Misplaced channel free-rotating hydraulic piston multipass supercharger

A technology of hydraulic piston and supercharger, which is applied in the direction of fluid pressure converter, osmosis/dialysis water/sewage treatment, mechanical equipment, etc., which can solve the additional costs such as frequent occurrence of accidents, increased equipment investment and daily management and maintenance , huge supporting engineering and other problems, to achieve the effect of avoiding electrical accidents, prolonging the support friction force, and simple single-machine management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The structure and working principle of the present invention and the application in the reverse osmosis seawater desalination system are further elaborated in conjunction with the accompanying drawings and embodiments:

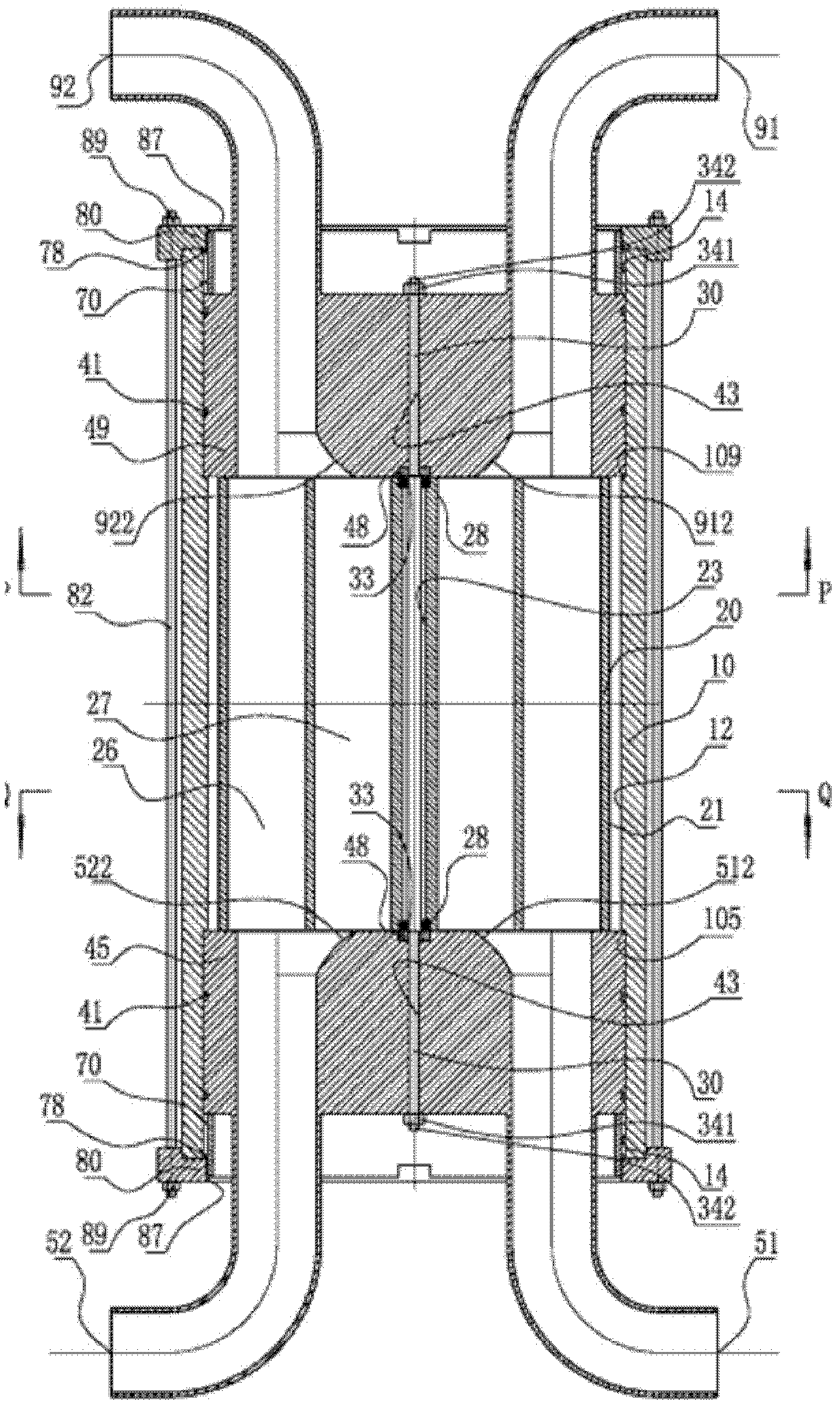

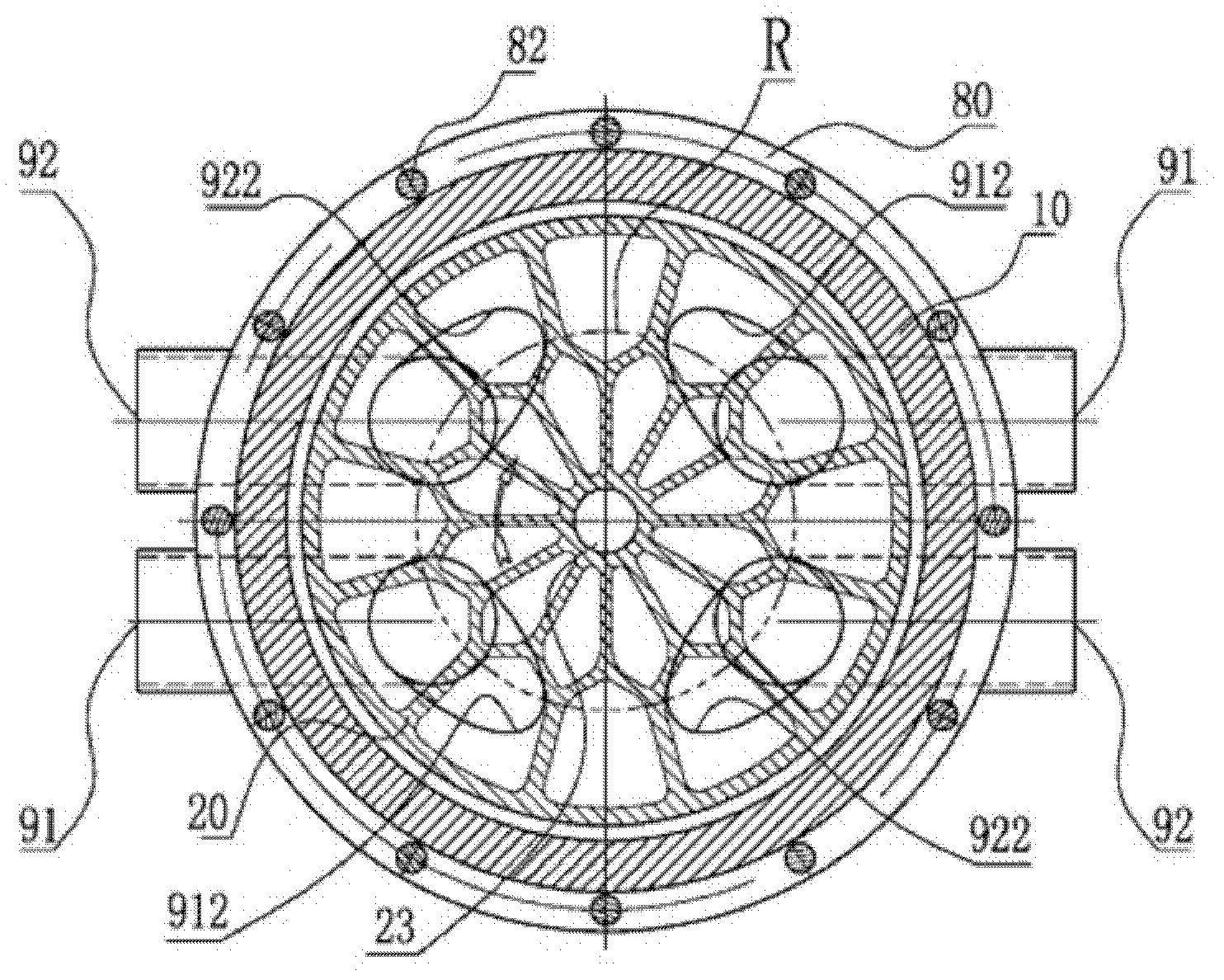

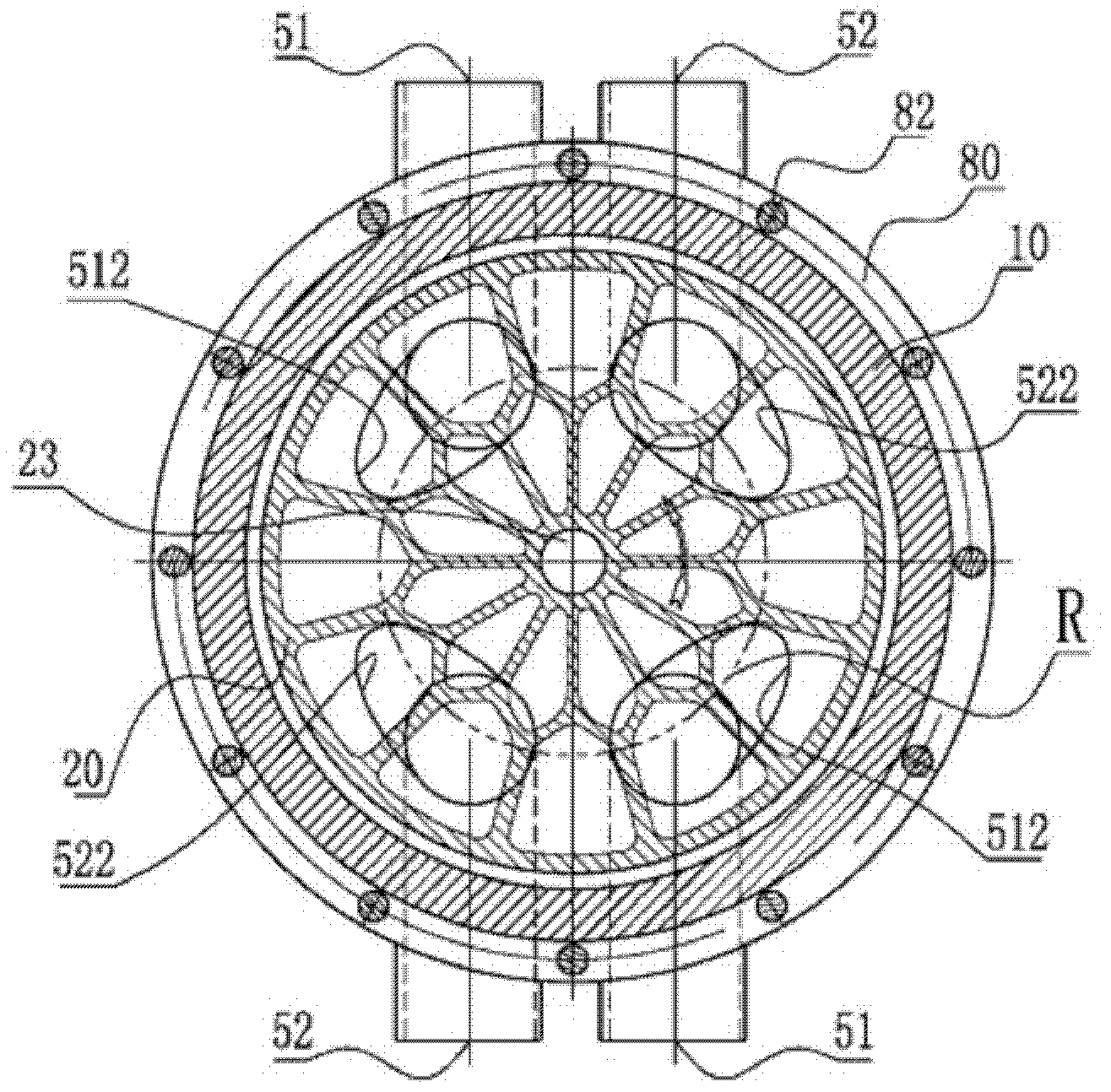

[0041] figure 1 It is a structural schematic diagram of a self-rotating hydraulic piston supercharger with dislocation channels, reflecting the overall assembly relationship of the present invention. Cooperate figure 2 , image 3 , Figure 4 as well as Figure 5 is true figure 1 The cross-sectional views of different parts reflect the mutual positional relationship between the inlet and outlet channels of the present invention.

[0042] A multi-pass turbocharger with dislocation channel self-rotating hydraulic piston. The two ends of the cylindrical shell 10 are end cover flanges 80, and the outer edge of the end cover flange 80 is provided with flange bolts 82; the inner hole of the end cover flange 80 is Thread 87 is connected with the screw ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com