Column tube type impinging stream reactor and operating system for producing toluene diisocynate

A technology of toluene diisocyanate and impinging flow reactor, which is applied in the field of organic isocyanate production, can solve the problems of by-product blockage, complex structure, reactor blockage amplification effect, etc., to reduce the generation of by-products, good mixing effect, and large small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

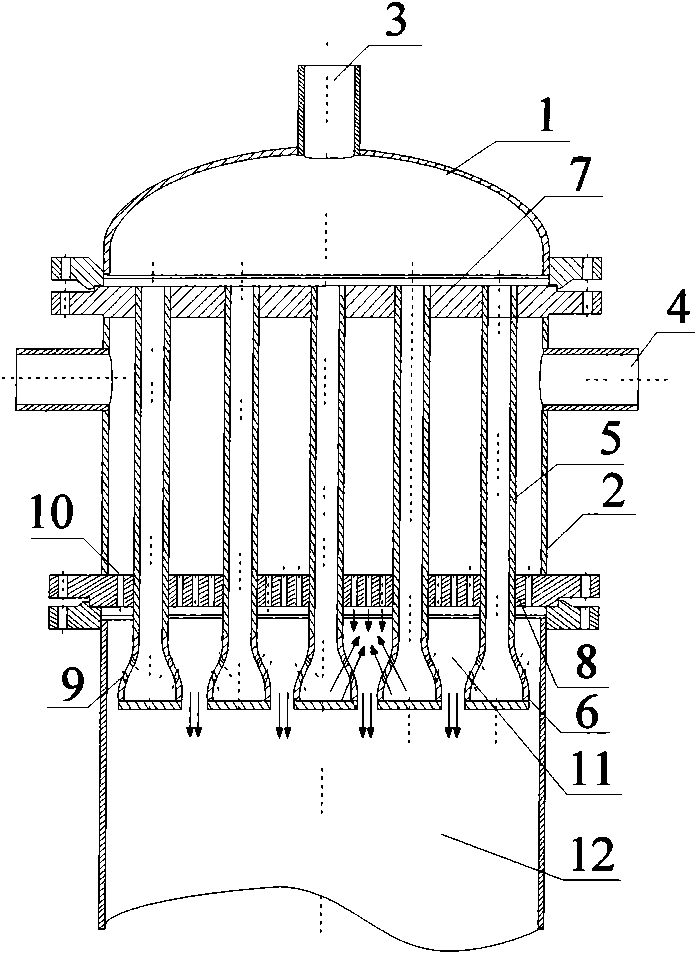

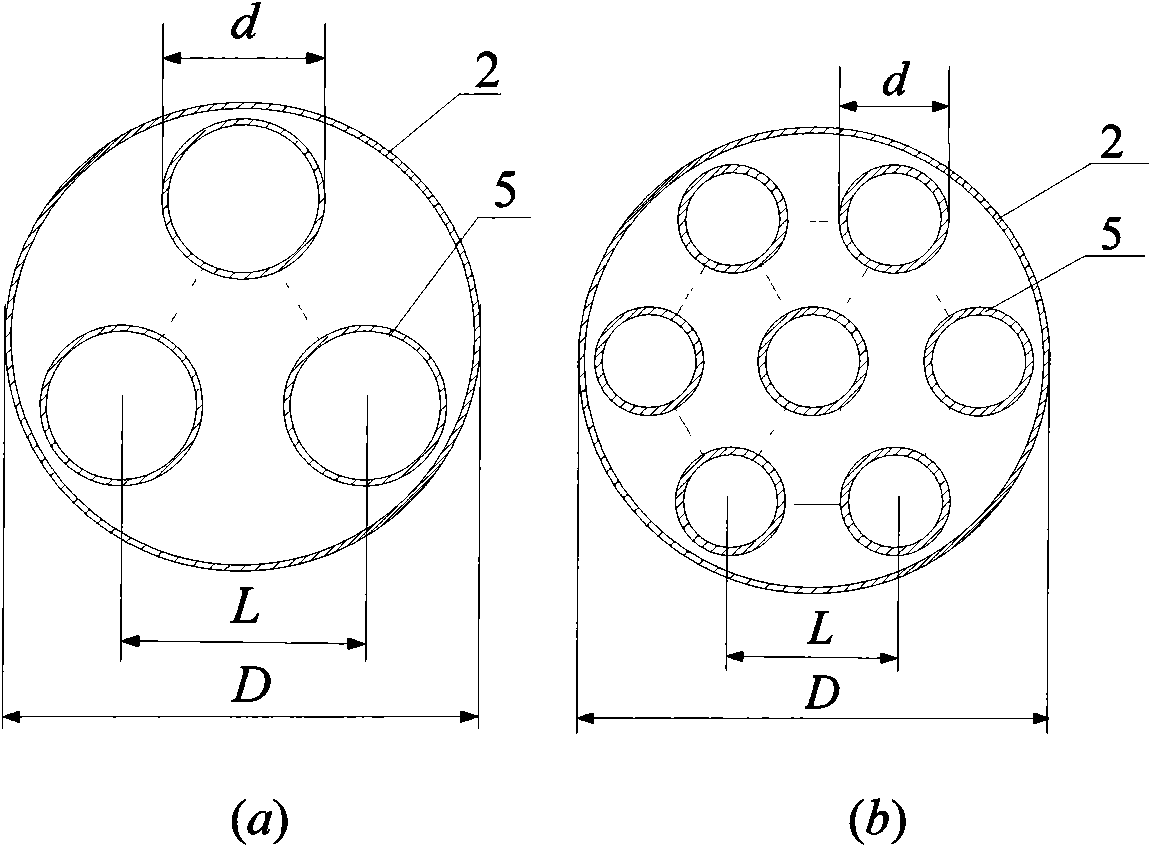

[0046] Adopt impingement flow reactor of the present invention to carry out toluene diamine phosgenation reaction to produce toluene diisocyanate (TDI), reactor structure is as figure 1 As shown, there are 2 cylinder feed ports; the arrangement of the tubes on the lower distribution plate is as follows figure 2 As shown in b: 7 tubes are arranged in an equilateral triangle, 6 mixing zones, the height of the mixing zone is 36mm, and the volume of a single mixing zone is about 23800mm 3 . The cylinder diameter D is 150mm, the tube diameter d is 32mm, and the tube center distance L is 52mm. Diameter of jet hole in lower tube sheet d 1 0.5mm, regular triangle arrangement, center distance L 1 is 2mm, and there are 222 jet holes in the lower tube plate in a single mixing zone. The diameter of the end of the tube expansion section is 44.8mm. The tube jet holes are arranged in three layers in the tube tube and the expansion section, with a diameter of 1.0mm. The total number of t...

Embodiment 2

[0051] Toluene diisocyanate (TDI) production was carried out by changing the structure and parameters of the impinging flow reactor in Example 1.

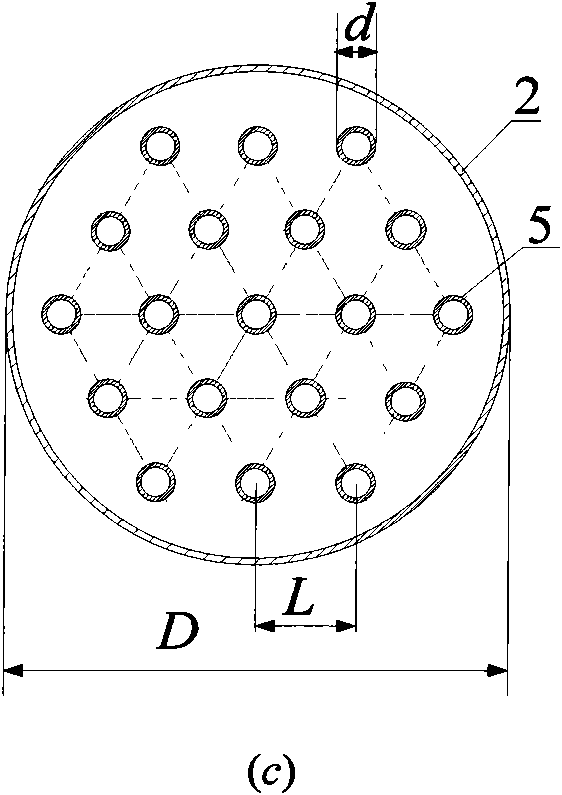

