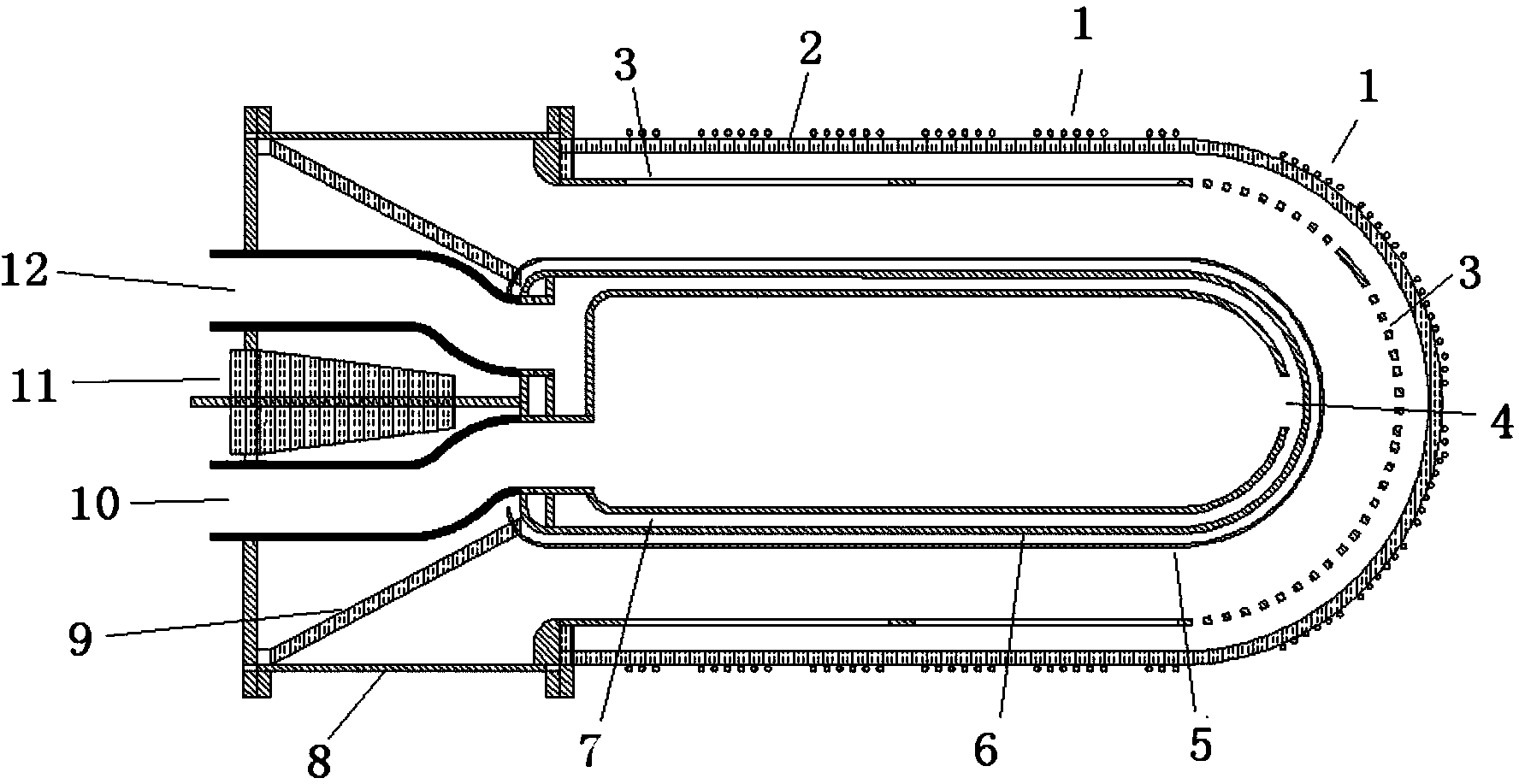

Small high-yield deuterium-deuterium neutron generator

A neutron generator, high-yield technology, applied in nuclear technology and application fields, can solve the problems of low output, large volume, complex structure, etc., and achieve the effect of reducing use and management costs, small size, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Ion beam energy 100keV, current intensity 100mA, power 10kW, target diameter 150mm, cylinder length 150mm, target area about 1000cm 2 , heat flux 10W / cm 2 , the vacuum inside the vacuum chamber is at 1Pa. The temperature rise of the cooling oil is controlled within 5 degrees, the flow rate of the cooling oil is about 1L / s, the thickness of the pure titanium is 2mm, and the target surface temperature rises about 80 degrees, and the neutron output is 1.3×10 10 n / s.

[0041] Changing to a 95 ceramic self-forming target with a thickness of 10mm, the temperature rise of the target surface is about 110 degrees, and the neutron yield is reduced by about half. However, under the same cooling conditions, the ceramic self-forming target is more resistant to bombardment and can withstand Higher deuterium ion beam bombardment, longer lifetime and lower metal sputtering products. If the intensity of the deuterium ion beam is doubled (200mA), the output can be equivalent to that o...

Embodiment 2

[0043] In Example 1, the self-forming target of pure titanium with a thickness of 2mm is replaced with a ceramic self-forming target with a thickness of 10mm. The vacuum degree inside the vacuum chamber is 0.5Pa, and the deuterium ion beam is increased to 400mA, and the power density deposited on the target surface is increased. 4 times, the neutron yield is doubled, about 2.6×10 10 n / s. The temperature rise of the target surface is 440 degrees, which can still work reliably for a long time for ceramics.

Embodiment 3

[0045] The ion beam energy is 200keV, the current intensity is 1A, the power is 200kW, the diameter of the target surface is 500mm, the length of the cylindrical part is 1000mm, and the target area is about 20000cm 2 , the target surface heat flux is about 10W / cm 2 , the vacuum degree inside the vacuum chamber is 0.1Pa. The temperature rise of the cooling oil is controlled at 5 degrees, the flow rate of the cooling oil is 20L / s, the pure titanium with a thickness of 2mm forms a self-target, the temperature rise of the target surface is about 80 degrees, and the neutron yield is about 5×10 11 n / s.

[0046] If it is replaced with a 95 ceramic self-forming target with a thickness of 10mm, the temperature rise of the target surface is about 110 degrees, and the neutron yield is reduced by about half. However, under the same cooling conditions, the ceramic self-forming target is more resistant to bombardment and can withstand Higher deuterium ion beam bombardment, longer lifetime...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com