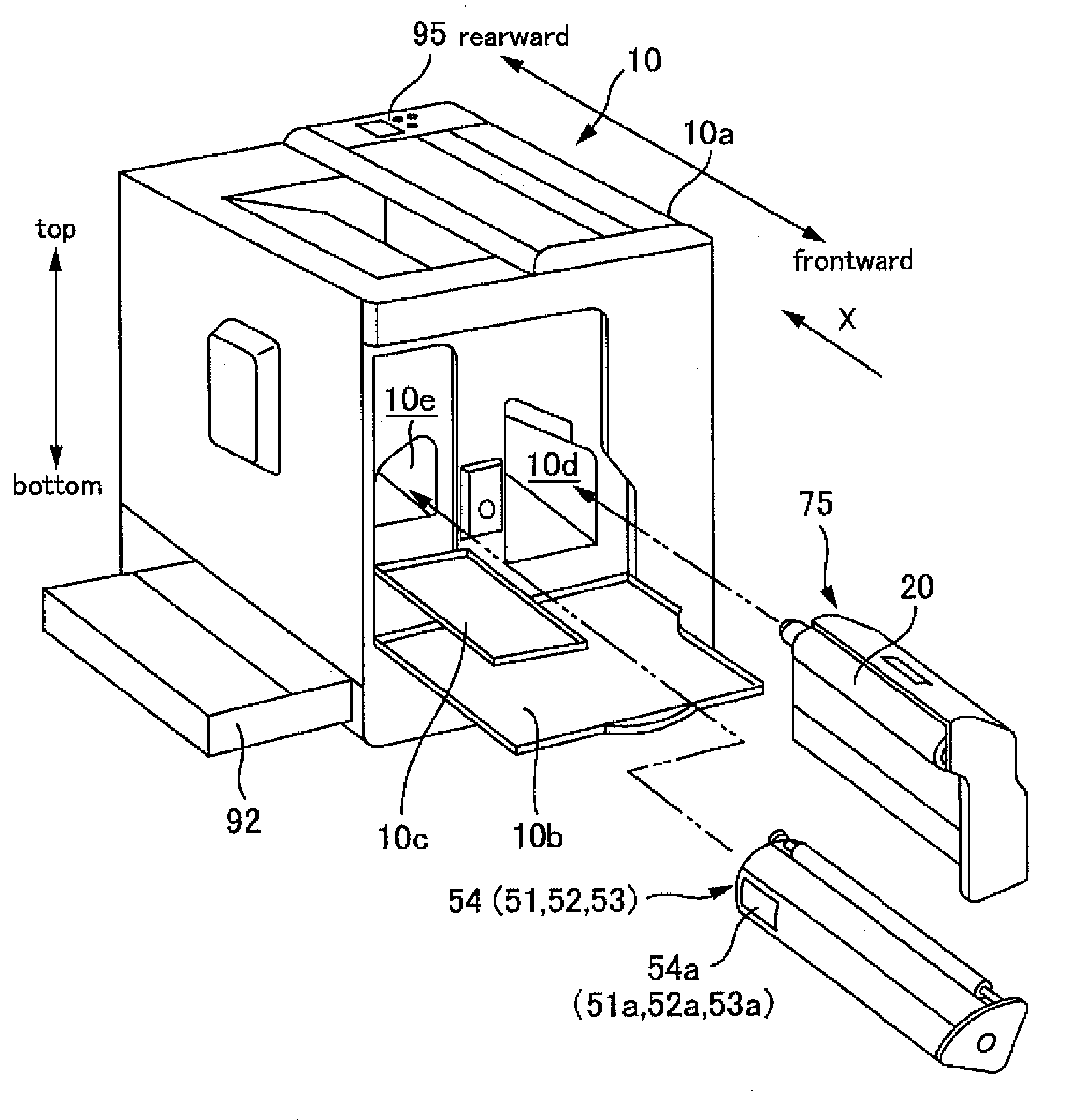

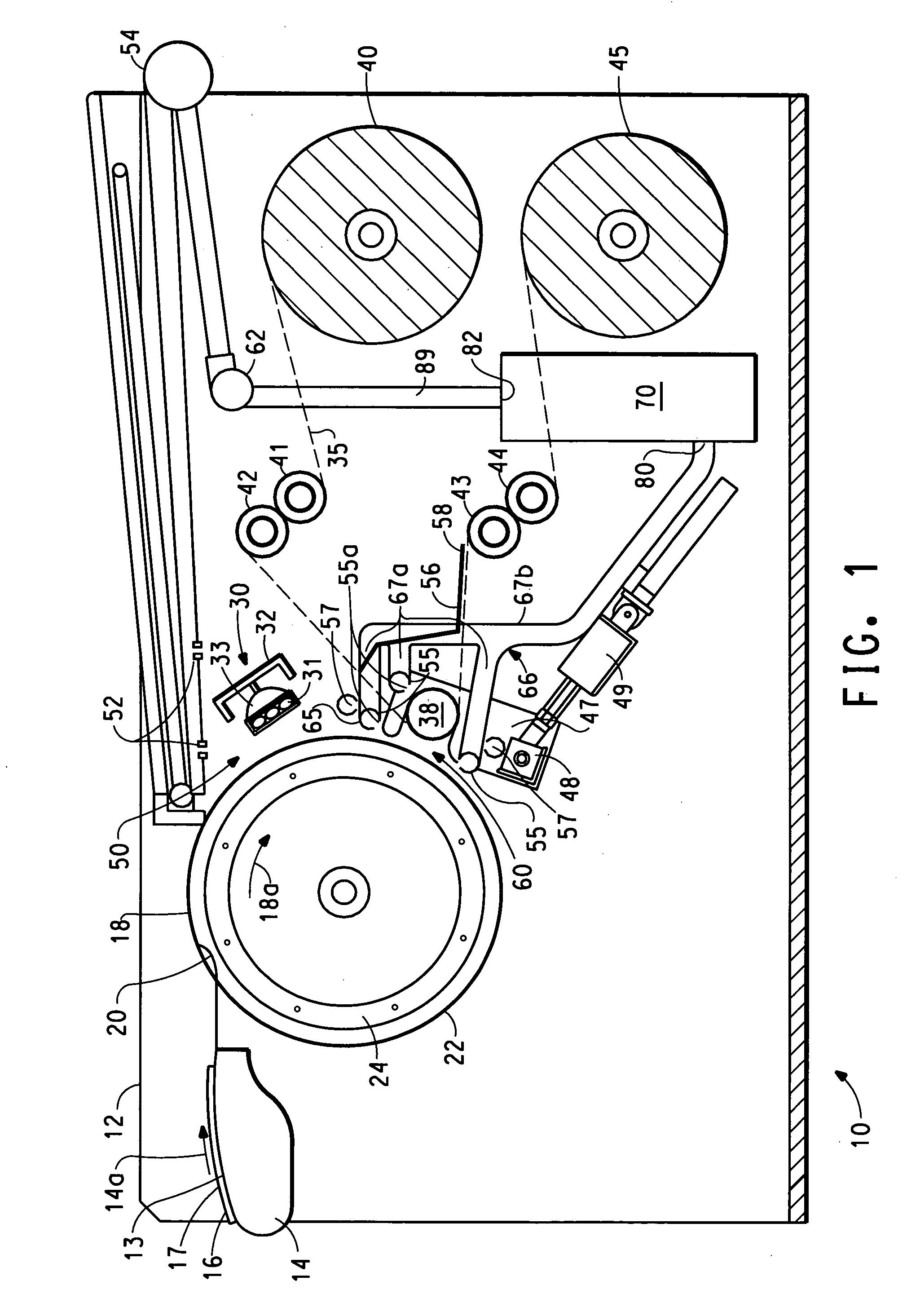

Cluster tool substrate throughput optimization

ActiveUS20060130751A1Liquid surface applicatorsSemiconductor/solid-state device testing/measurementEngineeringDependability

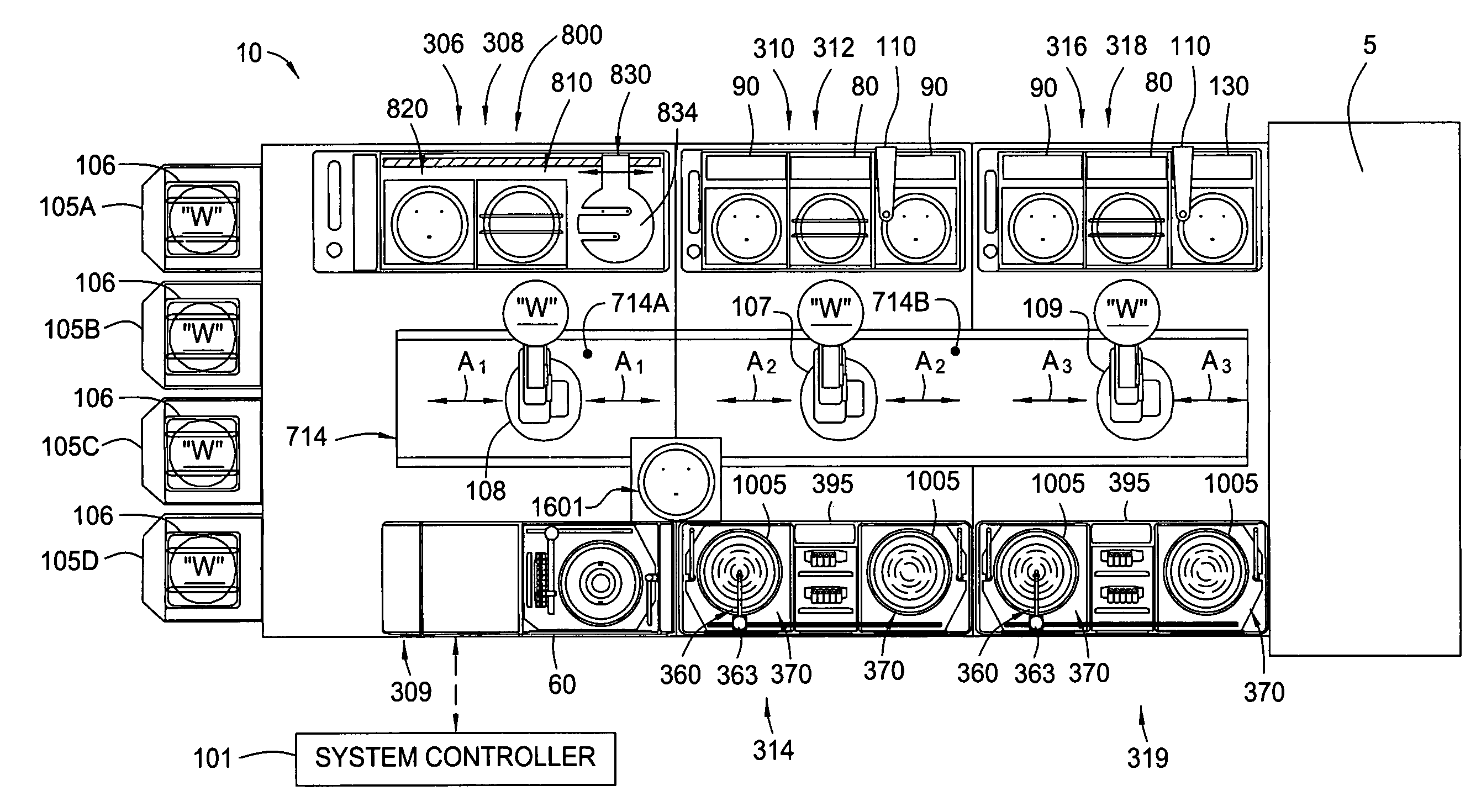

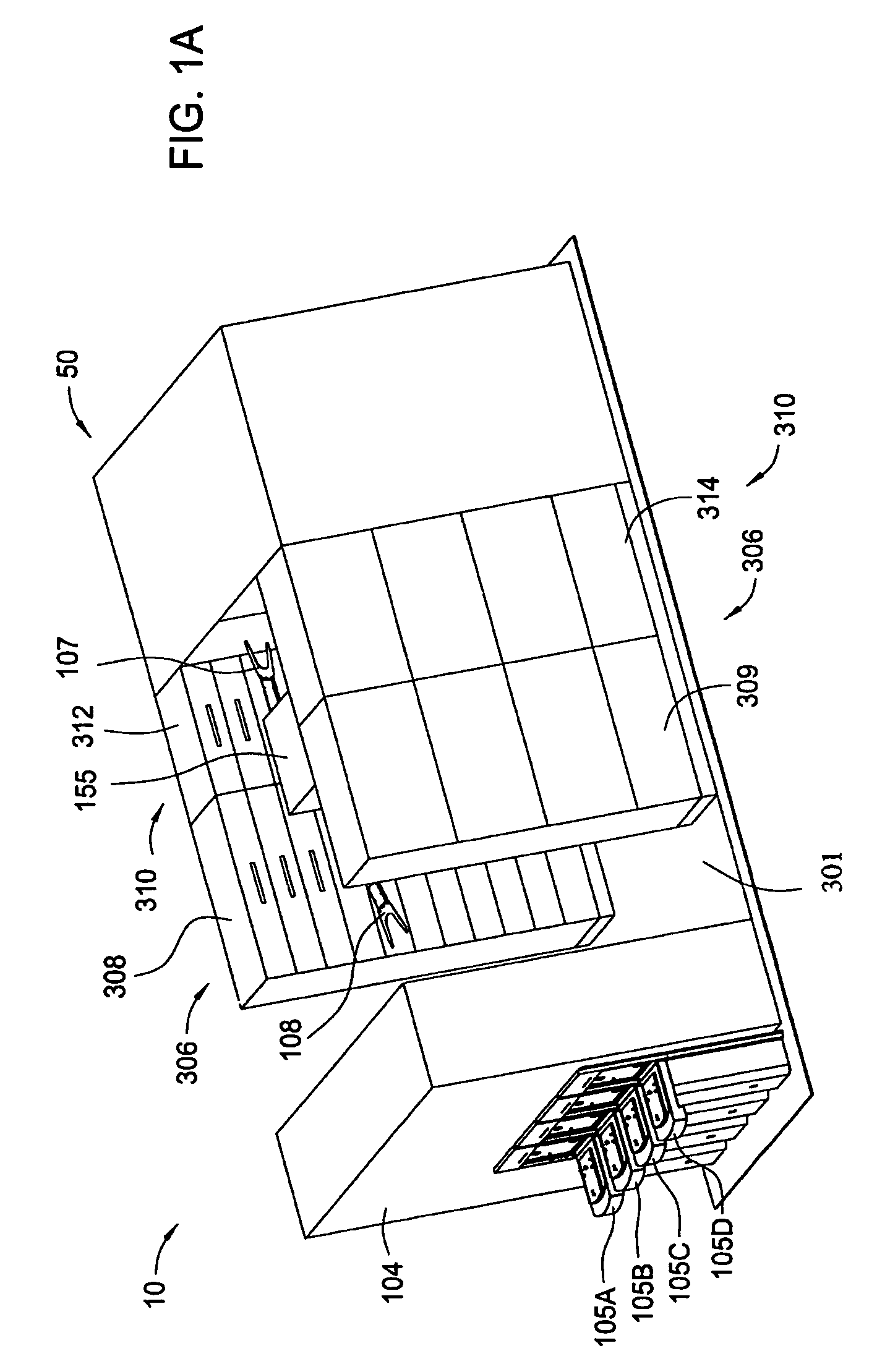

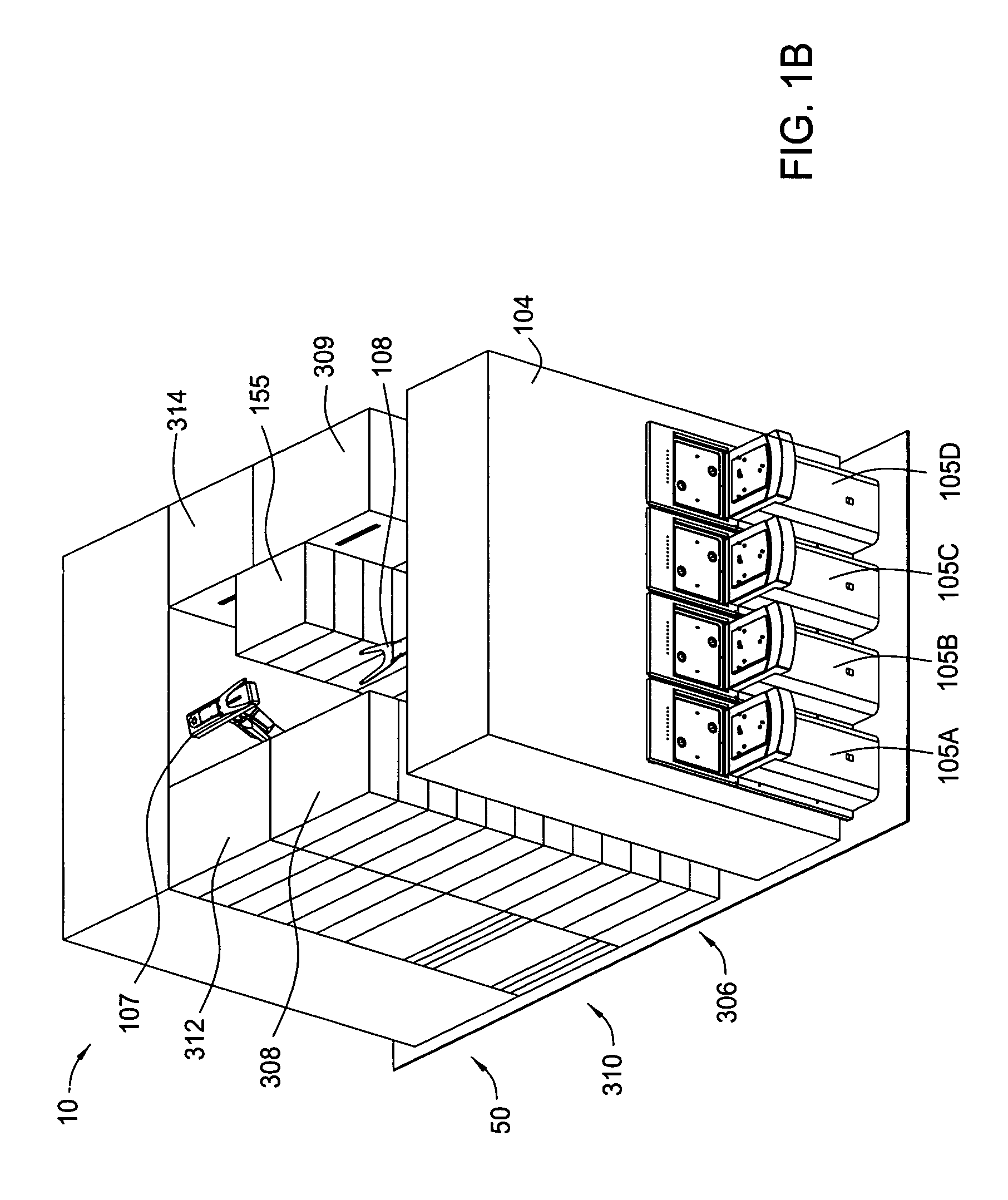

Embodiments generally provide an apparatus and method for processing substrates using a multi-chamber processing system (e.g., a cluster tool) that has an increased system throughput, increased system reliability, substrates processed in the cluster tool have a more repeatable wafer history. In one embodiment, non-orthogonal robot trajectories are used to assure reliable and high speed substrate transfer. In another embodiment, at least one buffering station is used to avoid collision and improve throughput. In another embodiment, optimal positioning of the robots are used to improve throughput.

