A kind of high-speed printing flexographic water-based ink and preparation method thereof

A water-based ink, high-speed printing technology, applied in ink, household utensils, applications, etc., can solve the problems of being unable to adapt to high-speed flexographic printing, and achieve excellent leveling and overprinting effects, high color saturation, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

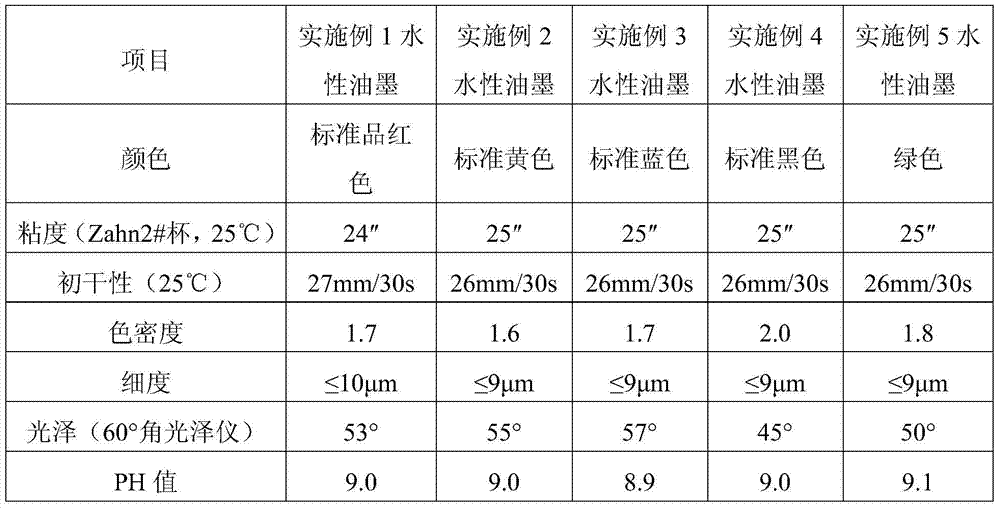

Examples

Embodiment 1

[0029] The flexographic water-based ink of the high-speed printing of the present embodiment is made up of the following components by weight: 32.9 parts of acrylic acid film-forming emulsion, 5 parts of acrylic acid film-forming emulsion, 15 parts of acrylic resin solution A, 39 parts of water-based color paste, poly 1.5 parts of ethylene wax, 1 part of film-forming aid, 0.3 part of leveling agent, 0.1 part of defoamer, 0.2 part of pH regulator and 5 parts of deionized water.

[0030] Among the above-mentioned flexographic water-based inks:

[0031] Acrylic non-film-forming emulsion uses acrylic emulsion Basf Joncryl 89, its solid content is 48%, Tg value is 98°C, acid value is 50mgKOH / g, pH value is 8.3; acrylic film-forming emulsion uses acrylic emulsion Basf Joncryl 77, its solid content The content is 46%, the Tg value is 21°C, the acid value is 55mgKOH / g, and the pH value is 8.3; the polyethylene wax is specifically polyethylene wax MD-2000; the film-forming aid is speci...

Embodiment 2

[0043] The flexographic water-based ink of the high-speed printing of the present embodiment is made up of the following components by weight: 34.7 parts of acrylic acid film-forming emulsions, 5 parts of acrylic acid film-forming emulsions, 18 parts of acrylic resin solution A, 35 parts of water-based colorants, poly 1 part of ethylene wax, 1.5 parts of film-forming aid, 0.5 part of leveling agent, 0.1 part of defoamer, 0.2 part of pH regulator and 4 parts of deionized water; except for water-based color paste, other components are the same as in Example 1 .

[0044] The water-based color paste consists of the following components by weight: 45 parts of yellow pigment (PY14), 26 parts of acrylic resin solution B, 28.4 parts of deionized water, 1.5 parts of wetting and dispersing agent (TEGO dispersers 760) and defoamer BYK0930. 1 part; wherein: acrylic resin solution B is the same as in Example 1.

[0045] Above-mentioned flexographic water-based ink can be prepared by the f...

Embodiment 3

[0051] The flexographic water-based ink of the high-speed printing of the present embodiment is made up of the component of following parts by weight: 35 parts of acrylic acid film-forming emulsions, 6 parts of acrylic acid film-forming emulsions, 17 parts of acrylic resin solution A, 35 parts of water-based colorants, poly 1 part of ethylene wax, 1 part of film-forming aid, 0.5 part of leveling agent, 0.1 part of defoamer, 0.2 part of pH regulator and 4.2 parts of deionized water.

[0052] Among the above-mentioned flexographic water-based inks:

[0053] Acrylic non-film-forming emulsion uses acrylic emulsion Indulor SE900; acrylic film-forming emulsion uses acrylic emulsion Indulor SE 2872; polyethylene wax is specifically polyethylene wax AQUAACER552; film-forming aid is specifically butyl carbitol; leveling agent is specifically SURFYNOL 420; the defoamer is specifically TEGO 1488; the pH regulator is specifically AMP-95; all of them are commercially available.

[0054] A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com