[0052] The reactor structure is as figure 1 As shown, there are 2 cylinder feed ports; the arrangement of the tubes on the lower distribution plate is as follows figure 2 As shown in c: 19 tubes are arranged in an equilateral triangle, 24 mixing zones, the height of the mixing zone is 21.6mm, and the volume of a single mixing zone is 4938mm 3 . The tube sheet diameter D is 150mm, the tube diameter d is 18mm, and the tube center distance L is 30mm. Diameter of the nozzle of the lower tube sheet d 1 0.5mm, regular triangle arrangement, center distance 2mm, 76 jet holes in the lower tube plate in a single mixing zone. The diameter of the end of the tube expansion section is 25.2mm. The tube jet holes are arranged in three layers in the tube tube and the expansion section, with a diameter of 1.0mm. The total number of tube jet por...

Embodiment 3

[0057] Toluene diisocyanate (TDI) production was carried out by changing the structure and parameters of the impinging flow reactor in Example 1 and Example 2.

[0058] The reactor structure is as figure 1 As shown, there are 2 cylinder feed ports; the arrangement of the tubes on the lower distribution plate is as follows figure 2 As shown in a: 3 tubes are arranged in an equilateral triangle, 1 mixing zone, the height of the mixing zone is 50.4mm, and the volume of a single mixing zone is 70129mm 3 . The tube sheet diameter D is 150mm, the tube diameter d is 50mm, and the tube center distance L is 78mm. Diameter of jet hole in lower tube sheet d 1 0.5mm, regular triangle arrangement, center distance 2mm, 76 jet holes in the lower tube plate in a single mixing zone. The diameter of the end of the expanded section of the tube array is 28mm. The nozzles of the tube array are arranged in three layers in the tube array and the expanded section, with a diameter of 1.0mm. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com