Insulated beverage or food container

a beverage or food container technology, applied in the field of insulated beverage containers and container stock materials, can solve the problems of user inconvenience, device and method of background art suffer, user's hand becomes uncomfortably or sometimes even painfully hot, etc., to reduce energy transfer through the container wall, increase functionality and usefulness, and improve hold time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

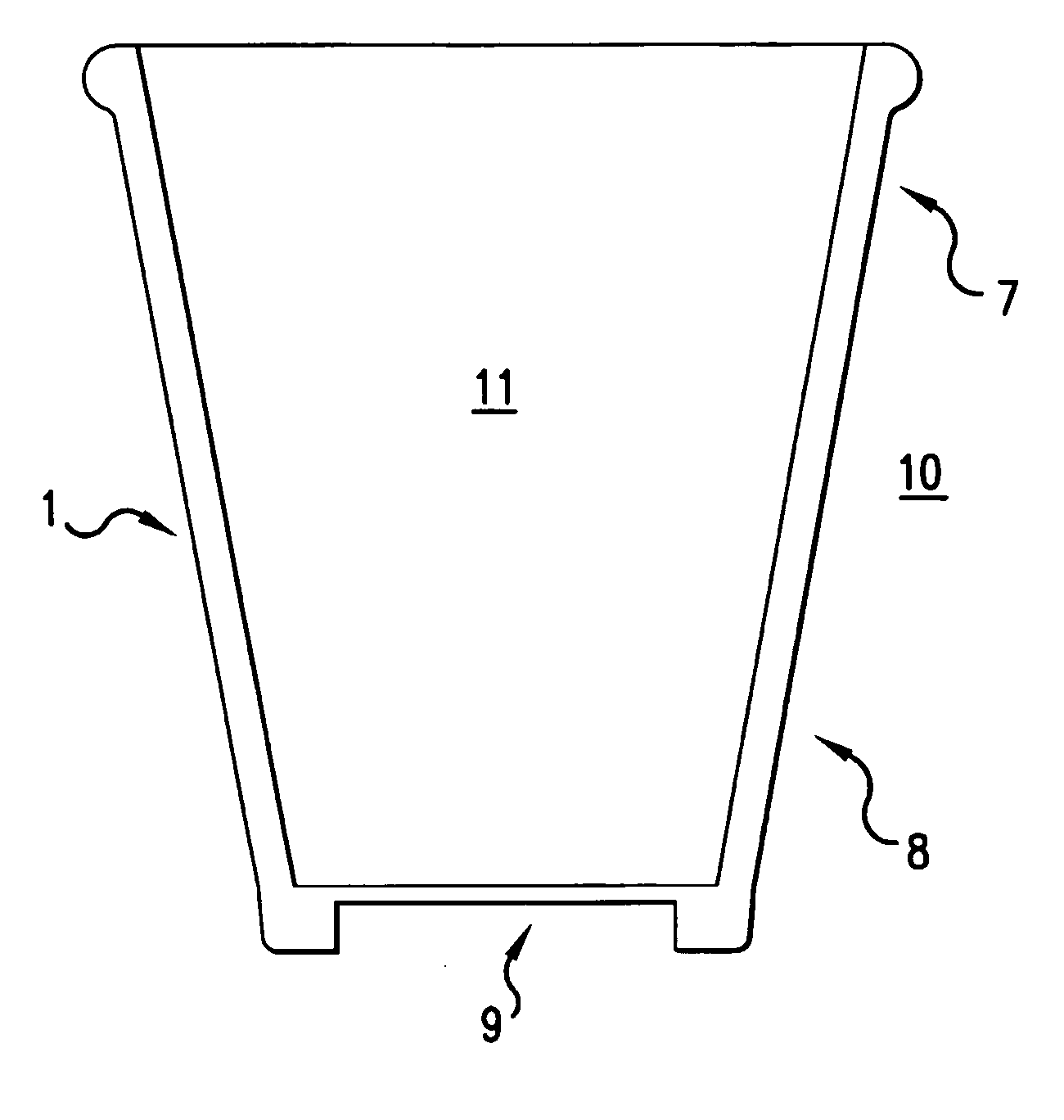

first embodiment

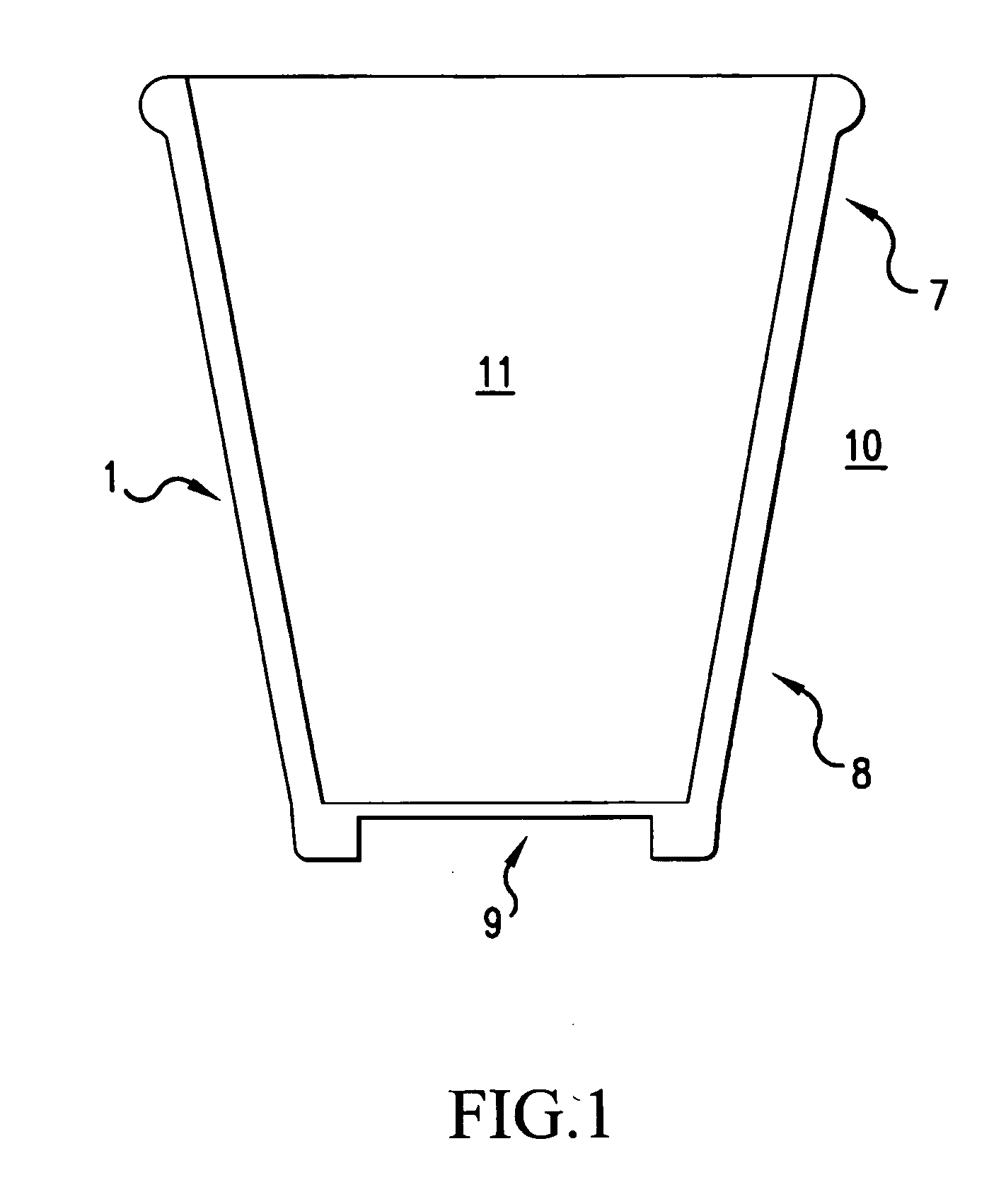

[0034]FIG. 2 is a cross-sectional view of an insulated beverage container wall or sleeve 1 according to the present invention. A beverage container wall or sleeve 1 includes a paper stock 2, and an extruded or laminated foam layer 3. The paper stock 2 provides structural rigidity and forms the desired shape of the container 10 or a portion of a sleeve wall. The extruded or laminated foam layer 3 is adhered to an inner surface (e.g. facing the beverage containing space 11) of the paper stock 2 and performs the function of a gas containing film layer. The foam layer 3 is designed to provide thermal insulation properties to the container.

[0035] The paper stock 2 is standard paper used for making beverage cups and other food containers. The paper stock 2 may be chosen with a thickness that provides optimized physical characteristics for cup construction. Important physical characteristics include fold strength, stiffness, tear and tensile strength.

[0036] A desired paper thickness is ch...