Owner:SCREEN SEMICON SOLUTIONS CO LTD

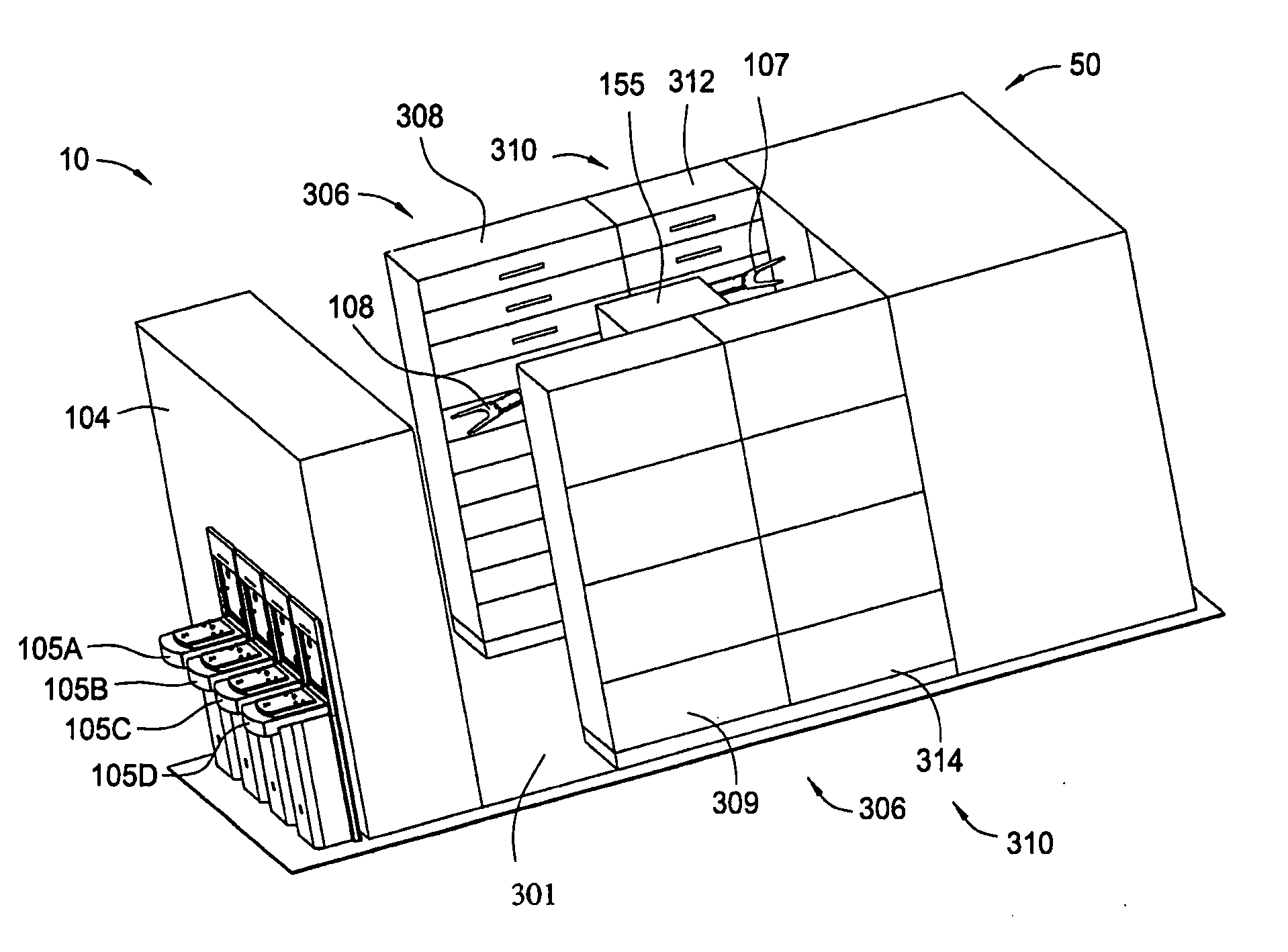

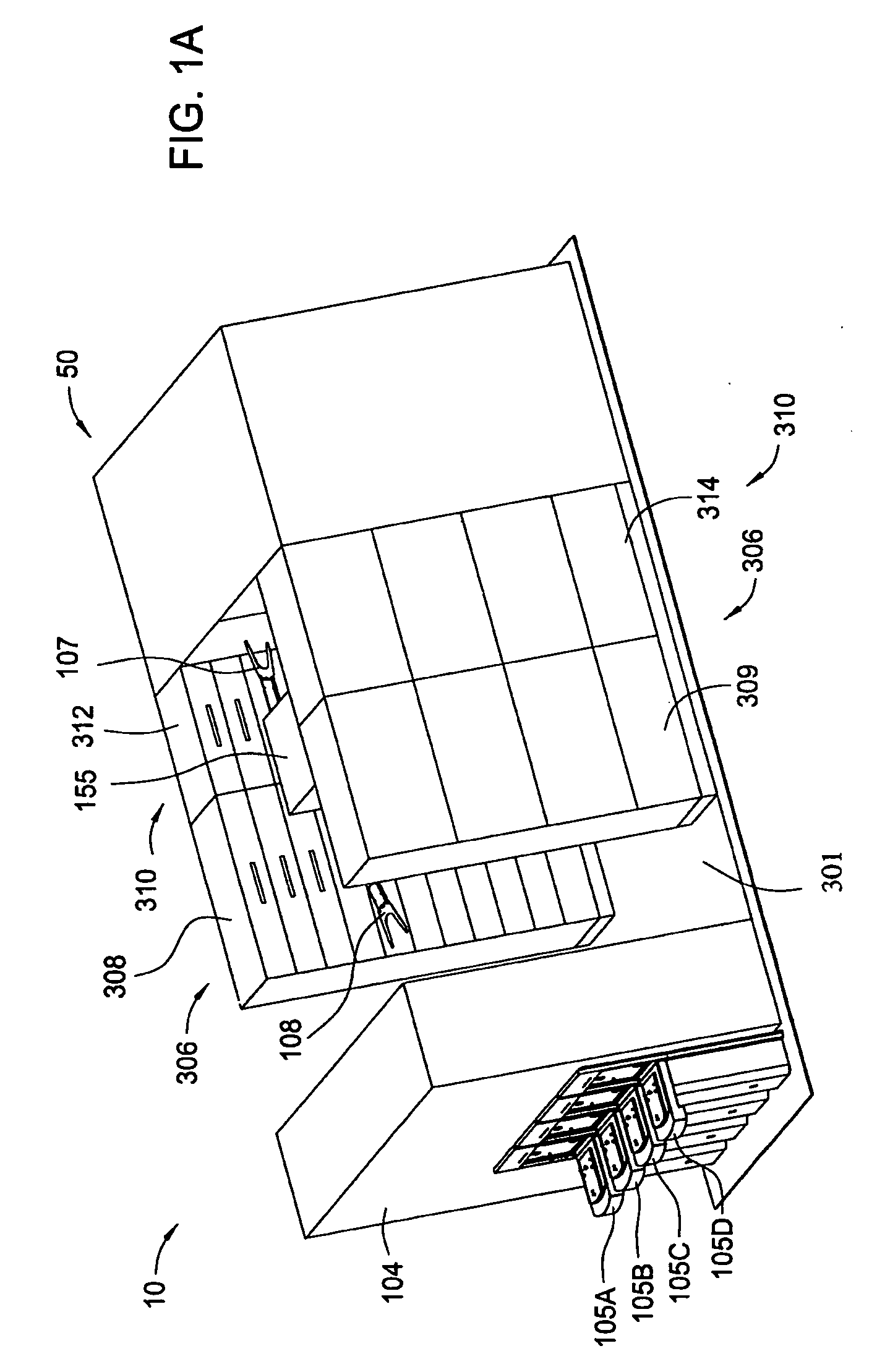

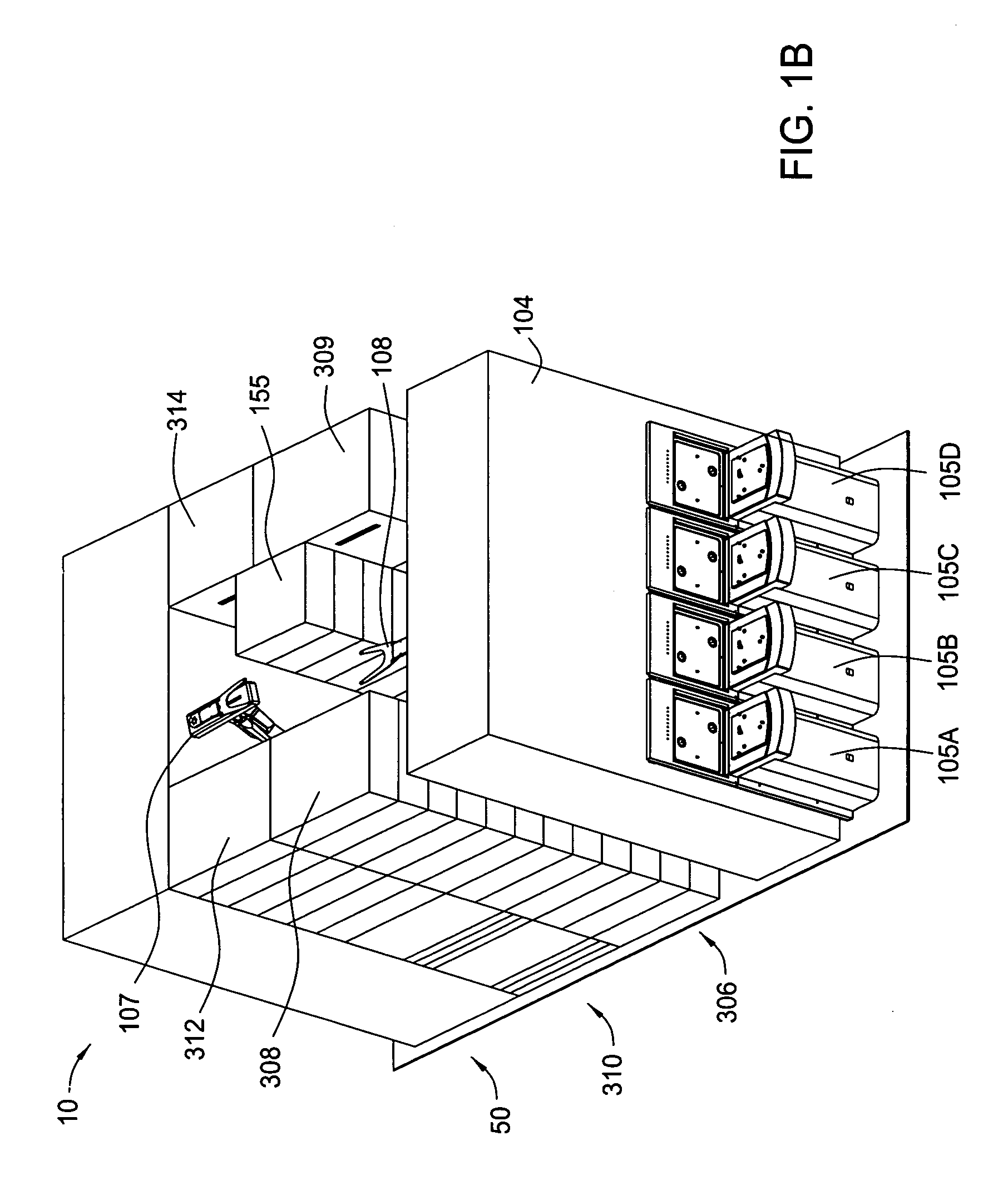

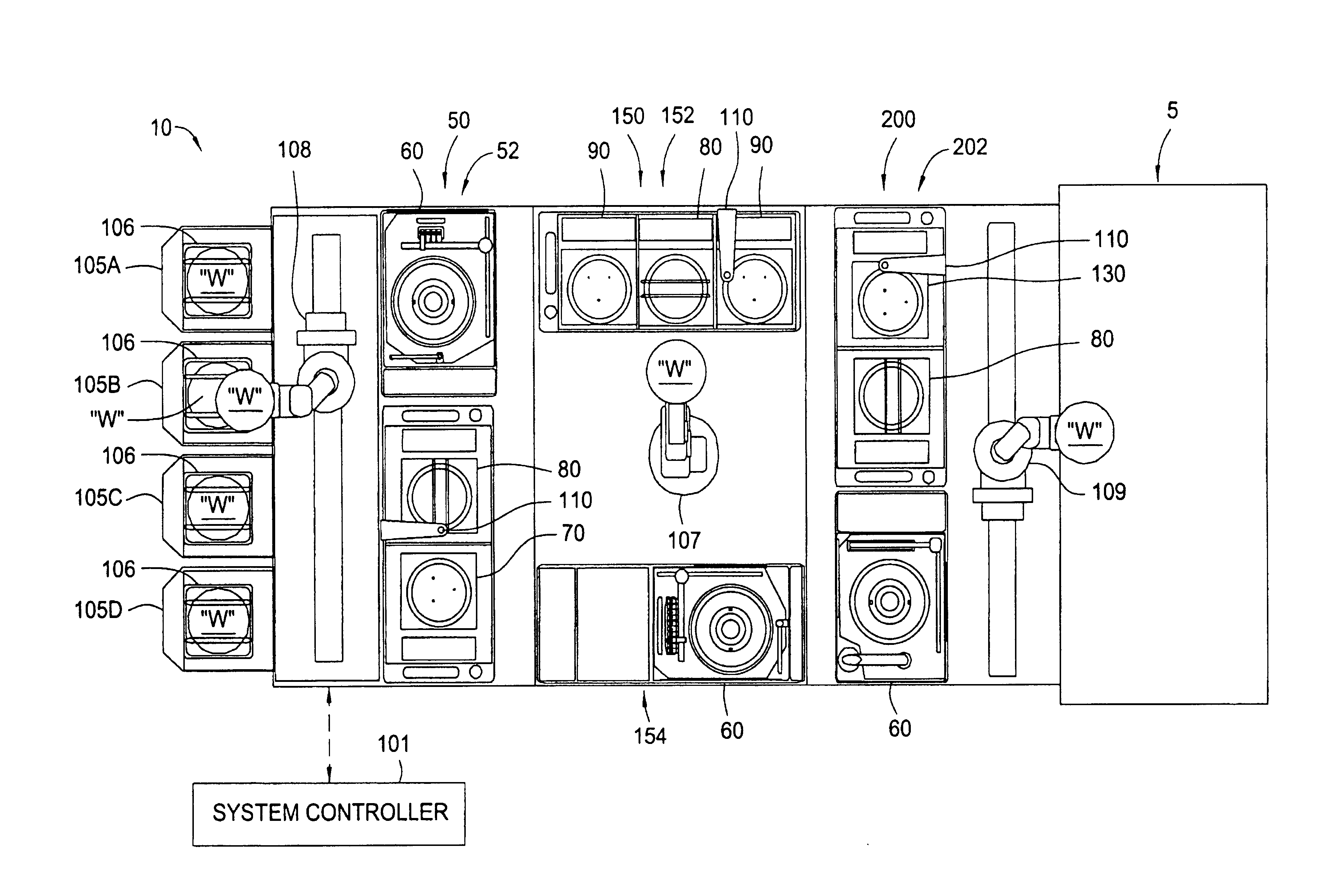

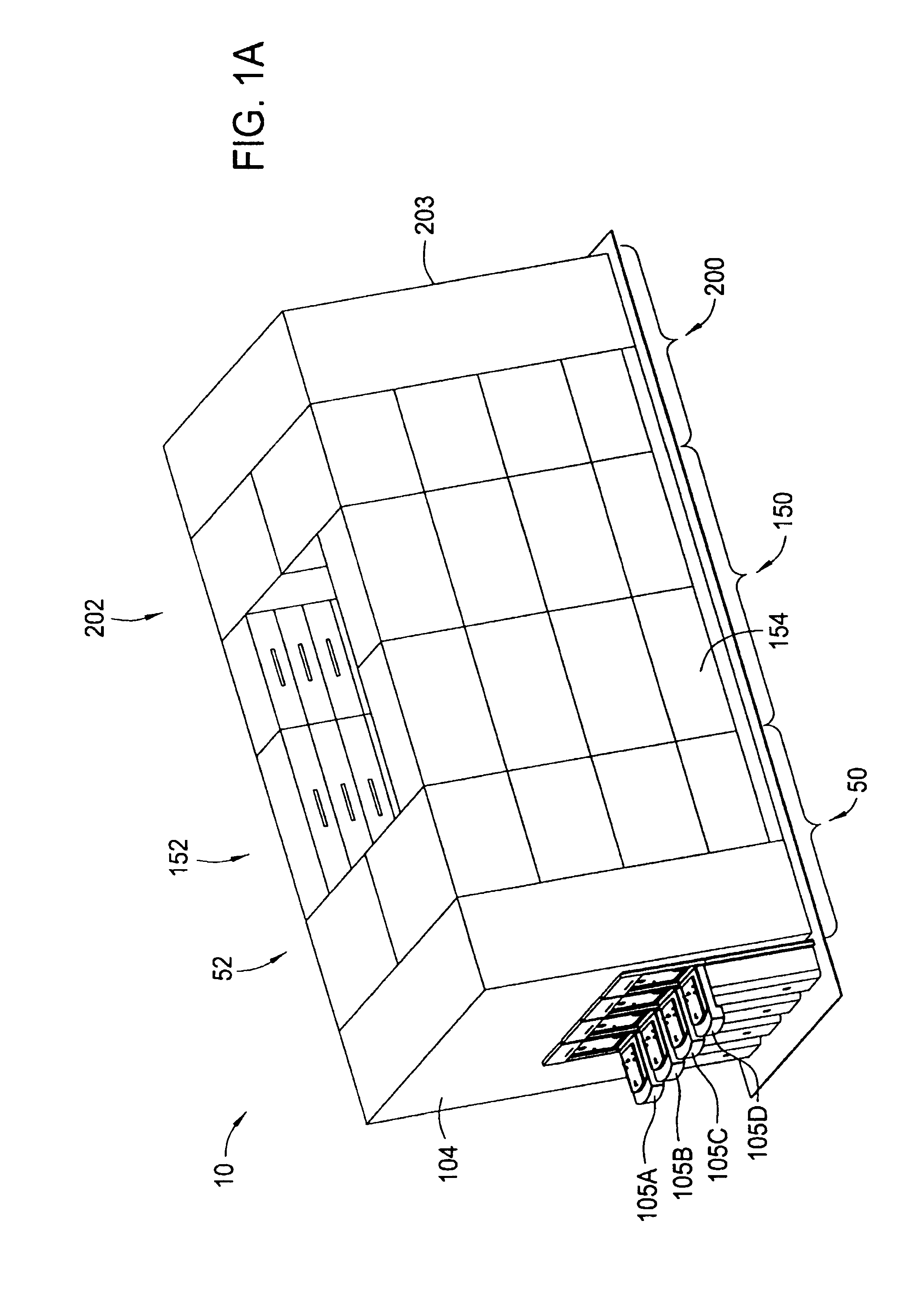

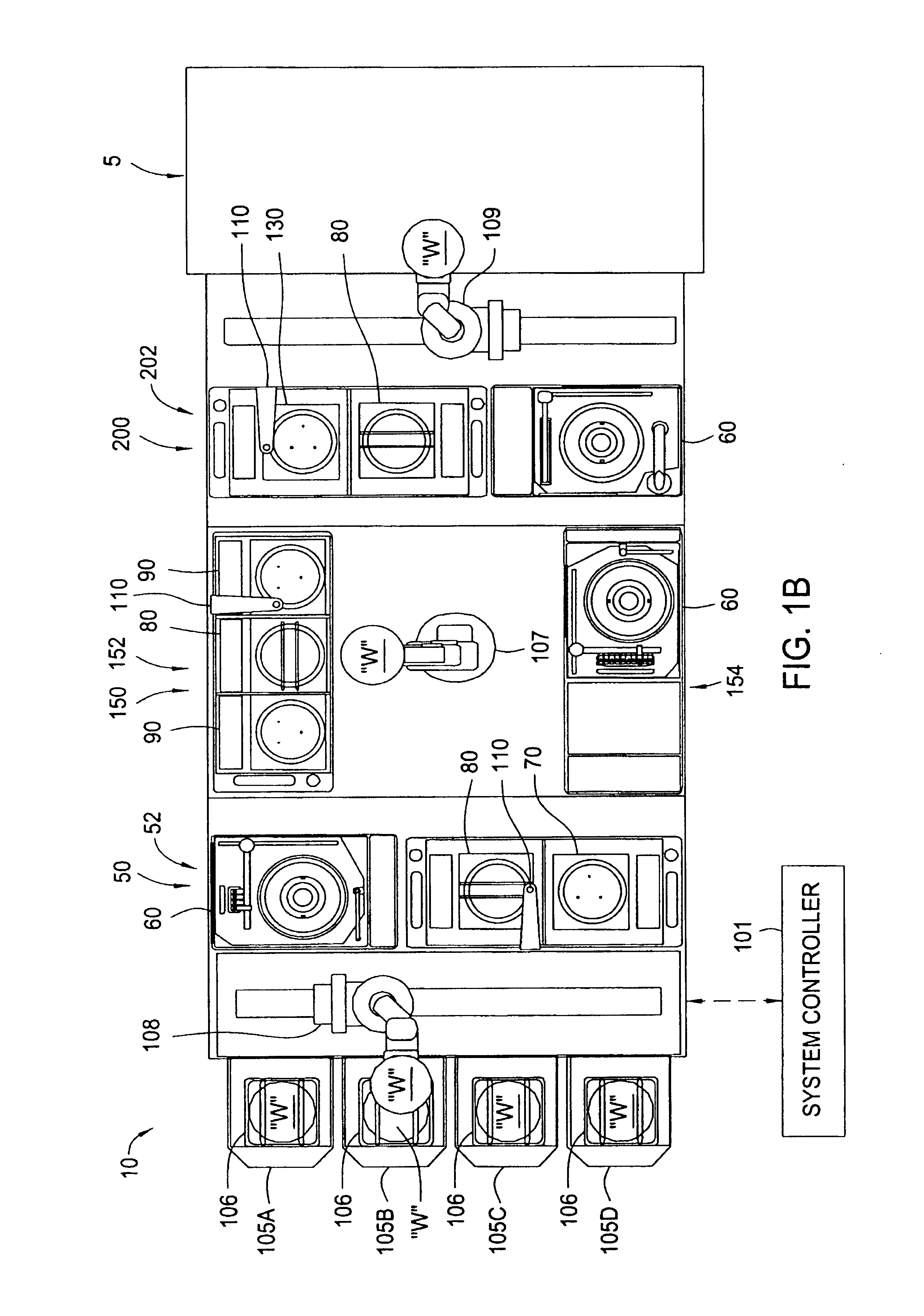

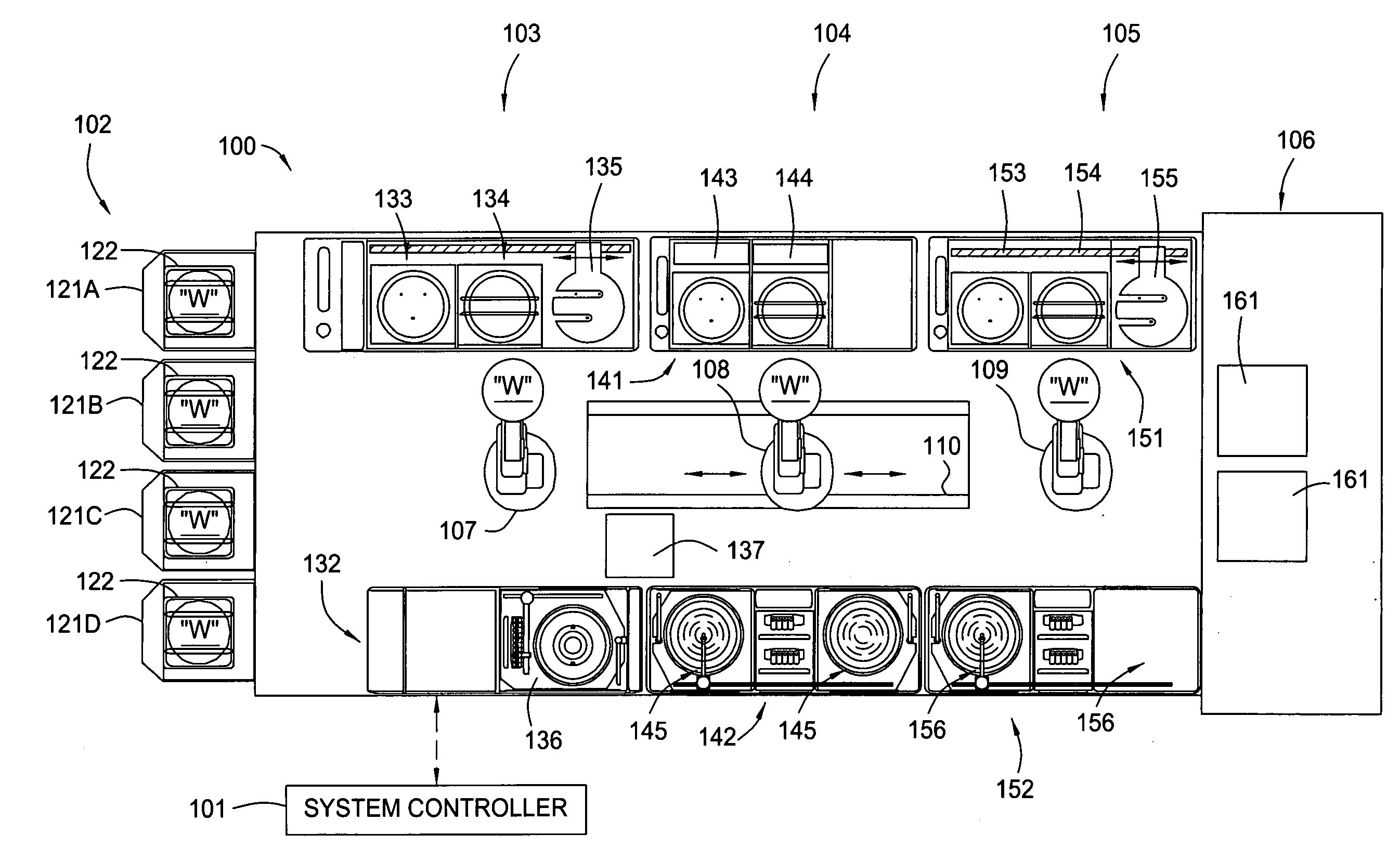

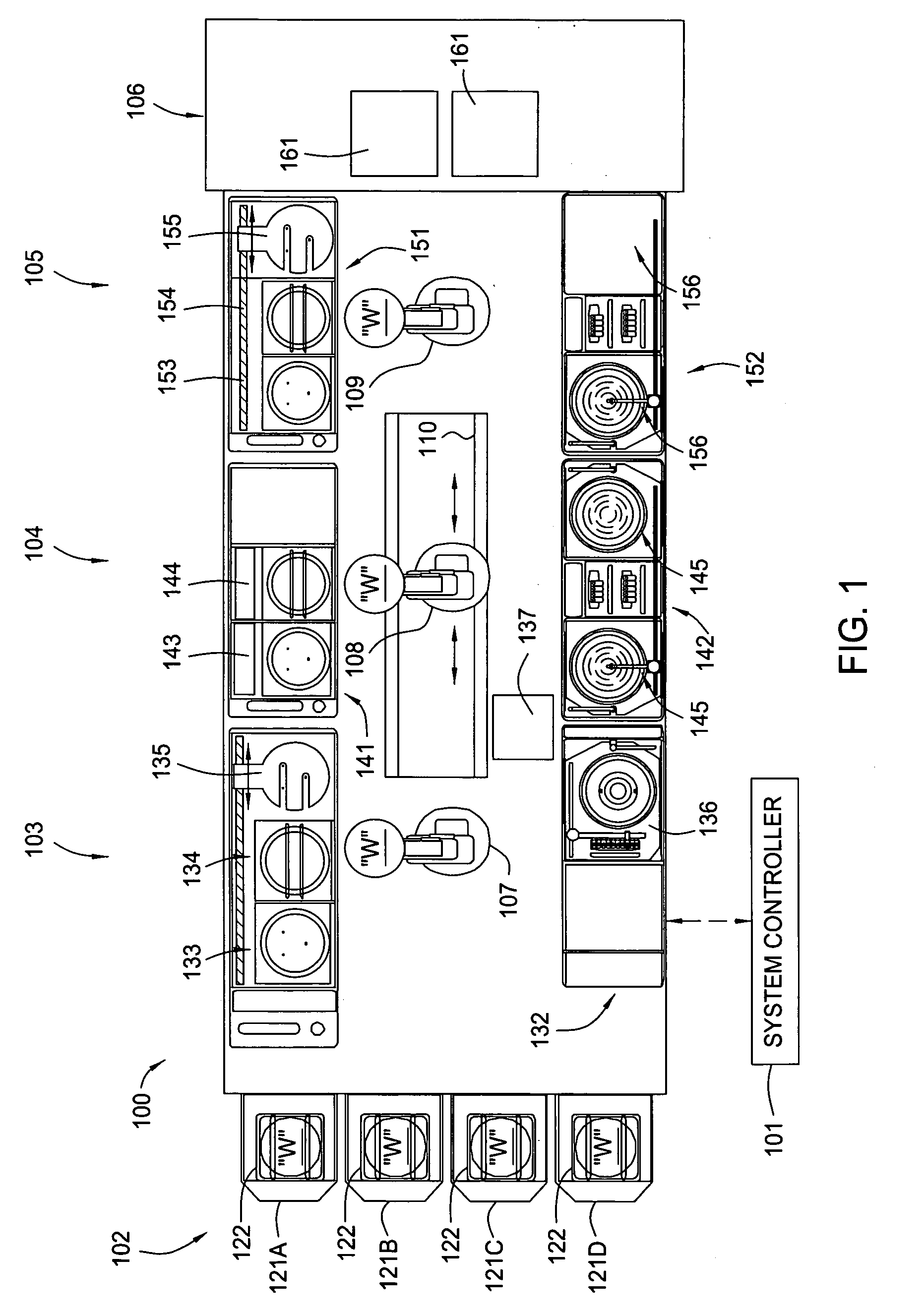

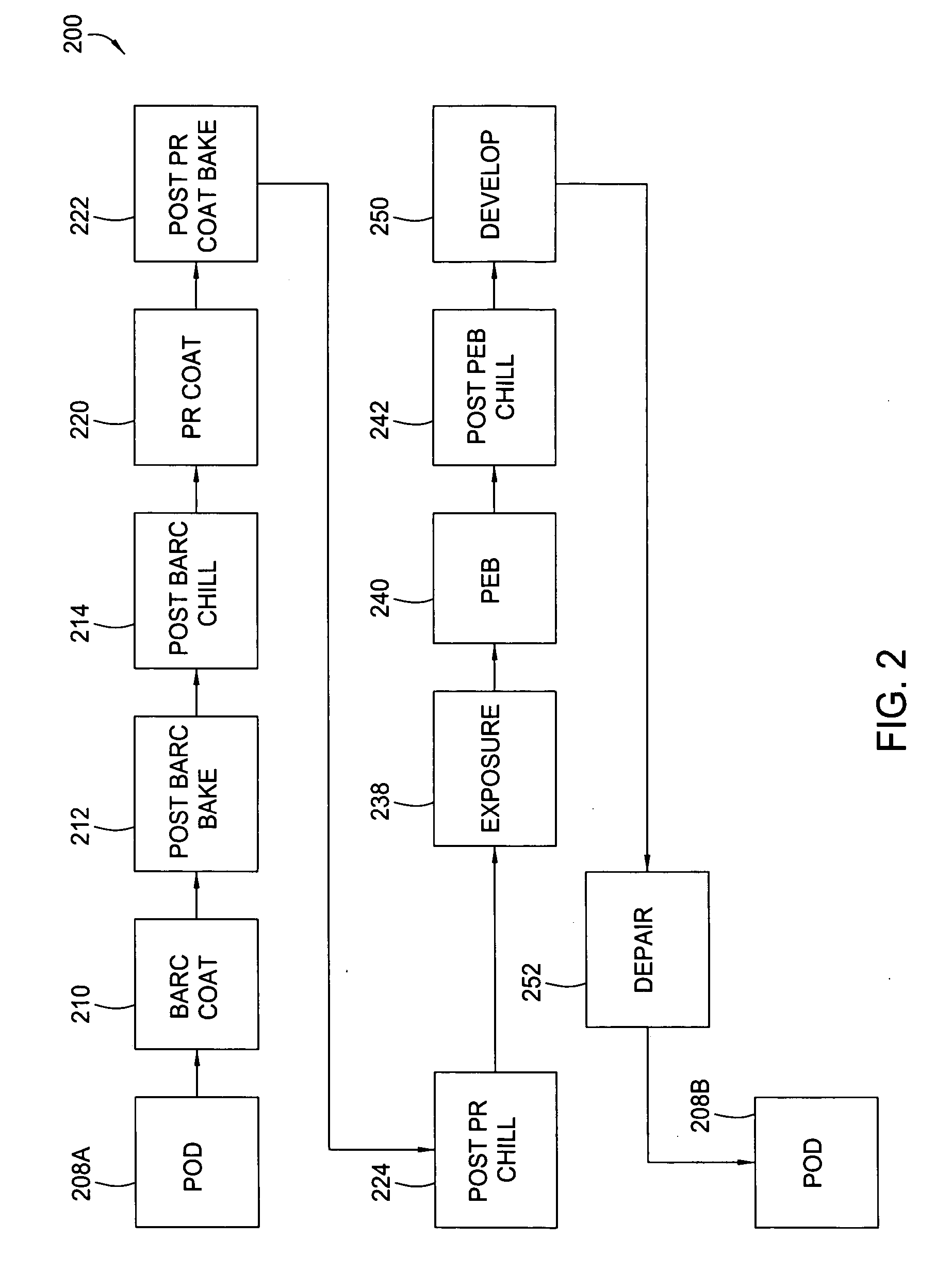

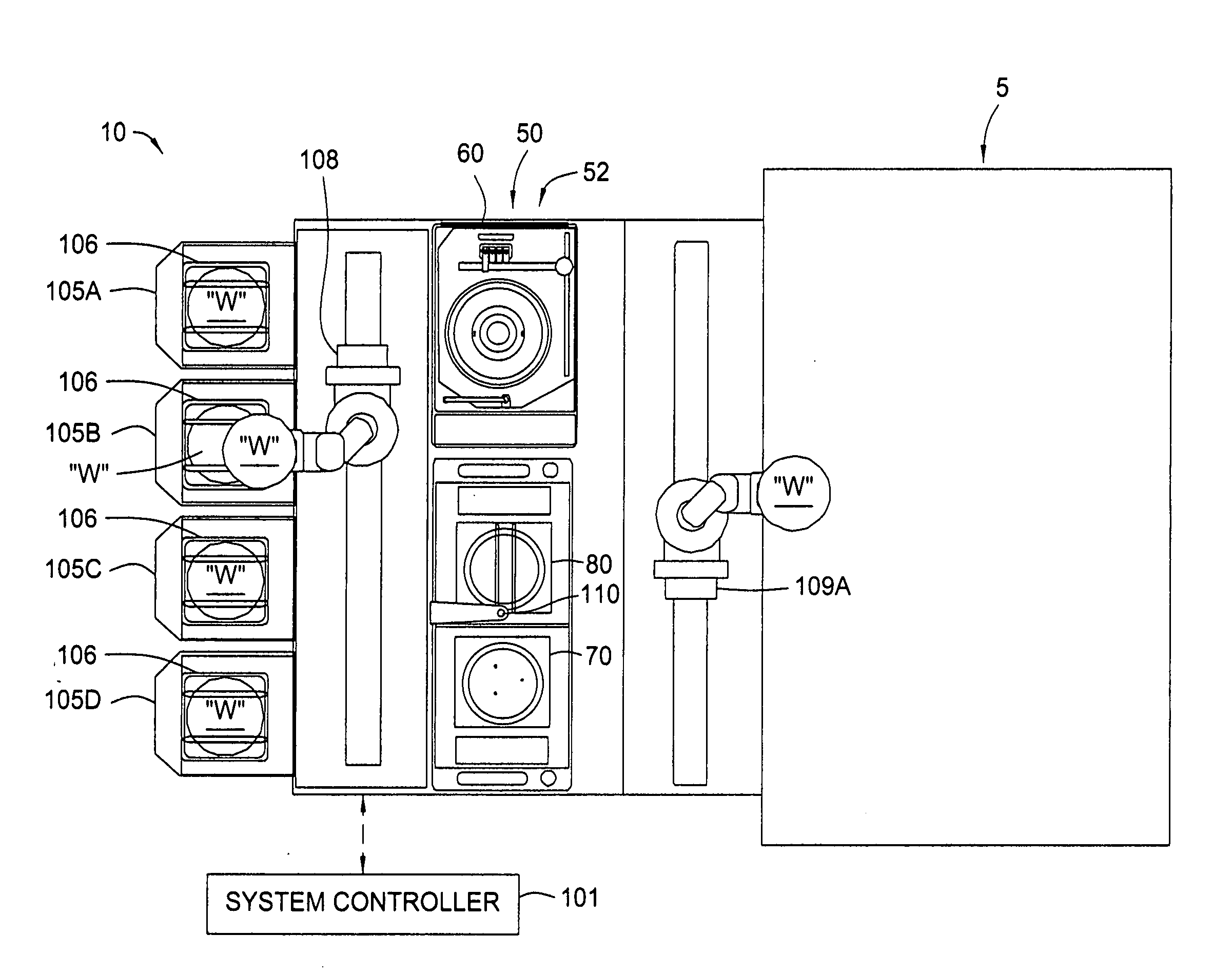

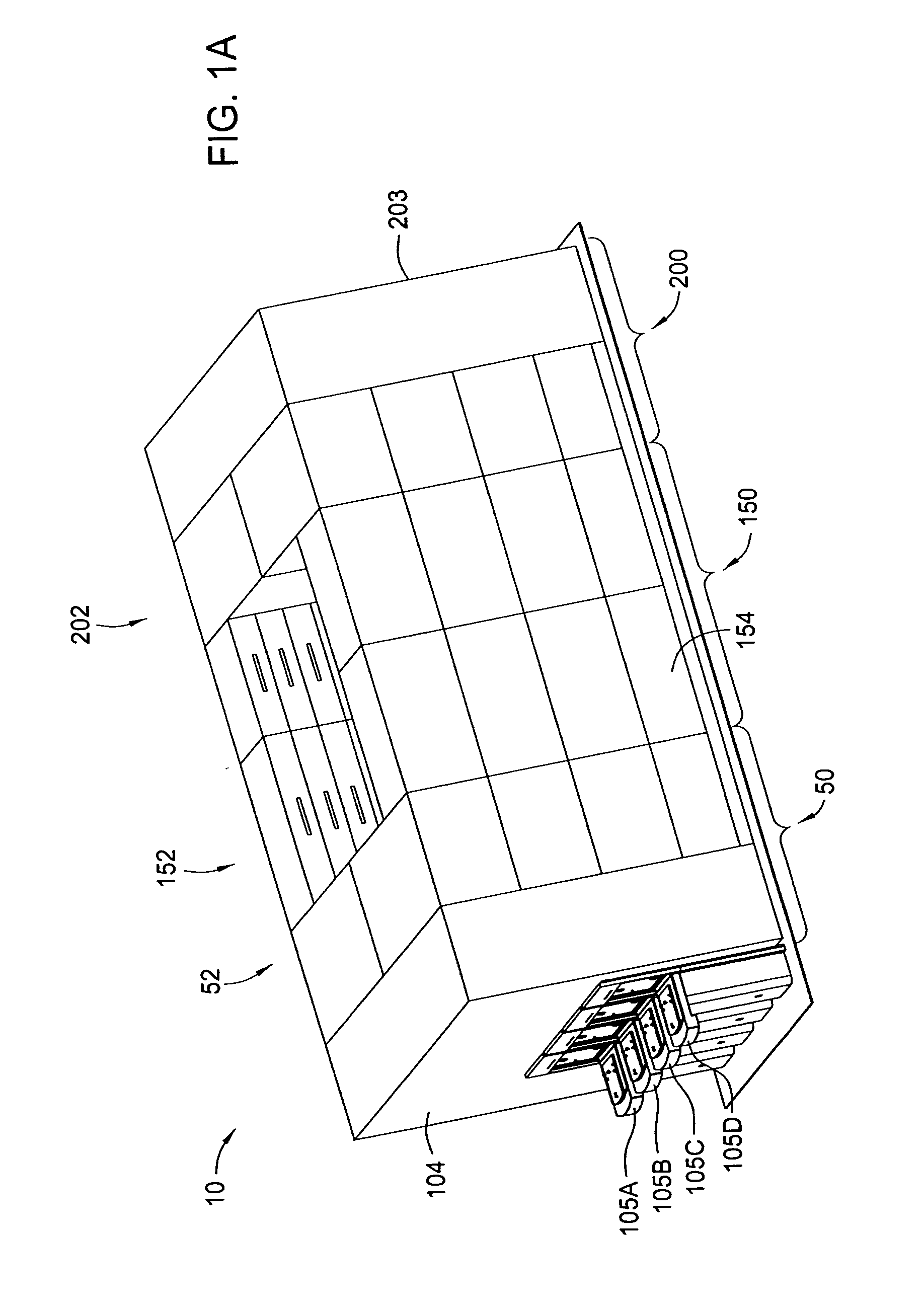

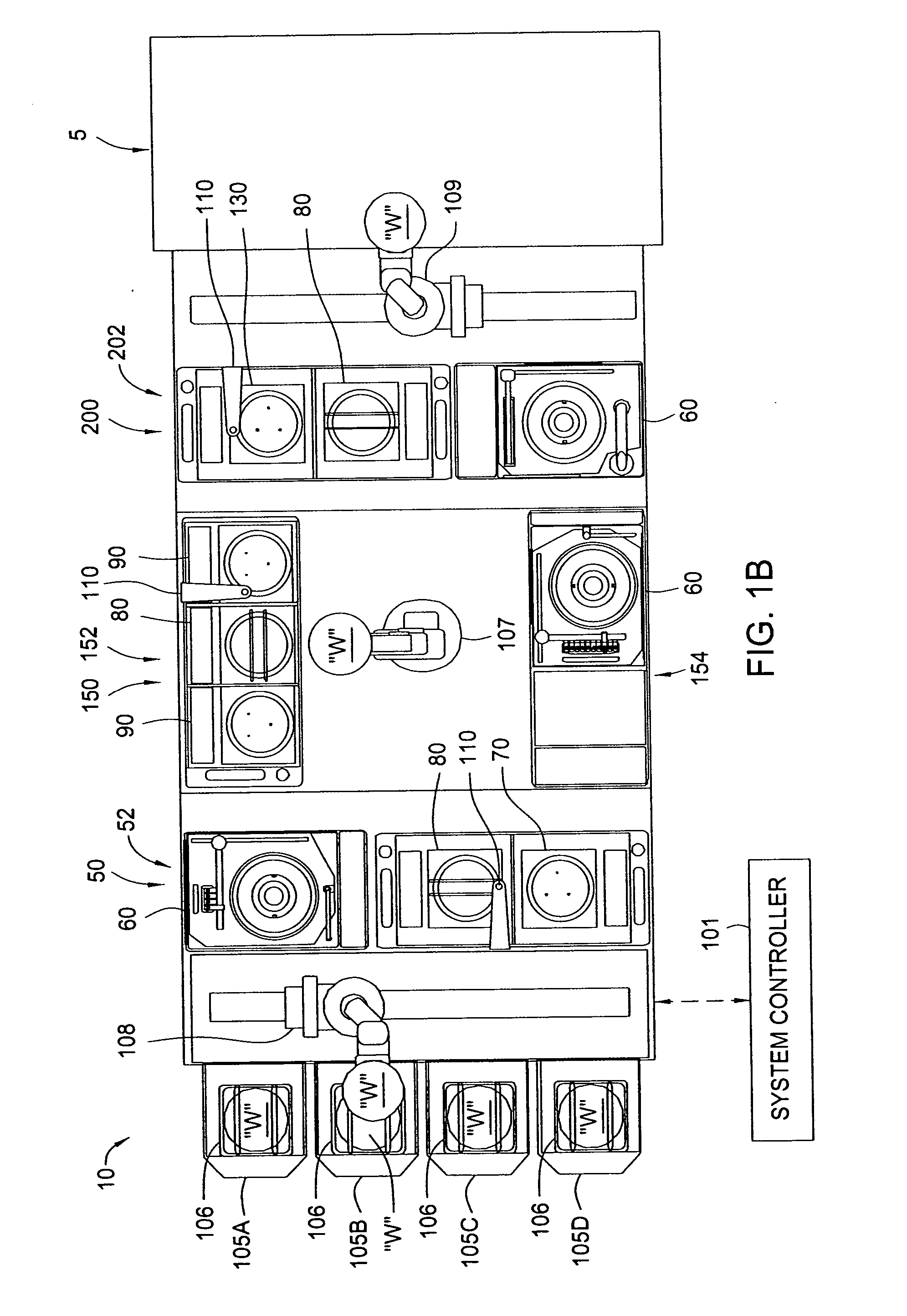

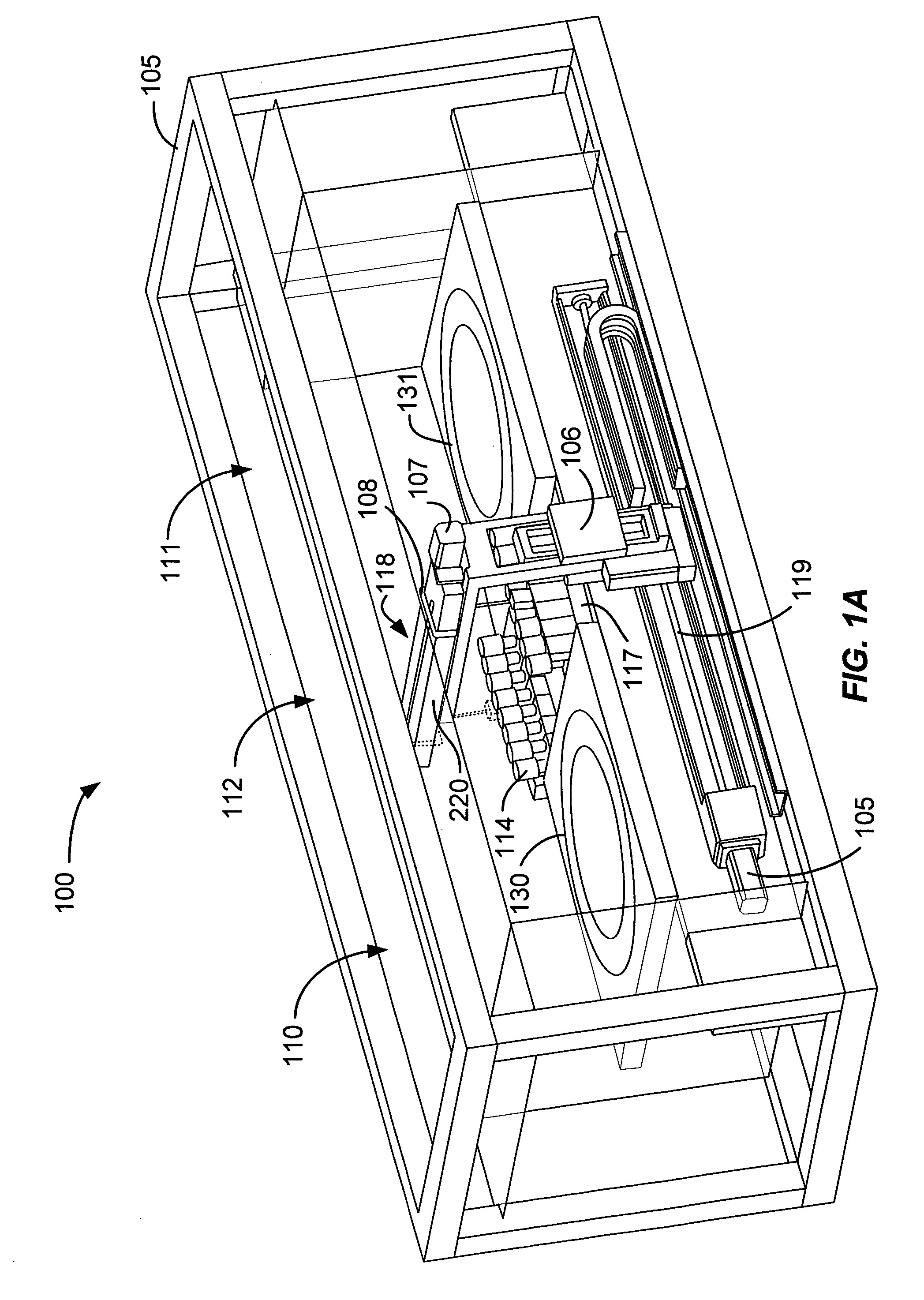

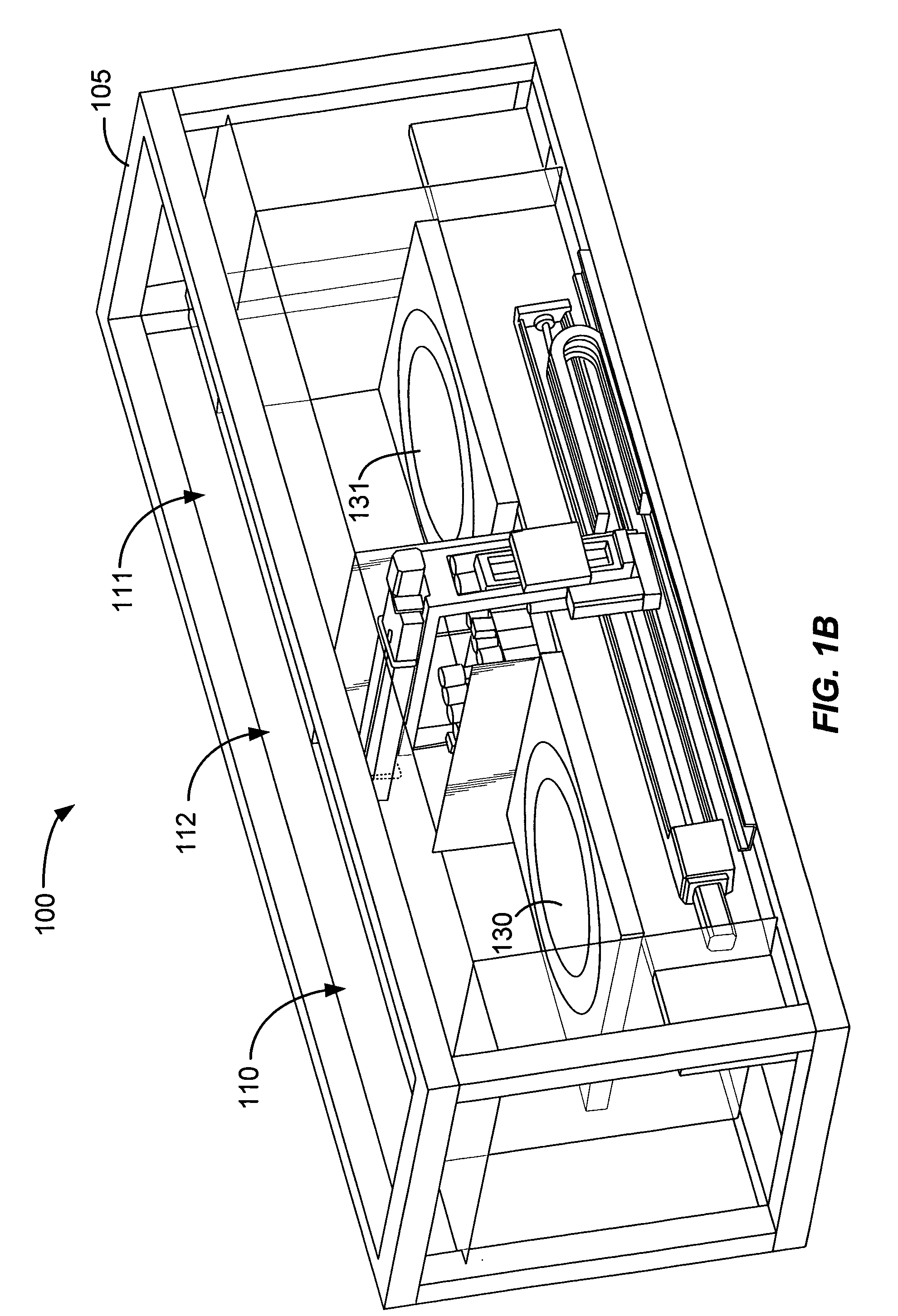

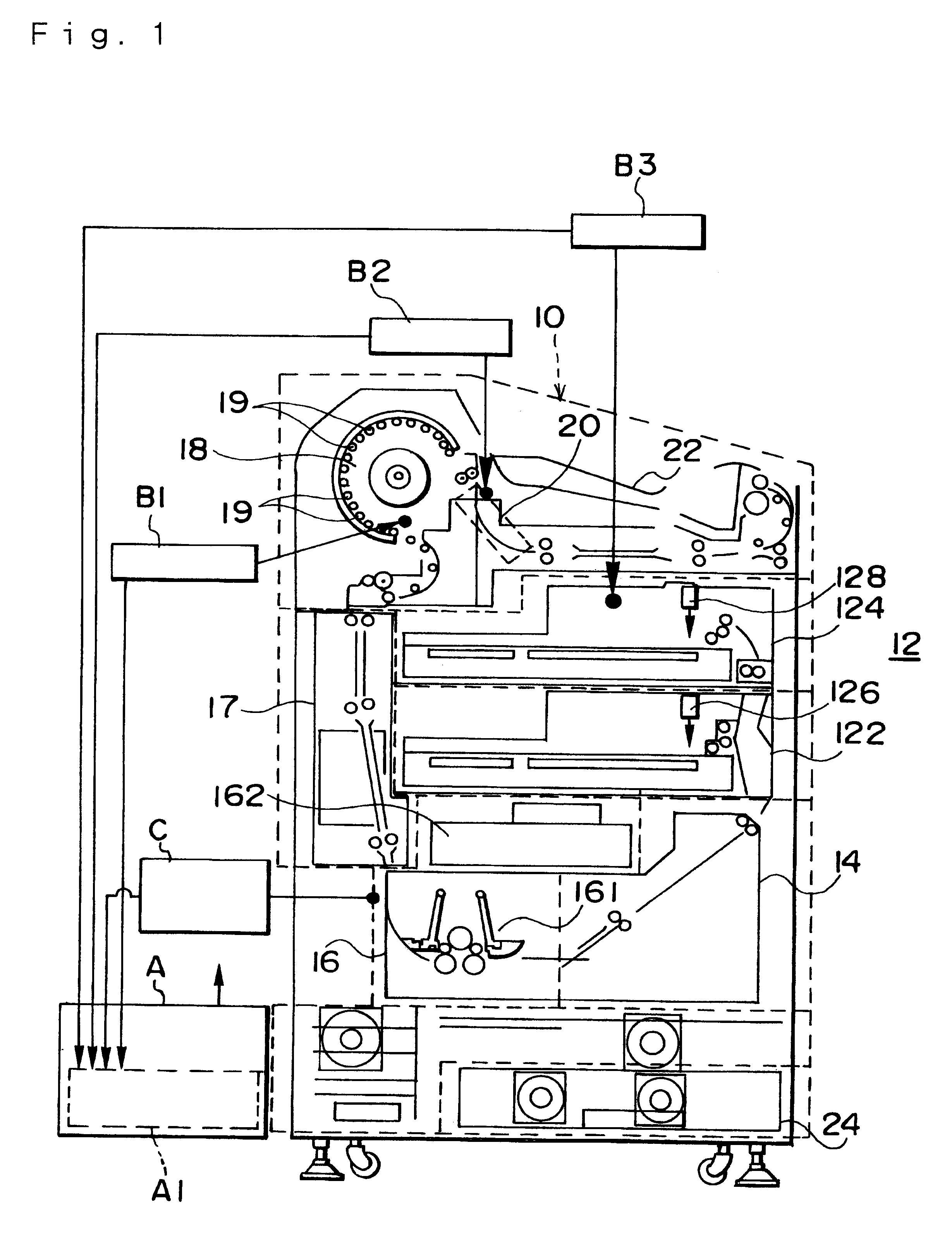

Cluster tool architecture for processing a substrate

ActiveUS20060130750A1Temperature controlMore repeatable wafer processing historyLiquid surface applicatorsSemiconductor/solid-state device testing/measurementLithography processEngineering

