Combined ablation and exposure system and method

a technology of flexographic printing plate and exposure system, which is applied in the field of combination ablation and exposure system, can solve the problems of flexographic plate loss, unsatisfactory handling, and high cost of flexographic pla

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

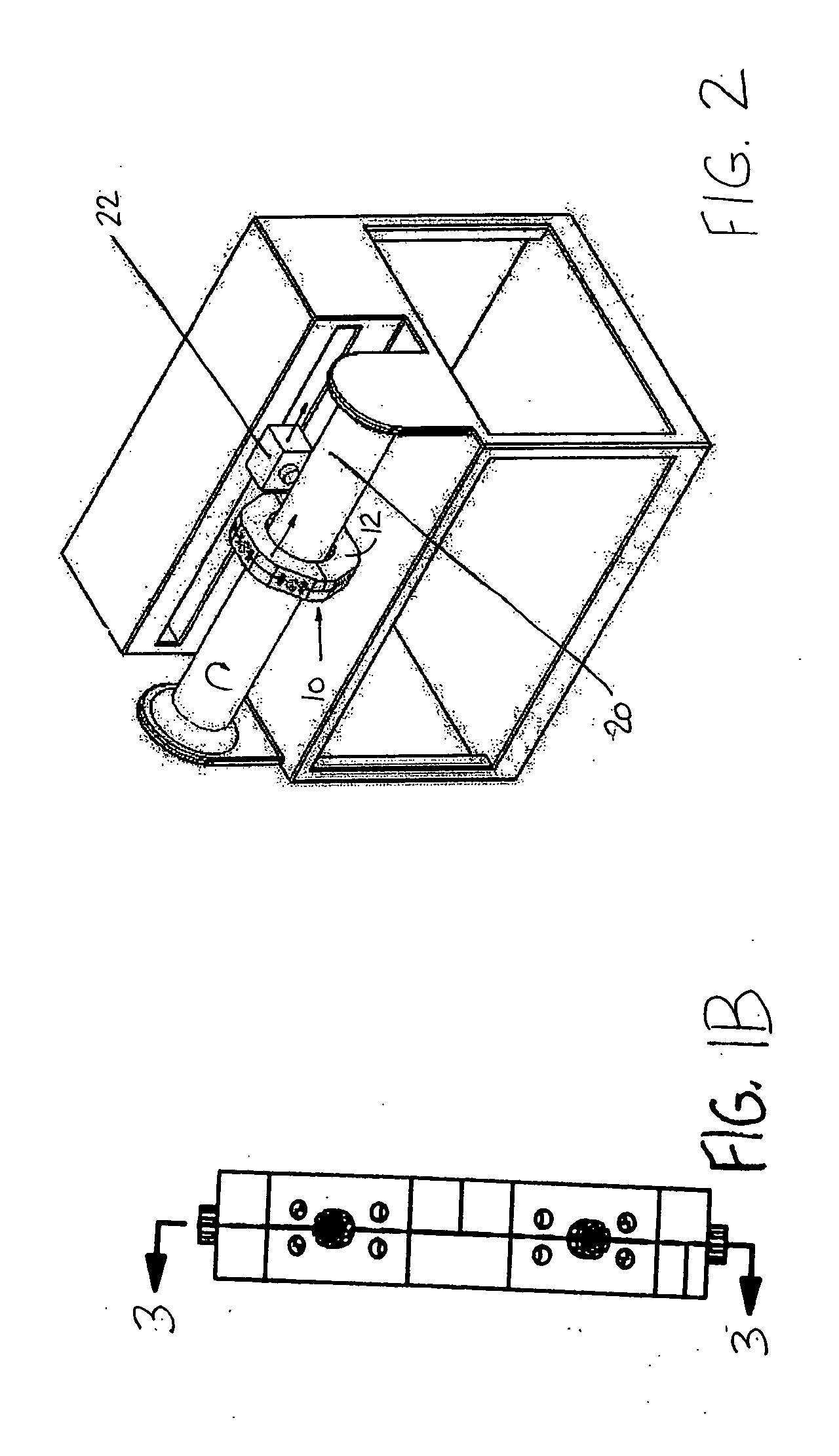

[0013] The present invention provides an exposure system that surrounds a photopolymer such as a flexographic plate in a rotating cylinder ablation system, the exposure system linearly following the ablation source and operating to expose the ablated (masked) plate with high intensity illumination from all sides so as to continuously expose all points on the plate. The flexographic printing plate may be mounted to a rotating cylinder, or may itself be a cylindrical sleeve type of plate.