second embodiment

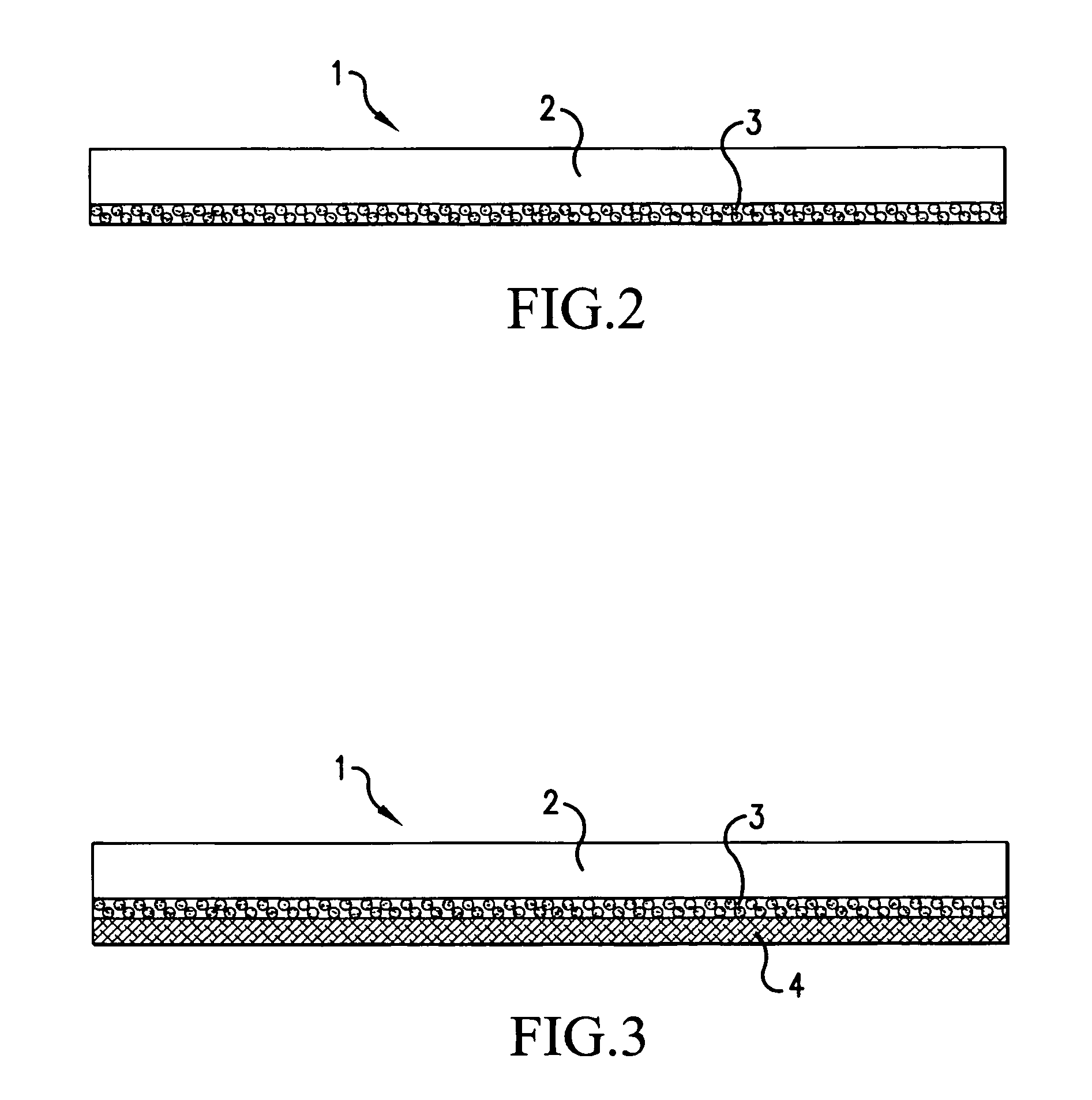

[0044]FIG. 3 is a cross sectional view of a container wall according to the present invention. A film layer 4 is extruded, laminated, or coated in a position between the foam containing layer 3 and the beverage containing space 11. The foam layer 3 is therefore interposed between the paper stock 2 and the film layer 4. The film layer 4 will hereinafter be referred to as a PE layer 4. The PE layer 4 can be used as a barrier against moisture transmission and aids in seam sealing during container construction.

[0045] In a preferred embodiment, the foam layer 3 is first formed and then it is melt extruded, laminated or melt fused to the surface of the paper stock 2. The residual moisture held within the paper stock 2 which is characteristically relied upon in the related art, is not relied upon as the mechanism for creating the foam layer 3. The foam can also be extruded to the paper stock 2, but in each instance the foaming is created by mixing a blowing agent into the polymer prior to ...

third embodiment

[0047]FIG. 4 is a cross sectional view of a container wall according to the present invention. A PE layer 4 is extruded, laminated, or coated in a position interposed between the foam containing layer 3 and the paper stock 2. However, PE layer 4 can also be used as a barrier against moisture transmission and aids in seam sealing during container construction.

[0048] The PE layer 4, although not limited to, can be formed from any of the following exemplary materials: high density polyethylene (HDPE), low density polyethylene (LDPE), linear low density polyethylene (LLDPE), orientated polypropylene (OPP), etc. HDPE and LDPE are desirable materials in a preferred embodiment of the present invention.

[0049] Additives may also be included to enhance various material properties or to aid in the manufacturing process. These additives include, but are not limited to, any of the following exemplary additives: ethylene vinyl acetate (EVA), ethylene vinyl alcohol (EVOH), and plasticizers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com