A method for directly preparing hzsm-5 molecular sieve and forming hzsm-5 molecular sieve

A technology of molecular sieve and silicon source, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of long process flow, achieve high yield, reduce waste liquid discharge, and prepare And the effect of short molding process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

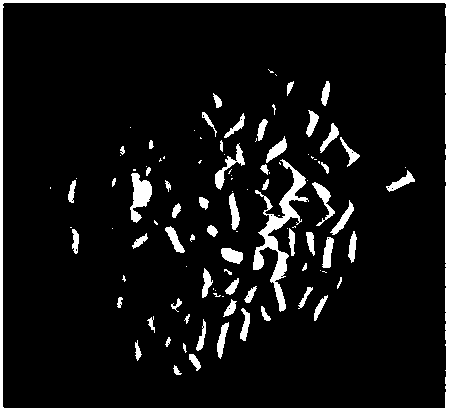

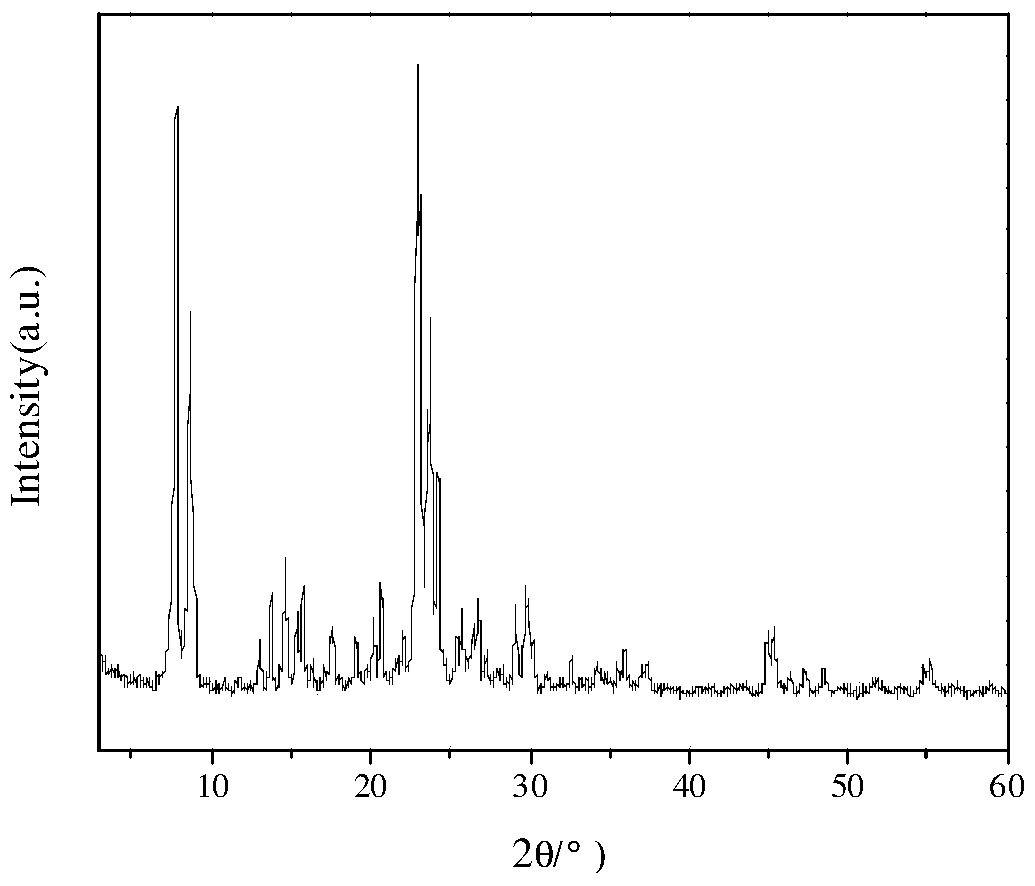

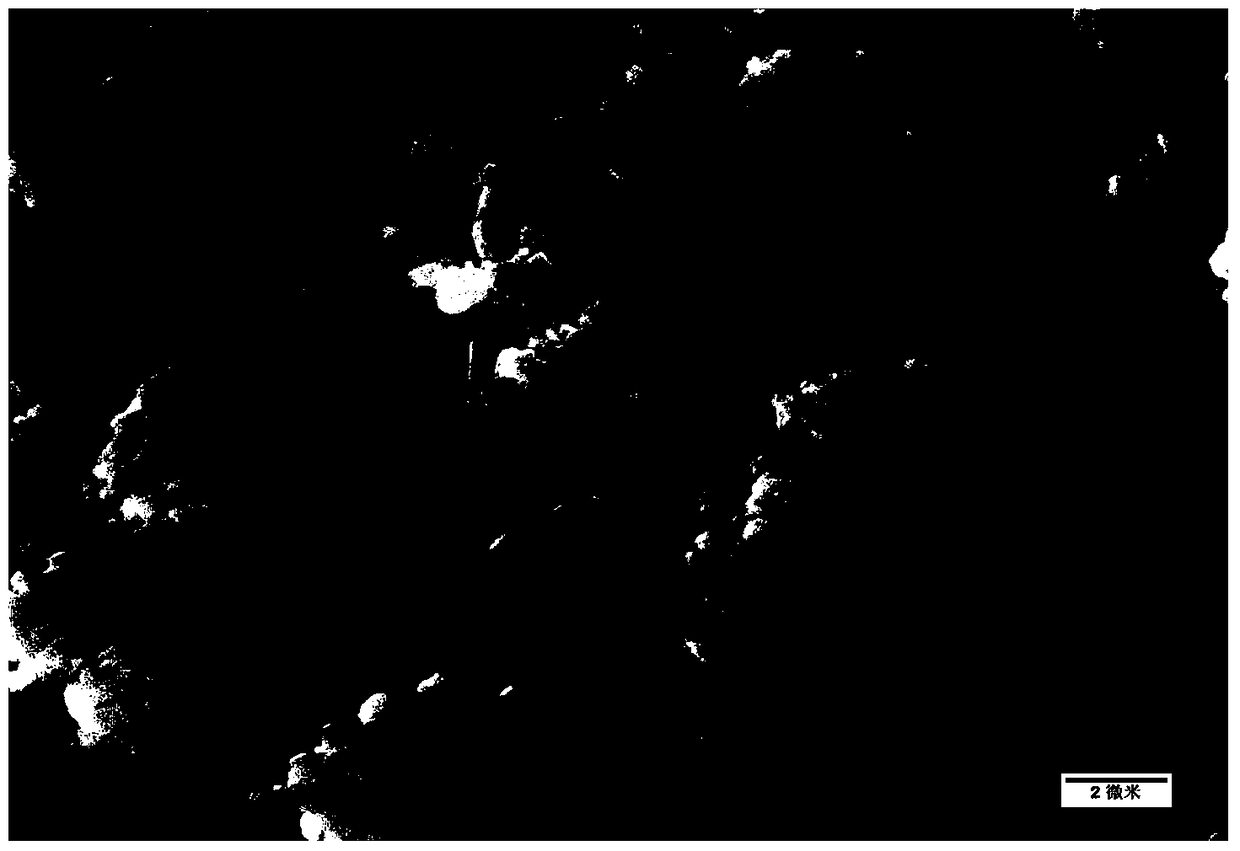

[0025] Weigh 10 grams of ground coarse-pore silica gel powder, 1.1 grams of aluminum sulfate, and commercially available 0.4 grams of HZSM-5 as seed crystals. After fully grinding and mixing, put them into a crystallization kettle together with 8.2 grams of 40 wt% ethylenediamine solution. Crystallized at 180°C for 3 days, the obtained sample was washed with distilled water until neutral, dried overnight and calcined at 550°C for 6 hours to obtain HZSM-5 molecular sieve with a crystallinity of 87.3% and a specific surface area of 441m 2 / g.

Embodiment 2

[0027] Weigh 10 grams of ground coarse-pore silica gel powder, 1.25 grams of aluminum nitrate, and 0.4 grams of commercially available ZSM-5 seed crystals. After fully grinding and mixing, add 4.0 grams of tetrapropylammonium hydroxide solution (25wt%), put into the crystal Crystallize at 180°C for 3 days in a chemical kettle, wash the obtained sample with distilled water until neutral, dry overnight and roast at 550°C for 4 hours to obtain HZSM-5 molecular sieve with a crystallinity of 93.5% and a specific surface area of 463m 2 / g.

Embodiment 3

[0029] Weigh 10 grams of ground coarse-pore silica gel powder, 0.1 grams of aluminum phosphate, and 0.4 grams of commercially available ZSM-5 seed crystals. After fully grinding and mixing, add 4.0 grams of ethylamine (analytical pure), put into a crystallization kettle at 170 Crystallization at ℃ for 4 days, the obtained sample was washed with distilled water to neutrality, dried overnight and calcined at 550℃ for 10 hours to obtain HZSM-5 molecular sieve with a crystallinity of 85.3% and a specific surface area of 429m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com