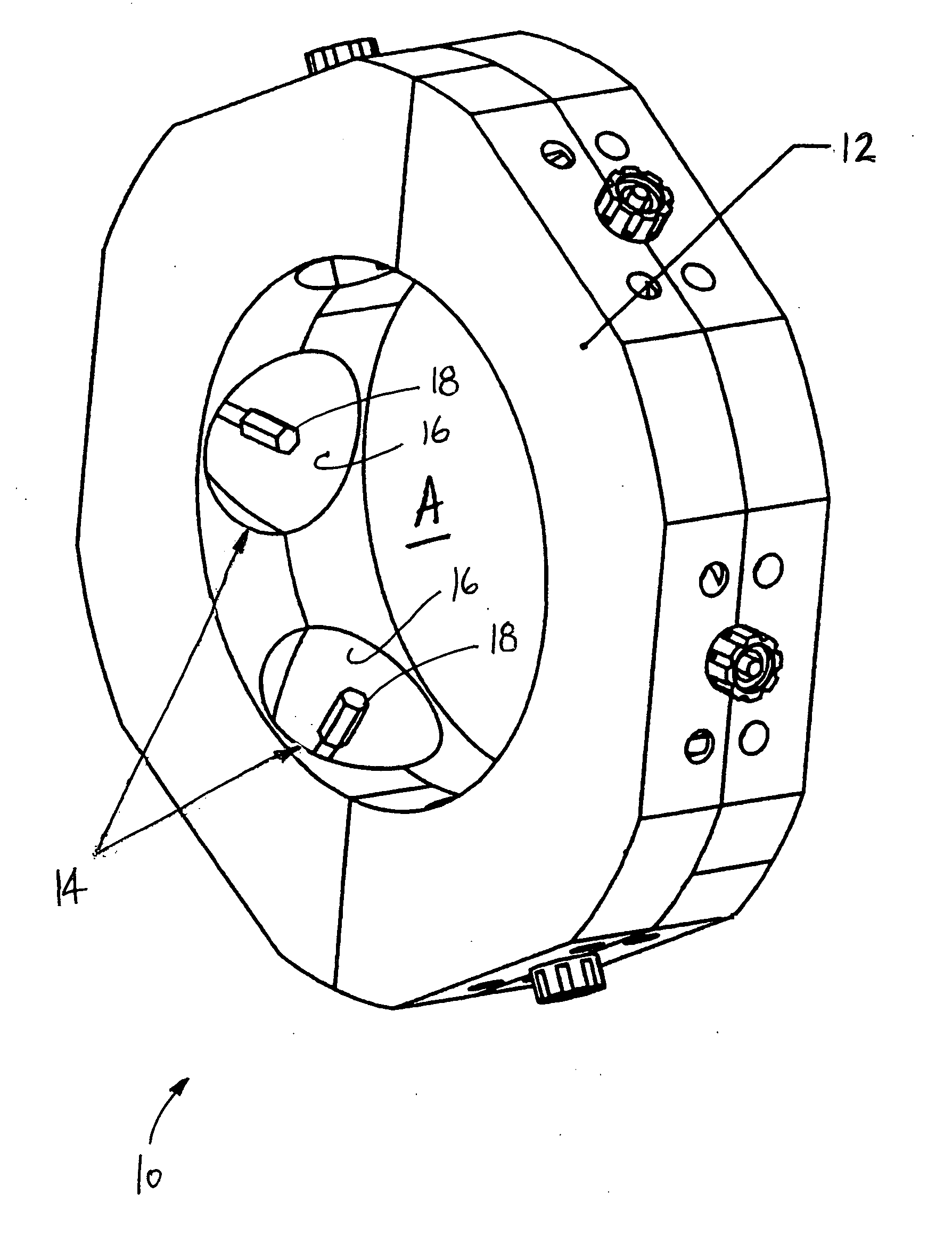

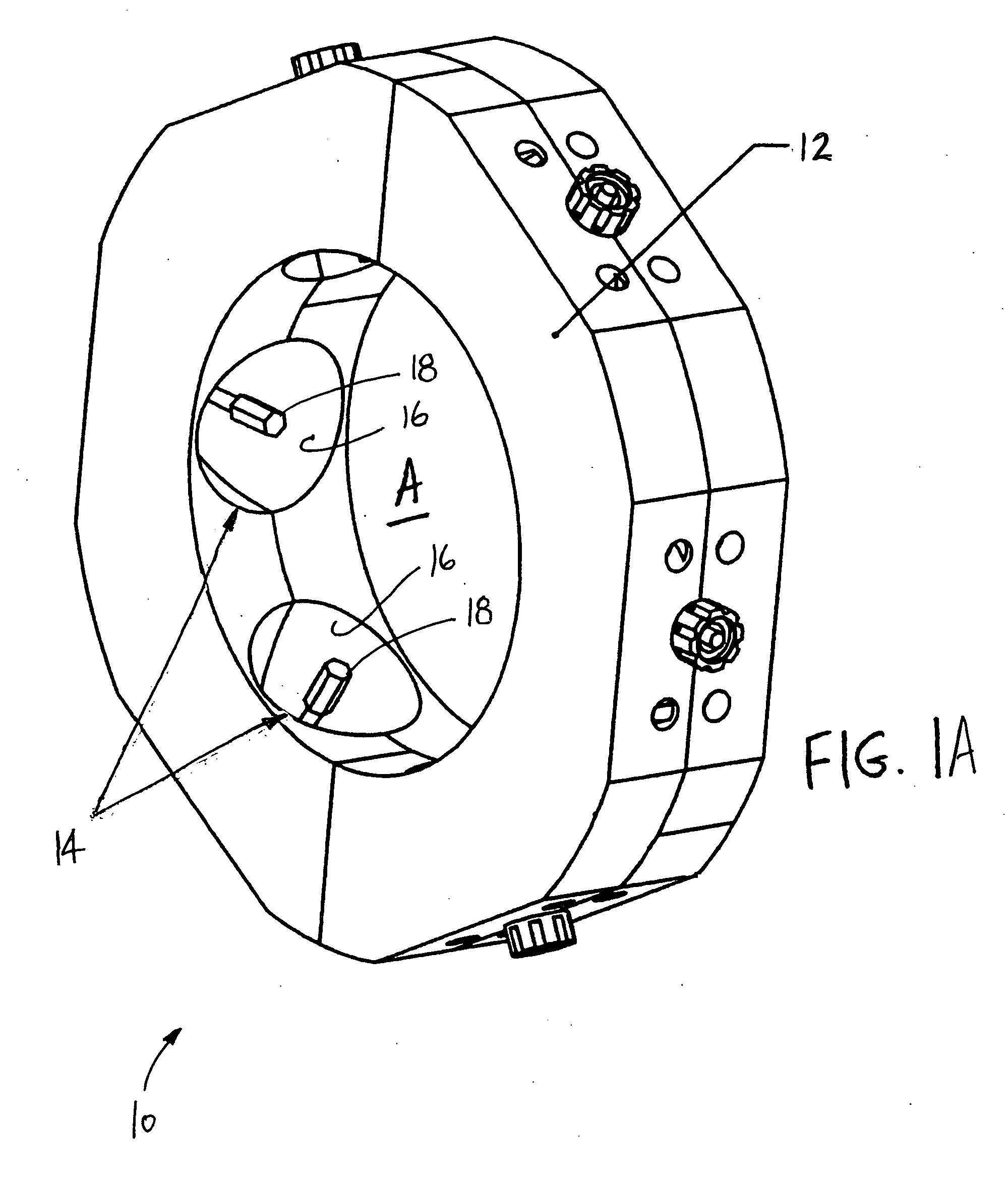

[0014]FIG. 1A is a perspective diagram, and FIG. 1B is a side view, of exposure system 10 of the present invention. Body 12, having a toroidal geometry and being made of a material such as aluminum for example, is provided to surround a rotating cylinder (not shown in FIG. 1, but which fits inside aperture A) on which a flexographic plate is mounted. A plurality of high intensity light sources 14 are provided in body 12, each of which is operable to direct high intensity light inward toward the flexo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| illumination angle | aaaaa | aaaaa |

| rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com