Coat/develop module with shared dispense

a technology of a dispense module and a dispense device, which is applied in the direction of programme control, printers, and total factory control, etc., can solve the problems of large processing time, large processing time, and inability to provide a number of different coatings, so as to reduce the number of redundant systems, reduce the cost of the dispense system, and reduce the complexity and footprint of the system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

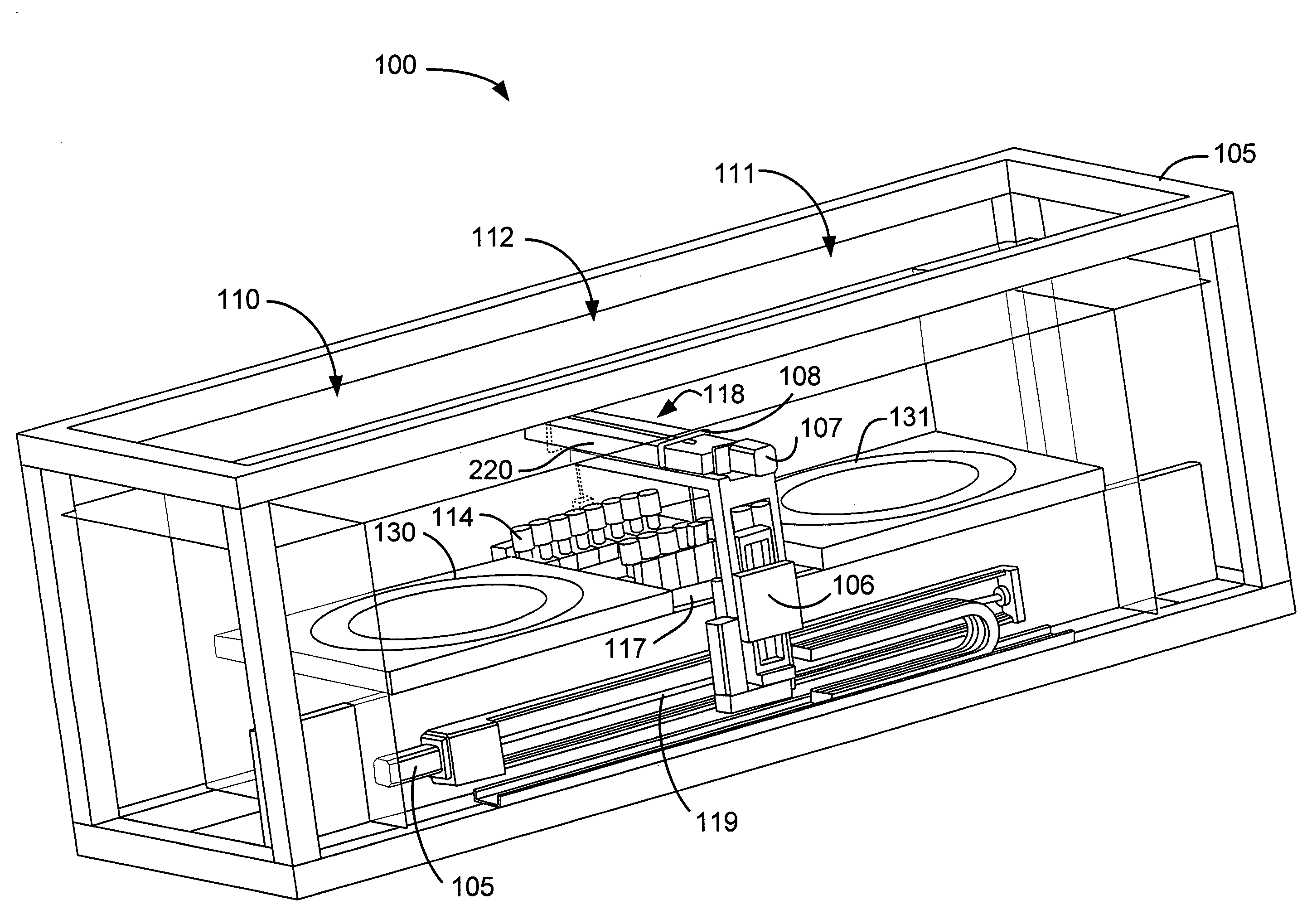