Embodiments generally provide an apparatus and method for processing substrates using a multi-chamber processing system (e.g., a cluster tool) that has an increased system throughput, increased system reliability, substrates processed in the cluster tool have a more repeatable wafer history, and also the cluster tool has a smaller system footprint. In one embodiment, the cluster tool is adapted to perform a track lithography process in which a substrate is coated with a photosensitive material, is then transferred to a stepper / scanner, which exposes the photosensitive material to some form of radiation to form a pattern in the photosensitive material, which is then removed in a developing process completed in the cluster tool. In track lithography type cluster tools, since the chamber processing times tend to be rather short, and the number of processing steps required to complete a typical track system process is large, a significant portion of the time it takes to process a substrate is taken up by the processes of transferring the substrates in a cluster tool between the various processing chambers. In one embodiment of the cluster tool, the cost of ownership is reduced by grouping substrates together and transferring and processing the substrates in groups of two or more to improve system throughput, and reduces the number of moves a robot has to make to transfer a batch of substrates between the processing chambers, thus reducing wear on the robot and increasing system reliability. In one aspect of the invention, the substrate processing sequence and cluster tool are designed so that the substrate transferring steps performed during the processing sequence are only made to chambers that will perform the next processing step in the processing sequence. Embodiments also provide for a method and apparatus that are used to improve the coater chamber, the developer chamber, the post exposure bake chamber, the chill chamber, and the bake chamber process results. Embodiments also provide for a method and apparatus that are used to increase the reliability of the substrate transfer process to reduce system down time.

Owner:SCREEN SEMICON SOLUTIONS CO LTD

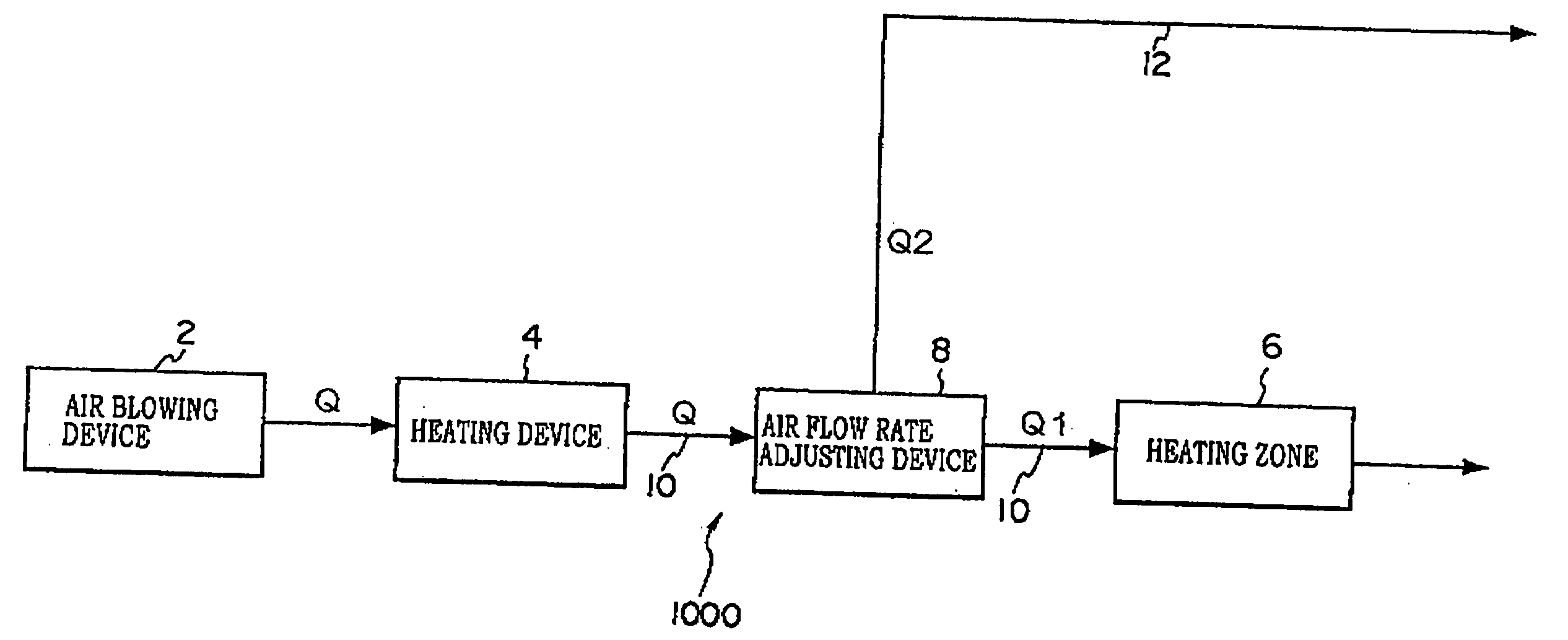

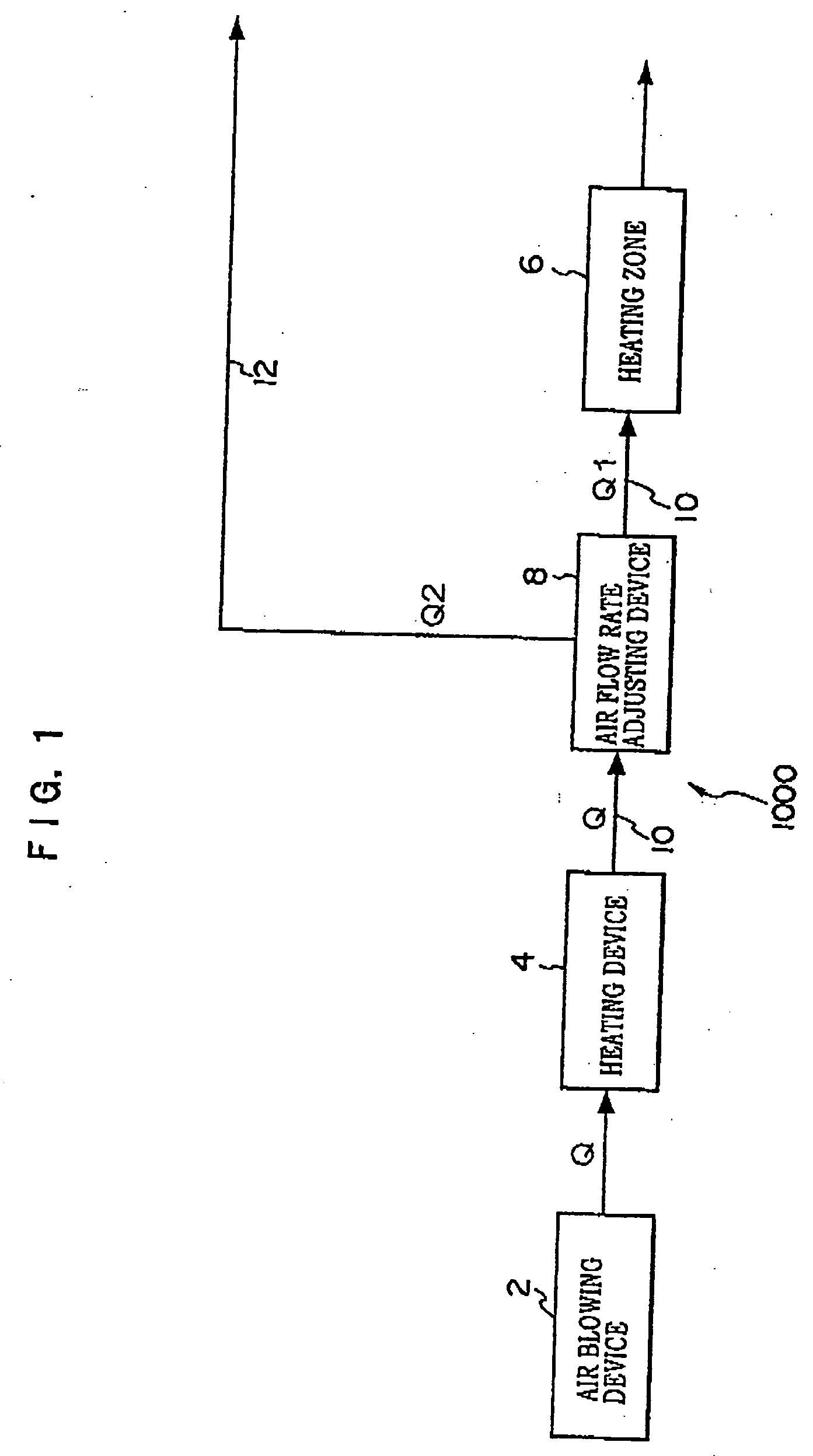

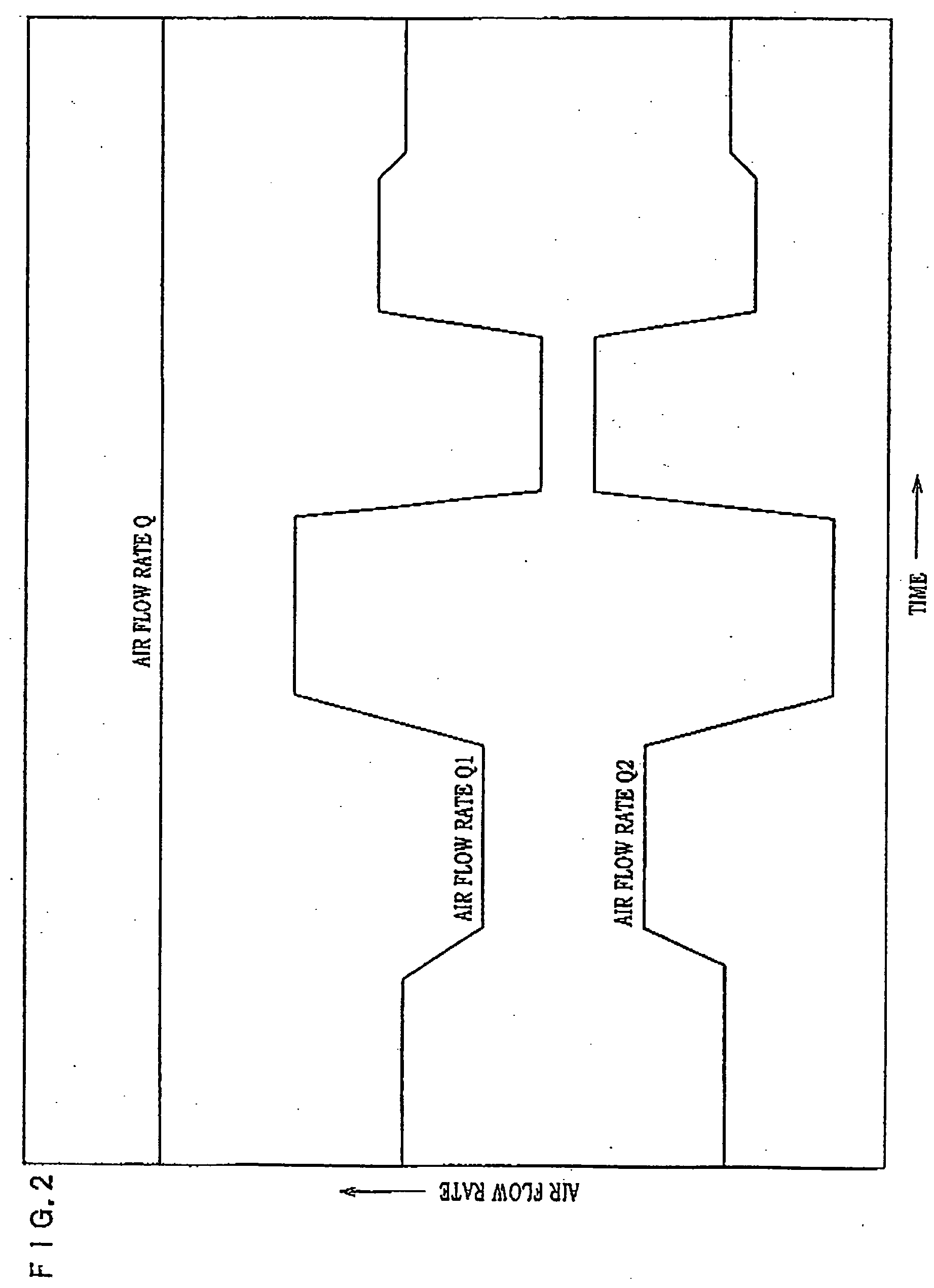

Heating method for a band-shaped body and heating apparatus for a band-shaped body

InactiveUS20050121436A1Minimize fluctuationMaterial minimizationDrying solid materials with heatPhotomechanical apparatusBand shapeElectrical and Electronics engineering

Owner:FUJIFILM HLDG CORP +1

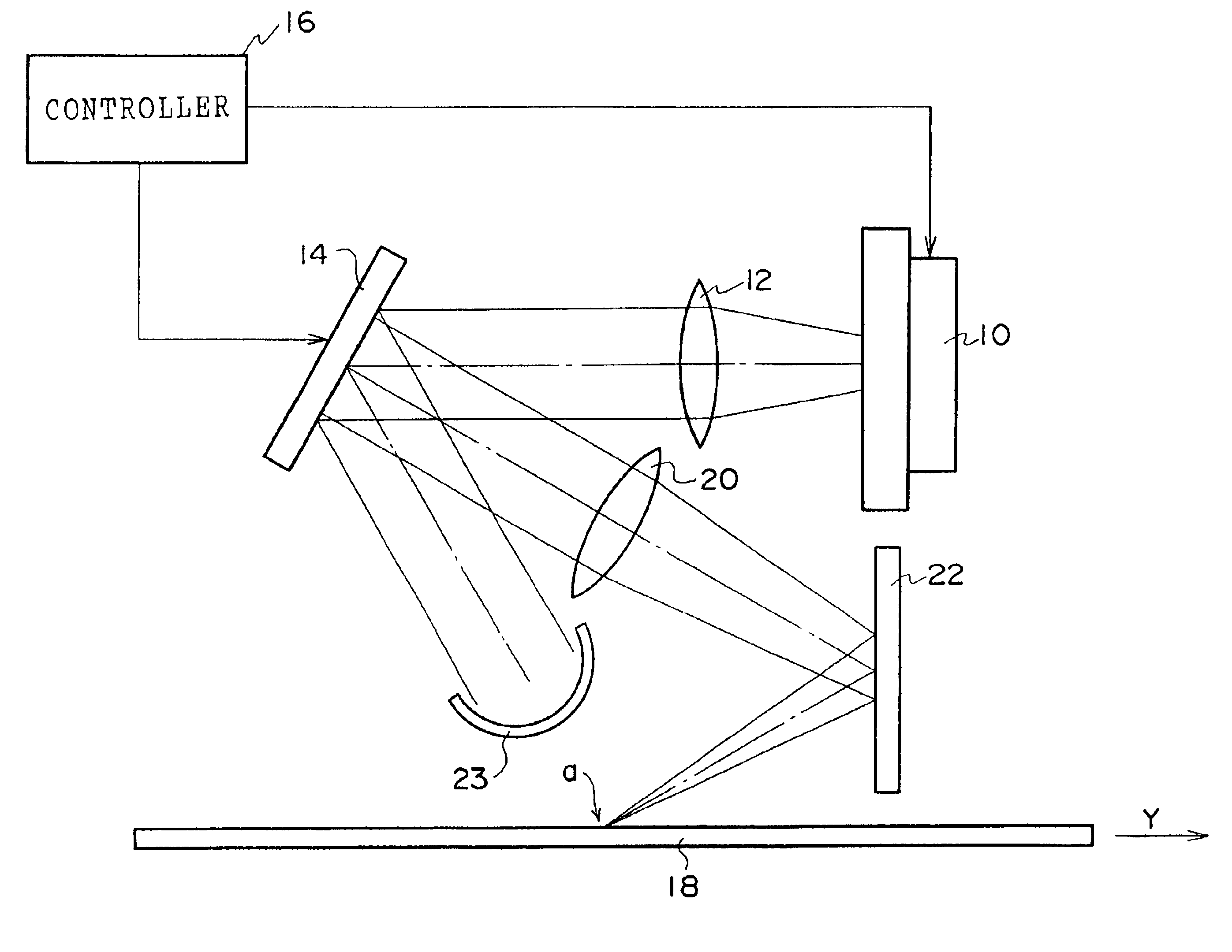

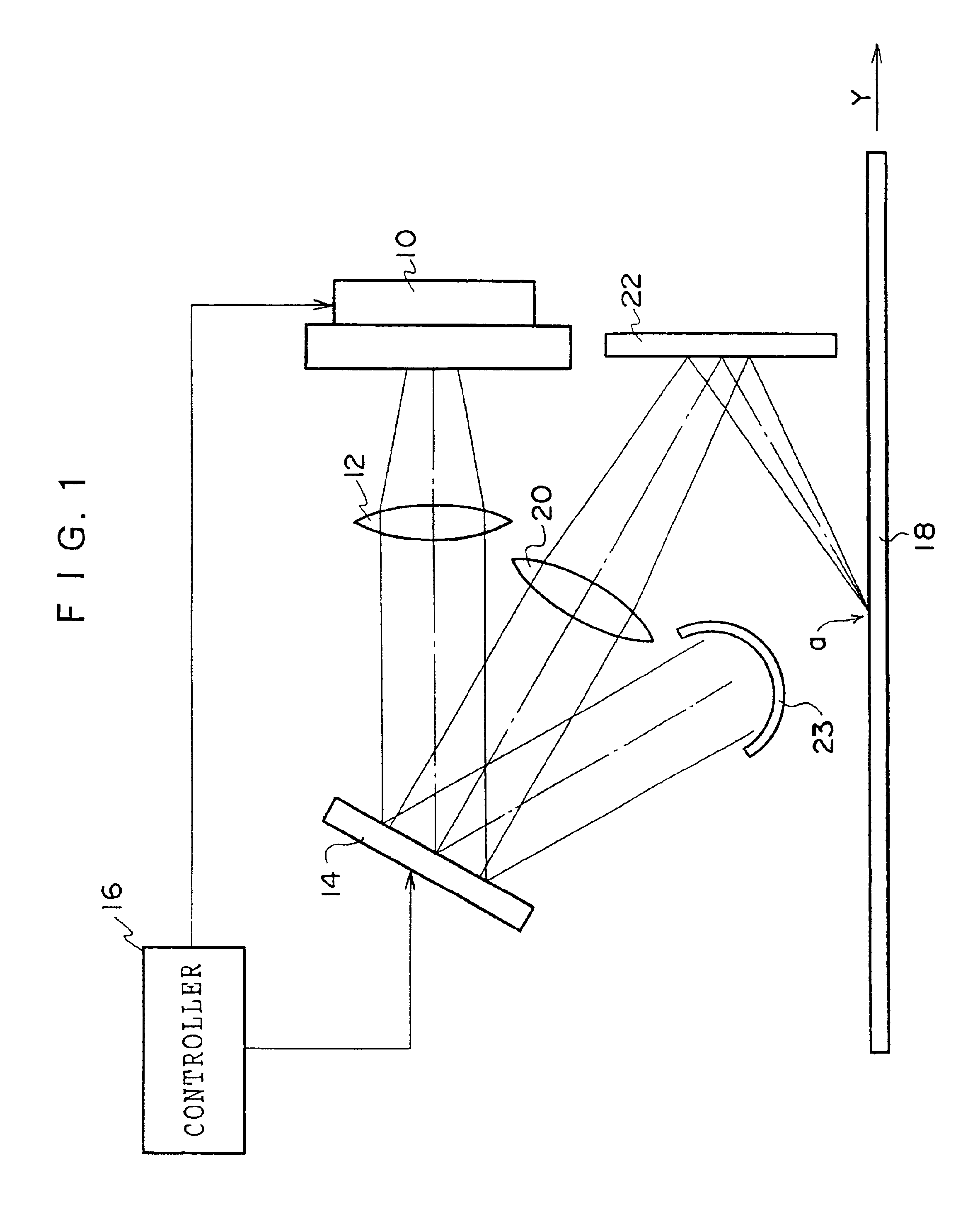

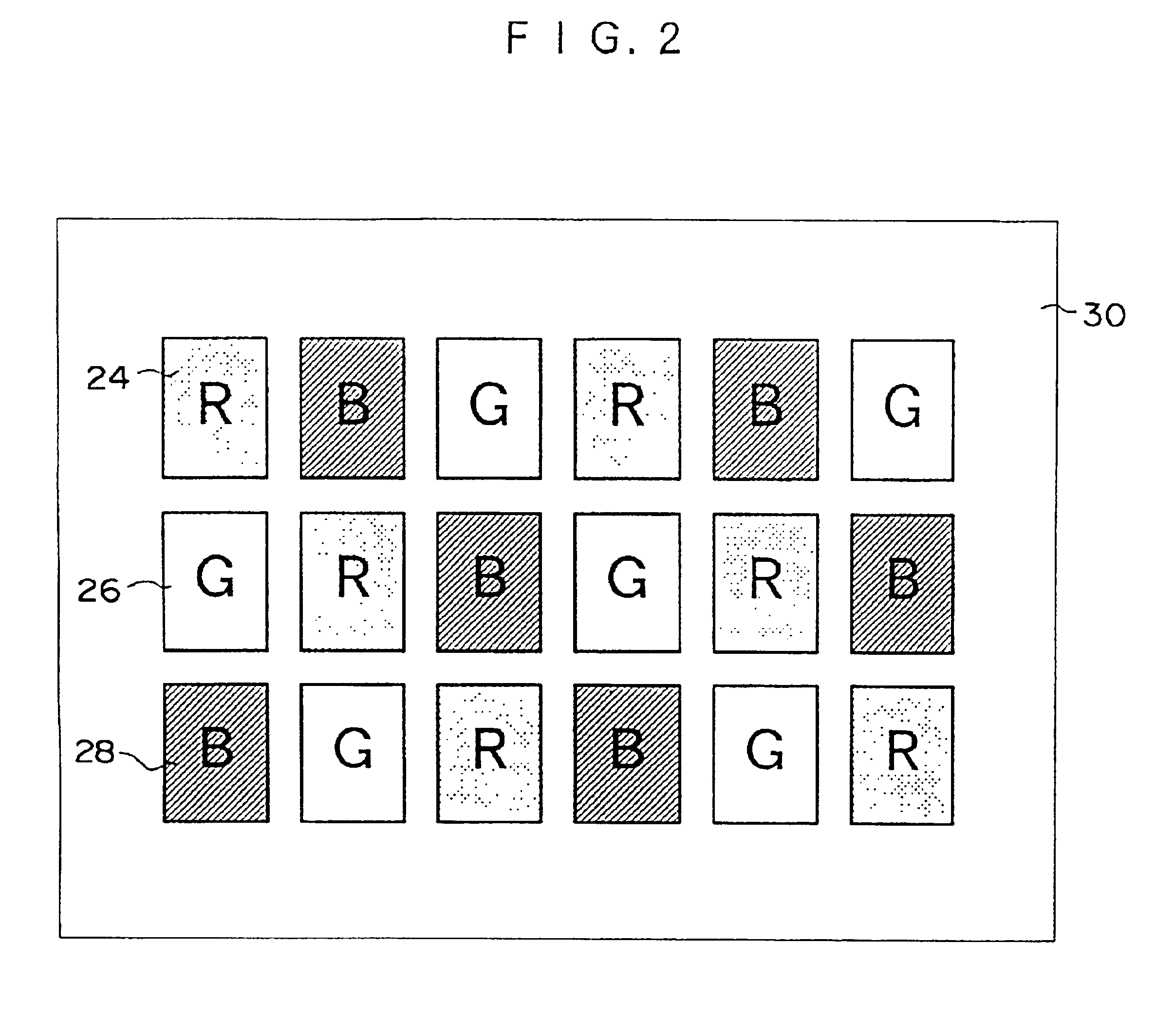

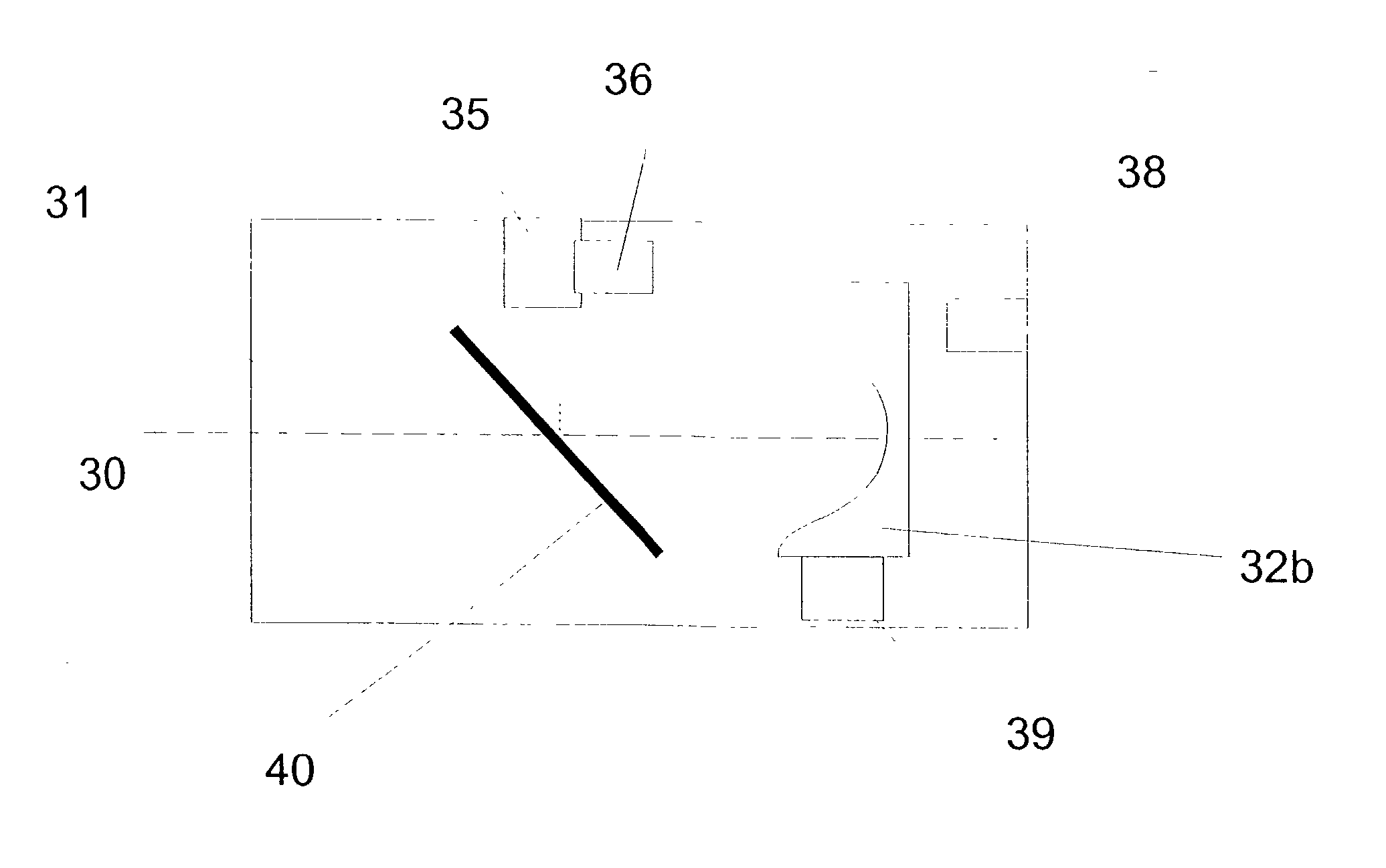

Image recording device

InactiveUS6900901B2Prevents generation of crosstalkSmall and inexpensiveDigitally marking record carriersOptical filtersLight beamImage recording

When a recording starting point of a color photosensitive material reaches a position on which light beams are focused by a condenser lens and a reflecting mirror, a light beam is emitted from a red organic EL element of a light source by a controller, and red image data corresponding to a plurality of lines is transferred to a DMD. In accordance with the image data, on-off control of micromirrors of the DMD is carried out, and the red light beam emitted from the light source is made incident on the DMD. When the micromirrors are on, the incident light beam is reflected toward the reflecting mirror. The light beam is focused onto a recording surface of the color photosensitive material by the condenser lens and the reflecting mirror, and red exposure is carried out. Subsequently, green exposure and blue exposure are carried out in the same way.

