Organic contaminated soil thermal desorption waste gas catalytic oxidation purification catalyst and preparation method and application thereof

A technology for purifying catalysts and catalytic oxidation, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of inconvenient natural gas acquisition, catalyst carbon deposition and sintering , the catalyst is easily deactivated, etc., to achieve the effect of weakening the limitation of oxygen transport, improving the resistance to alkali metals, and improving the catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

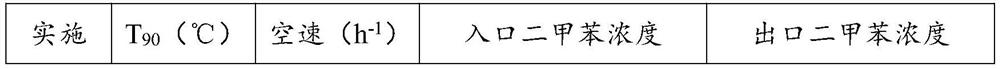

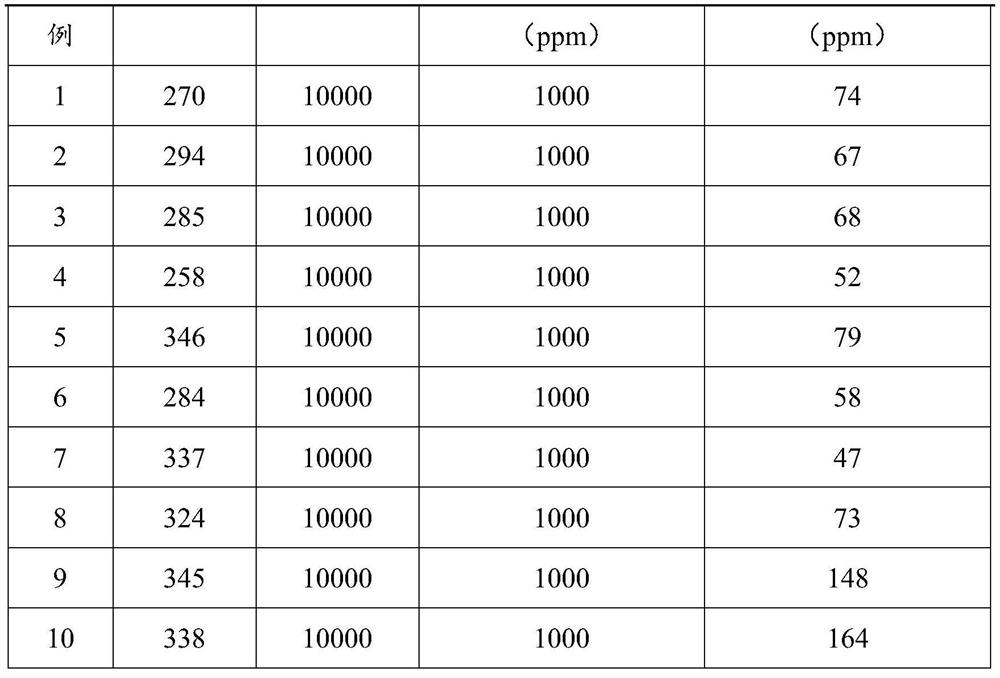

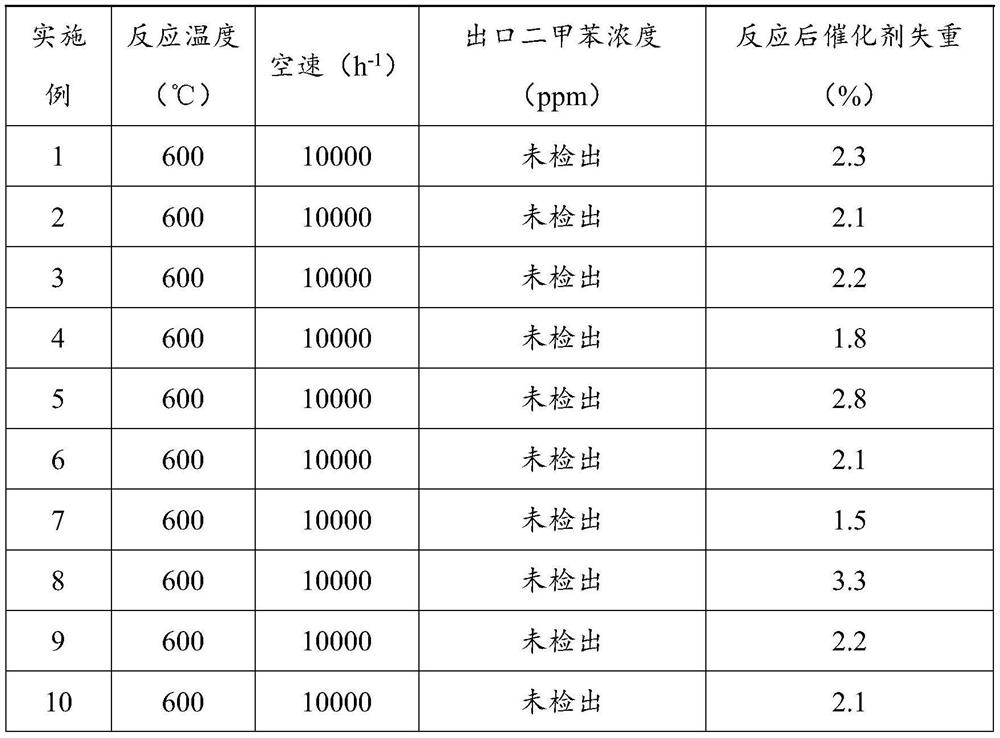

Examples

preparation example Construction

[0039] The present invention also provides a method for preparing a catalytic oxidation purification catalyst for organic polluted soil thermal desorption exhaust gas described in the above scheme, comprising the following steps:

[0040] (1) Dissolve soluble cerium salt and soluble zirconium salt in water, or dissolve soluble cerium salt, soluble zirconium salt and R component in water to obtain an aqueous solution; adjust the pH value of the resulting aqueous solution to 9-12, and then Carrying out hydrothermal reaction and first roasting to obtain a carrier; the R component is one or more of soluble lanthanum salt, soluble cobalt salt, soluble yttrium salt and silica sol;

[0041] (2) impregnating the carrier in a mixed solution of a soluble manganese salt and a soluble ruthenium salt, and then performing a second roasting to obtain a catalyst component;

[0042] (3) Slurrying the catalyst component and coating it on the honeycomb cordierite, and then performing the third c...

Embodiment 1

