Aqueous flexographic ink for electron beam-curable surface printing and pouches for boiling/retorting using the same

An electron beam, surface printing technology, applied in chemical instruments and methods, bags, sacks, etc., can solve the problem of abrasion resistance cooking sachets that cannot be said to have sufficient boiling/cooking properties, and achieves excellent boiling/cooking adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

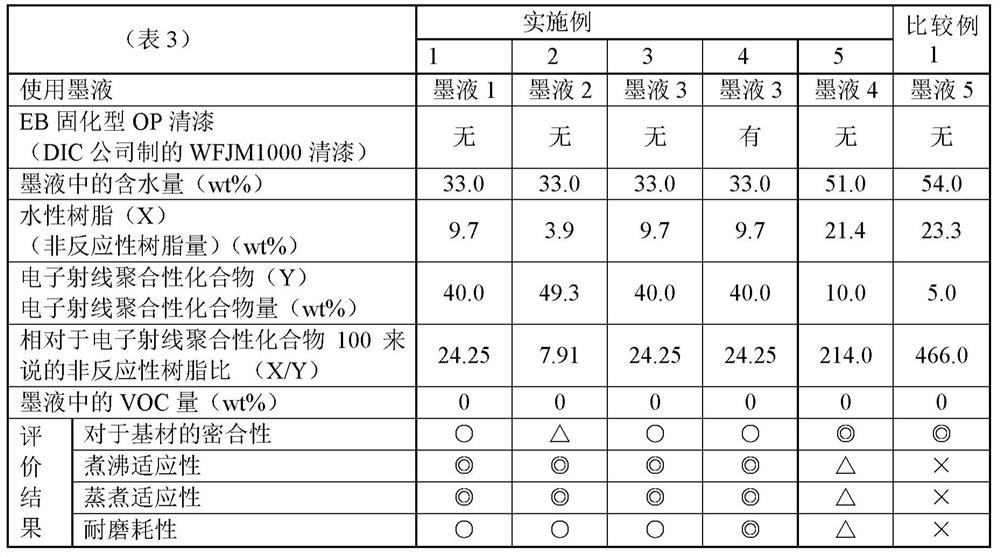

[0070] Hereinafter, the present invention will be specifically described by way of examples and comparative examples. Hereinafter, both "part" and "%" are based on mass basis.

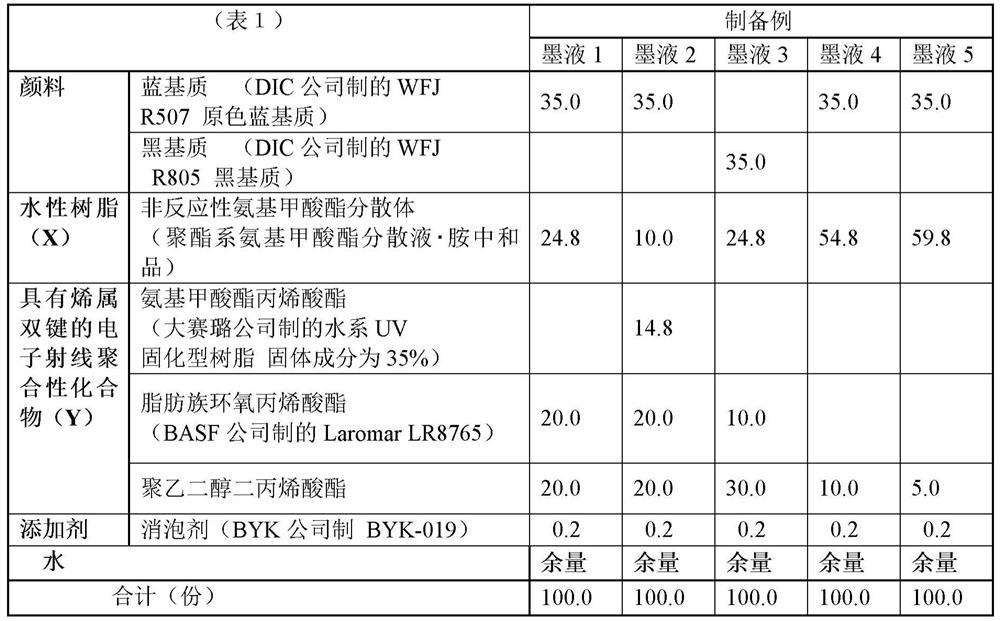

[0071] (Manufacturing method of water-based flexographic ink for electron beam curing type surface printing)

[0072] A flexographic ink based on the composition shown in Table 1 was prepared as an electron beam-curable surface printing water-based flexographic ink containing an aqueous resin (X), an electron beam-polymerizable compound (Y) having an ethylenic double bond, and water. .

[0073] Taking ink 1 as an example, a blue pigment dispersion base manufactured by DIC Corporation (WFJ R507 primary color blue base, containing 40% by mass of phthalocyanine pigment relative to the dispersion base), non-reactive urethane dispersion, After aliphatic epoxy acrylate, (Laromar LR8765 manufactured by BASF) polyethylene glycol diacrylate and defoamer (BYK-019 manufactured by BYK Company) are fully stirred ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com