Owner:FUJIFILM HLDG CORP +1

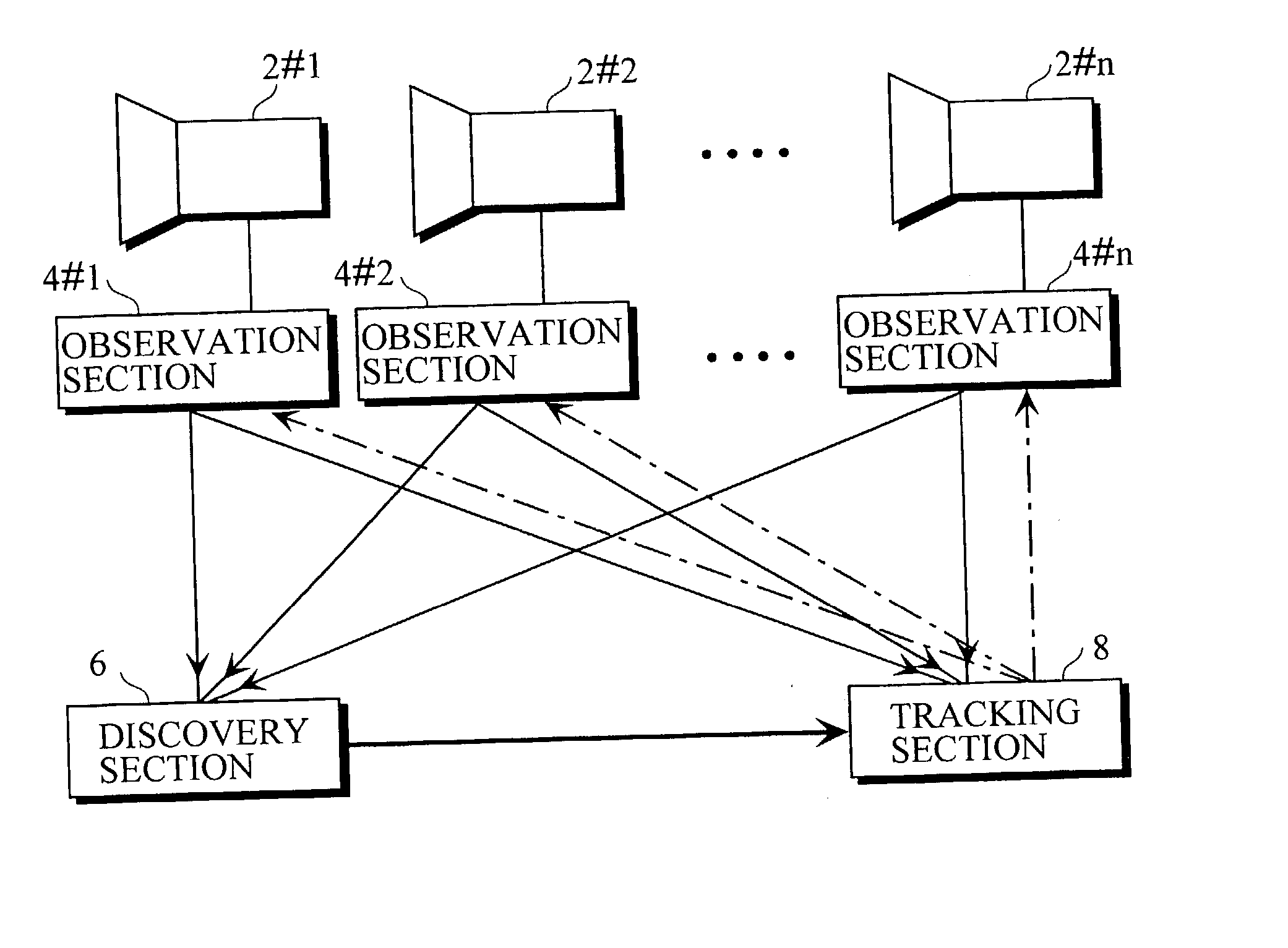

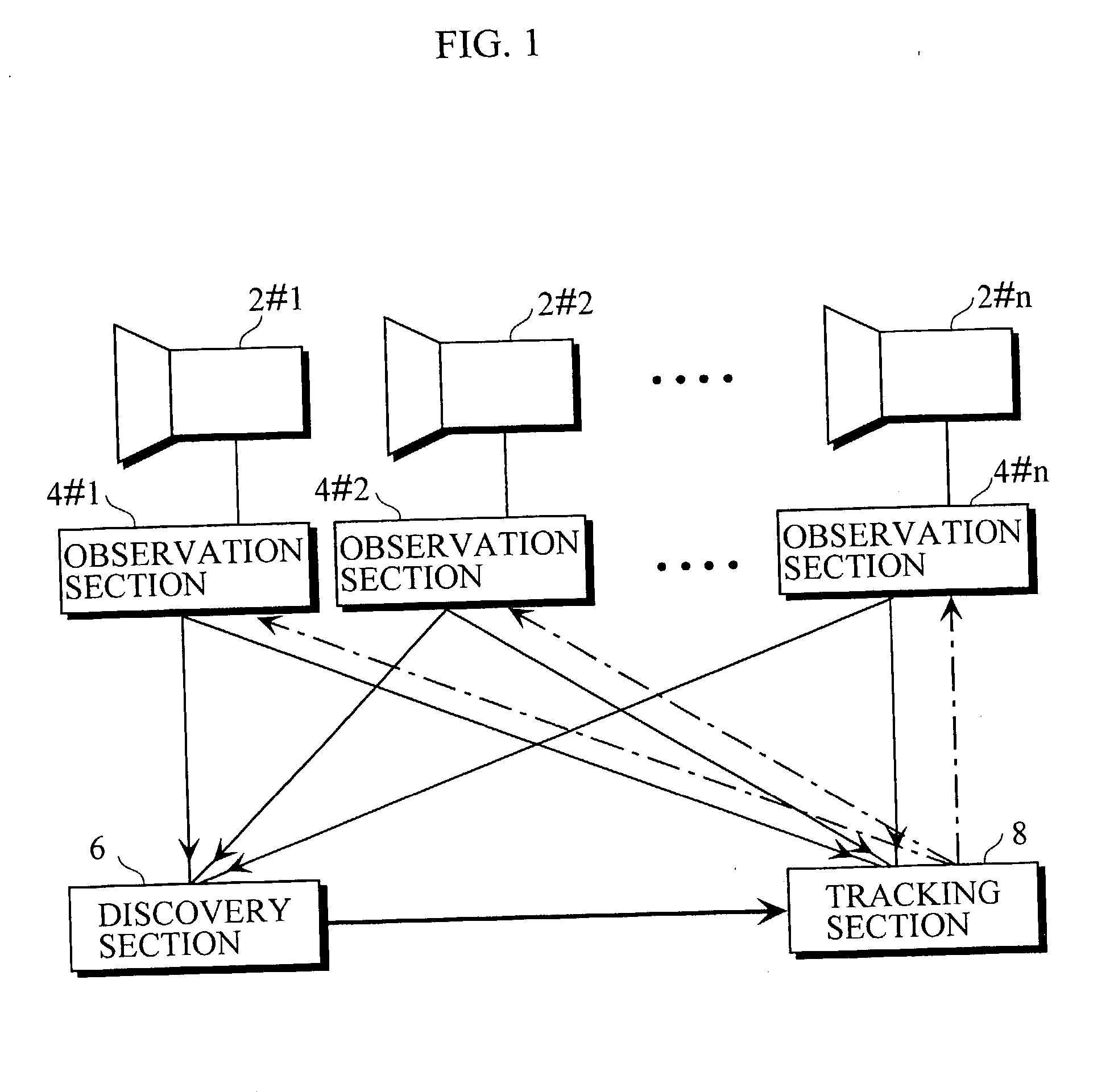

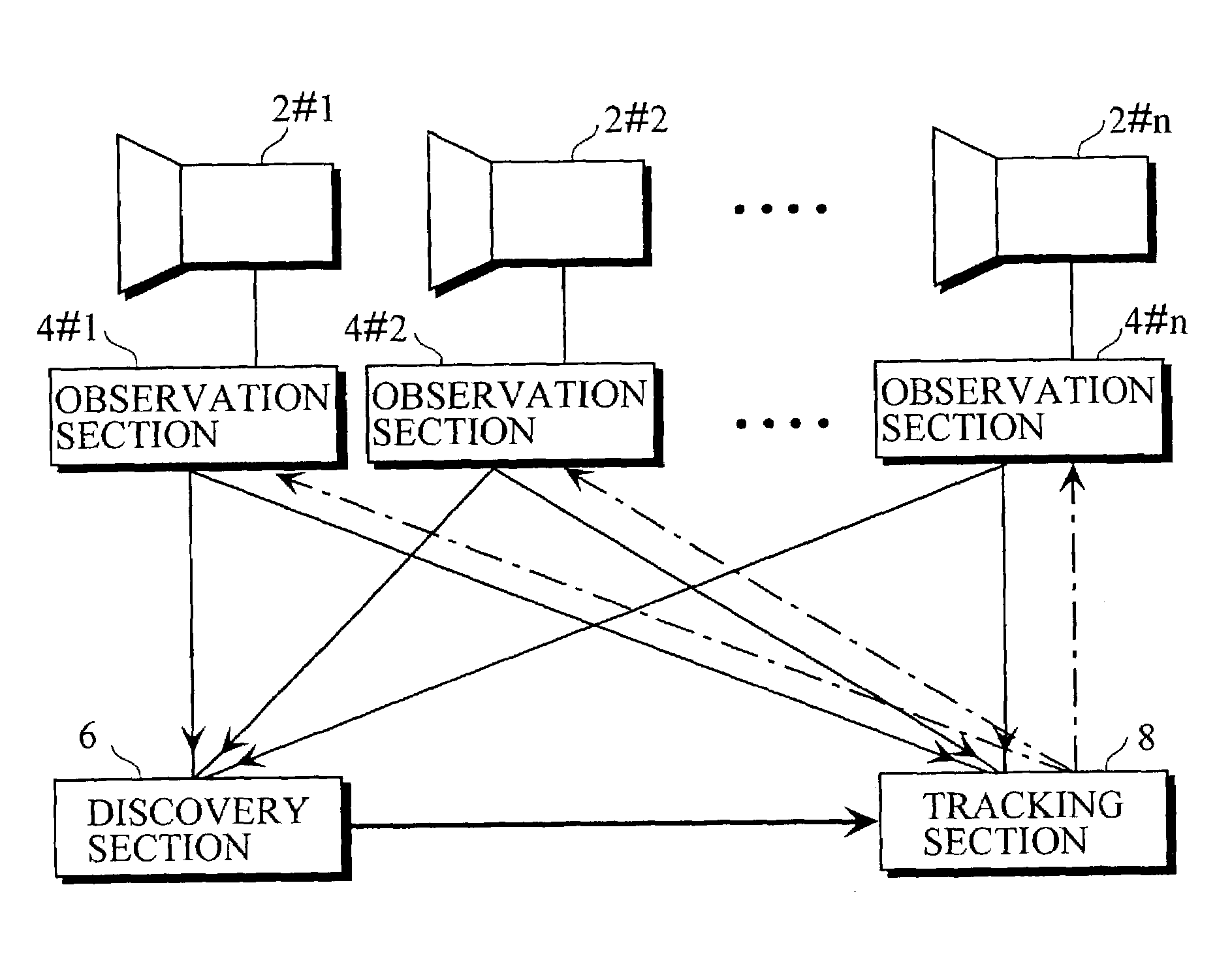

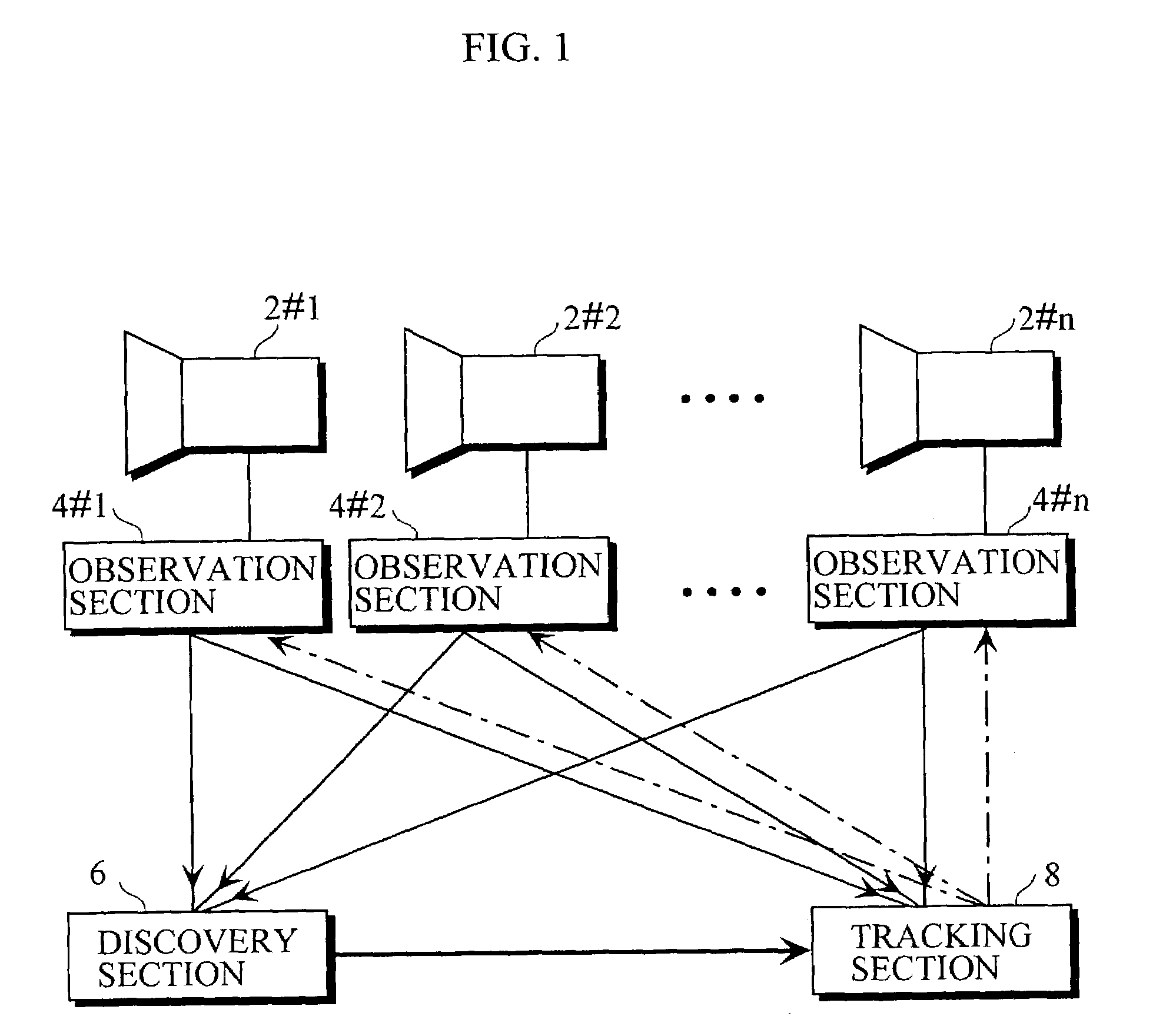

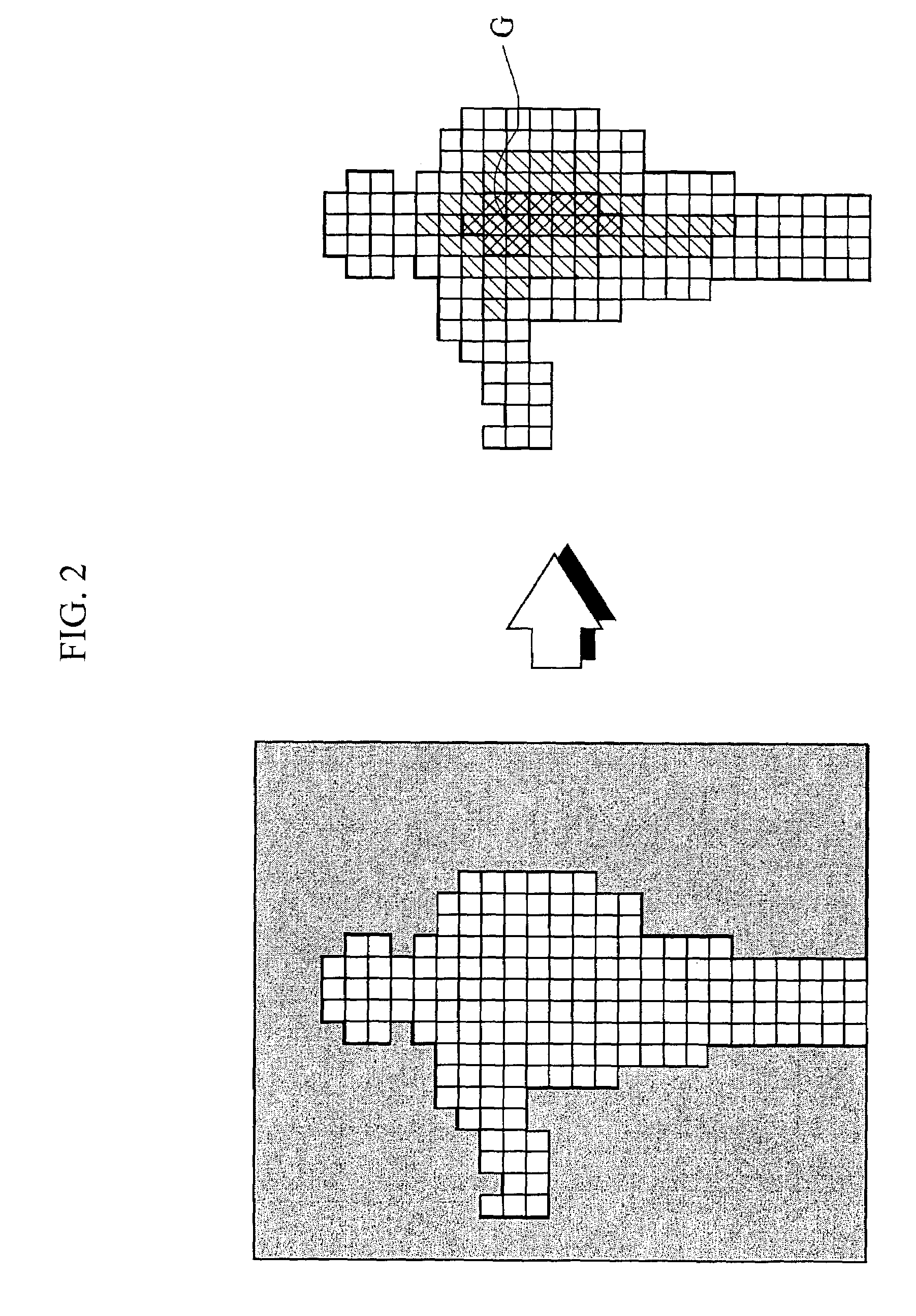

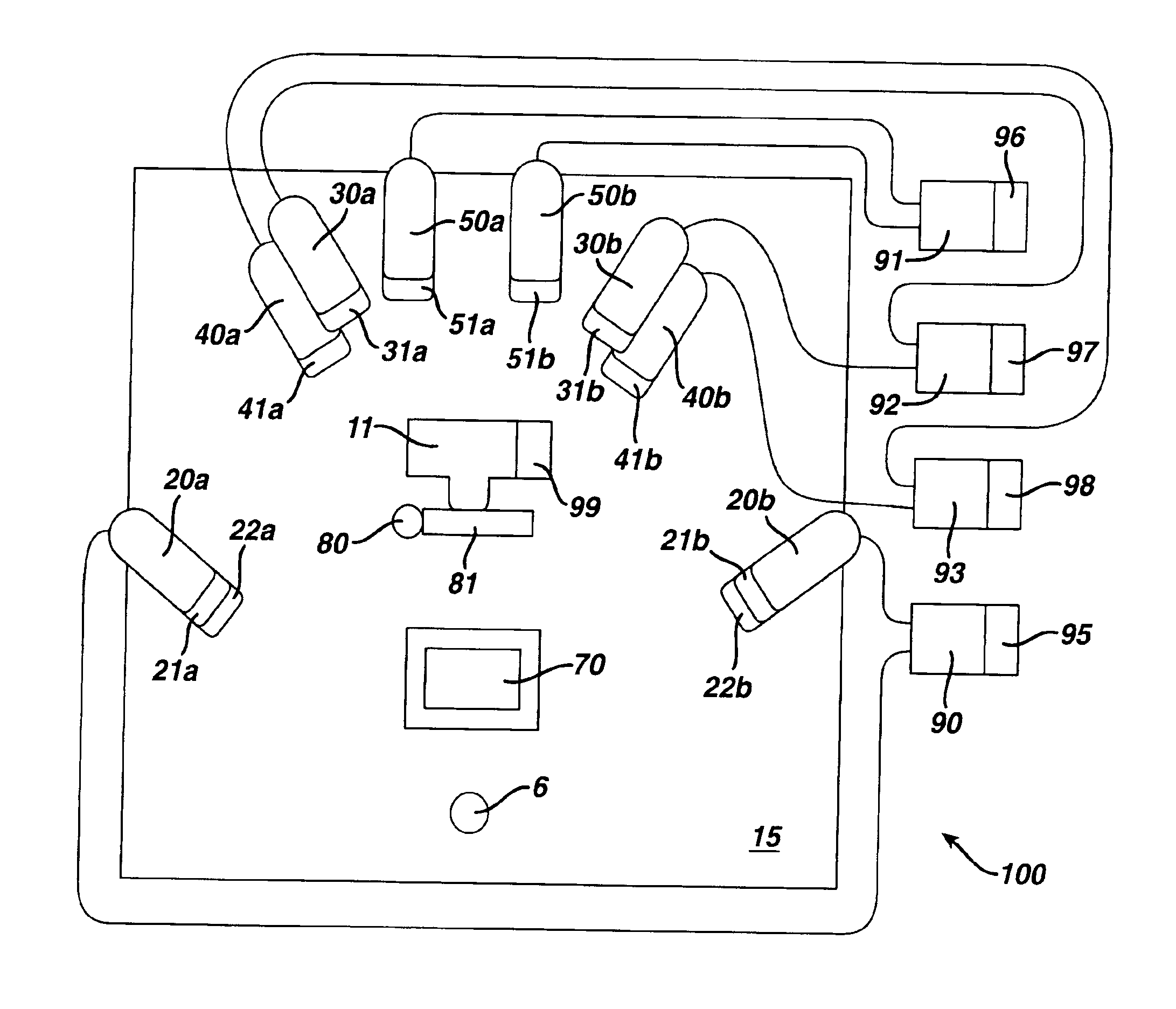

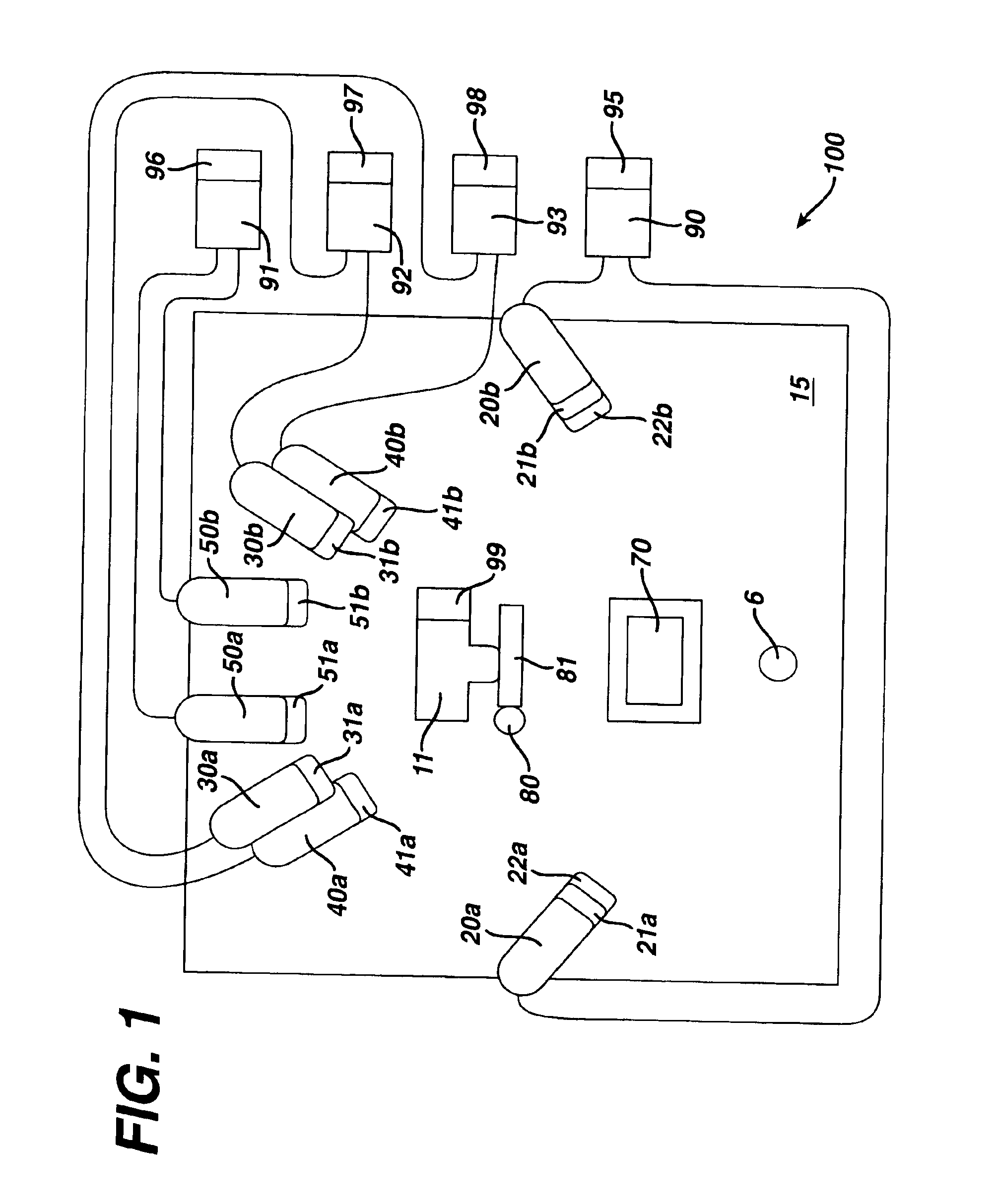

Automatic camera calibration method

InactiveUS20030156189A1Easy to addEasy to deleteProjector film strip handlingCamera film strip handlingComputer scienceImage plane

In an automatic camera calibration method in a system comprising a plurality of cameras, the automatic camera calibration method is characterized in that for each of the cameras, the estimated values of the position and posture of the camera are updated on the basis of observation information shared with the surrounding cameras and the estimated values of the respective current positions and postures of the surrounding cameras. An example of the observation information is the two-dimensional coordinate value of an image to be observed on an image plane of the camera and the size of the image to be observed.

Owner:ATR ADVANCED TELECOMM RES INST INT

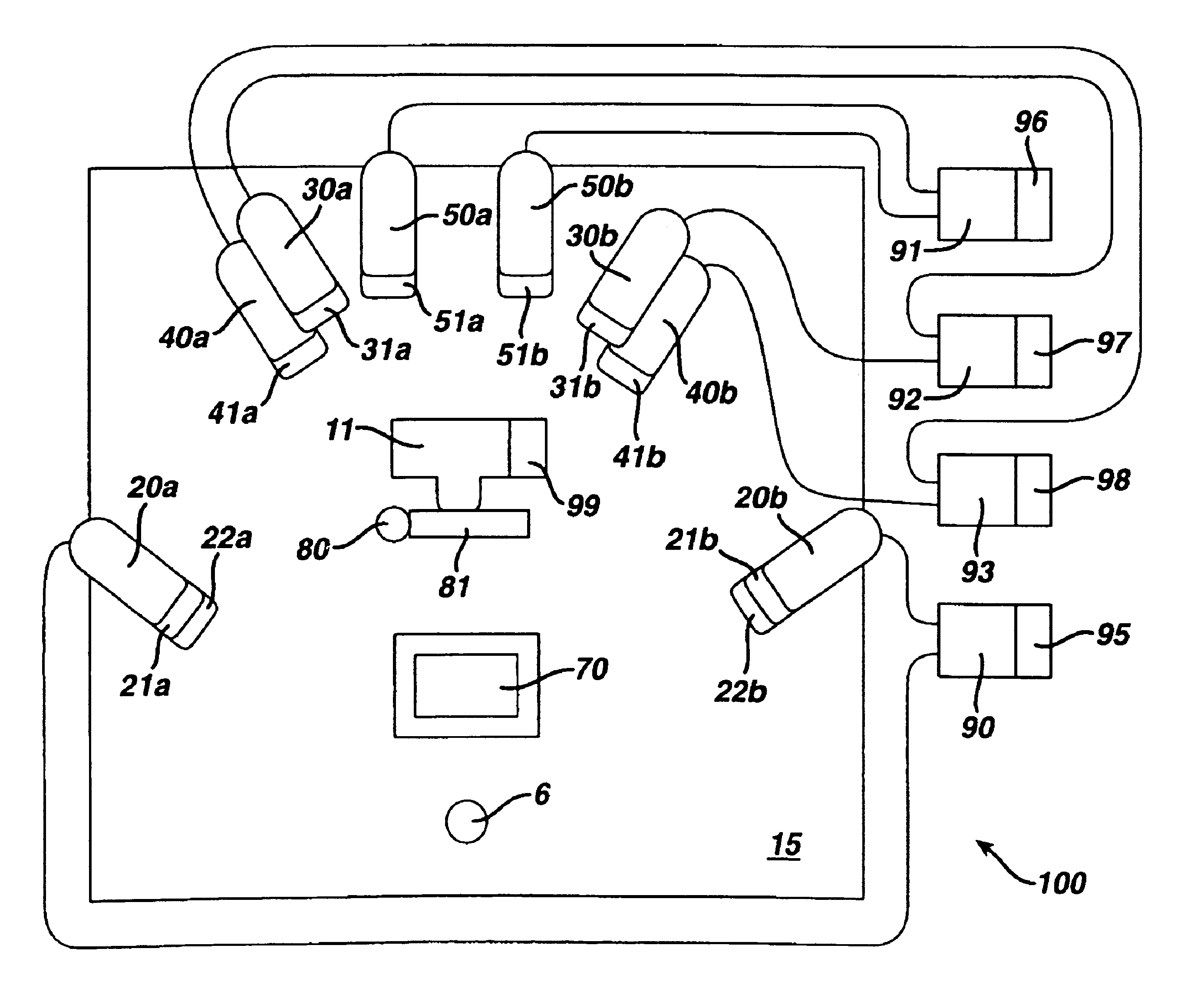

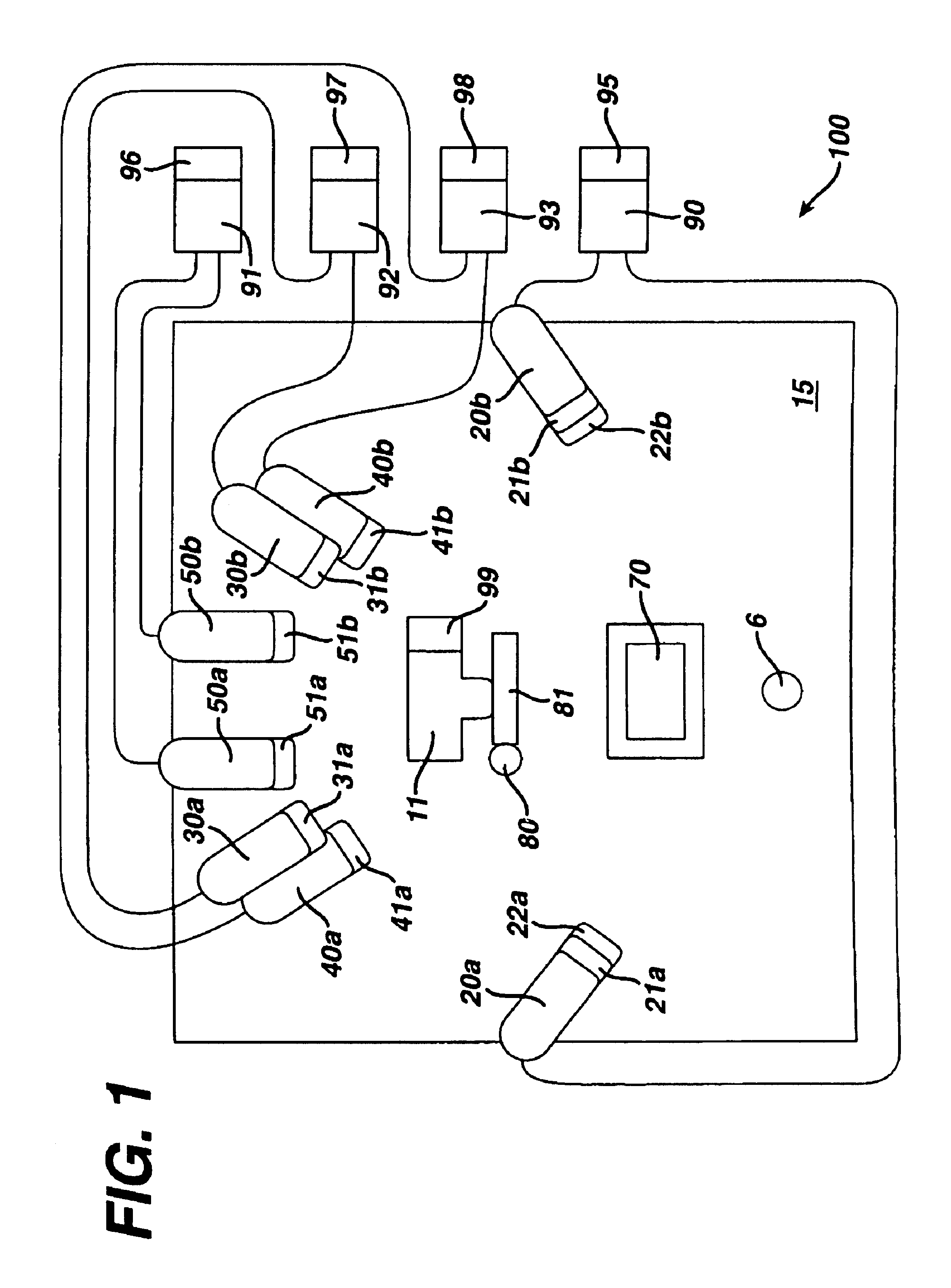

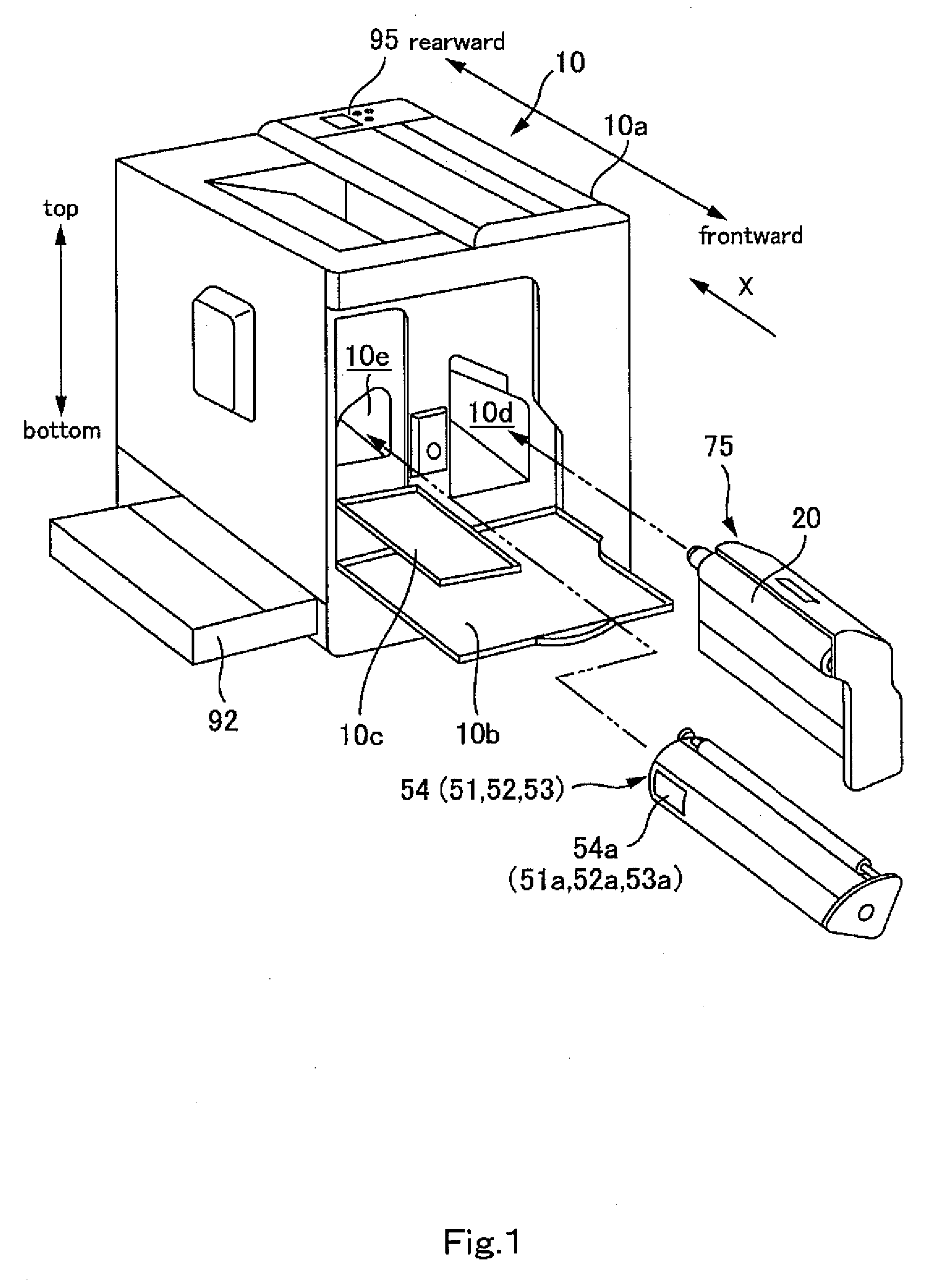

Optimized cluster tool transfer process and collision avoidance design

InactiveUS20060241813A1Improving trajectory pathSemiconductor/solid-state device testing/measurementComputer controlEngineeringRobot

The present invention relates to apparatus and method of collision avoidance in a cluster tool having a plurality of processing stations and at least two robots. In one embodiment of the invention, the system is configured such that each of the processing stations is accessible by only one of the at least two robots. For each of the at least two robots, a set of trajectories is determined so that each robot is capable of transferring substrates among the corresponding processing stations, wherein the envelope formed by the set of trajectories of each robot does not overlap.

