Axial-flow type jet flow gas wave pressure supercharger

An air wave supercharger, axial flow technology, applied in the direction of fluid pressure converter, mechanical equipment, etc., can solve the problems of high rotation speed, low efficiency, complex structure, etc., to achieve simple structure, low rotation speed, and energy transfer speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

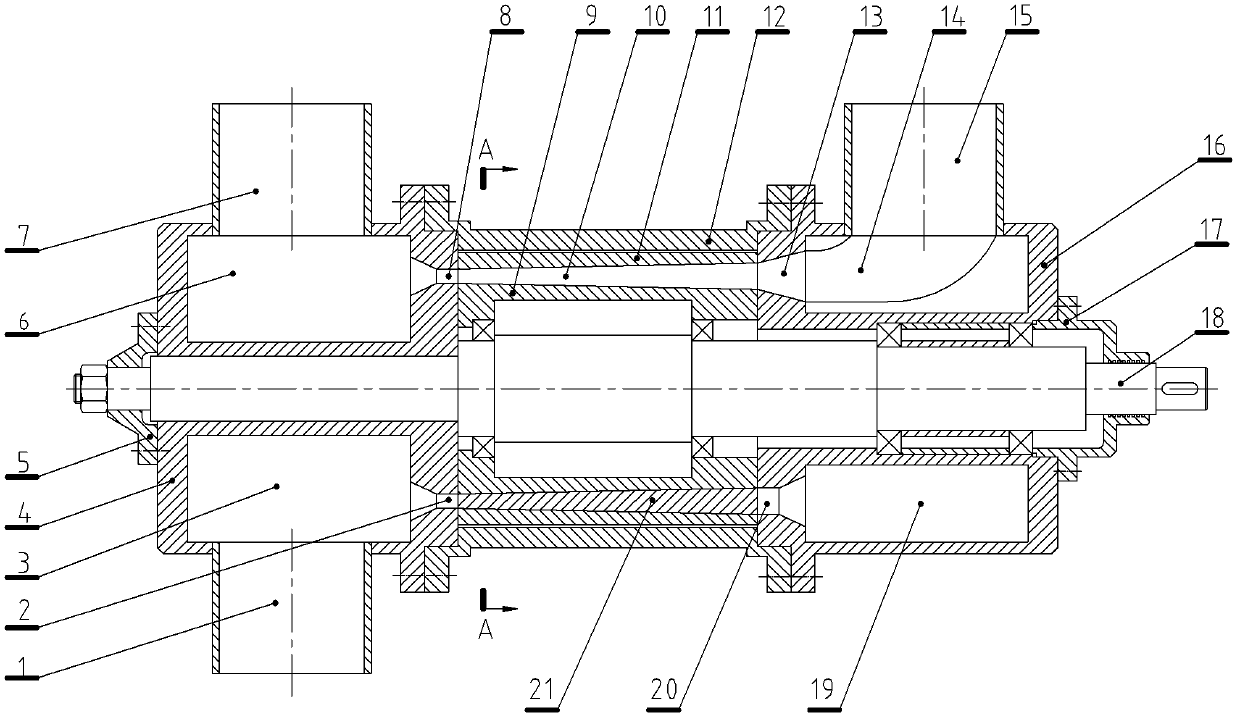

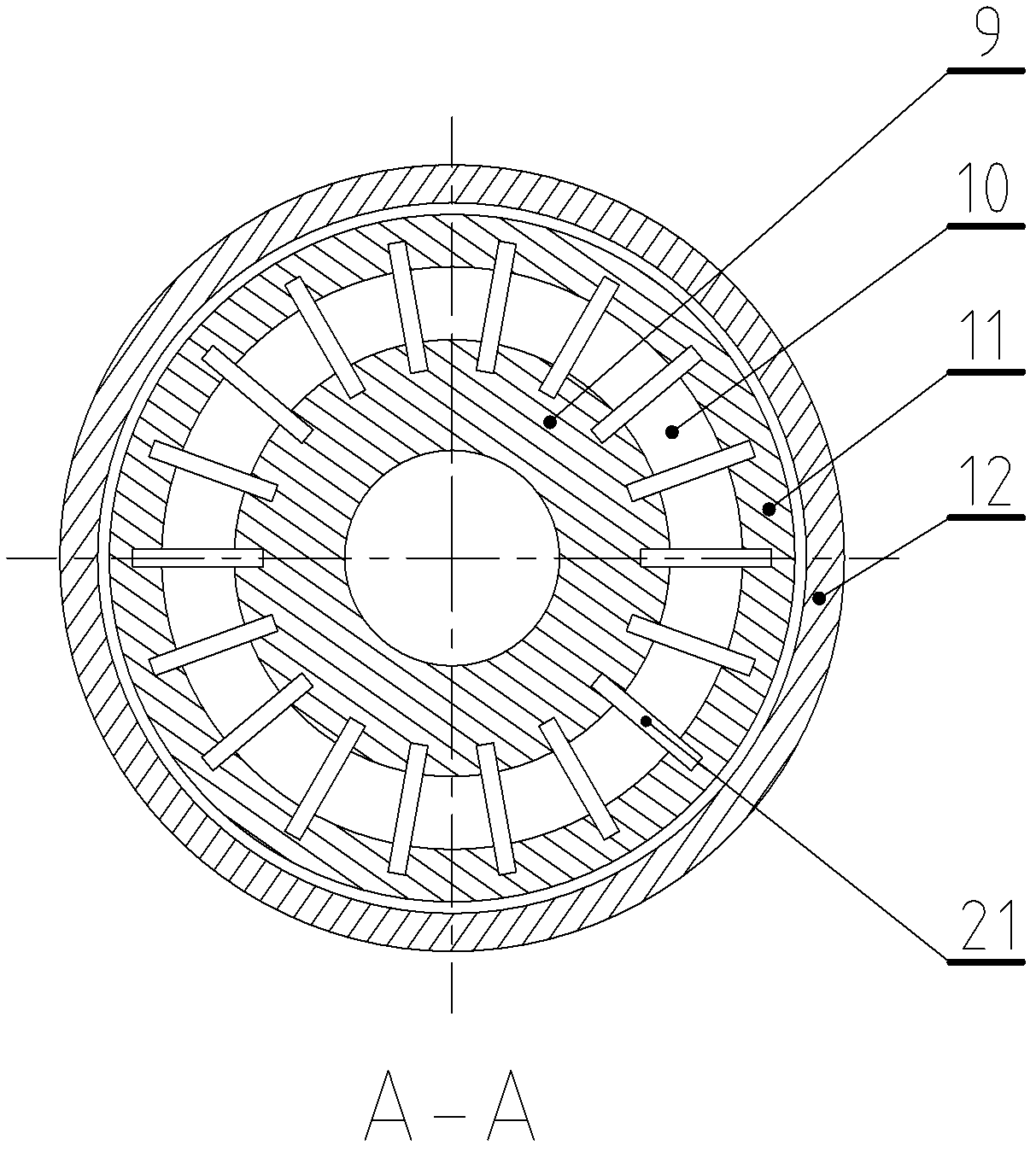

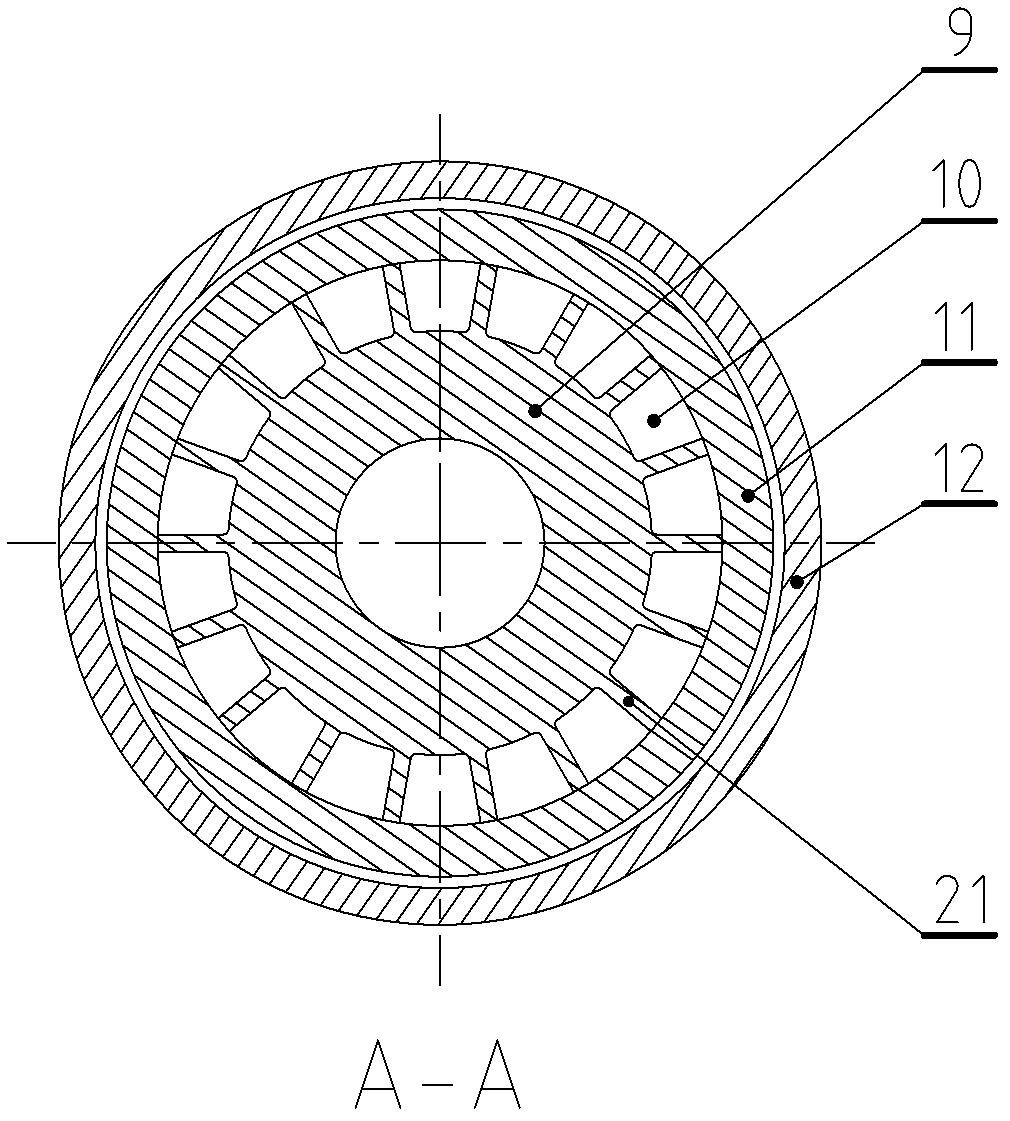

[0024] Axial-flow jet air wave supercharger mainly consists of a cylindrical, truncated, or combined cylindrical and truncated drum 9, a drum jacket 11, multiple pressure oscillation pipe channels 10, a main shaft 18, a left body 4, Right body 16, shell 12, high-pressure jet nozzle 2, low-pressure air injection port 8, medium-pressure outlet 13, pressure equalization port 20, high-pressure air inlet 1 and high-pressure buffer chamber 3, low-pressure air inlet 7 and low-pressure buffer Cavity 6, medium pressure air outlet 15 and medium pressure buffer chamber 19 are formed. Between the outer circle of drum 9 and the inner circle of drum jacket 11, a plurality of long and longitudinally separated narrow walls 21 pair the outer circle of drum 9 and the inner circle of drum jacket 11. The ring cavity surrounded by the inner circle of the drum jacket 11 is divided to form a plurality of circumferentially arranged grooves 10 with both ends open and the periphery closed. The grooves 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com