A kind of water-based flexo printing ink for tobacco pine paper printing and preparation method thereof

A water-based technology of tipping paper, applied in the fields of polymer chemistry and fine chemical industry, can solve the problems of paper shrinkage and deformation, decrease of tensile strength, and paper brittleness, so as to avoid curling deformation, improve moisture retention and good water resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 1. Preparation of Modified Acrylic Emulsion

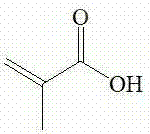

[0053]180g of deionized water was added to the reaction kettle, the temperature was raised to 50°C, 0.2g of polycaprolactone was added to dissolve it completely, 10g of methyl methacrylate, 3g of methacrylic acid, 20g of butyl acrylate and 0.1g of methacrylate were added. Octamethylcyclotetrasiloxane, stirred for 20min, stirring speed 300r / min, and adjusted the pH to 7 with 15% sodium carbonate aqueous solution, then heated to 75℃, added 0.2g ammonium persulfate at 60℃, reacted for 1h Begin dropwise addition of 1 g of the emulsifier sodium alkyl phenyl polyether sulfonate. After dripping, the reaction was continued for 0.5 h, and the pH value of the emulsion was controlled with an aqueous sodium carbonate solution during the entire reaction process to keep it at 7 to obtain a modified acrylic emulsion.

[0054] The obtained emulsion was milky white and translucent, with a solid content of 40.0% and a viscosity of 150 mpa.s ...

Embodiment 2

[0060] 1. Preparation of Modified Acrylic Emulsion

[0061] Add 230g of deionized water to the reaction kettle, heat it up to 60°C, add 1g of polycaprolactone to dissolve it completely, add 18g of methyl methacrylate, 4g of methacrylic acid, 40g of butyl acrylate and 0.2g of octanoate Methylcyclotetrasiloxane, stir for 30min, stirring speed is 300r / min, and adjust the pH value to 7 with sodium carbonate aqueous solution with a concentration of 15%, then increase the temperature to 85 °C, add 1 g of ammonium persulfate at 65 °C, and start dripping after 1h of reaction Add 3g of emulsifier sodium alkyl benzene polyether sulfonate. After dropping, the reaction was continued for 1 h, and the pH value of the emulsion was controlled with an aqueous sodium carbonate solution during the entire reaction process to keep it at 7 to obtain a modified acrylic emulsion.

[0062] The obtained emulsion was milky white and translucent, with a solid content of 42.2% and a viscosity of 165 mpa....

Embodiment 3

[0068] 1. Preparation of Modified Acrylic Emulsion

[0069] Add 285g of deionized water to the reaction kettle, heat it up to 70°C, add 2g of polycaprolactone to dissolve it completely, add 25g of methyl methacrylate, 5g of methacrylic acid, 55g of butyl acrylate and 0.3g of octanoate Methylcyclotetrasiloxane, stir for 30min, stirring speed is 300-400r / min, and adjust the pH value to 8 with 15% sodium carbonate aqueous solution, then heat up to 95℃, add 2g ammonium persulfate at 70℃, react for 1h Begin dropwise addition of 5 g of the emulsifier sodium alkyl phenyl polyether sulfonate. Continue to react for 1h after dripping, and control the pH value of the emulsion with sodium carbonate aqueous solution during the whole reaction process to keep it at 8 to obtain a modified acrylic emulsion.

[0070] The obtained emulsion was milky white and translucent, with a solid content of 45.0% and a viscosity of 180 mpa.s at 25°C.

[0071] 3. Prepare water-based flexographic ink accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com