Owner:SOKUDO CO LTD

Cluster tool architecture for processing a substrate

InactiveUS20060134330A1More repeatable wafer processing historyReduced footprintProgramme controlSemiconductor/solid-state device testing/measurementLithography processEngineering

Embodiments generally provide an apparatus and method for processing substrates using a multi-chamber processing system (e.g., a cluster tool) that has an increased system throughput, increased system reliability, substrates processed in the cluster tool have a more repeatable wafer history, and also the cluster tool has a smaller system footprint. In one embodiment, the cluster tool is adapted to perform a track lithography process in which a substrate is coated with a photosensitive material, is then transferred to a stepper / scanner, which exposes the photosensitive material to some form of radiation to form a pattern in the photosensitive material, which is then removed in a developing process completed in the cluster tool. In track lithography type cluster tools, since the chamber processing times tend to be rather short, and the number of processing steps required to complete a typical track system process is large, a significant portion of the time it takes to process a substrate is taken up by the processes of transferring the substrates in a cluster tool between the various processing chambers. In one embodiment of the cluster tool, the cost of ownership is reduced by grouping substrates together and transferring and processing the substrates in groups of two or more to improve system throughput, and reduces the number of moves a robot has to make to transfer a batch of substrates between the processing chambers, thus reducing wear on the robot and increasing system reliability. In one aspect of the invention, the substrate processing sequence and cluster tool are designed so that the substrate transferring steps performed during the processing sequence are only made to chambers that will perform the next processing step in the processing sequence. Embodiments also provide for a method and apparatus that are used to improve the coater chamber, the developer chamber, the post exposure bake chamber, the chill chamber, and the bake chamber process results. Embodiments also provide for a method and apparatus that are used to increase the reliability of the substrate transfer process to reduce system down time.

Owner:SOKUDO CO LTD

Magnification Observation Apparatus and Method For Photographing Magnified Image

ActiveUS20080297597A1High toneEasy to distinguishTelevision system detailsColor signal processing circuitsImaging conditionUsability

A high tone image is saved in a versatile image file format to enhance usability. There are provided an imaging unit that images an original image having a predetermined dynamic range, which is a ratio between minimum luminance and maximum luminance; a synthesized image generating part that generates a synthesized image data that is higher in tone than a tone width of the original image by synthesizing a plurality of original images imaged under different imaging conditions at the same observation position; a display unit that displays the images imaged by the imaging unit; a tone conversion part that converts the synthesized image data generated by the synthesized image generating part to low tone image data having a tone width capable of being displayed on the display unit; and a tone data saving part that generates a high tone data-attached display file including a high tone image region for saving the synthesized image data serving as a basis as an image file for saving the low tone image data.

Owner:KEYENCE

System and method for storing and presenting images and related items to a user

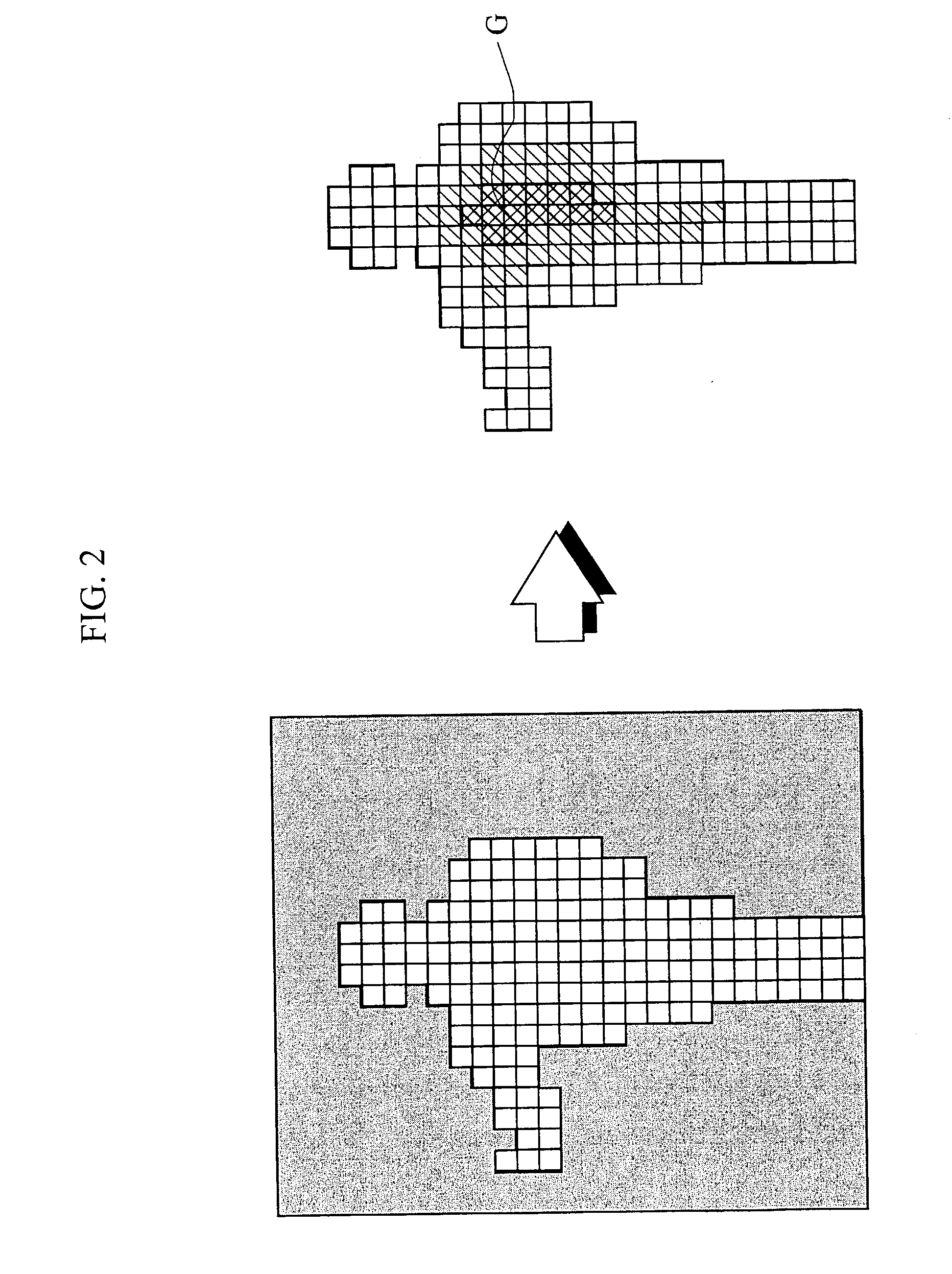

A system and method for presenting images and related items to a user. A digital image from a data store is assessed, and a portion of the image is defined as a region of interest. Properties are associated with this defined region, and these properties are utilized to infer relationships between the region of interest and related items in the data store. Optionally, a user input indicating a desire to view related content may be received and such content may be presented to the user.

Owner:MICROSOFT TECH LICENSING LLC

Cluster tool substrate throughput optimization

ActiveUS7699021B2Liquid surface applicatorsSemiconductor/solid-state device testing/measurementEngineeringHandling system

Embodiments generally provide an apparatus and method for processing substrates using a multi-chamber processing system (e.g., a cluster tool) that has an increased system throughput, increased system reliability, substrates processed in the cluster tool have a more repeatable wafer history. In one embodiment, non-orthogonal robot trajectories are used to assure reliable and high speed substrate transfer. In another embodiment, at least one buffering station is used to avoid collision and improve throughput. In another embodiment, optimal positioning of the robots are used to improve throughput.

Owner:SCREEN SEMICON SOLUTIONS CO LTD

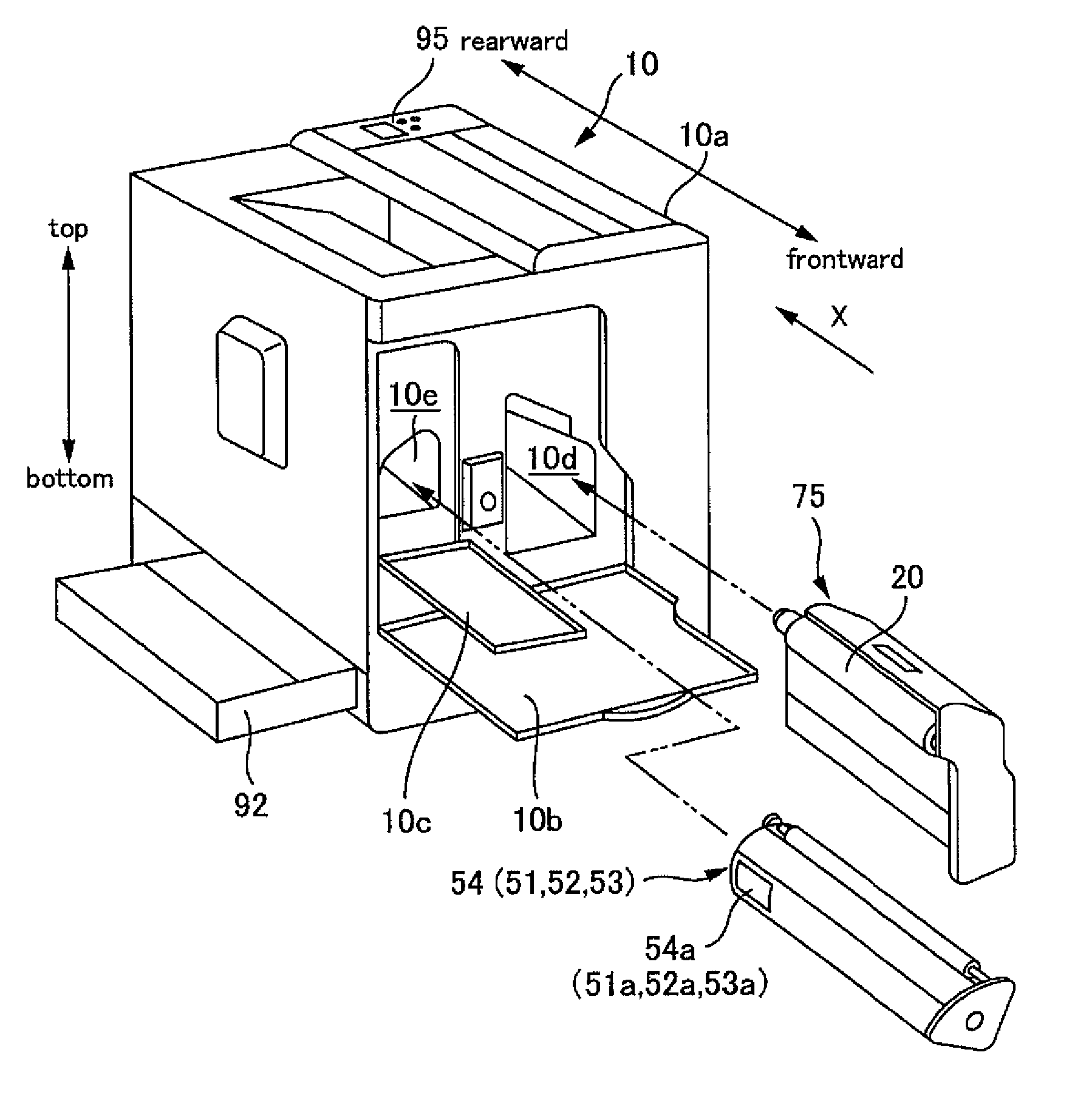

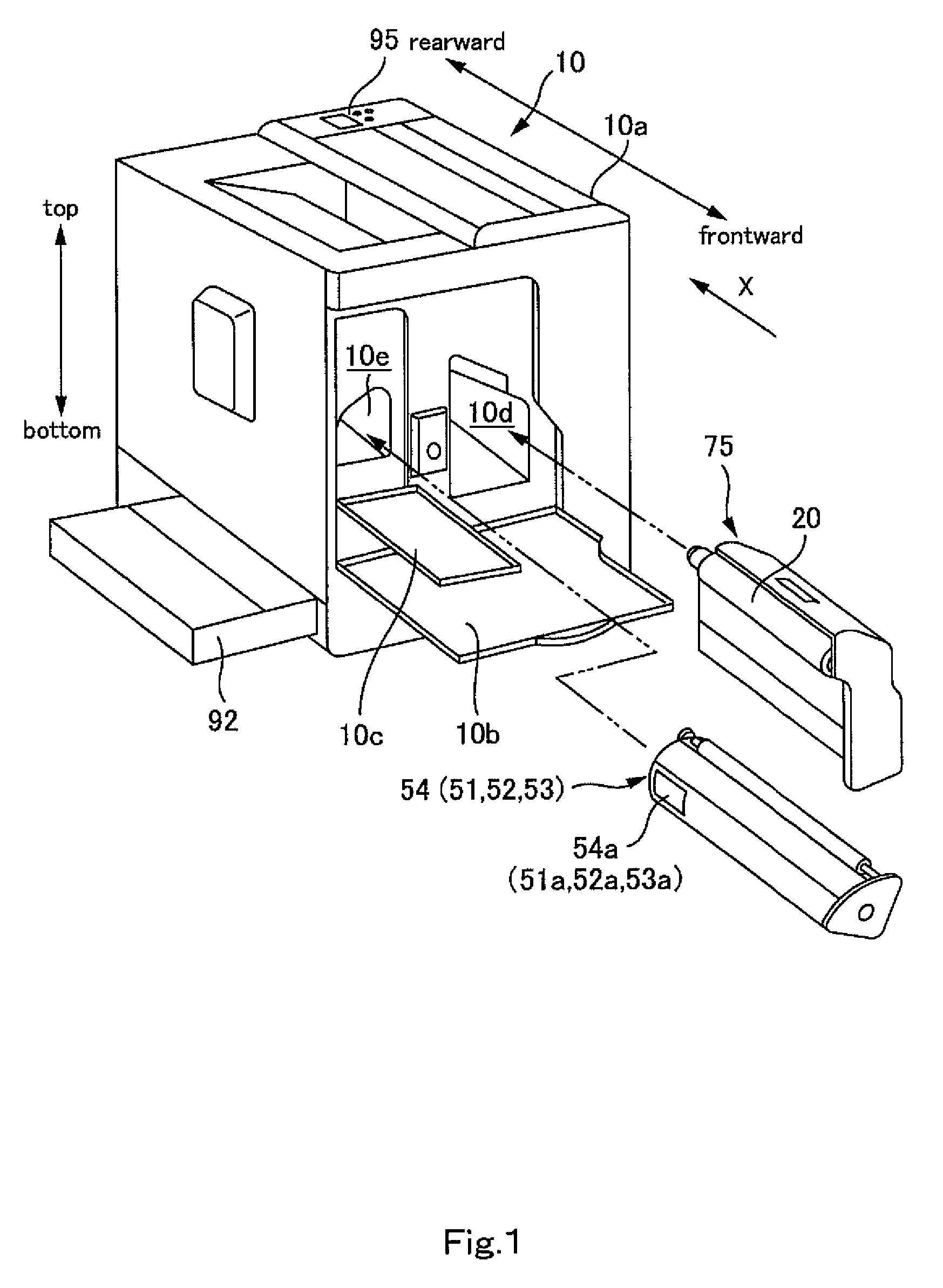

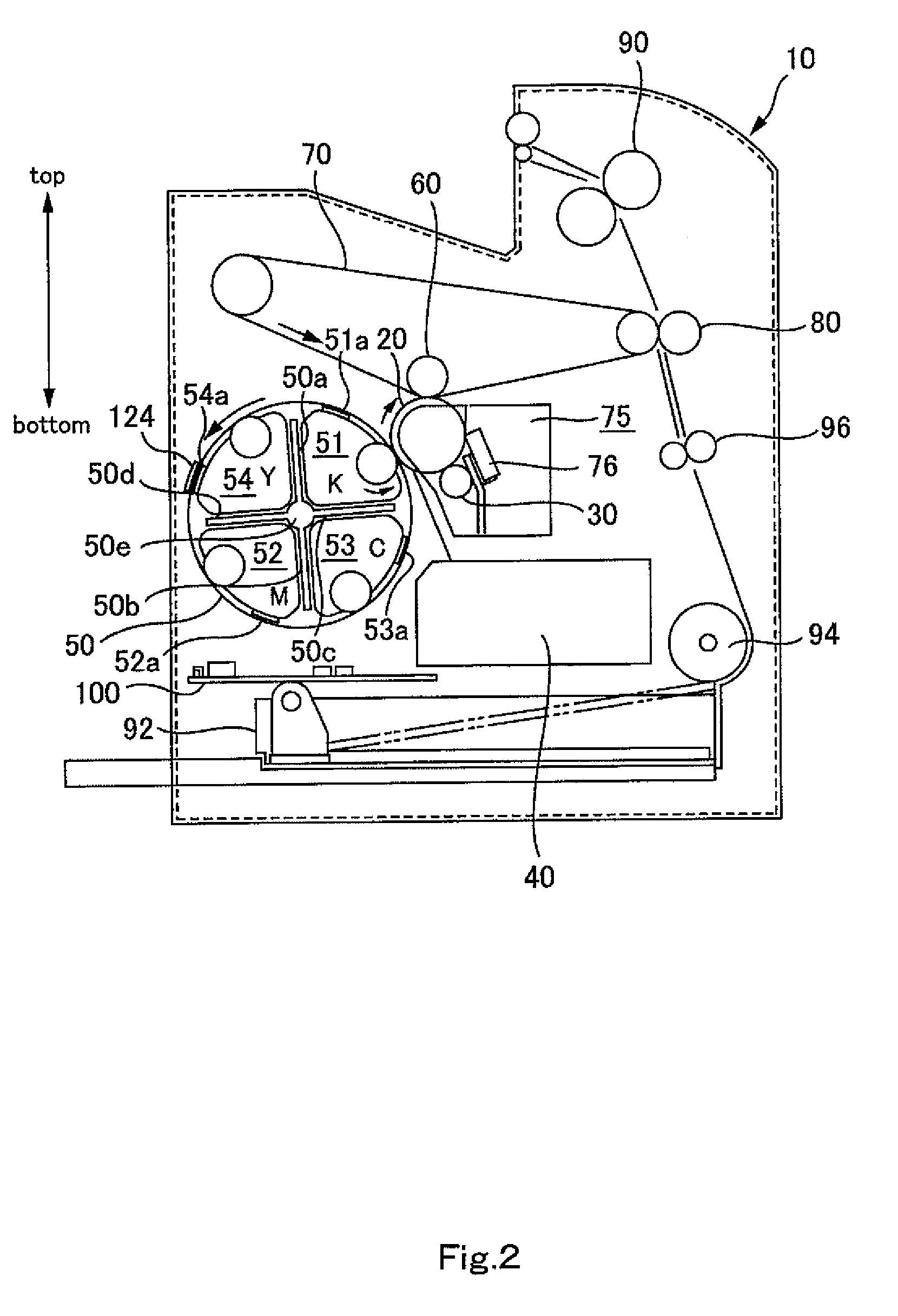

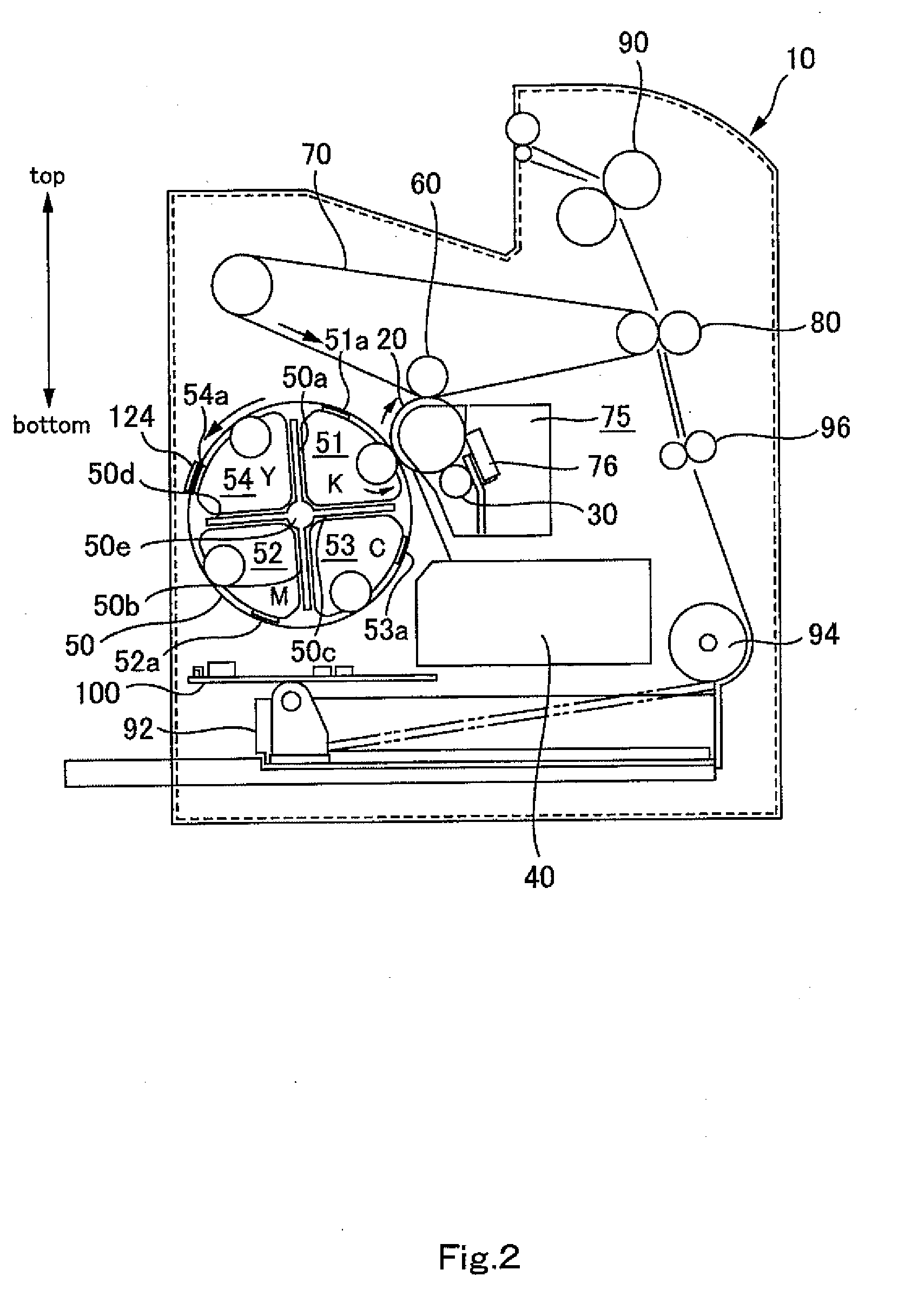

Developing device, image forming apparatus, image forming system, cartridge, developing unit and photoconductor unit

InactiveUS7885554B2No drop in communication performanceUtilized accurately and quicklyProcessingElectrographic process apparatusImage formationMechanical engineering

A developing device that can be mounted to and dismounted from a mounting and dismounting section provided in an image forming apparatus main unit, the developing device includes: a developing device main unit; a positioning member for positioning the developing device main unit with respect to the mounting and dismounting section by engaging the mounting and dismounting section when the developing device is mounted to the mounting and dismounting section, the positioning member being fixed on a one end side in a longitudinal direction of the developing device main unit; a coupling member that is to be coupled to the mounting and dismounting section when the developing device is mounted to the mounting and dismounting section, the coupling member being attached to the other end side in the longitudinal direction of the developing device main unit in such a manner that its relative position to the developing device main unit can be changed; and an element capable of communication in a noncontacting manner with the image forming apparatus main unit side when the developing device is mounted to the mounting and dismounting section, the element being provided at the one end side in the longitudinal direction of the developing device main unit.

Owner:SEIKO EPSON CORP

Coat/develop module with shared dispense

ActiveUS20060130747A1Reduce system costReduce complexityProgramme controlLiquid surface applicatorsBiomedical engineeringSemiconductor

An apparatus for dispensing fluid during semiconductor substrate processing operations. The apparatus includes a central fluid dispense bank comprising a plurality of dispense nozzles coupled to a plurality of fluid sources and a first processing chamber positioned to a first side of the central fluid dispense bank. The apparatus also includes a second processing chamber positioned to a second side of the central fluid dispense bank and a dispense arm adapted to translate between the central fluid dispense bank, the first processing chamber, and the second processing chamber.

Owner:SCREEN SEMICON SOLUTIONS CO LTD

Method of promoting skin care products

The present invention relates to a method of promoting a skin care product comprising taking a standard photograph of the skin of a person; (ii) taking at least one additional photograph of the skin of the person, the additional photograph selected from the group consisting of an ultraviolet photograph, a blue fluorescence photograph, and a polarized photograph; (iii) presenting the standard photograph and the at least one additional photograph to the person; and (iv) suggesting skin care products based upon the person's review of the presented photographs.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

Automatic camera calibration method

InactiveUS7212228B2Easy to addEasy to deleteProjector film strip handlingCamera film strip handlingImage planeVideo camera

Owner:ATR ADVANCED TELECOMM RES INST INT

System and method for measuring the refraction

InactiveUS20030108350A1Precise positioningDetecting distanceProjector film strip handlingCamera film strip handlingControl unitPhysics

Owner:PLUSOPTIX MBO

Developing Device, Image Forming Apparatus, Image Forming System, Cartridge, Developing Unit and Photoconductor Unit

InactiveUS20080267666A1No drop in communication performanceUtilized accurately and quicklyProcessingElectrographic process apparatusImage formationEngineering

A developing device that can be mounted to and dismounted from a mounting and dismounting section provided in an image forming apparatus main unit, the developing device includes: a developing device main unit; a positioning member for positioning the developing device main unit with respect to the mounting and dismounting section by engaging the mounting and dismounting section when the developing device is mounted to the mounting and dismounting section, the positioning member being fixed on a one end side in a longitudinal direction of the developing device main unit; a coupling member that is to be coupled to the mounting and dismounting section when the developing device is mounted to the mounting and dismounting section, the coupling member being attached to the other end side in the longitudinal direction of the developing device main unit in such a manner that its relative position to the developing device main unit can be changed; and an element capable of communication in a noncontacting manner with the image forming apparatus main unit side when the developing device is mounted to the mounting and dismounting section, the element being provided at the one end side in the longitudinal direction of the developing device main unit.

Owner:SEIKO EPSON CORP

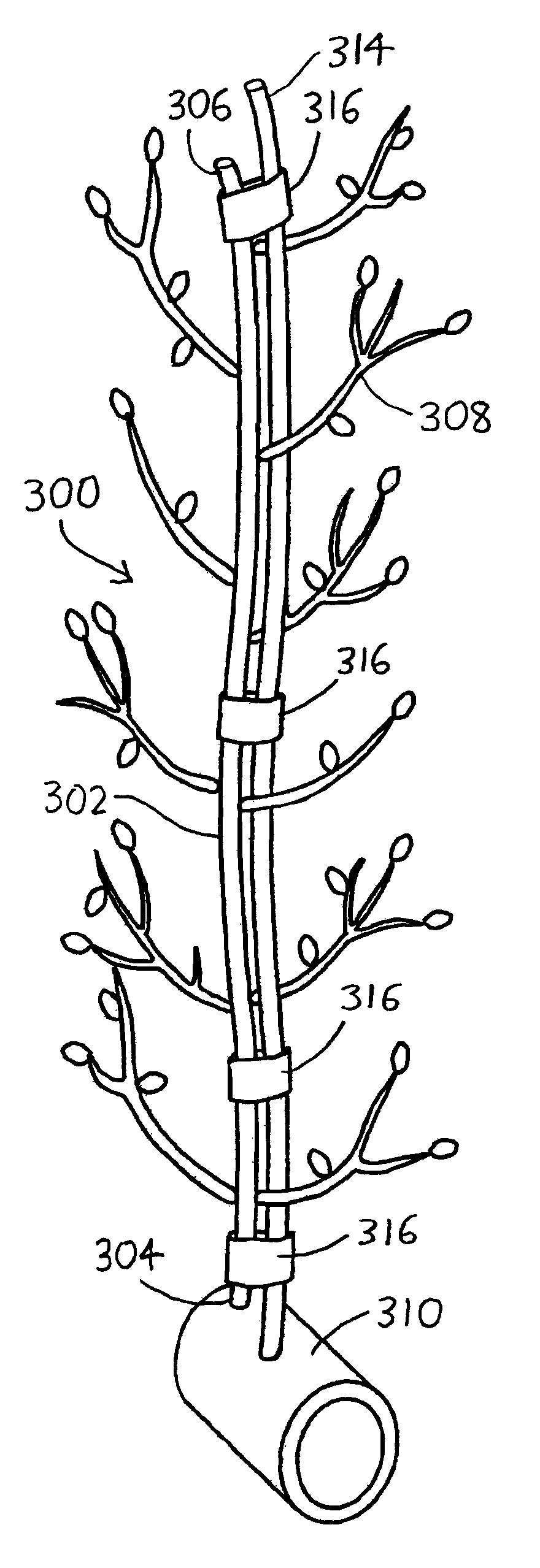

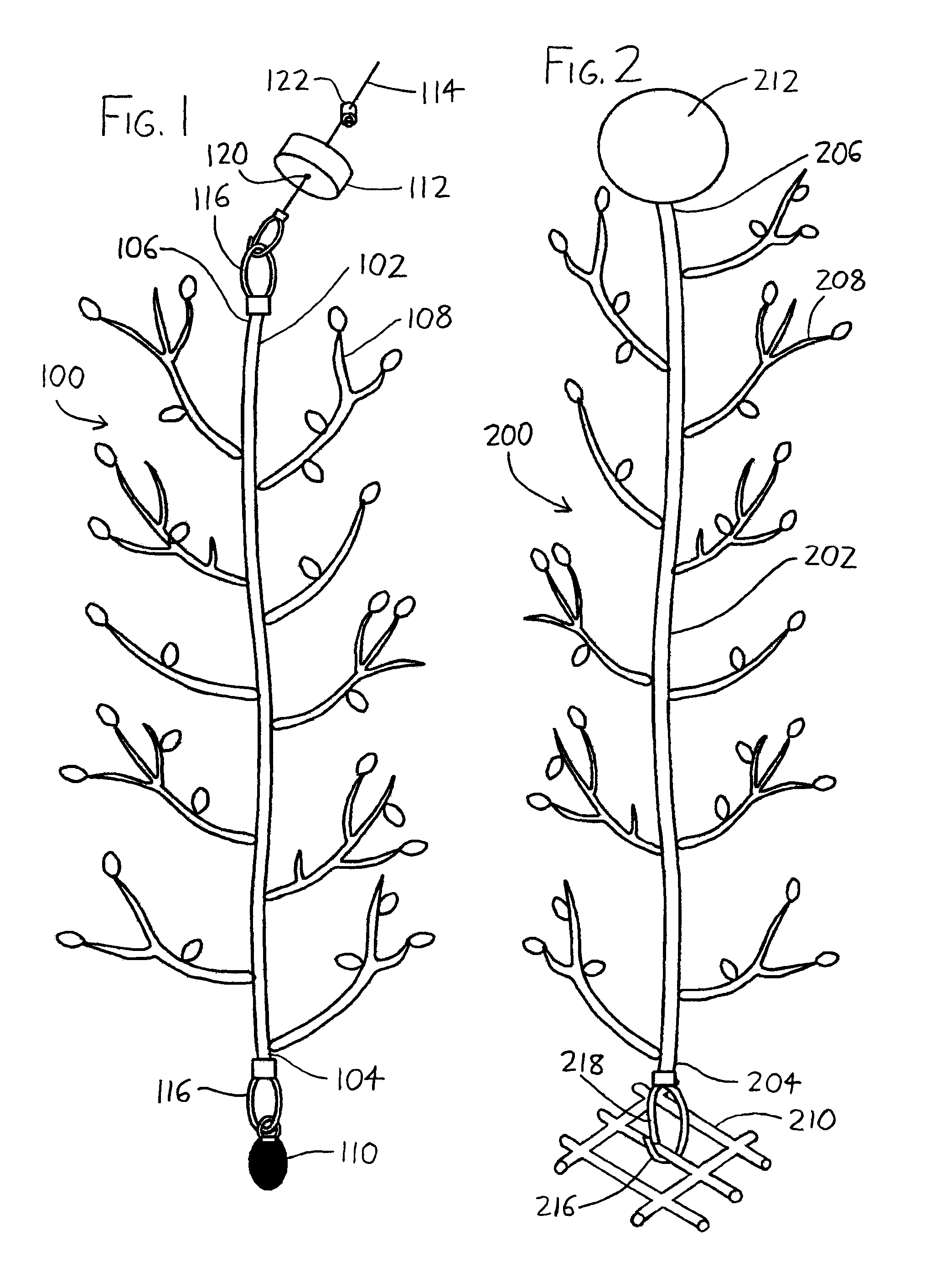

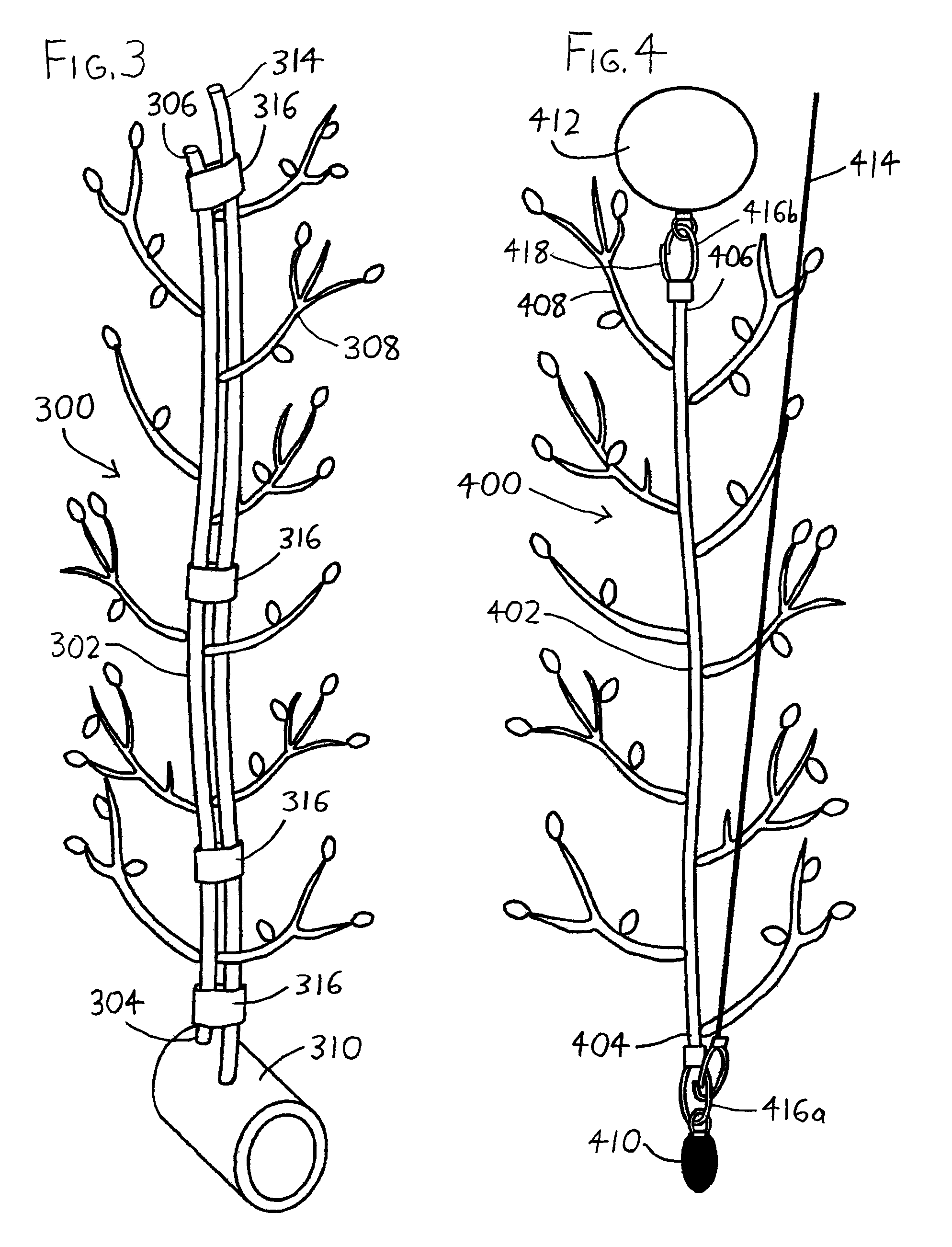

Artificial foliage for underwater camouflage and decoy purposes

InactiveUS7512326B1Effectively camouflage them and attract aquatic lifeEfficiently provideWaterborne vesselsFishing netsVegetationShoot

Artificial foliage is described for use in camouflaging underwater structures, and / or for serving as cover vegetation which attracts aquatic life. A preferred version of the artificial foliage includes an elongated stem having shoots (e.g., leaves and / or branches) extending therefrom, a ballast weight connected to one of the stem ends, and a float and / or tensioning line connected to the opposite stem end for supporting the stem at least partially upright in the water above the ballast. The ballast may take a variety of forms, such as a conventional fishing sinker, sinkable structures such as bait traps or anchors, or an underwater camera.

