Stress corrosion tensile sample adopting ion irradiation to simulate neutron irradiation and preparation method of stress corrosion tensile sample

A tensile specimen and stress corrosion technology, which is used in the preparation of test samples, the use of stable tension/pressure to test the strength of materials, and sampling, etc. Large size and other problems, to avoid chemical composition changes, the preparation method is simple, and the cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

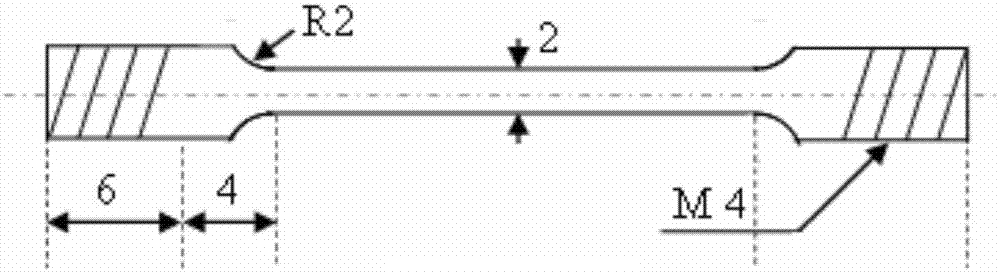

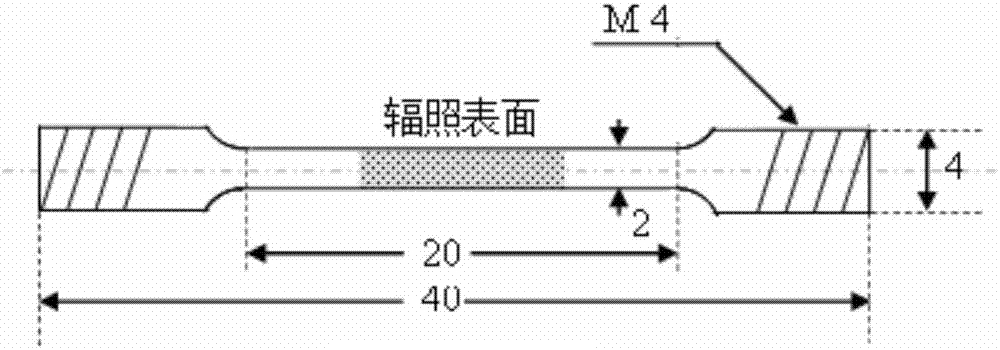

[0034] In this embodiment, the tensile sample includes a parallel part gauge length section of a rectangular cross section, a tangential transition arc part and a threaded clamping part. There is a tangential transition arc part between part of the gauge length section and the clamping part of the threaded connection, and the parallel part of the gauge length section is used for observing the stress corrosion behavior of the material after ion irradiation and testing. Take out the sample from the test base metal, the shape and size are shown in Figure 1(a)-(c), where the gauge length section of the parallel part of the rectangular cross-section of the sample is length × width × height = 20mm × 2mm × 2mm; The clamping part of the threaded connection at both ends of the tensile sample is M4mm, and the thread length is 6mm; the distance between the threaded end of the clamping part of the threaded connection and the end of the gauge length section of the parallel part is 4mm, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com