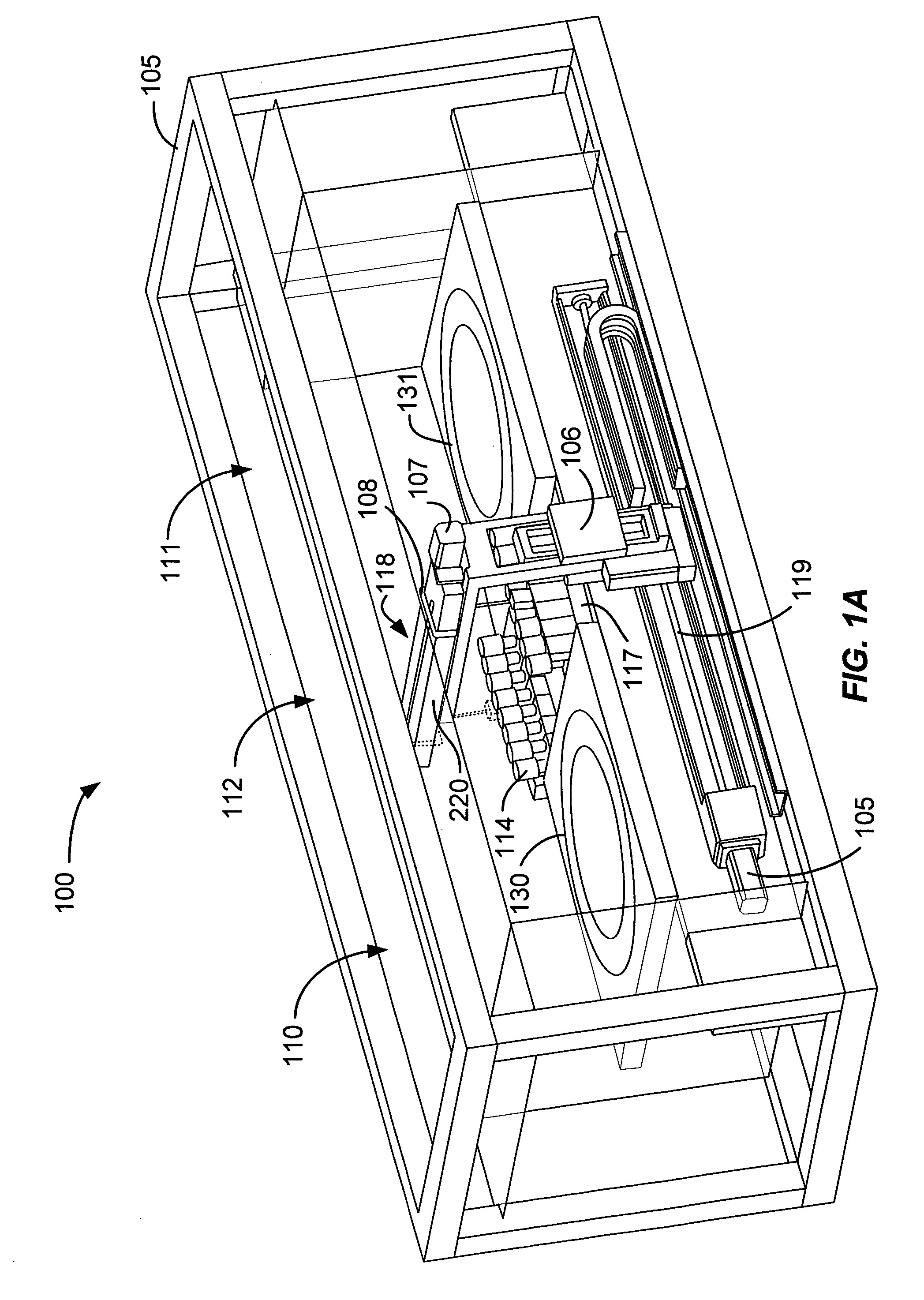

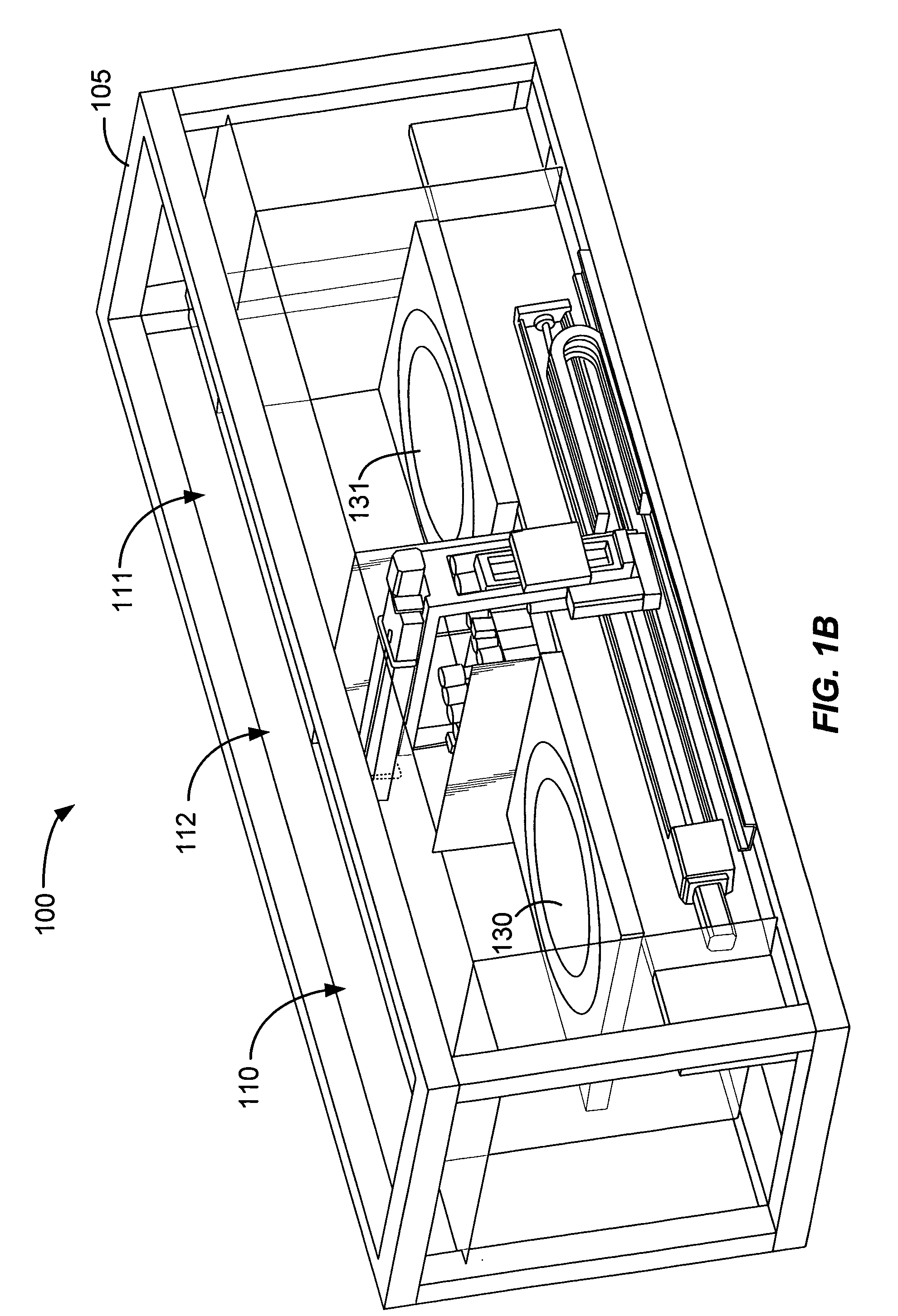

[0032] According to the present invention, techniques related to the field of semiconductor processing equipment are provided. More particularly, the present invention includes a method and apparatus for dispensing fluids onto a semiconductor substrate. Merely by way of example, the method and apparatus has been applied to two processing chambers in a coat / develop module sharing a central fluid dispense bank. But it would be recognized that the invention has a much broader range of applicability.

[0033]FIG. 7 is a plan view of one embodiment of a track lithography tool 710 that illustrates a number of the aspects of the present invention that may be used to advantage. One embodiment of the track lithography 710, as illustrated in FIG. 7, contains a front end module (sometimes referred to as a factory interface) 750, a central module 850, and a rear module (sometimes referred to as a scanner interface) 900. The front end module 750 generally contains one or more pod assemblies or FOU...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com