Owner:ELDREDGE JOHN T +2

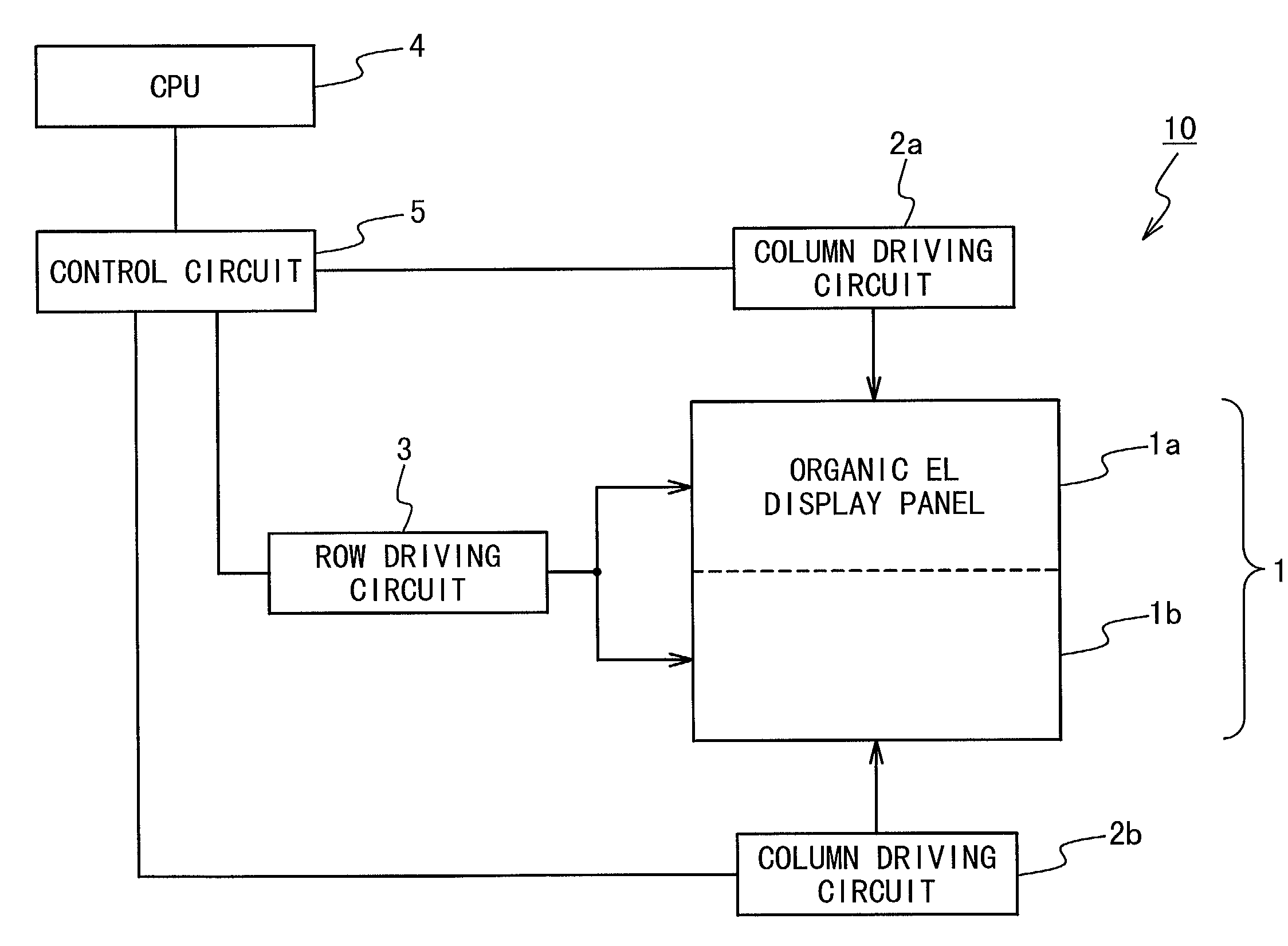

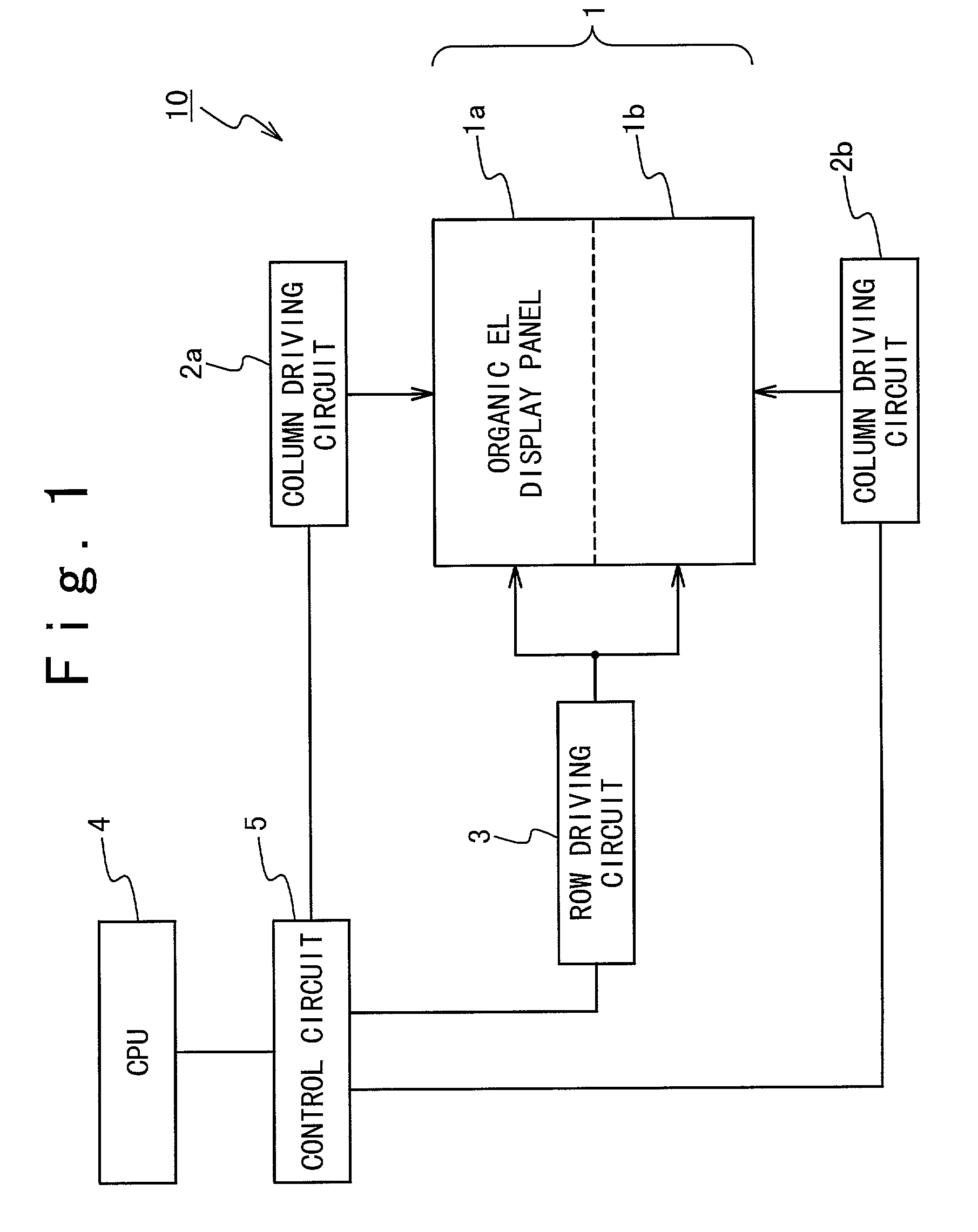

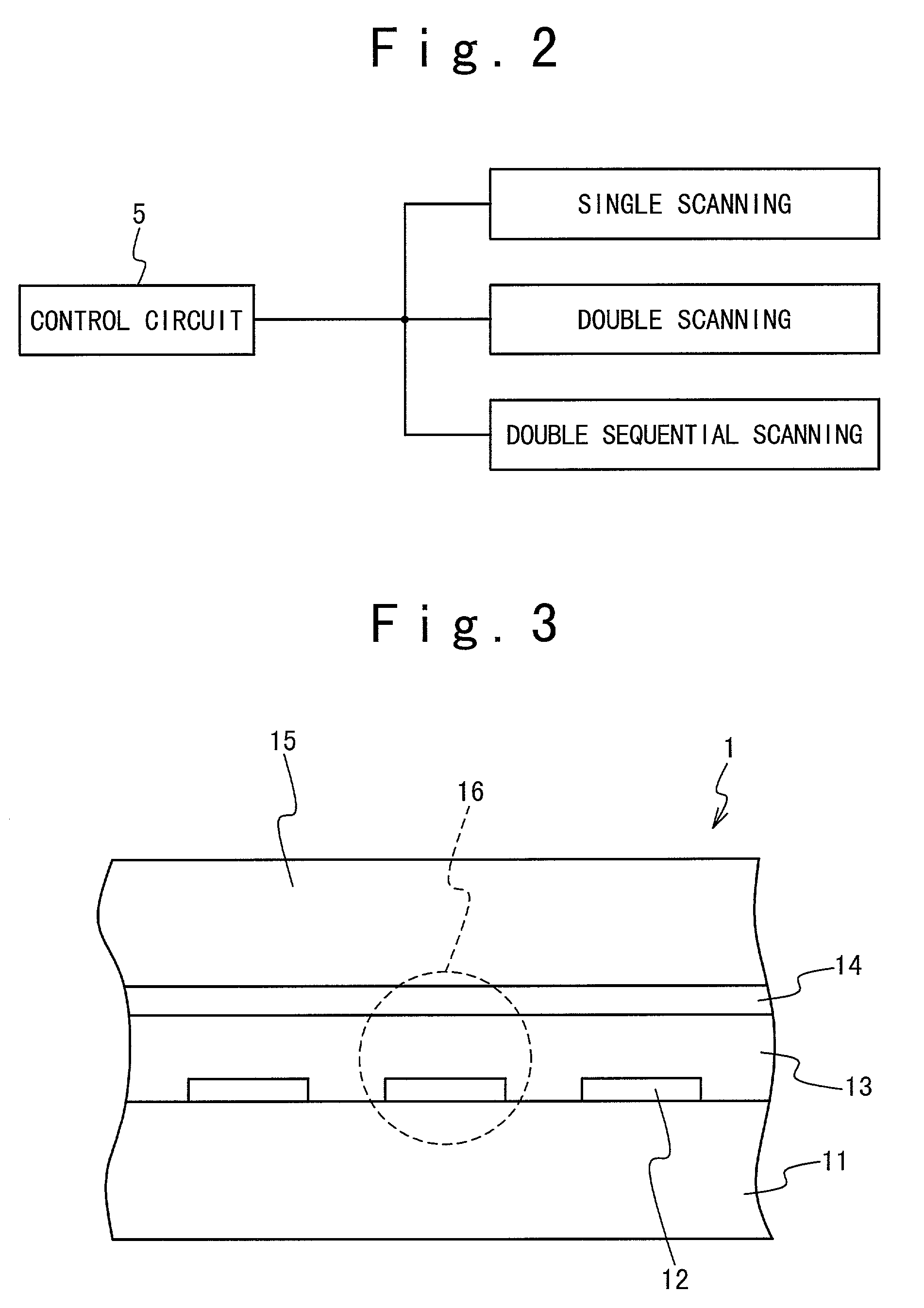

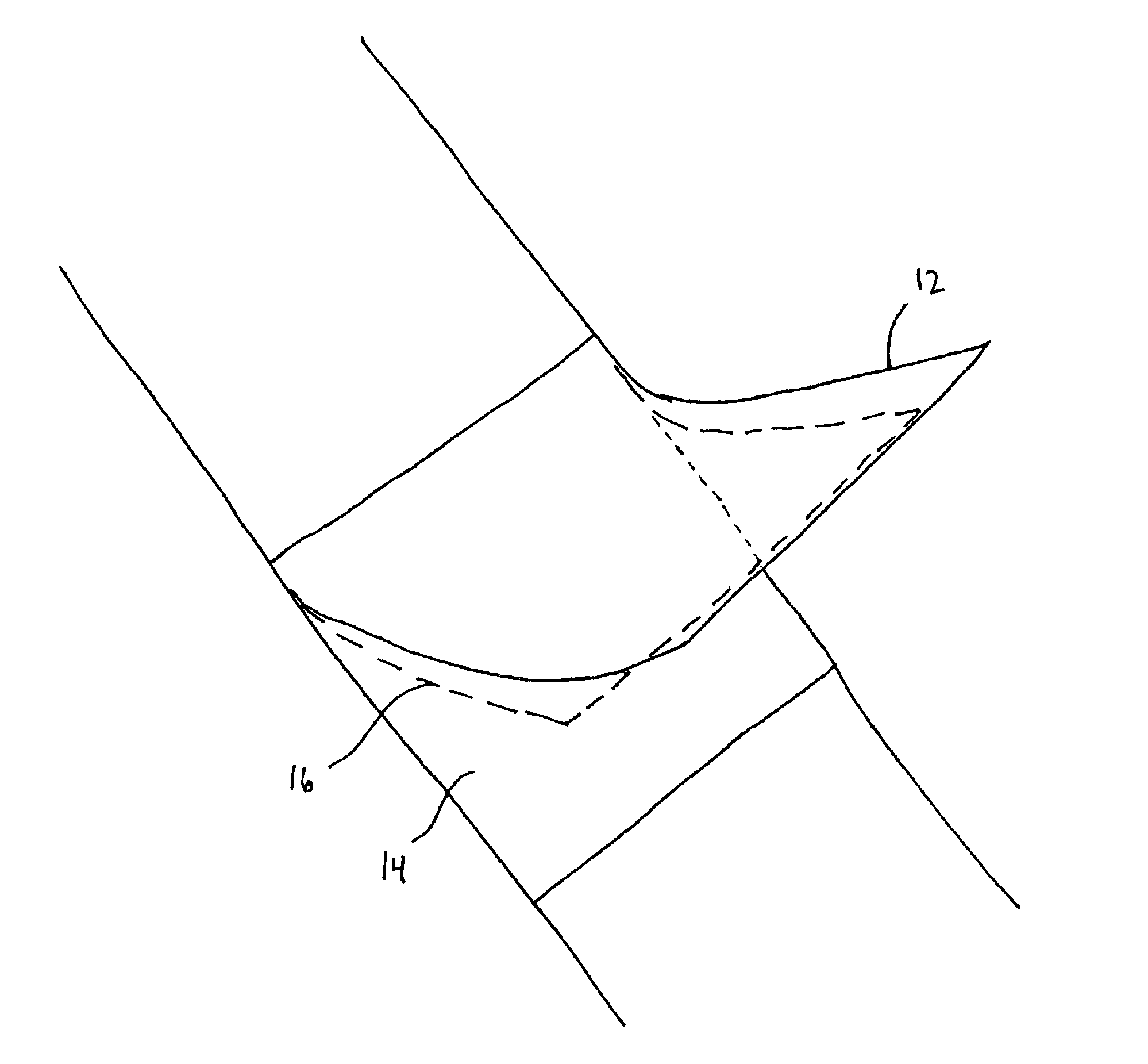

Image display apparatus with driving modes and method of driving the same

InactiveUS7176912B2Television system detailsProjector film strip handlingControl signalOperation mode

An image display apparatus includes an image display section in which a plurality of light emitting elements are arranged in a matrix at intersections of a plurality of scan lines and a plurality of data lines. A control circuit selects one of modes as an operation mode in response to a mode switching signal, and outputs a data signal and a scan control signal based on an image signal to be displayed and the selected mode. A row driving section is connected to the plurality of scan lines to sequentially drive the plurality of scan lines based on the scan control signal in a unit determined based on the operation mode. A column driving section is connected to the plurality of data lines to sequentially drive the plurality of data lines based on the data signal. In this way, an image corresponding to the image signal is displayed on the image display section.

Owner:SAMSUNG DISPLAY CO LTD

Toilet paper, paper towel and facial tissue

Toilet paper, paper towel and facial tissue products (10) are presented. Information may be placed, through printing or embossing, on the toilet paper, paper towels and facial tissues. The information (62) may comprise advertisements, coupons, prizes (such as stickers and crossword puzzles), games or other promotional materials. In addition, information (62) may be placed on a sheet separate from the toilet paper and / or paper towels and / or facial tissues. The information sheet may be then be placed in conjunction with the toilet paper, paper towel or facial tissue by rolling or by interleaving (16) the information sheet with the toilet paper, paper towel or facial tissue. In another aspect, different information may be place on two or more sheets to convey a story (39) or other information. The information (72) may, for example, be used to help potty train children, or to teach children numbers or the alphabet.

Owner:PENN DANIEL J +1

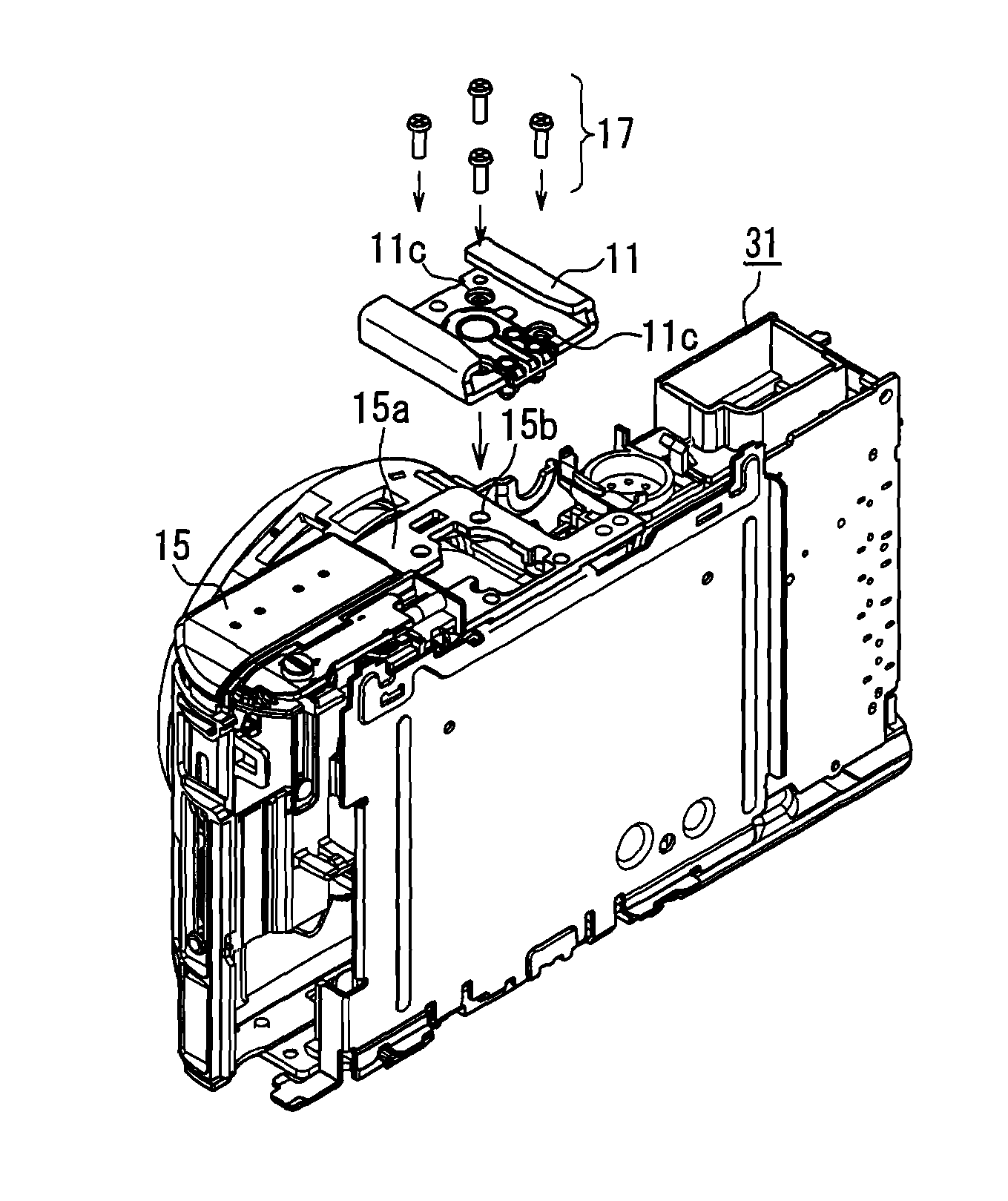

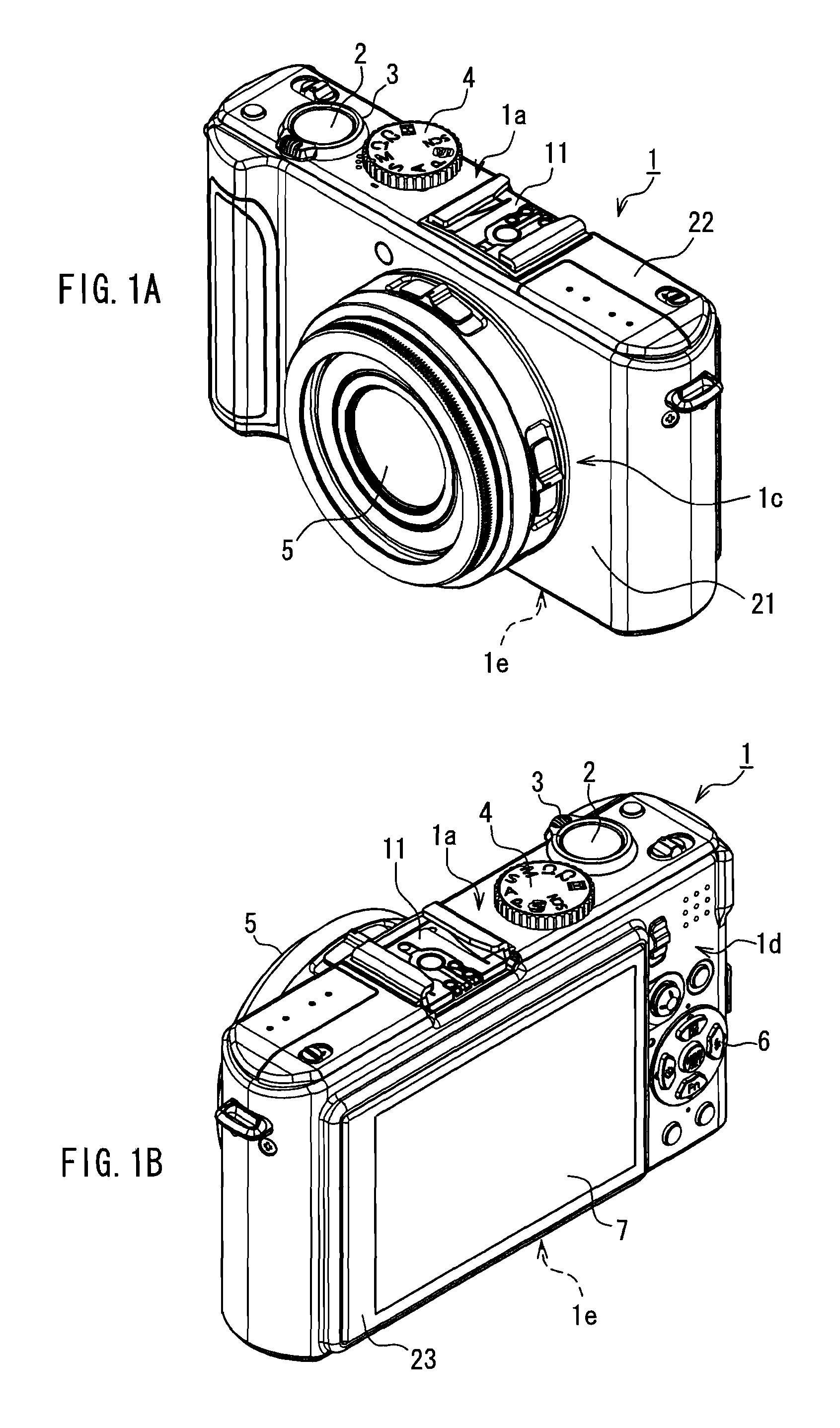

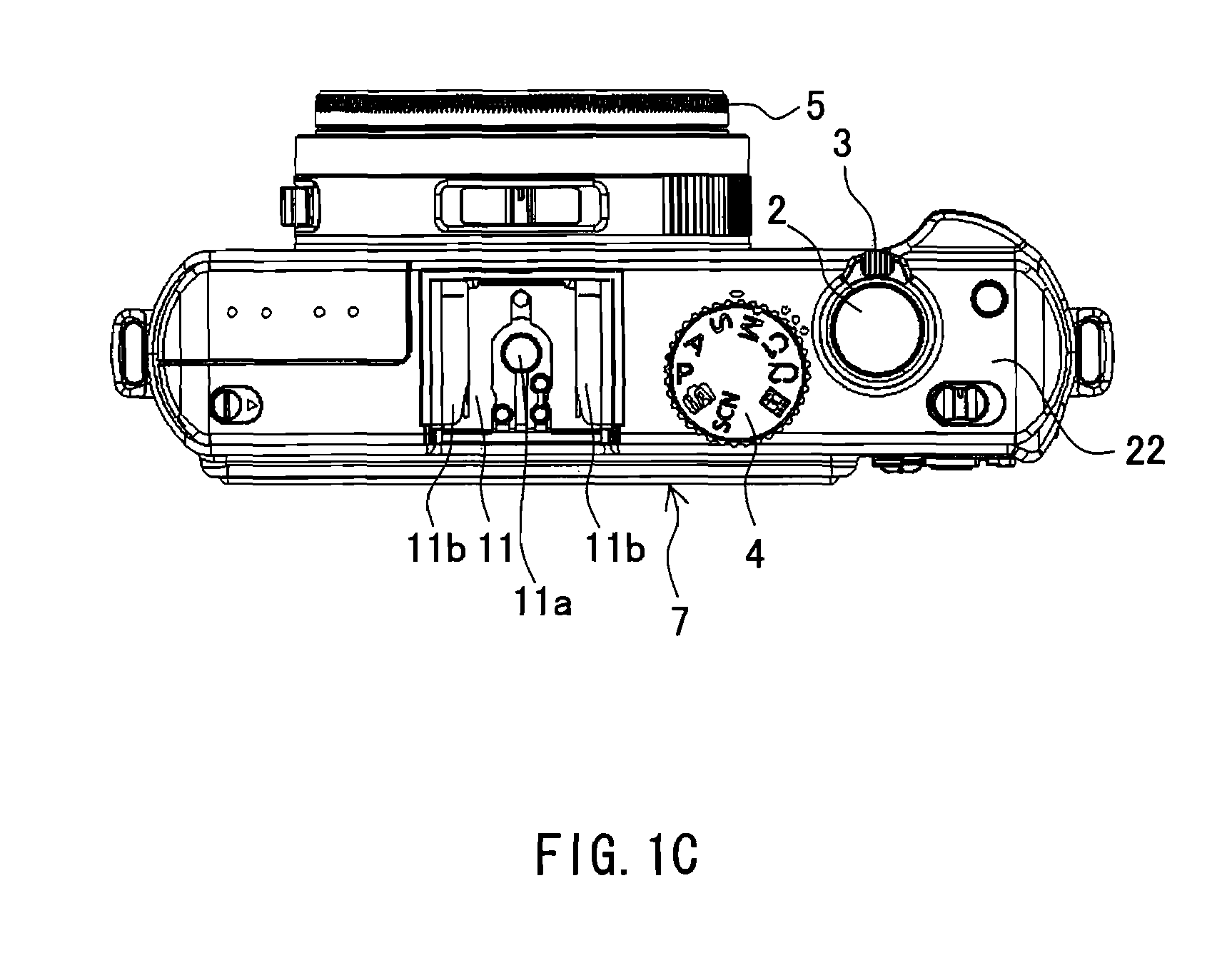

Camera casing including accessory shoe for allowing the attachment of various/plural external devices

ActiveUS8233082B2Avoid deformationAvoid damageTelevision system detailsProcessingEngineeringMechanical engineering

