Environment-friendly flexographic ink

An offset printing ink, environmental protection technology, applied in ink, household utensils, applications, etc., can solve problems such as pollution and environmental hazards, achieve good environmental compatibility, broaden the application field and the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] Embodiment The preparation of the yellow ink of environmental protection offset printing of the present invention

[0030] Preparation:

[0031] Vegetable dye Turmeric 2.4kg,

[0032] Liquid connecting material 6.6kg,

[0033] Viscosity regulator linseed oil 0.3kg,

[0034] Dispersant (nonionic surfactant) 0.35kg,

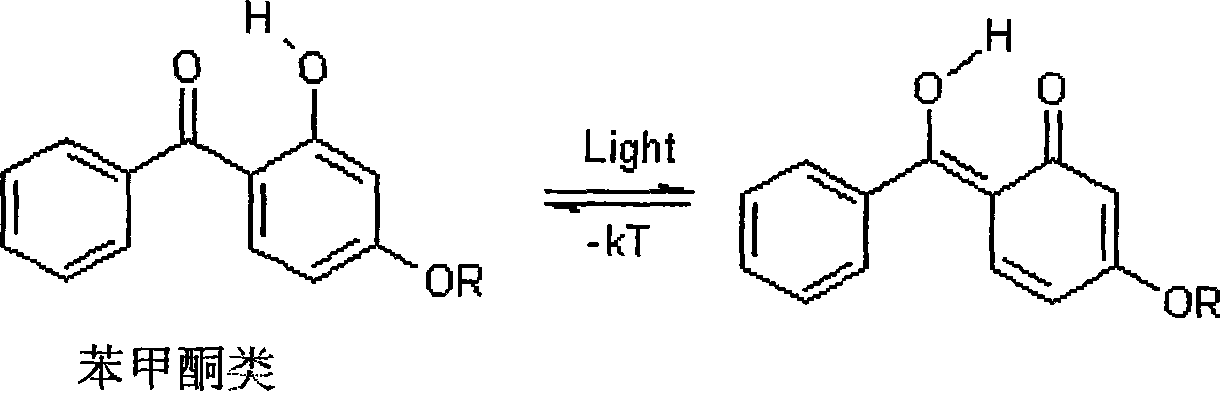

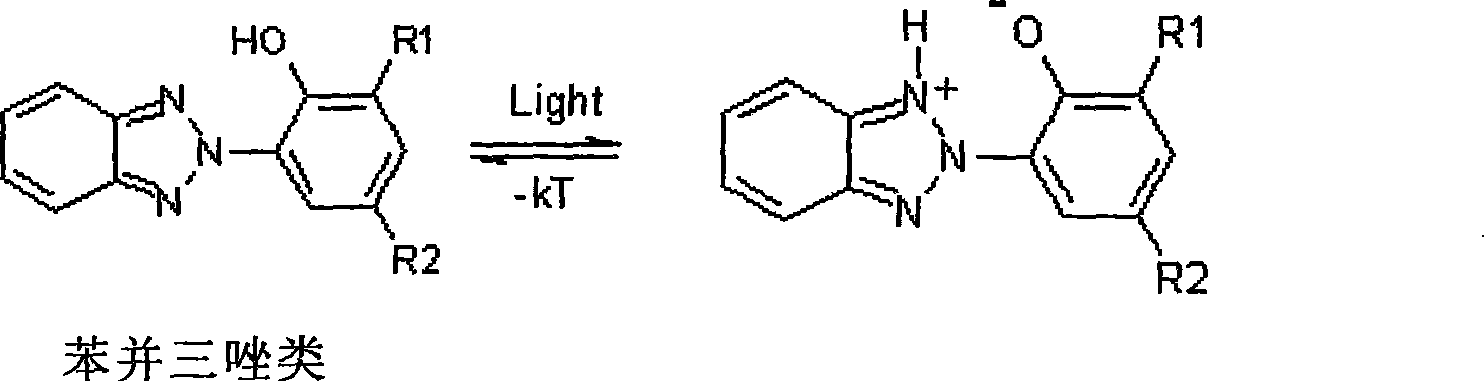

[0035] Light stabilizer 0.35kg, adopt HTUV100 type anti-ultraviolet finishing agent (triazine derivative).

[0036] Preparation Process:

[0037] It is divided into two stages: stirring pre-dispersion and grinding fine dispersion.

[0038] An example of the preparation of this ink is as follows:

[0039] In the mixing pot, according to the above ratio, add the liquid binder, turn on the mechanical stirring, then add the vegetable dye turmeric, and stir for 30 minutes. Then add dispersant non-ionic surfactant and stir for 40-60 minutes, so that the vegetable dye is gradually wetted and dispersed by the binder, and becomes a slurry with good fluidity. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com