Purged vacuum chuck with proximity pins

a vacuum chuck and proximity pin technology, applied in the field of vacuum chuck with proximity pins, can solve the problems of particulate contaminants entering the process environment, defects in the circuitry fabricated on the substrate, etc., and achieve the effects of reducing the time of substrate transition, reducing the proximity of height, and increasing the thermal transfer rate of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] According to the present invention, methods and apparatus related to semiconductor manufacturing equipment are provided. More particularly, embodiments of the present invention relate to a method and apparatus for supporting a substrate during semiconductor processing operations. The method and apparatus can be applied to electrostatic chucks, vacuum chucks, and other applications as well.

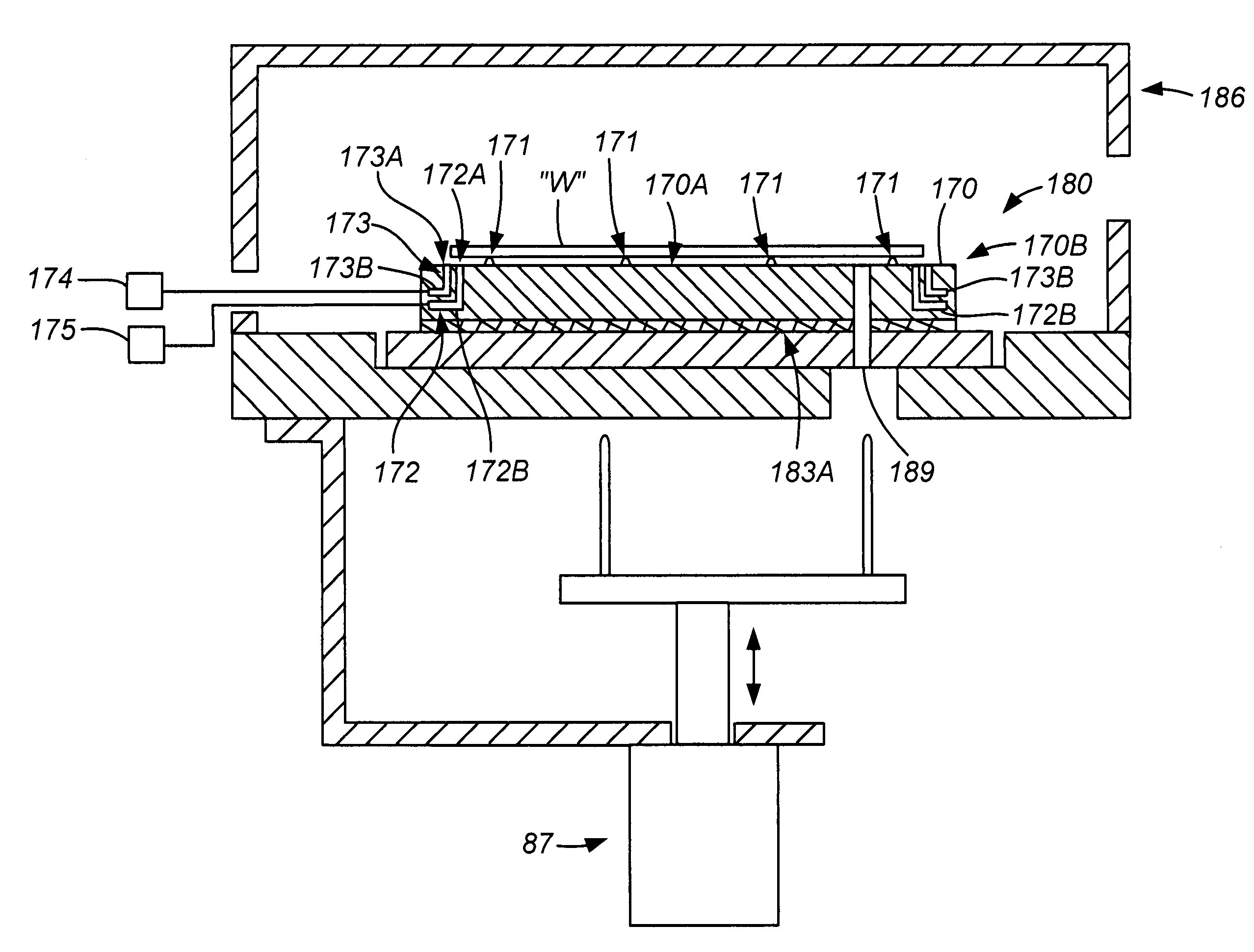

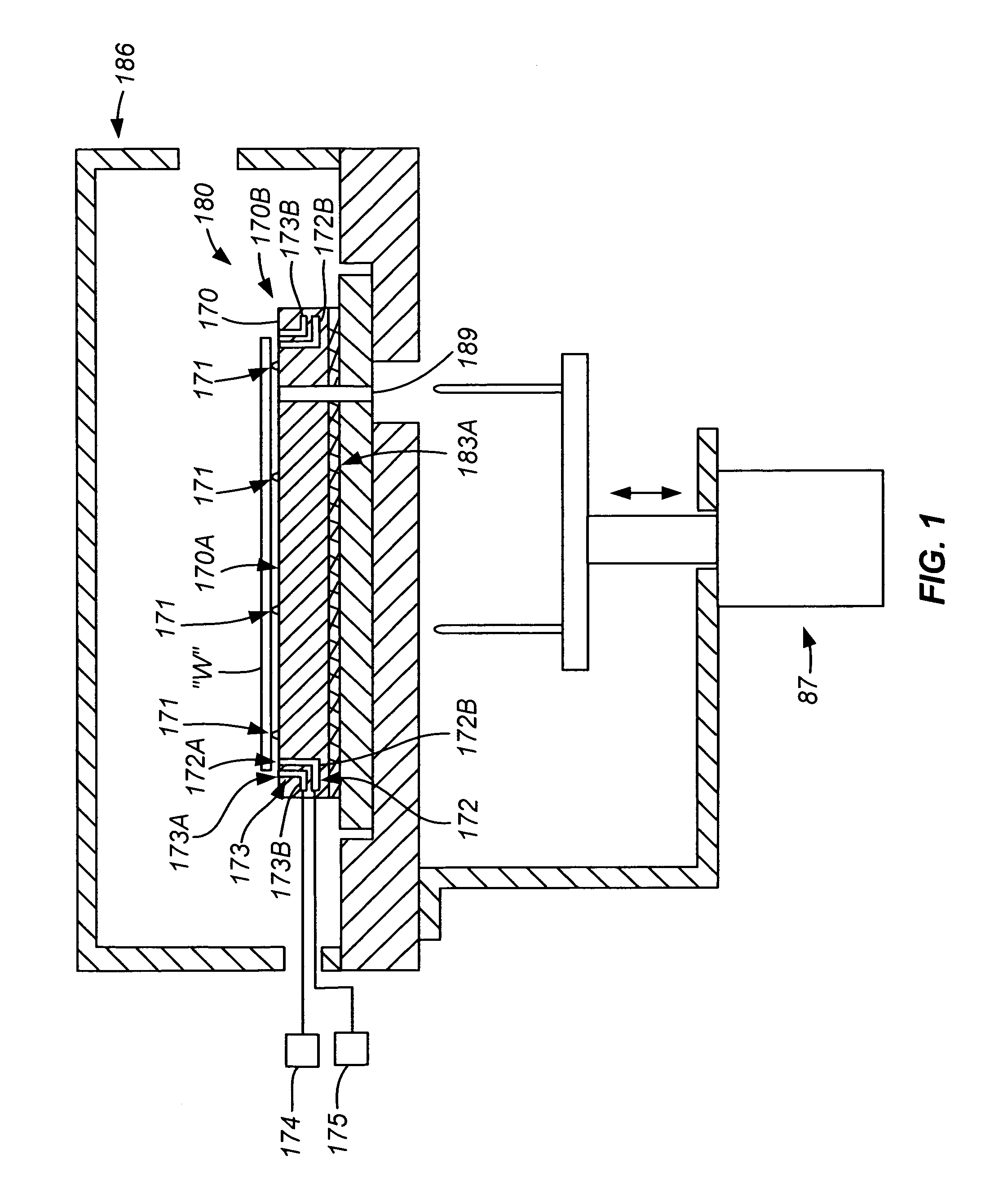

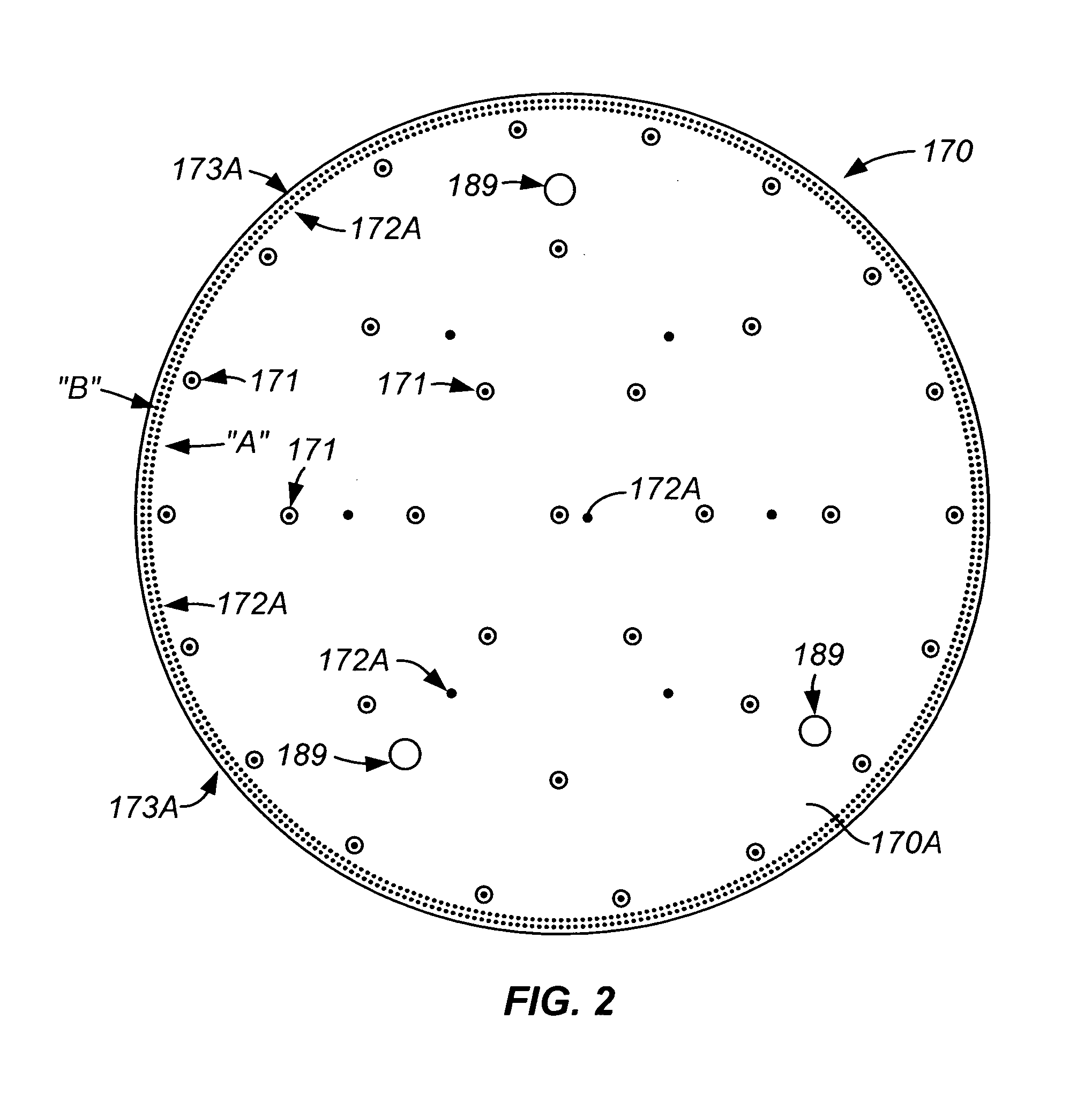

[0022]FIG. 1 is a simplified schematic side view illustration of a substrate processing chamber according to one embodiment of the present invention. In the embodiment illustrated in FIG. 1, the assembly 180 contains a plate assembly 170 and a vacuum source 175, which are mounted in a processing module 186. The plate assembly 170 generally contains a plate 170B, plate assembly surface 170A, protrusions 171, and a vacuum source port assembly 172. In this configuration the vacuum source 175 is used to create a negative pressure in the vacuum port plenum 172B, thus causing air to flow into a n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com