Owner:PANASONIC CORP

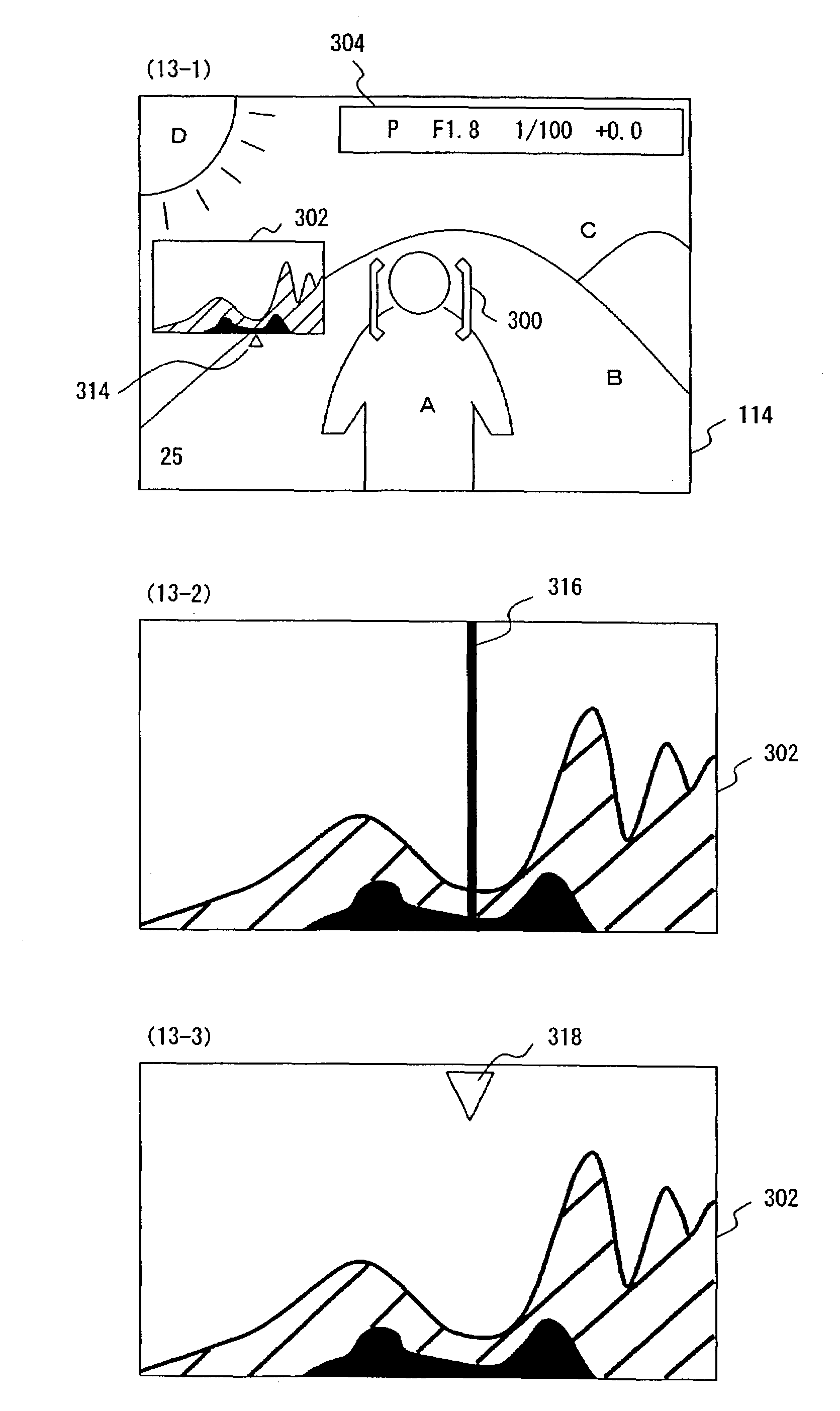

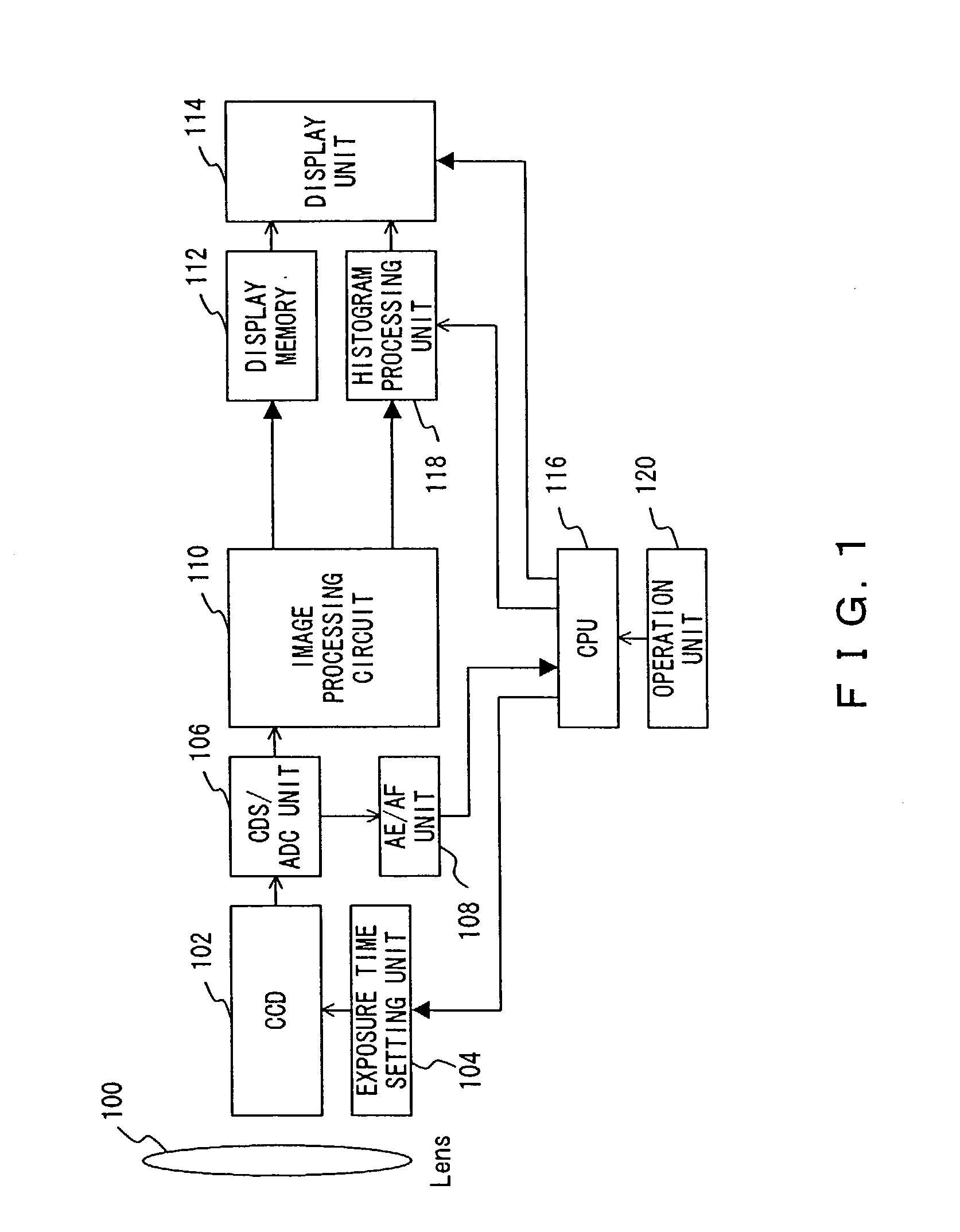

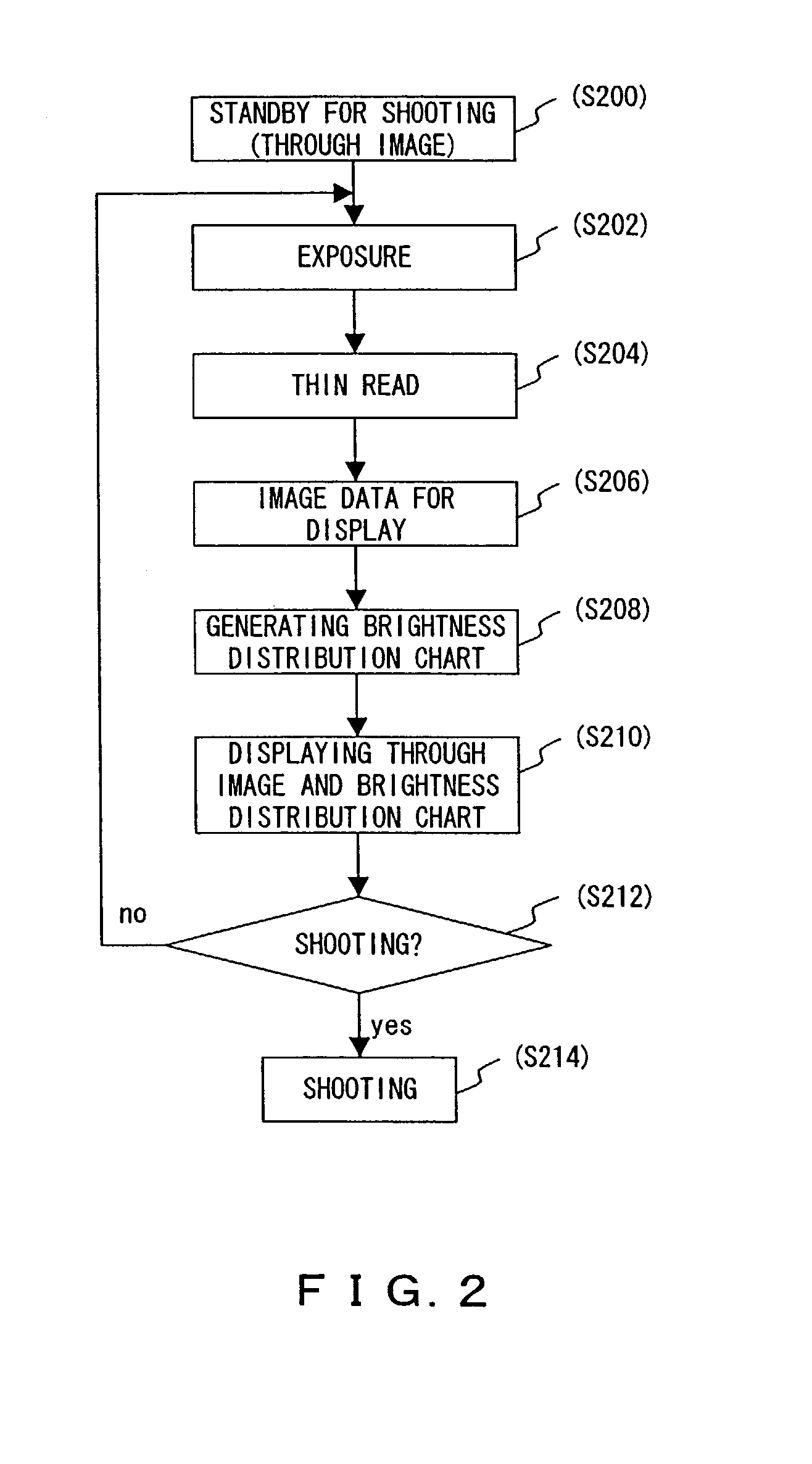

Image pickup apparatus with brightness distribution chart display capability

ActiveUS7271838B2Easy to adjustFeature validTelevision system detailsColor signal processing circuitsComputer graphics (images)Lightness

An image pickup apparatus includes an image pickup unit for outputting an electronic subject image, a metering unit for computing a metering value from the subject image, a brightness distribution chart generation unit for generating a brightness distribution chart from the subject image, and a display unit for overlaying the brightness distribution chart on the subject image and displaying them, and provides the brightness distribution chart for the display unit in various styles.

Owner:OM DIGITAL SOLUTIONS CORP +1

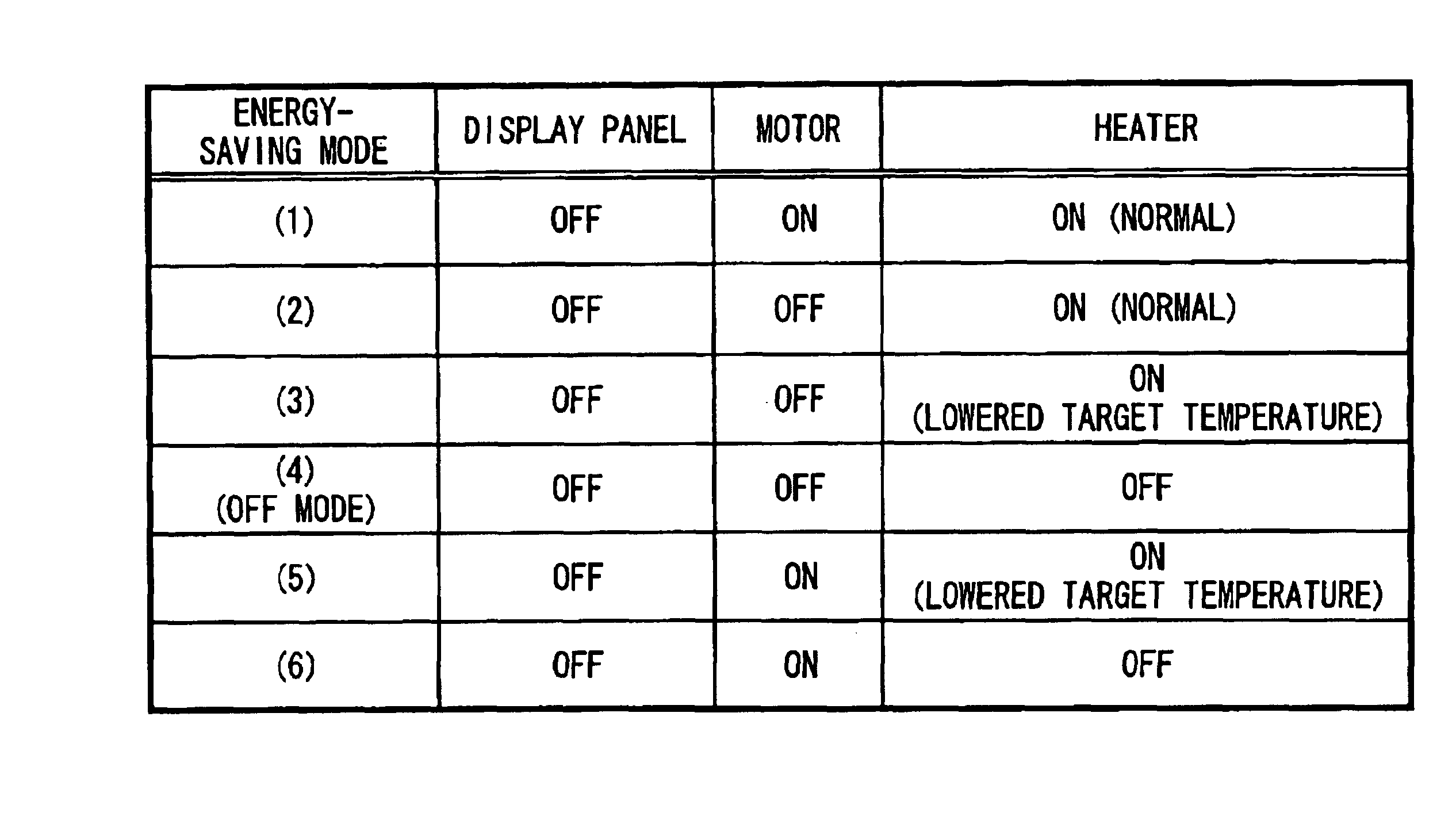

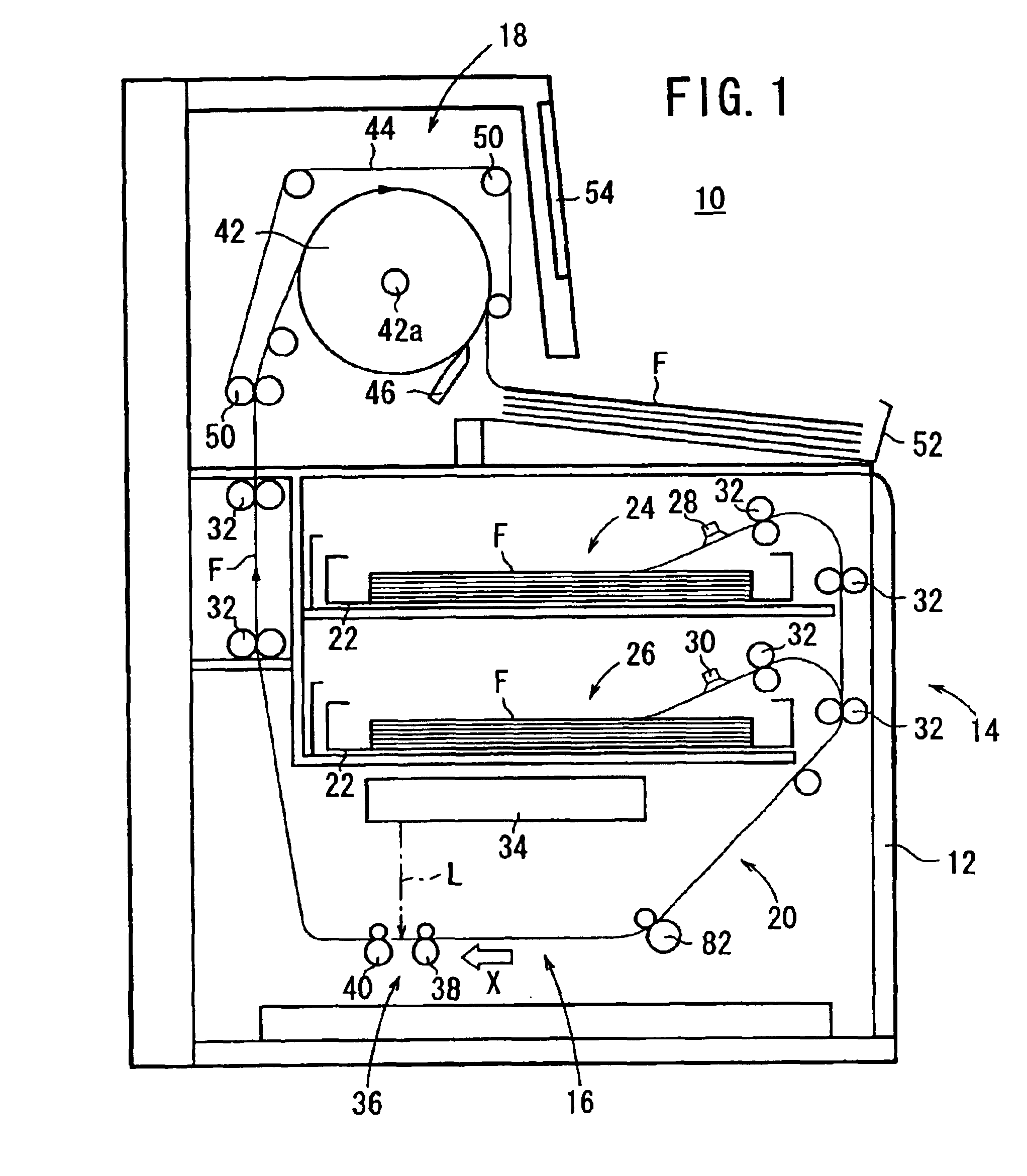

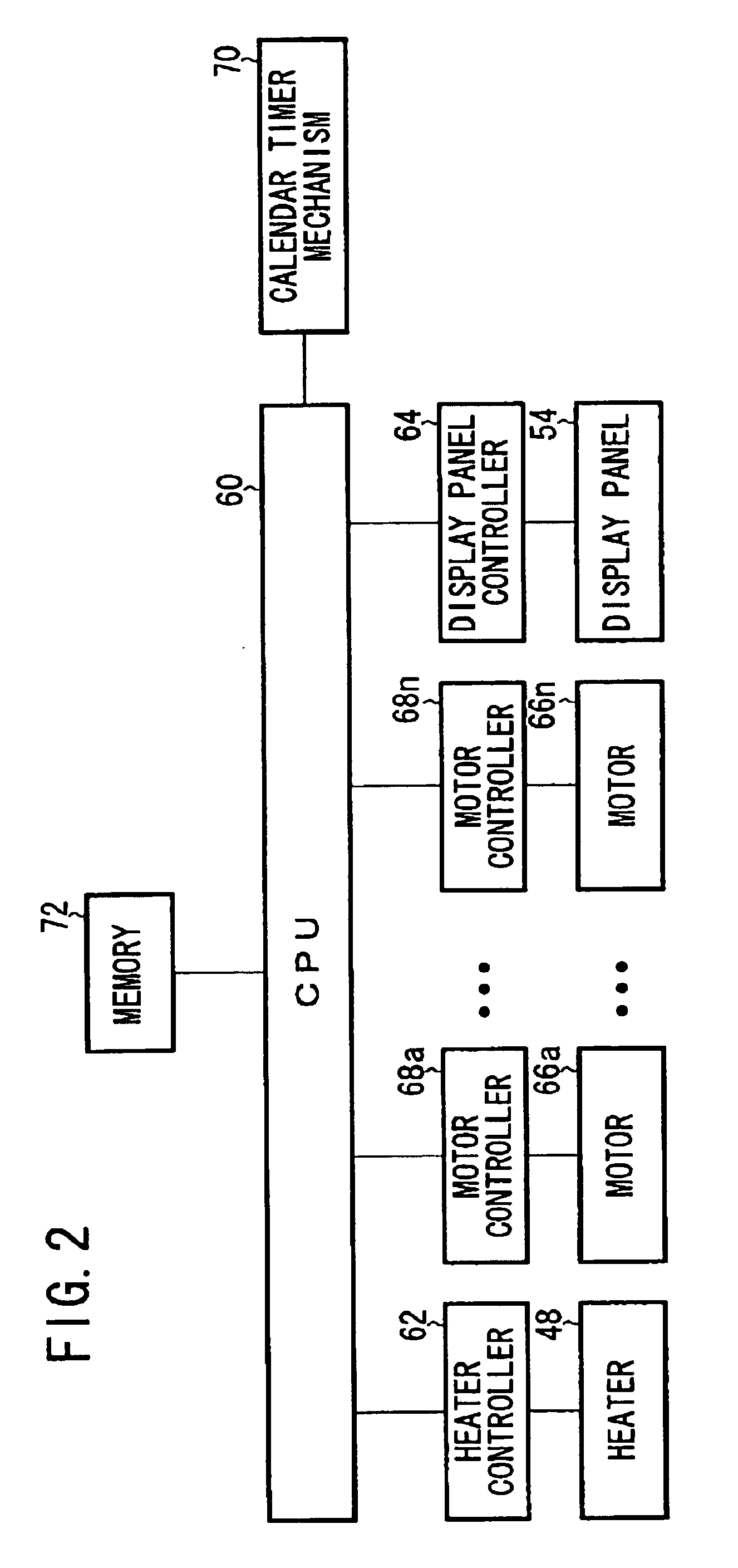

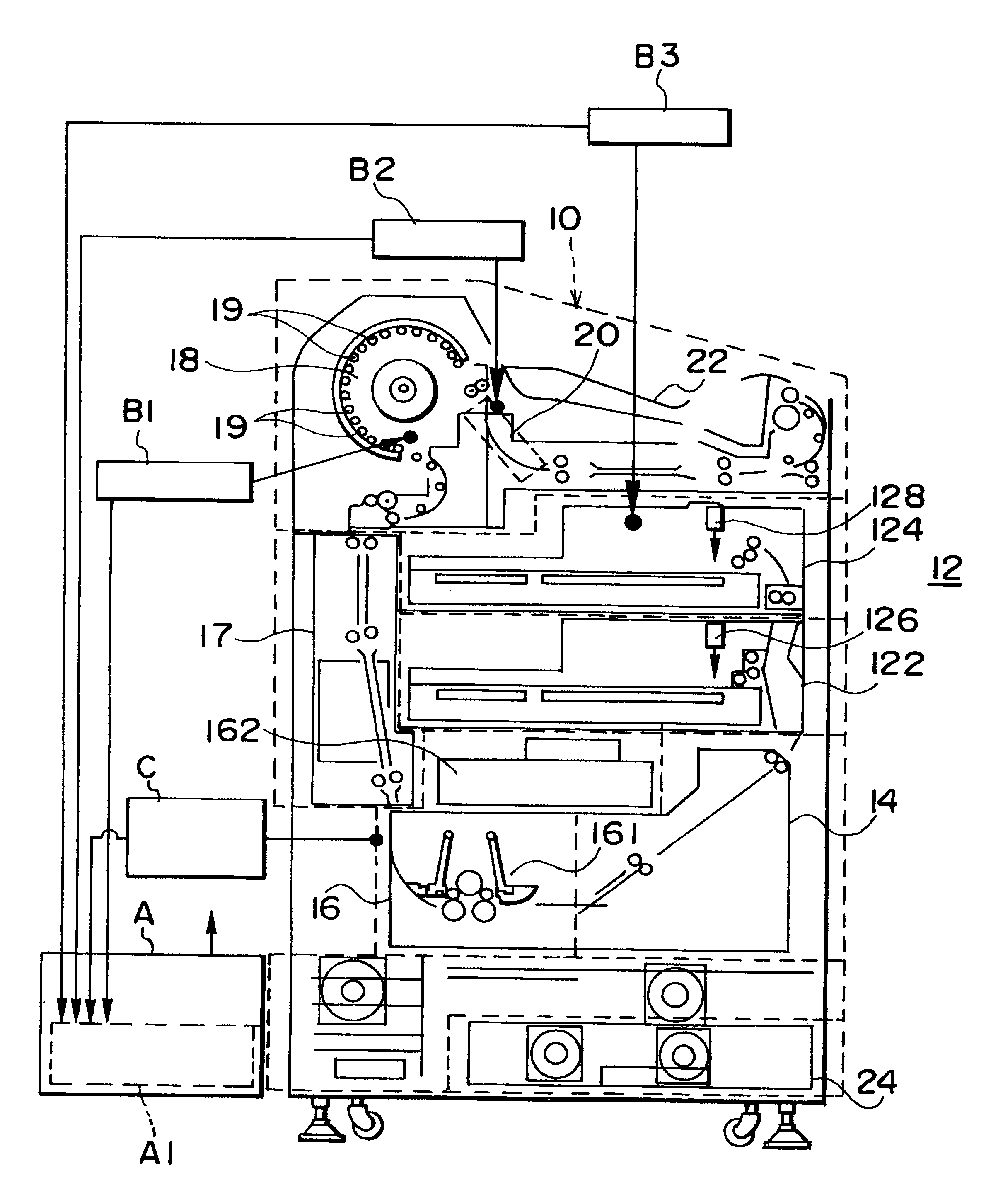

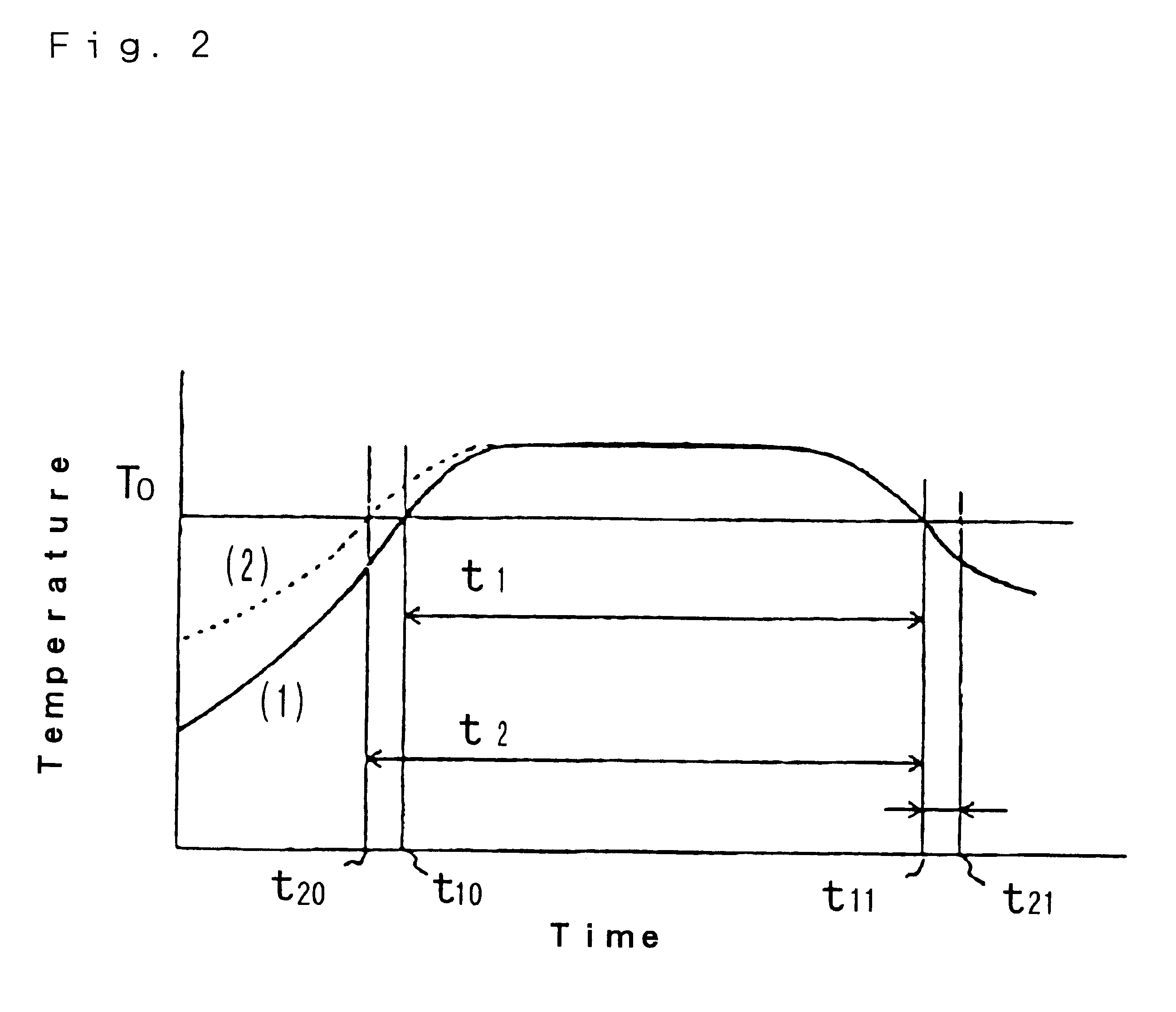

Calendar timer mechanism and processing apparatus

InactiveUS6895309B2Effectively turningEffectively offTime indicationLevel controlTransition timeComputer science

A calendar timer mechanism has an OFF mode for turning off all objects to be controlled, which include a heater, a display panel, and motors, an ON mode for turning on all the objects to be controlled, and at least two energy-saving modes for selectively turning off the objects to be controlled or turning on the objects to be controlled at a lower power consumption rate. Transitional times between at least three of the OFF mode, the ON mode, and the energy-saving modes can be set as desired.

Owner:FUJIFILM HLDG CORP +1

Method for producing image using a photothermographic material

Provided is a method for producing image using a photothermographic material in which the photothermographic material is exposed with a laser light using an image producing apparatus having a recording section and heat developing section, and then developed by heating, the photothermographic material containing elsewhere at least on one plane of the a support at least one kind of photosensitive silver halide, a non-photosensitive organic silver salt, a reducing agent for silver ion and a binder; characterized in that the photosensitive silver halide contains an iridium compound, and the image producing apparatus has an exposure corrective control means for correctively controlling exposure output according to a temperature profile of photothermographic material within the apparatus. This method can provide an image with a stable quality while not being affected by environmental conditions during the image production.

Owner:FUJIFILM CORP

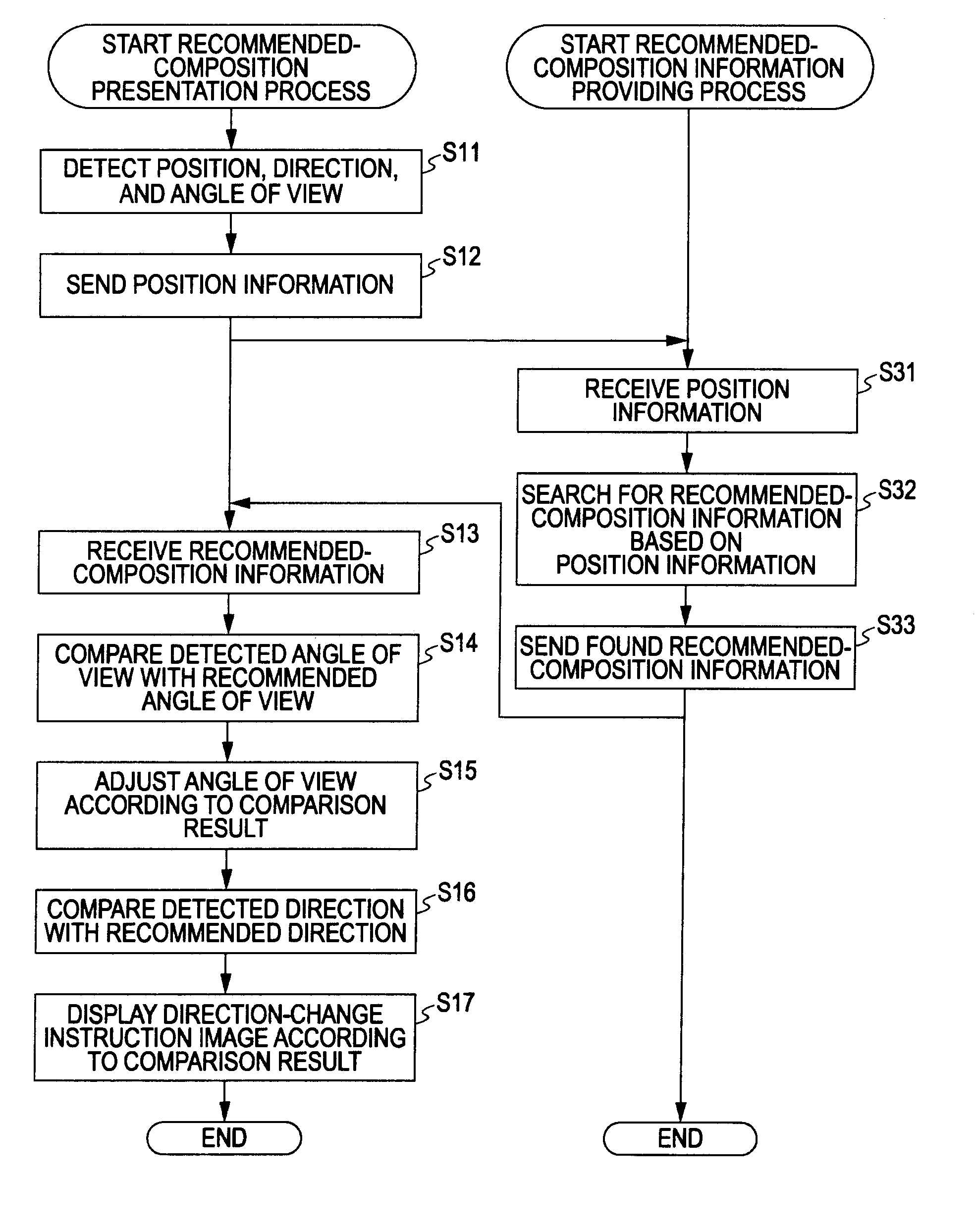

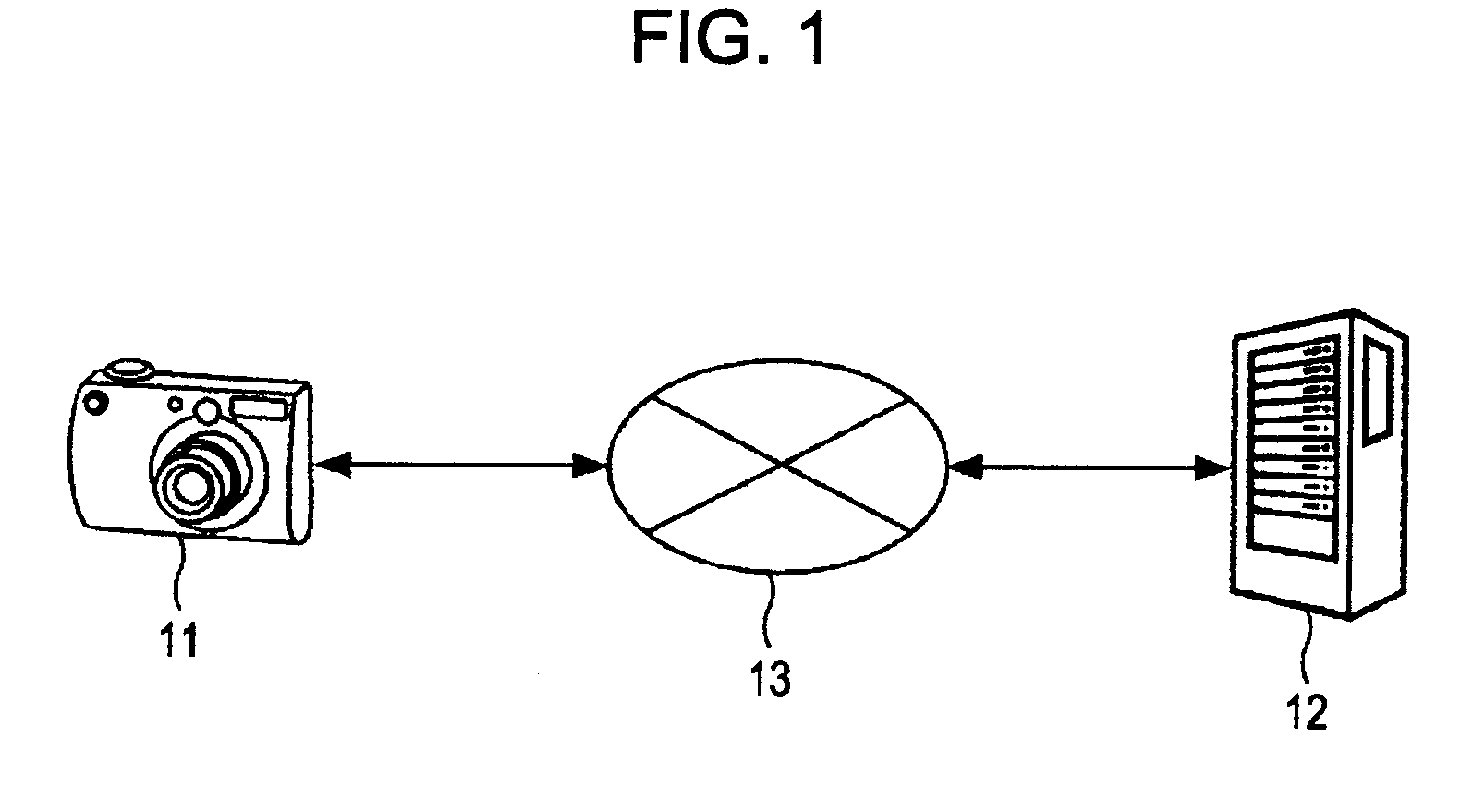

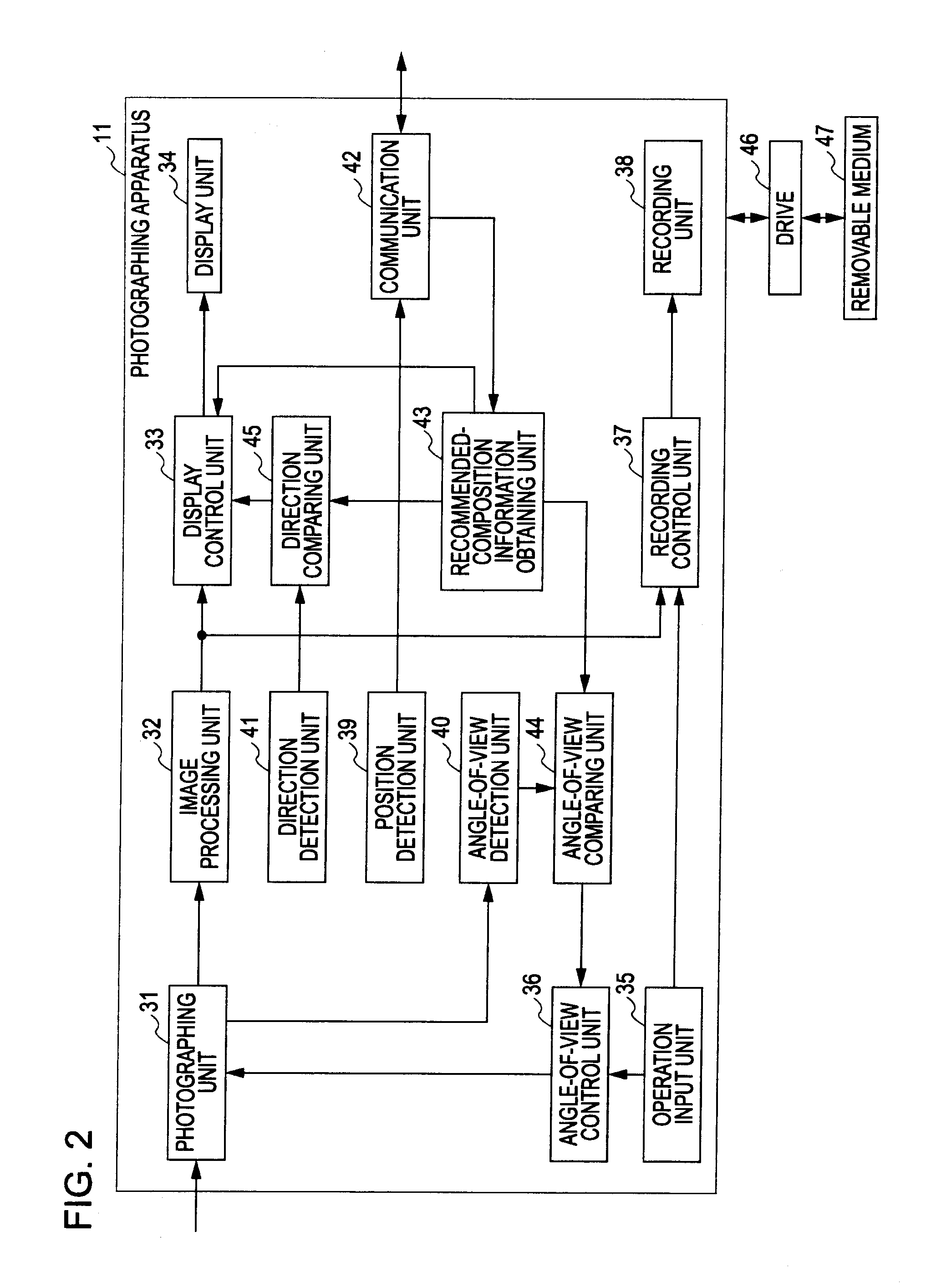

Photographing apparatus and method, and program

InactiveUS20100074613A1Small amountTelevision system detailsProcessingComputer graphics (images)Direction detection

A photographing apparatus includes the following elements. A photographing unit photographs an object. A position detecting unit detects the position of the photographing apparatus. A direction detecting unit detects the direction of the photographing apparatus when the object is photographed. An angle-of-view detecting unit detects the angle of view of the photographed image. A recommended-composition information obtaining unit obtains recommended-composition information including a recommended angle of view of the image photographed at the detected position and a recommended direction. An angle-of-view comparing unit compares the detected angle of view with the recommended angle of view. An angle-of-view adjusting unit adjusts the angle of view in accordance with the result of the comparison. A direction comparing unit compares the detected direction with the recommended direction. A presenting unit presents, in accordance with the result of the comparison, direction-change instruction information for instructing the direction of the photographing apparatus to be changed.