[0060] Weigh cerium nitrate (50.45g) and zirconium nitrate (104.53g) in a beaker of 1000mL deionized water, stir at a speed of 1500rpm for 30min to form a homogeneous solution, then slowly drop ammonia water, adjust the pH value to 10, and continue stirring After uniformity, it was transferred to a stainless steel reactor for hydrothermal reaction at 160°C for 24 hours, and the resulting product liquid was cooled to room temperature, followed by filtration and water washing, and then dried at 80°C overnight, and the obtained hydrothermal product was roasted at 500°C for 4 hours to obtain a carrier . Immerse the carrier in a mixed solution of manganese nitrate and ruthenium chloride for impregnation, heat and stir until the water is evaporated to dryness, dry in an oven at 80°C overnight, put the obtained powder in a muffle furnace and roast at 2°C / min to 500°C After 4h, the catalyst component was obtained after cooling. Among them, the carrier is CeO 2 -ZrO 2 complex, where...

Embodiment 2

[0063] Weigh cerium nitrate (50.45g), zirconium nitrate (95.81g), and lanthanum nitrate (6.65g) in a beaker of 1000mL deionized water, stir at a speed of 1500rpm for 30min to form a homogeneous solution, then slowly drip ammonia water, and adjust the pH Adjust to 10, continue stirring, after stirring evenly, then transfer to a stainless steel reactor for 24 hours at 160°C, cool to room temperature, then filter and wash in sequence, then dry at 80°C overnight, and roast at 450°C for 4 hours to obtain the carrier. Immerse the carrier in a mixed solution of manganese nitrate and ruthenium chloride for impregnation, heat and stir until the water is evaporated to dryness, dry in an oven at 80°C overnight, put the obtained powder in a muffle furnace and roast at 2°C / min to 450°C After 4h, the catalyst component was obtained after cooling. Among them, the carrier is CeO 2 -ZrO 2 -La 2 o 3 complex, where CeO 2 Content is 40%, ZrO 2 The content is 55%, La 2 o 3 The content is 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com