Owner:SONY CORP

Method of promoting skin care products

InactiveUS6922523B2Projector film strip handlingCamera film strip handlingSkin Care ProductGerontology

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

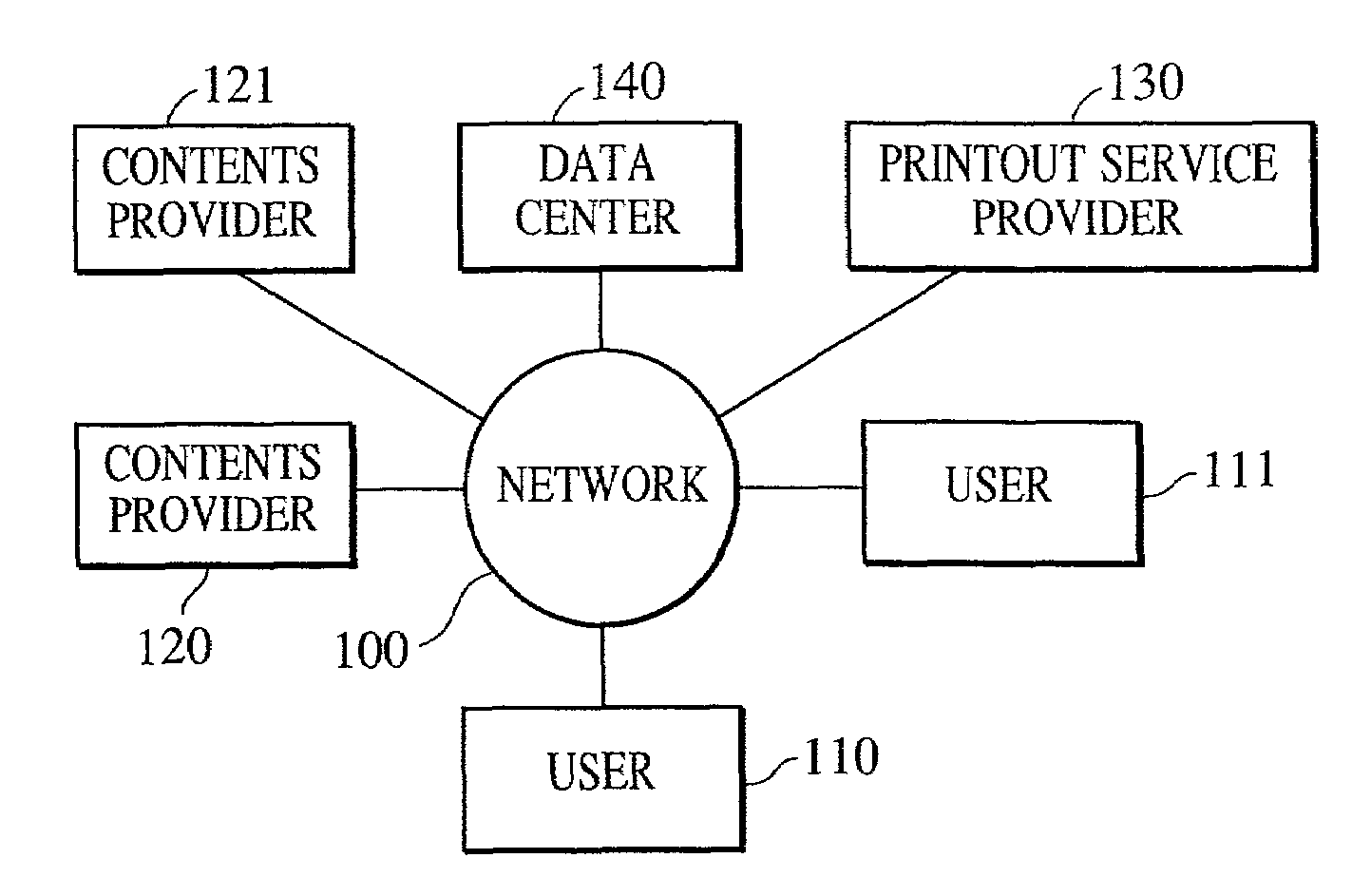

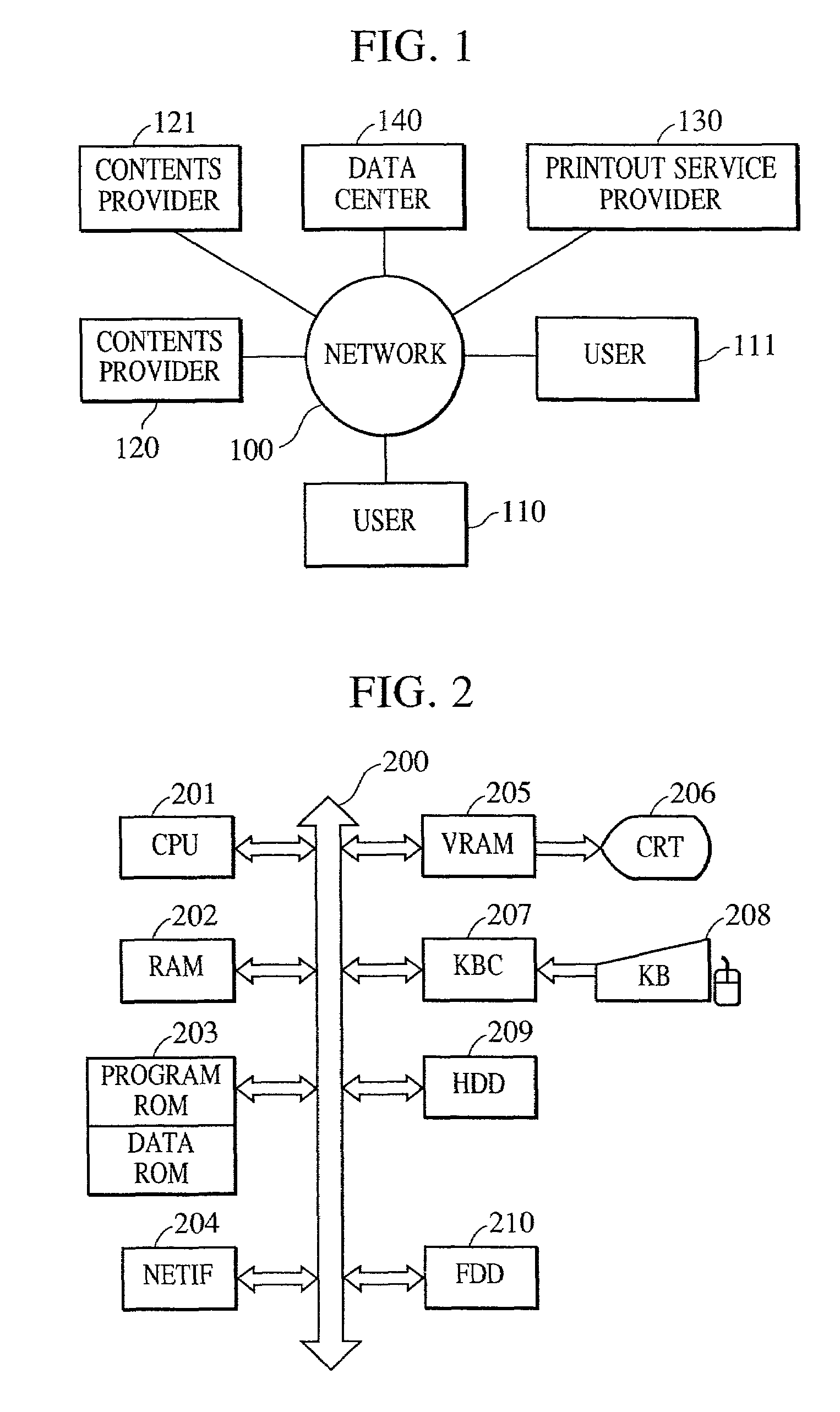

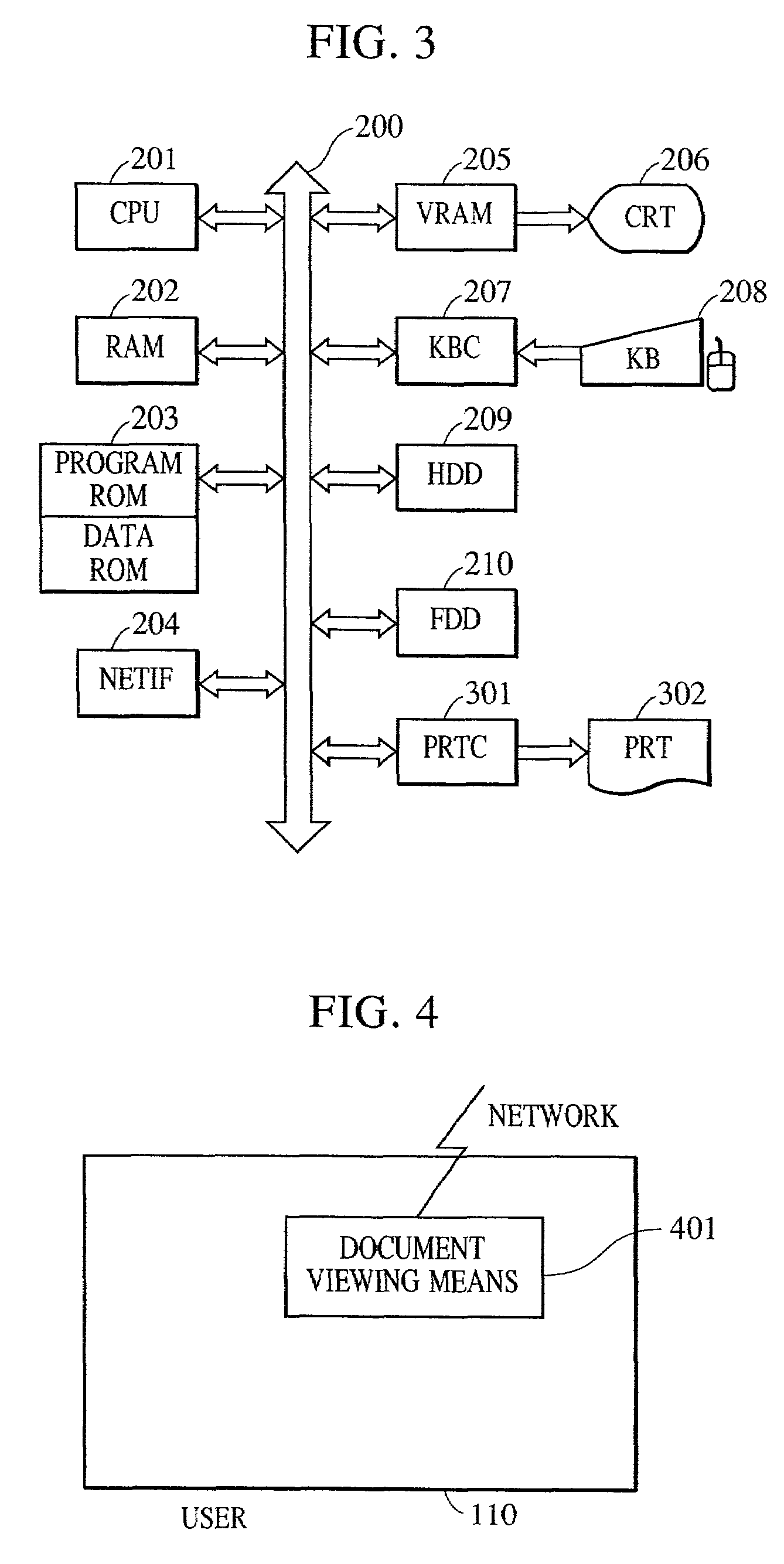

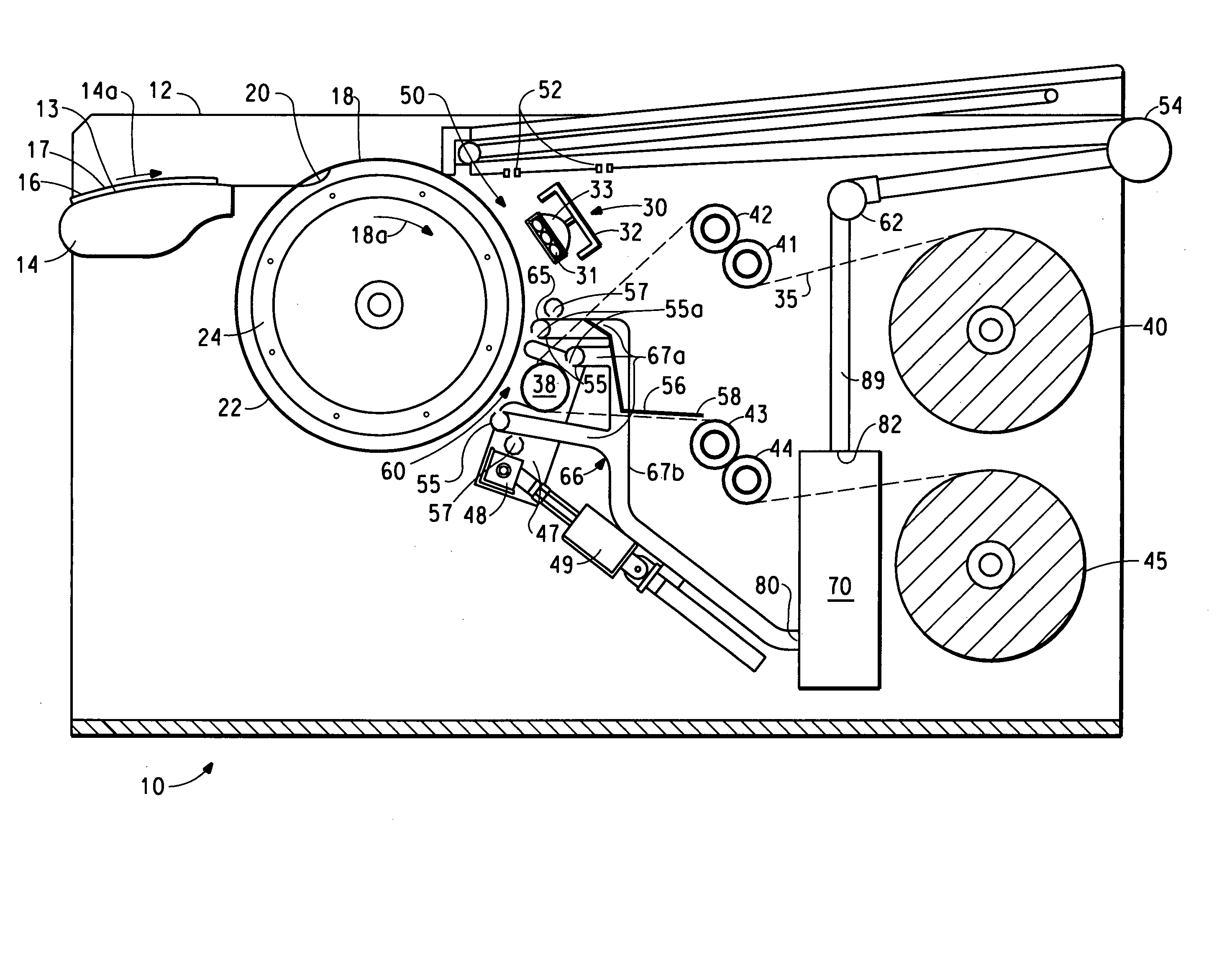

Printing control device and printing control method, printing control system, and recording medium

InactiveUS7142317B2Multiple digital computer combinationsBuying/selling/leasing transactionsNetwork connectionControl system

A printing control system has a contents provider and a printout service provider connected via a network. The contents provider comprises a device for generating viewing screens, a device for generating a conditions settings screen from printout information and service information obtained from a printout service provider, a device for generating a confirmation screen for setting the conditions, and a device for transmitting the contents selected with the viewing screen, and the printout service provider comprises a device for transmitting the service information, and a device for generating printing data from the contents provided from the contents provider. This provides contents providers with contents providing means other than downloading data, and users with services for various printing forms other than home-use printers.

Owner:CANON KK

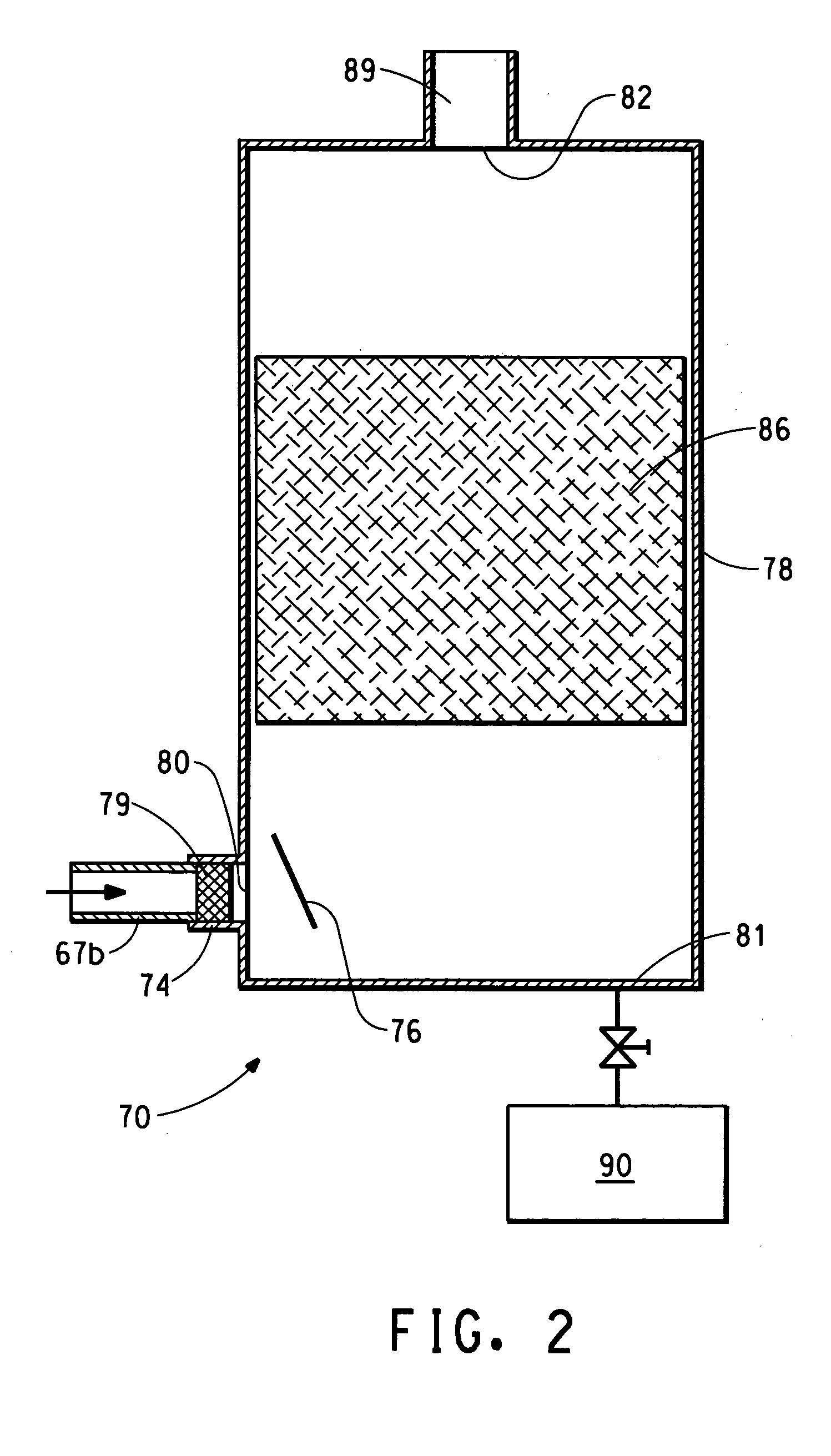

Method and apparatus for thermal development

Owner:EI DU PONT DE NEMOURS & CO

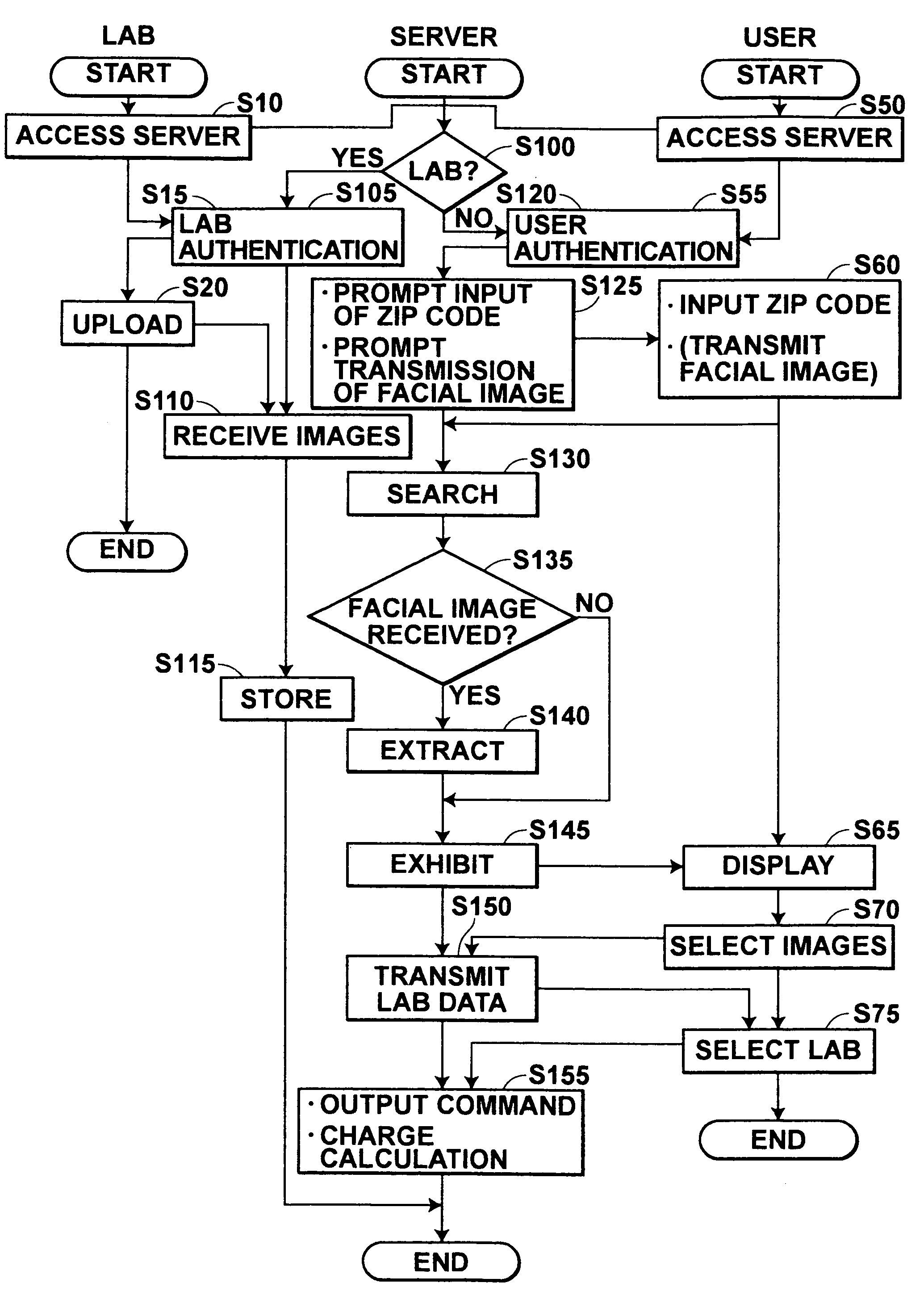

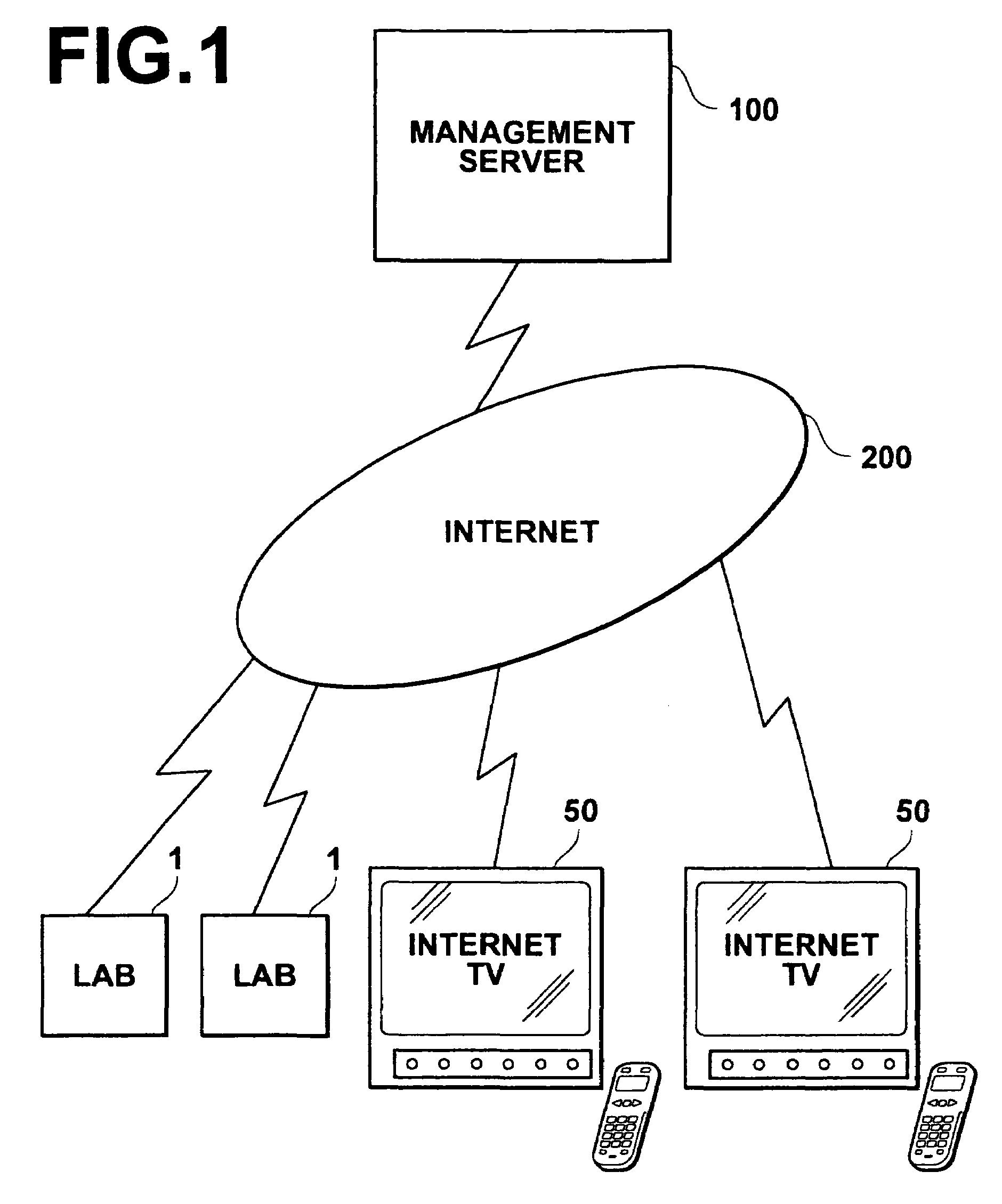

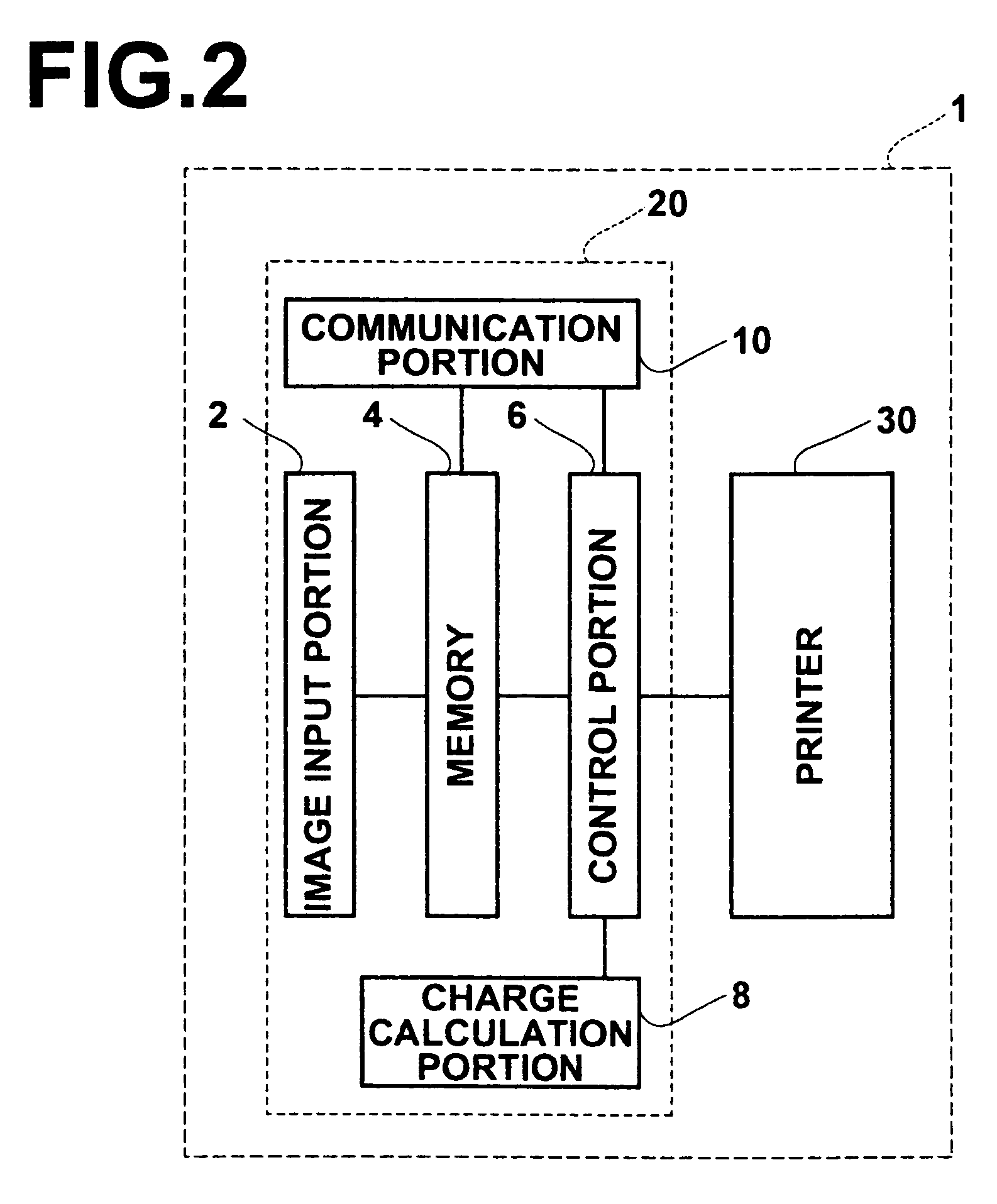

Photographic image service system

InactiveUS7209653B2Reduce image qualityAvoid downloadingTelevision system detailsReservationsComputer graphics (images)The Internet

Photographic images of local area events are efficiently provided. Each of a plurality of laboratories obtains photographic images of events in their local areas and uploads the images to a management server. The management server stores the images, correlated with area specifying data that specifies the location of the laboratory which has uploaded them. A user transmits the zip code of an area in which an event for which he desires photographic images was held, via an Internet television set. The management server searches for images uploaded by a laboratory in an area that matches the transmitted zip code, and transmits the images to the Internet television set. The user selects desired images. Then, the management server generates and transmits an output command that causes a laboratory to print the images selected by the user.

Owner:FUJIFILM CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com